Dust concentration sensor and dust concentration detection module

A technology for dust concentration detection and dust concentration, which is applied in the direction of measuring devices, scientific instruments, suspensions and porous material analysis, etc., can solve the problems of inability to calibrate the accuracy, and achieve the effect of reducing input costs and convenient and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0023] Example of dust concentration sensor:

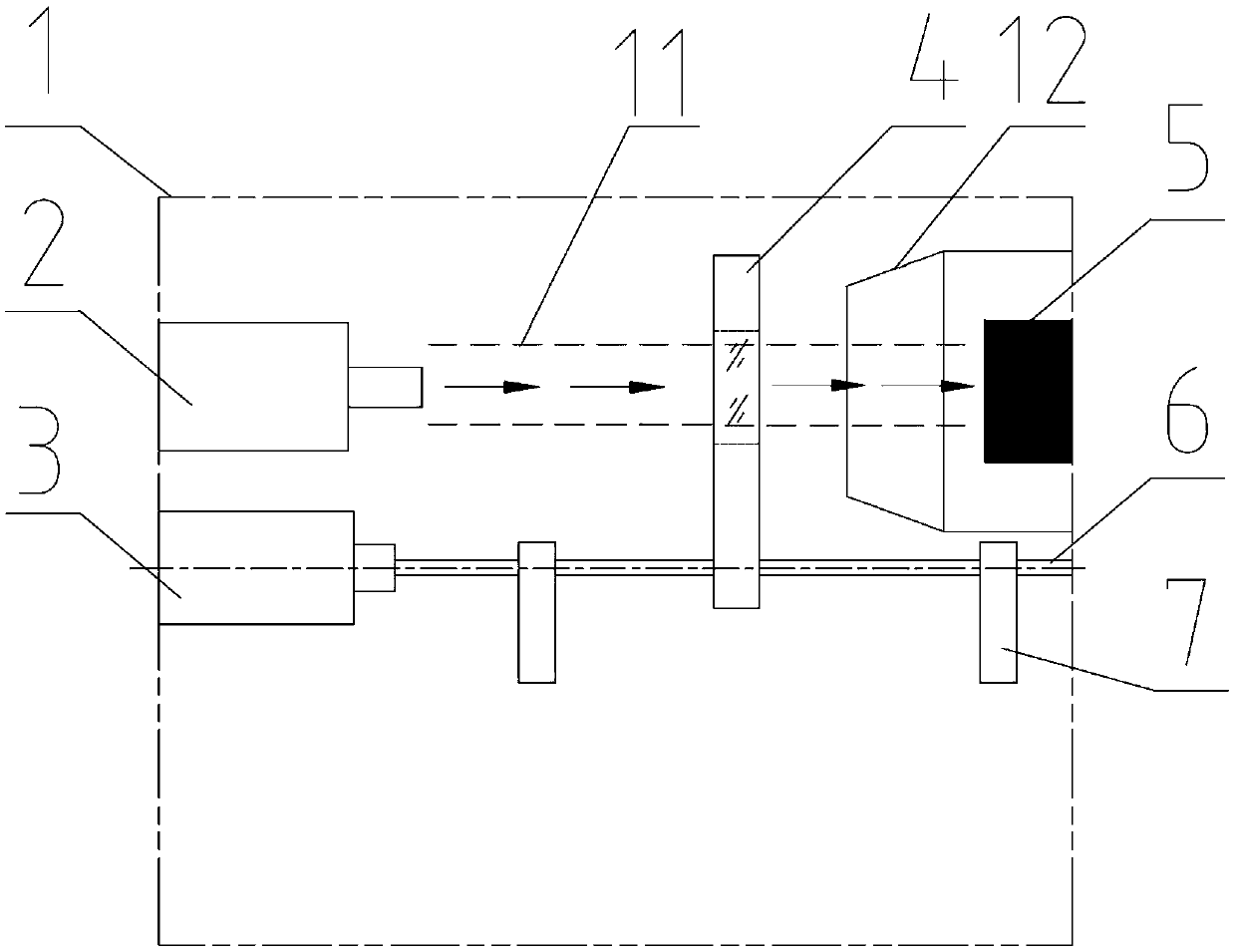

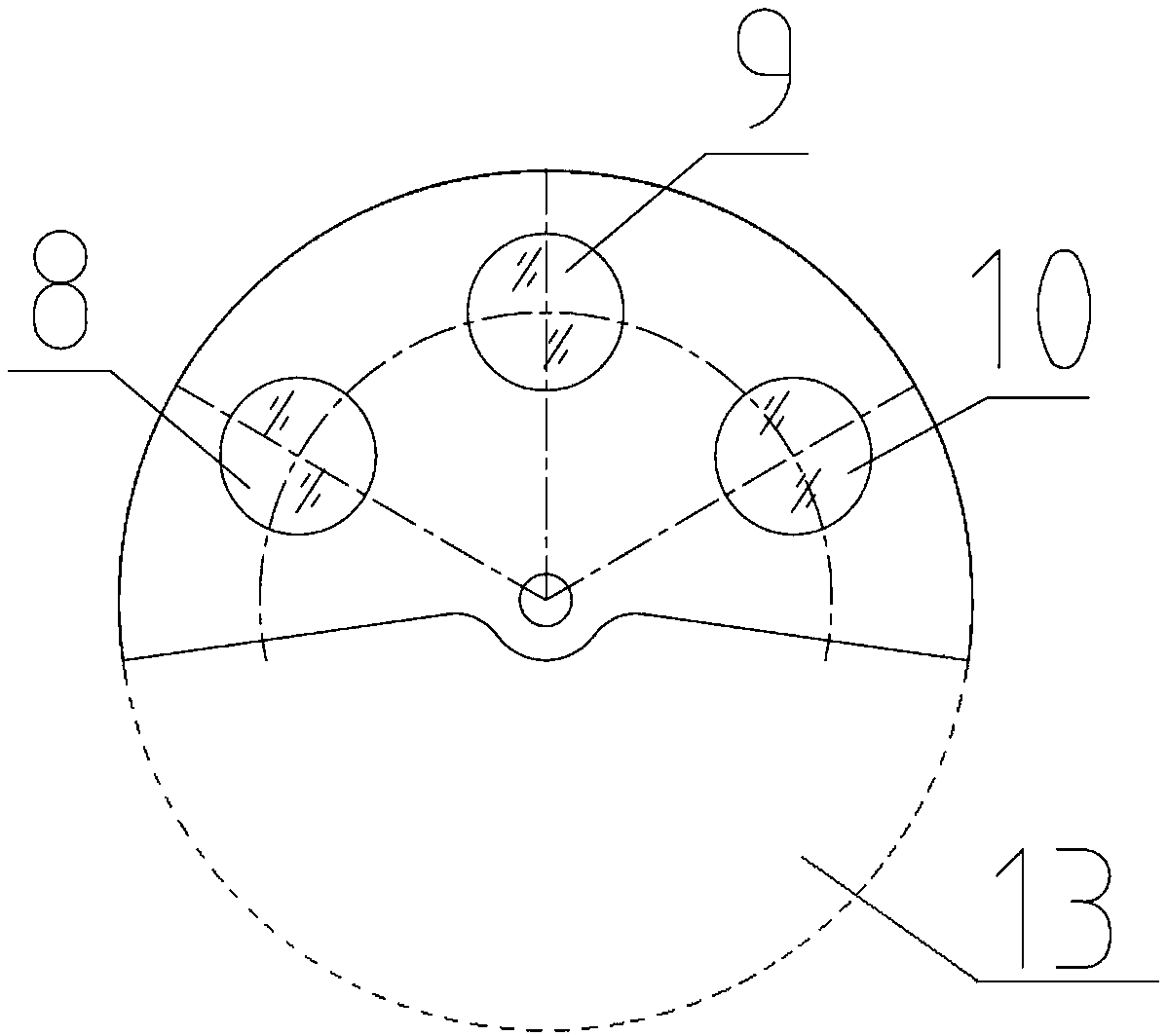

[0024] combine figure 1 and figure 2 , The dust concentration sensor of this embodiment includes a housing 1, and the housing 1 is provided with a light emitting module 2, a light receiving module 5 and a dust concentration detection module, and a dust concentration detection area is formed between the light emitting module 2 and the light receiving module 5. In this embodiment, the light emitting module 2 is a laser, and the light receiving module 5 is a detector.

[0025] The dust concentration detection module includes a calibration device, and the calibration device includes a light-transmitting structure part and a switching part. Wherein, the light-transmitting structure part includes t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap