Composition for polarizing film, polarizing film, method of manufacturing the same, and liquid crystal display provided with the polarizing film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

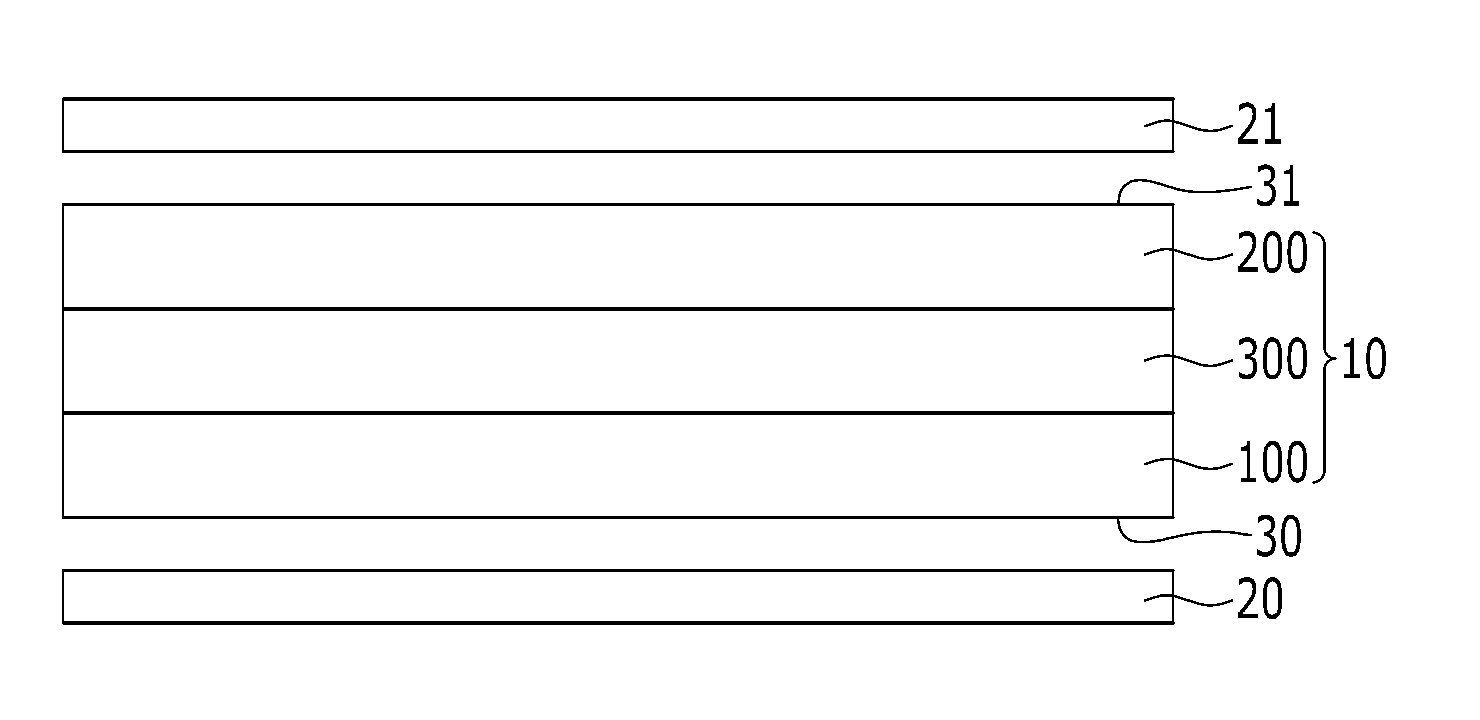

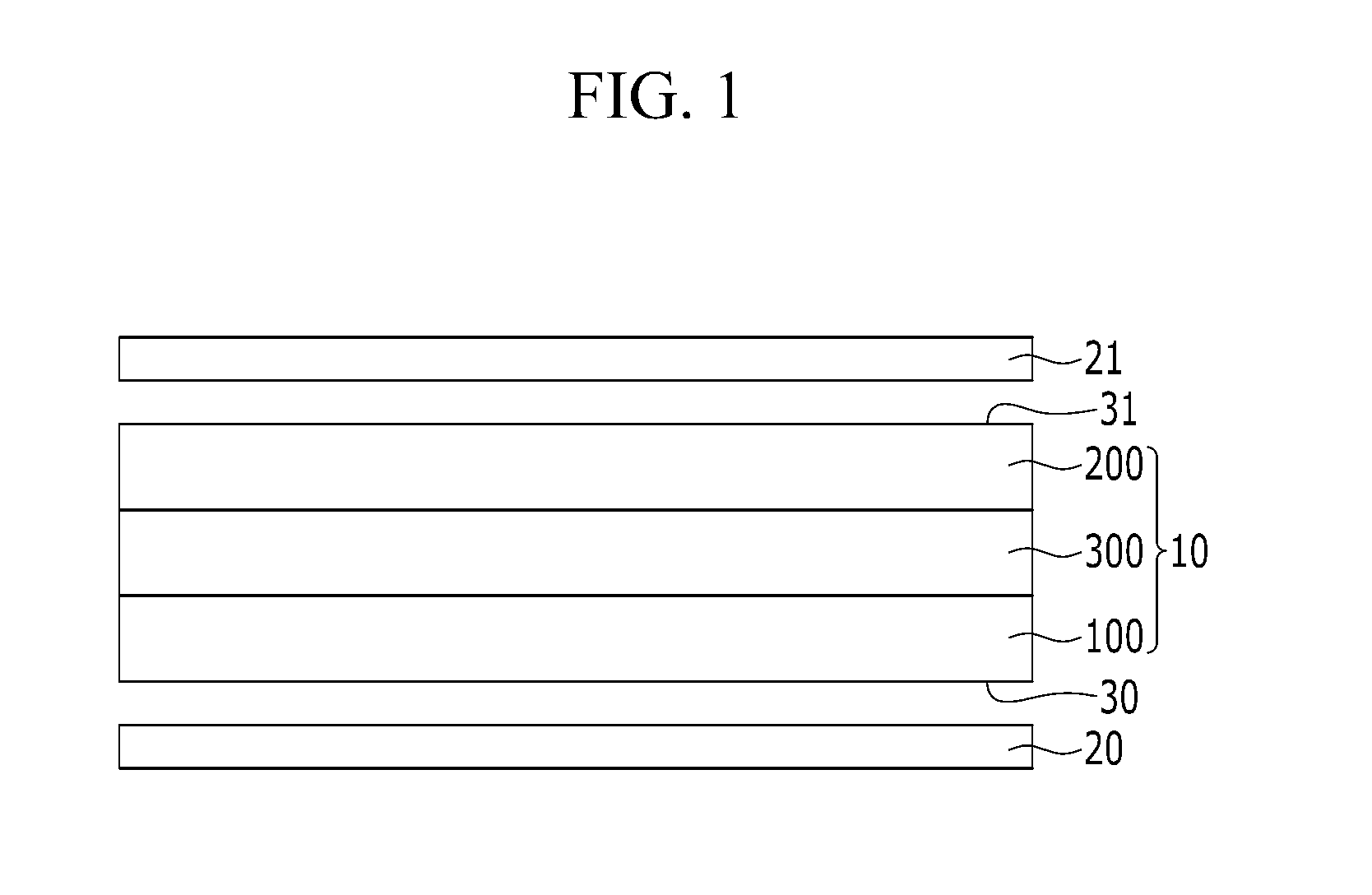

Image

Examples

example 1

Preparation of Composition for a Polarization Film and Manufacture of a Polarization Film

[0086]A composition for a polarization film is prepared by mixing about 100 parts by weight of a polyolefin component containing a polypropylene resin (HU300, Samsung Total Petrochemicals Co., Ltd.) and a polyethylene-polypropylene copolymer resin (polyethylene ratio: 10 wt %, RJ565, Samsung Total Petrochemicals Co., Ltd.) in a weight ratio of about 5:5, and about 0.5 parts by weight of CIBA-BLACK dichroic dye. Subsequently, the composition for a polarization film is made molten at a temperature of about 230° C. Subsequently, a film is formed by putting the molten mixture into a sheet-type mold and compressing the mold with a roller. Subsequently, the film is uniaxially elongated at about 115° C. to form the polarization film. The formed polarization film has a thickness of about 50 μm.

example 2

Preparation of Composition for a Polarization Film, and Manufacture of a Polarization Film

[0087]A composition for a polarization film and a polarization film are prepared and formed according to the same method as Example 1, except that about 0.25 parts by weight of CIBA-BLACK dichroic dye is used. The formed polarization film has a thickness of about 50 μm.

example 3

Preparation of Composition for a Polarization Film, and Manufacture of a Polarization Film

[0088]A composition for a polarization film and a polarization film are prepared and formed according to the same method as Example 1, except that a polyolefin component containing a polypropylene resin (HU300, Samsung Total Petrochemicals Co., Ltd.) and a polyethylene-polypropylene copolymer resin (polyethylene ratio: 10 wt %, RJ565, Samsung Total Petrochemicals Co., Ltd.) in a weight ratio of about 4:6 is used. The formed polarization film has a thickness of about 50 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap