Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43 results about "Polyolefin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A polyolefin is a type of polymer produced from a simple olefin (also called an alkene with the general formula CₙH₂ₙ) as a monomer. For example, polyethylene is the polyolefin produced by polymerizing the olefin ethylene. Polypropylene is another common polyolefin which is made from the olefin propylene.

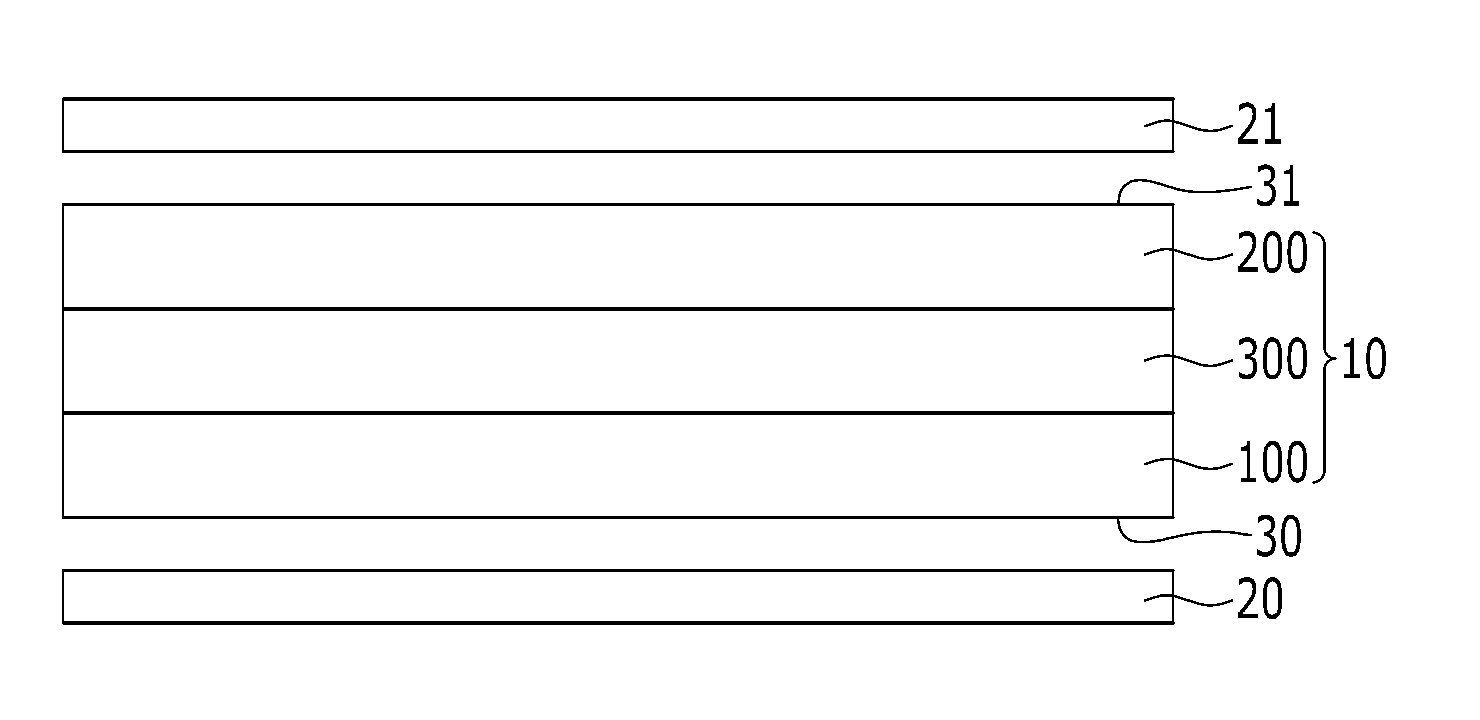

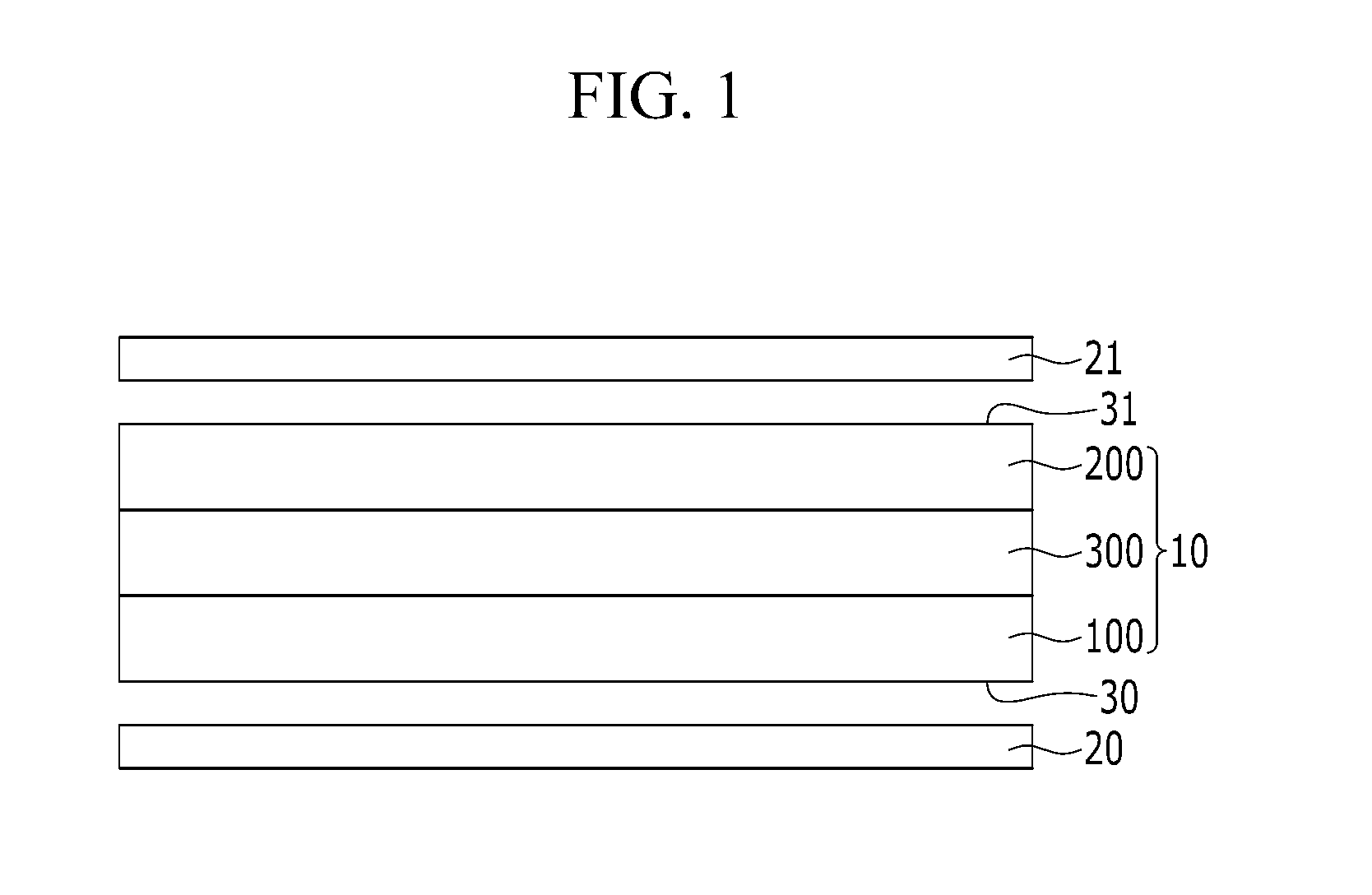

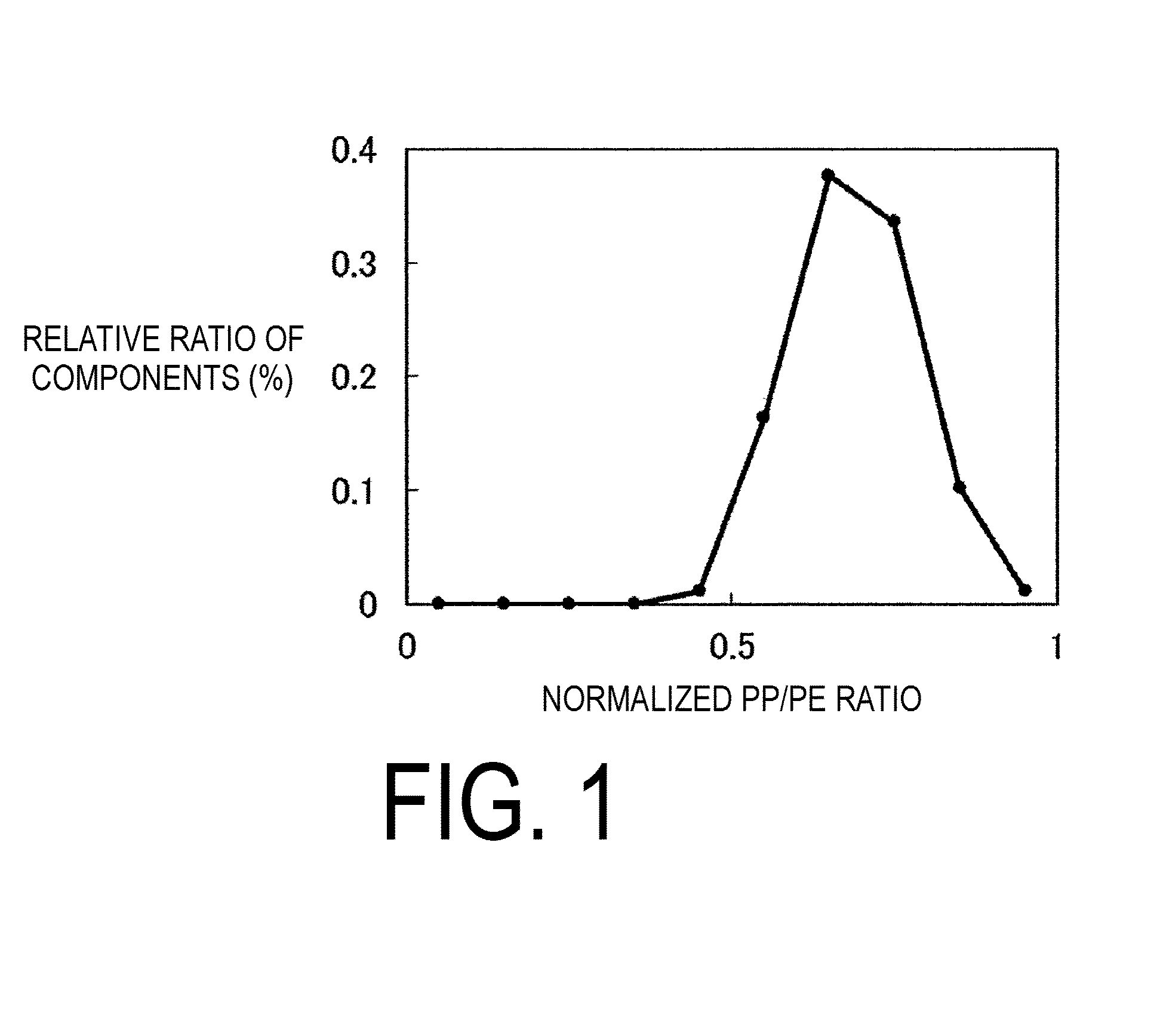

Composition for polarizing film, polarizing film, method of manufacturing the same, and liquid crystal display provided with the polarizing film

Owner:SAMSUNG ELECTRONICS CO LTD

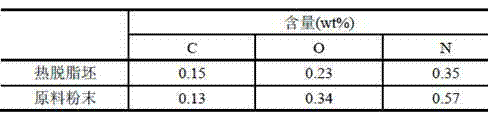

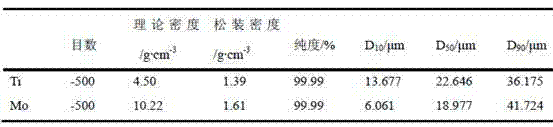

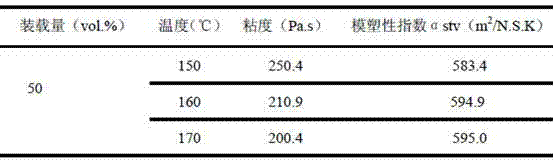

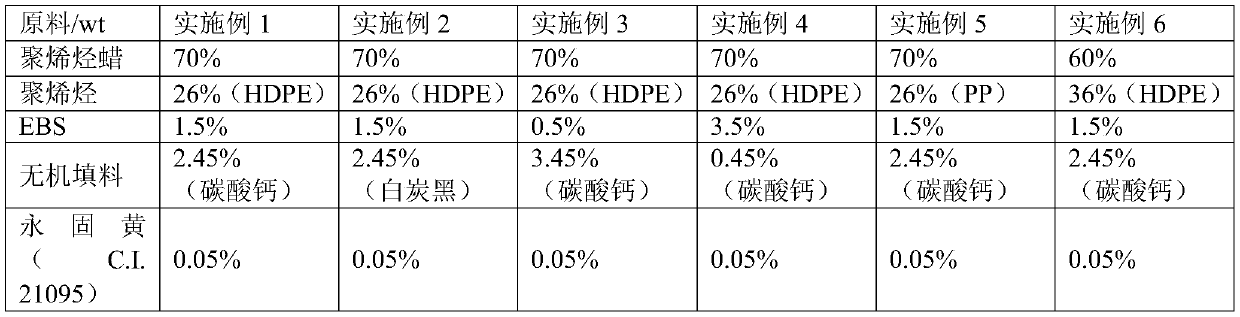

Wax-based binder for compacting process in powder metallurgy as well as preparation method and application thereof

ActiveCN103642253AGood compatibility of ingredientsEfficient mixingPolyethylene vinyl acetateParaffin wax

Owner:HUNAN UNIV

Asphalt modified thermoplastic polyolefin water-proof coiled material and preparation method thereof

InactiveCN101550729AImproves UV resistanceExcellent ozone resistanceRoof covering using flexible materialsBuilding insulationsPolymer sciencePolyolefin

Owner:胜利油田大明新型建筑防水材料有限责任公司

Aqueous Primer Composition

Owner:KANSAI PAINT CO LTD

Neutron-resistant radiation shield plate and preparation method thereof

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

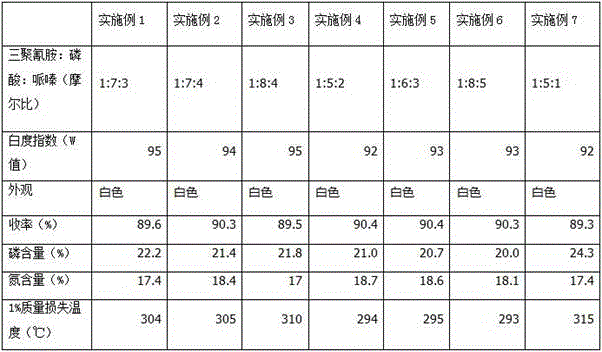

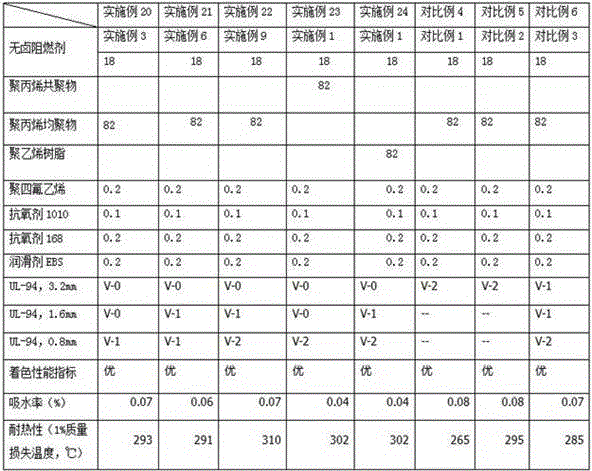

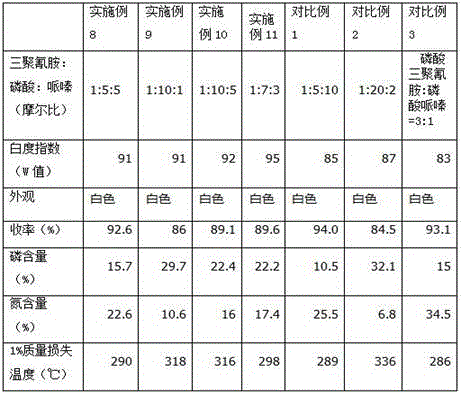

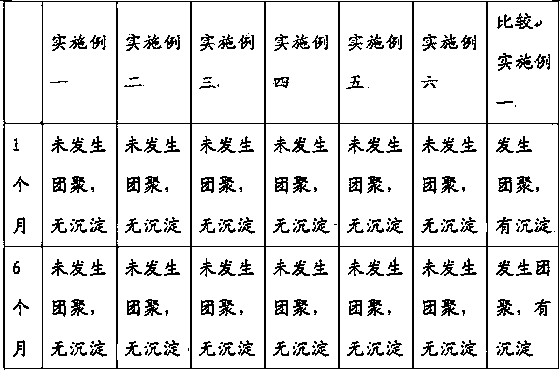

Halogen-free flame retardant and preparation method thereof and flame-retardant polyolefin composition composed of same

ActiveCN105837855AImprove thermal stabilityThe content of functional components is flexible and adjustableOrganic chemistryPolymer sciencePolyolefin

Owner:KINGFA SCI & TECH CO LTD

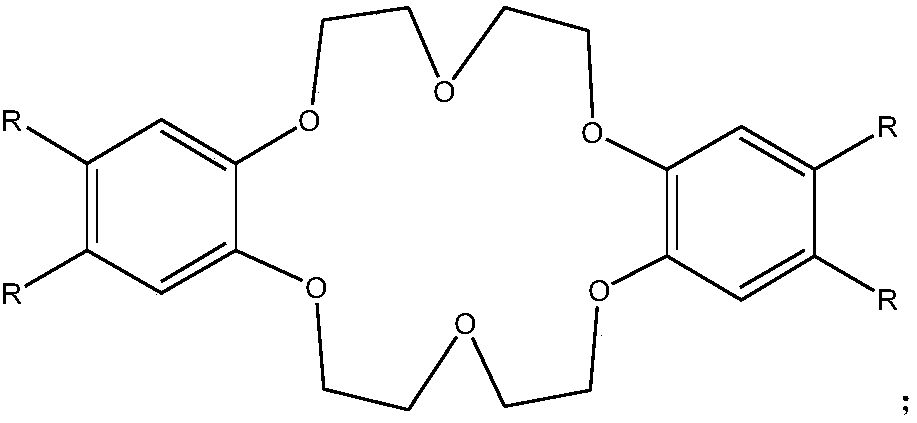

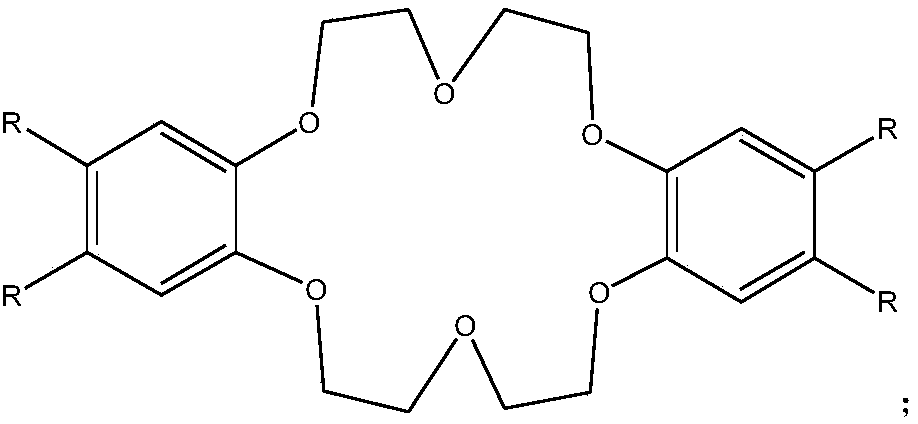

Low Dielectric Loss Power Cable Sheaths Comprising High Pressure Polyolefins Free of Silane Functionality

Power cables that comprise a sheath layer, e.g., an insulation layer, are produced from a mixture of a high pressure polyolefin free of silane functionality, e.g., high pressure low density polyethylene, and a polyether polyol of which at least 50 percent of its molecules comprise no more than a single hydroxyl functionality. Preferably, the power cable is a medium or high voltage power cable, and the polyolefin is crosslinked as the sheath layer is fabricated and / or subsequent to the fabrication of the sheath layer.

Owner:DOW GLOBAL TECH LLC

Mildew-resistant and antibacterial nano-silver decorative laminated board

ActiveCN103862988AAdequate defense against invasionImprove adhesionNon-macromolecular adhesive additivesSpecial ornamental structuresPolymer sciencePolyolefin

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

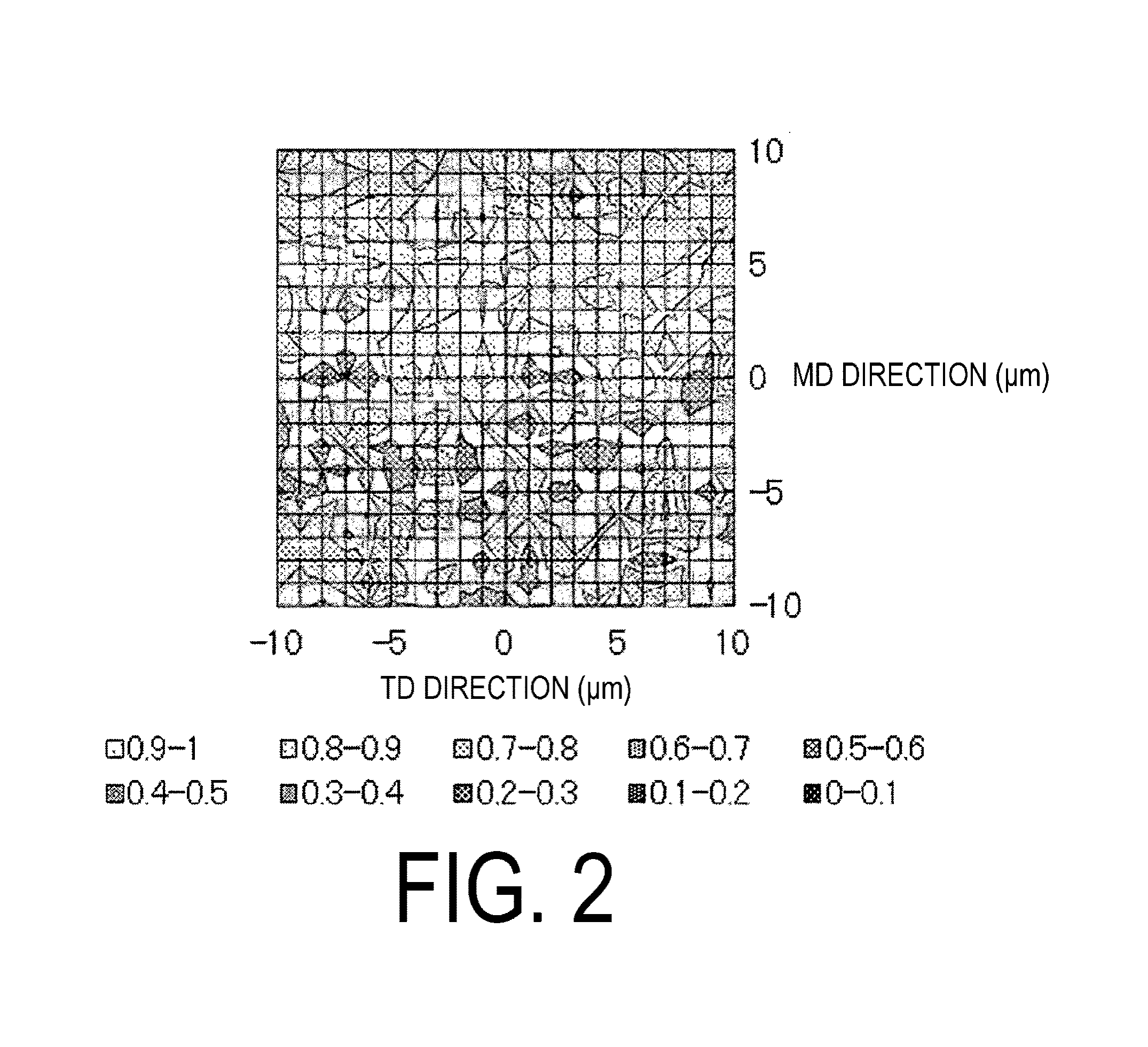

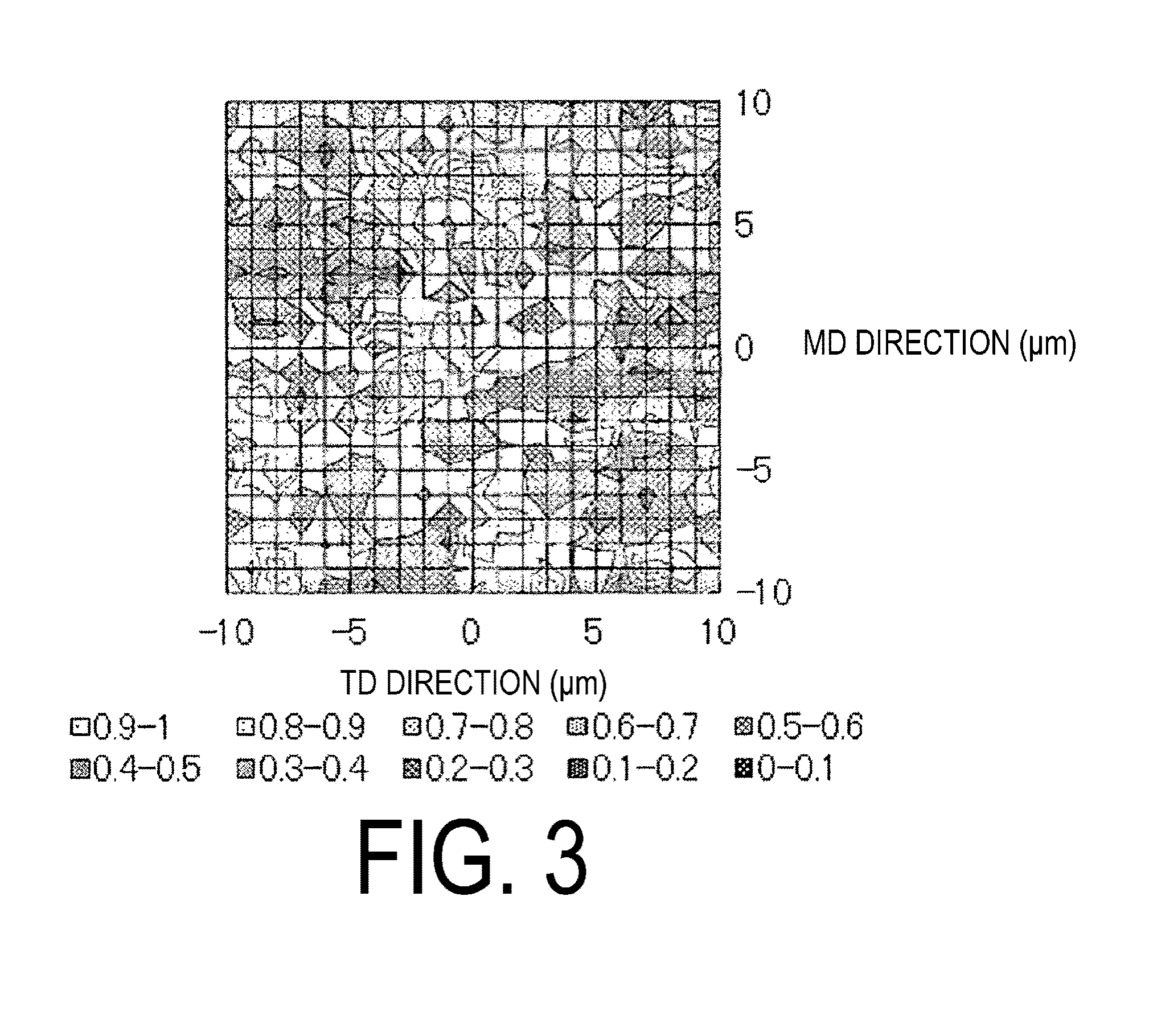

Multilayer, microporous polyolefin membrane, and production method thereof

ActiveUS20160118639A1Improve permeabilityHigh strengthSemi-permeable membranesMembranesIn planePolymer science

Owner:TORAY IND INC

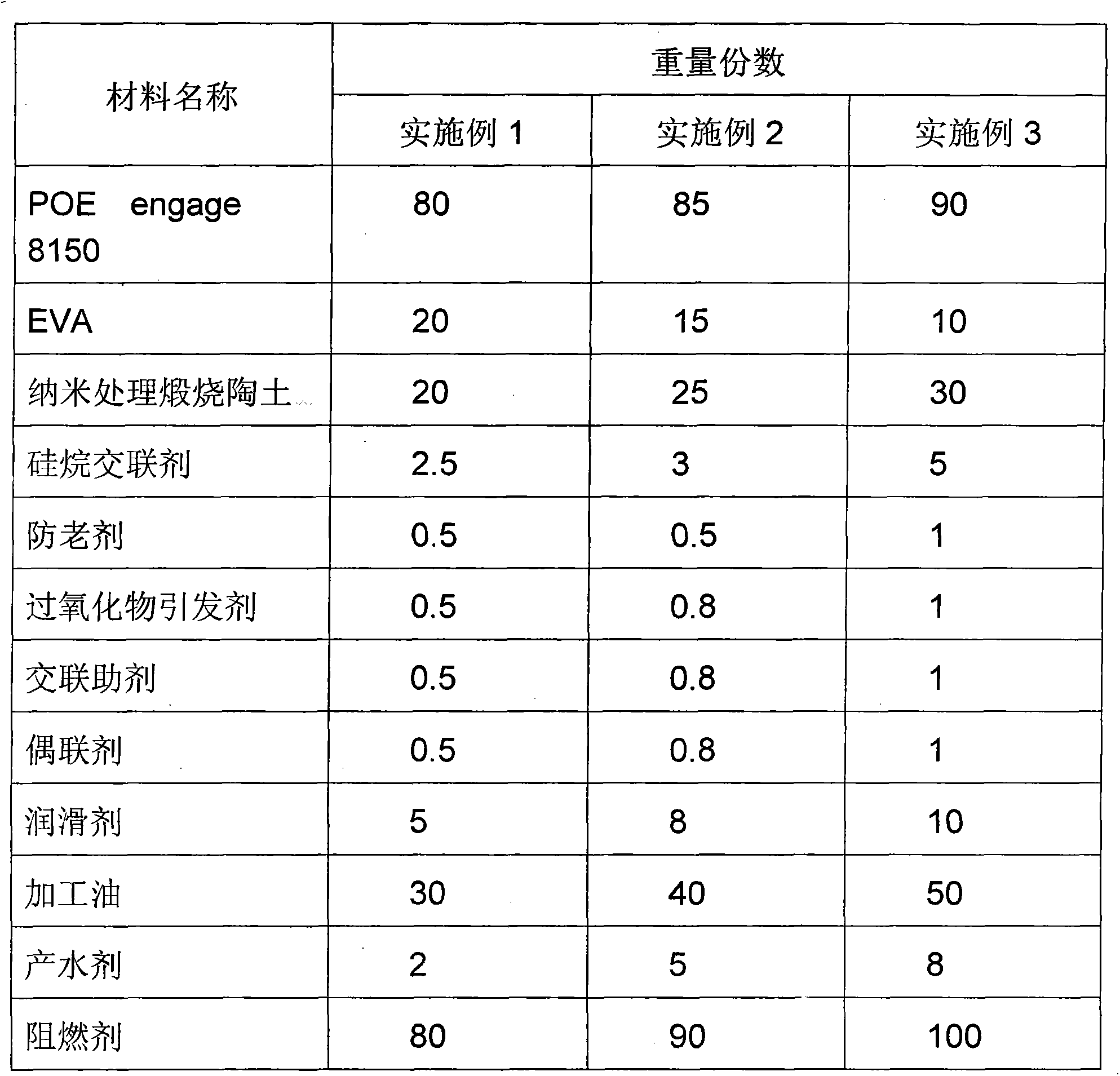

Cross-linking low-smoke halogen-free and flame-retardant POE and preparation method thereof

Owner:SHENYANG SHIELDING CABLE

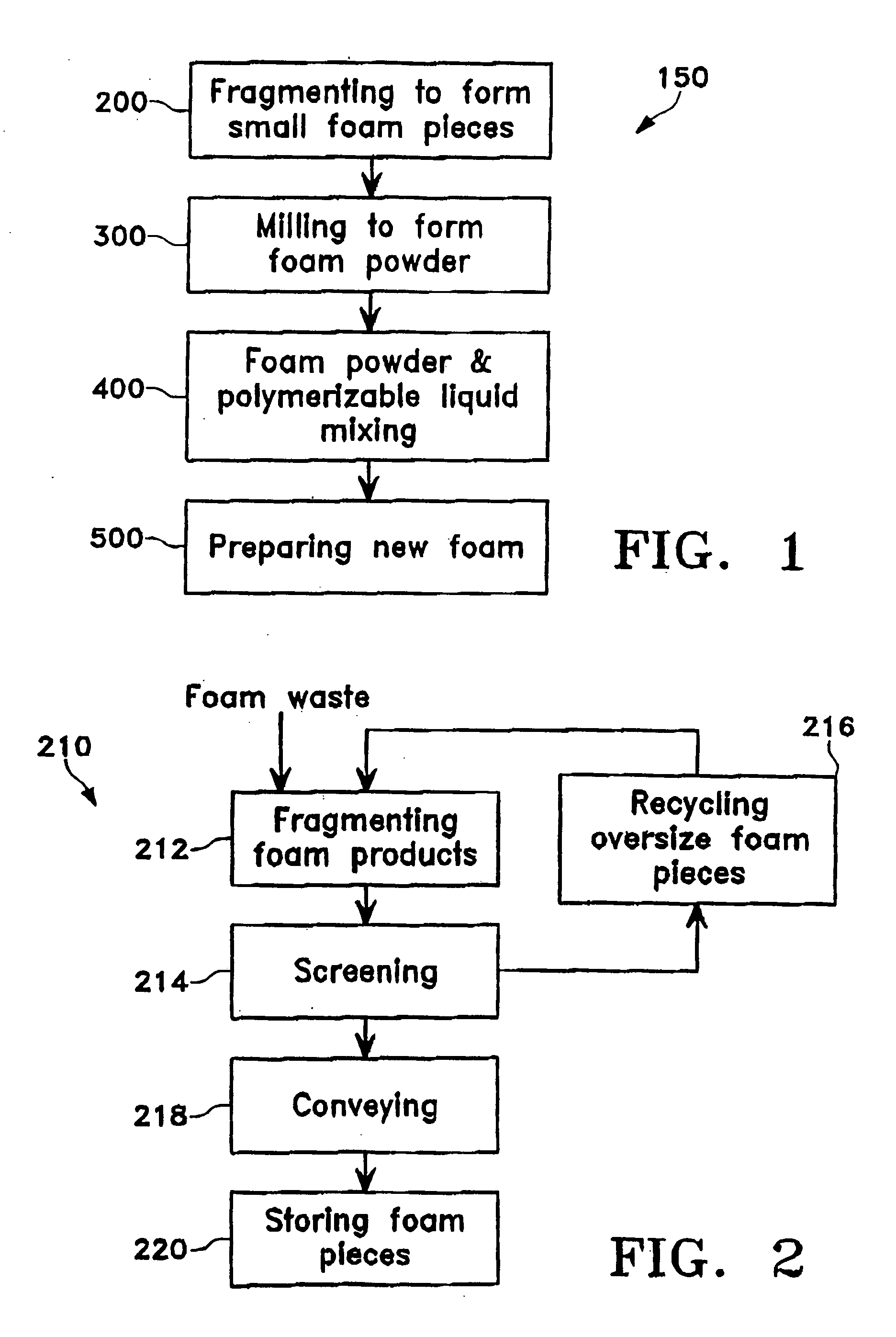

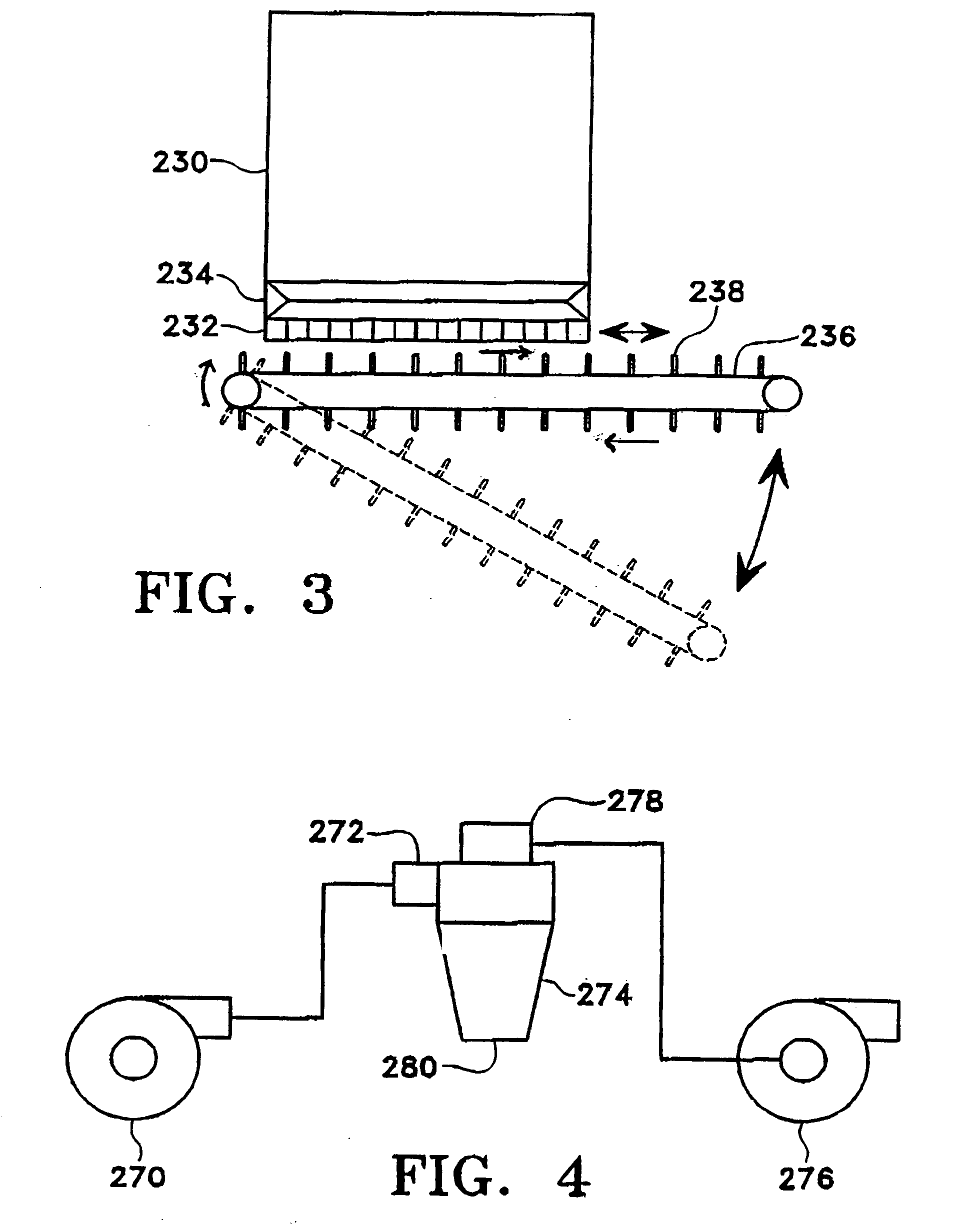

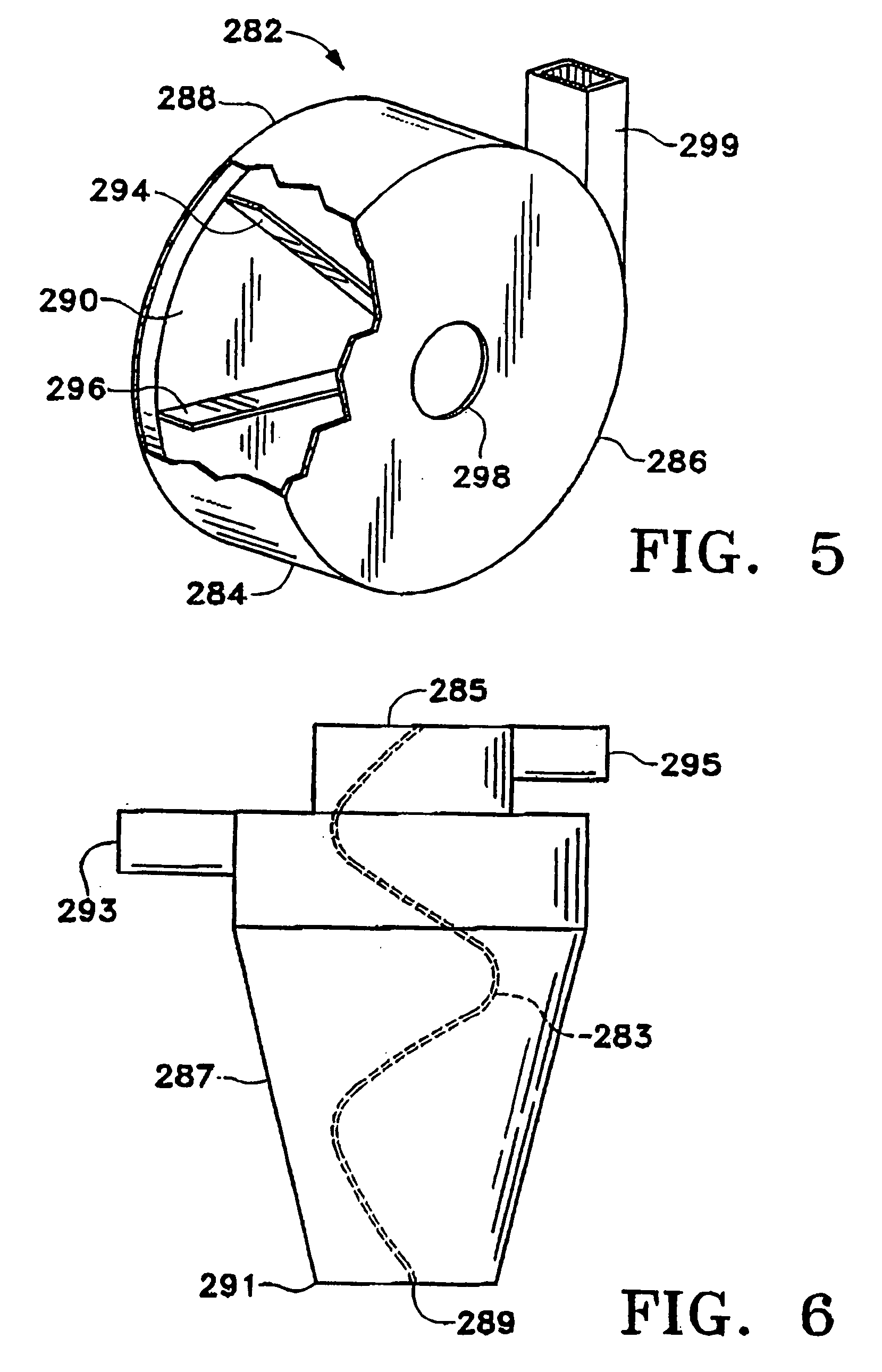

Polymeric foam powder processing techniques, foam powders products, and foams produced containing those foam powders

Owner:MOBIUS TECH

Polyamide toughening agent as well as preparation method and use thereof

InactiveCN104177825AImprove impact resistanceImprove low temperature impact resistanceElastomerPolyolefin

The invention provides a polyamide toughening agent as well as a preparation method and use thereof. The polyamide toughening agent is mainly prepared from the following raw materials in parts by weight: 50-95 parts of an ethylene-octene copolymer elastomer, 0.5-2.5 parts of a grafting monomer, 5-50 parts of polyolefin, 0.05-0.5 part of an initiator and 5-20 parts of polyamide. The toughening agent provided by the invention is simple in preparation method, have good mechanical property and low-temperature impact toughness when being used for toughening the polyamide, and can be widely applied to modification of polyamide materials in the fields of inner and outer decorative parts of automobiles, electric tools, rail bases, transformers, oil tubes and the like.

Owner:DONGGUAN CALVIN PLASTIC & TECH

Novel acrylic pressure-sensitive adhesive

ActiveCN108192019AWide range of bondingGood adhesionNon-macromolecular adhesive additivesAmide/imide polymer adhesivesFiberPolyester

Owner:SHANGHAI BAOLIJIA NEW MATERIAL CO LTD

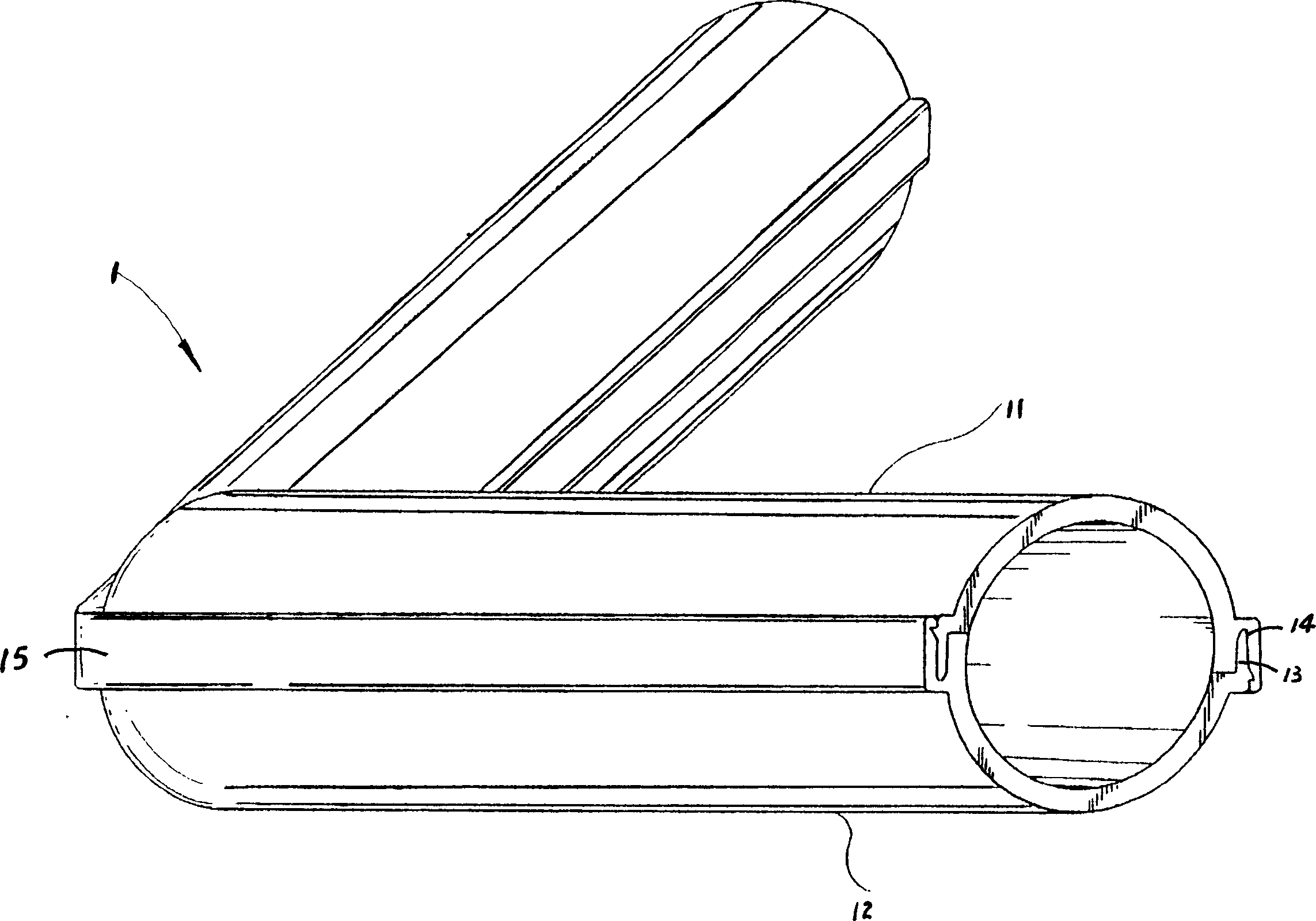

Microporous polyolefin film, separator for battery, and production processes therefor

ActiveUS20170274329A1Increase capacityReduce the numberMembranesSemi-permeable membranesPolymer sciencePolyolefin

A polyolefin microporous membrane is disclosed. The membrane has a width of not less than 100 mm, and a variation range of an F25 value in a width direction is not greater than 1 MPa. The F25 value is a value obtained by dividing a load at 25% elongation of a sample of the laminated polyolefin microporous membrane as measured with a tensile testing machine by a cross-sectional area of the sample.

Owner:TORAY IND INC

Method for forming multilayer coating film

InactiveUS20200010698A1Nice appearanceImprove chip resistanceLiquid surface applicatorsPolyurea/polyurethane coatingsPolymer sciencePolyolefin

Owner:HONDA MOTOR CO LTD +1

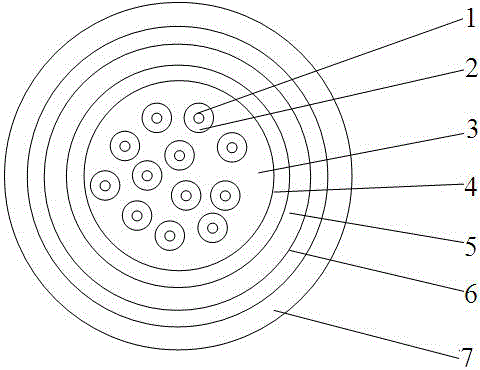

Marine low-smoke halogen-free low-toxicity frame-retardant fire-resistant soft optical cable and manufacturing method thereof

InactiveCN104570250AImprove transmission performanceFibre mechanical structuresLow smoke zero halogenPolyolefin

Owner:JIANGSU ZHONGTIAN TECH CO LTD

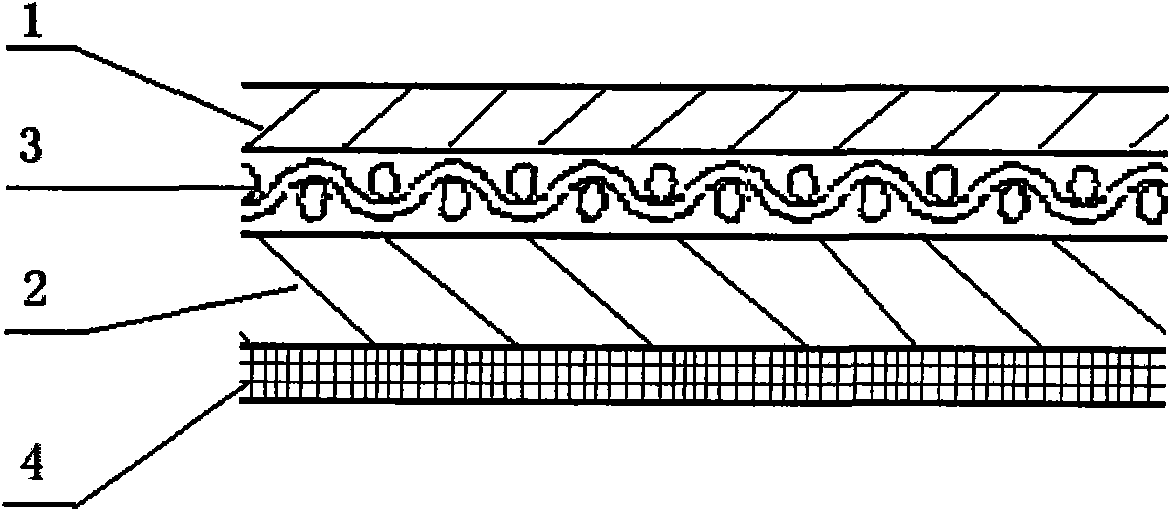

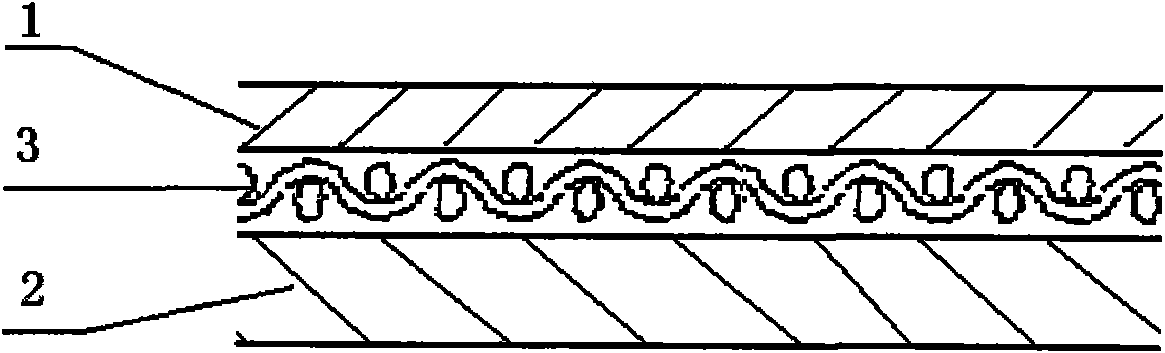

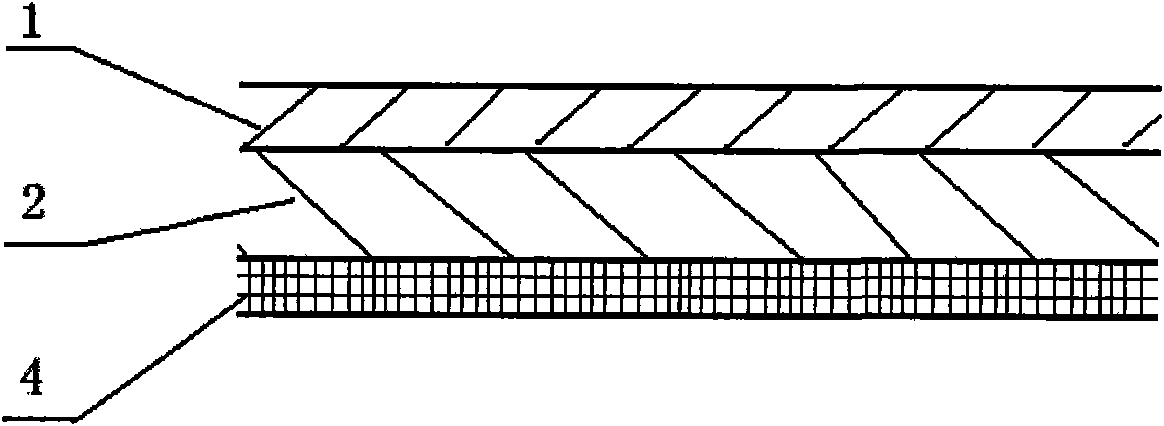

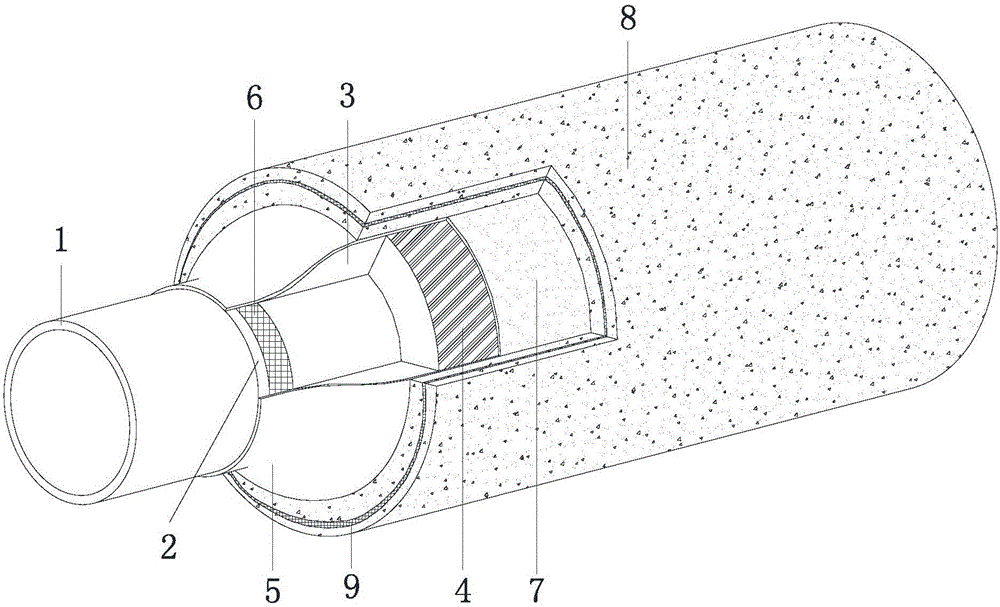

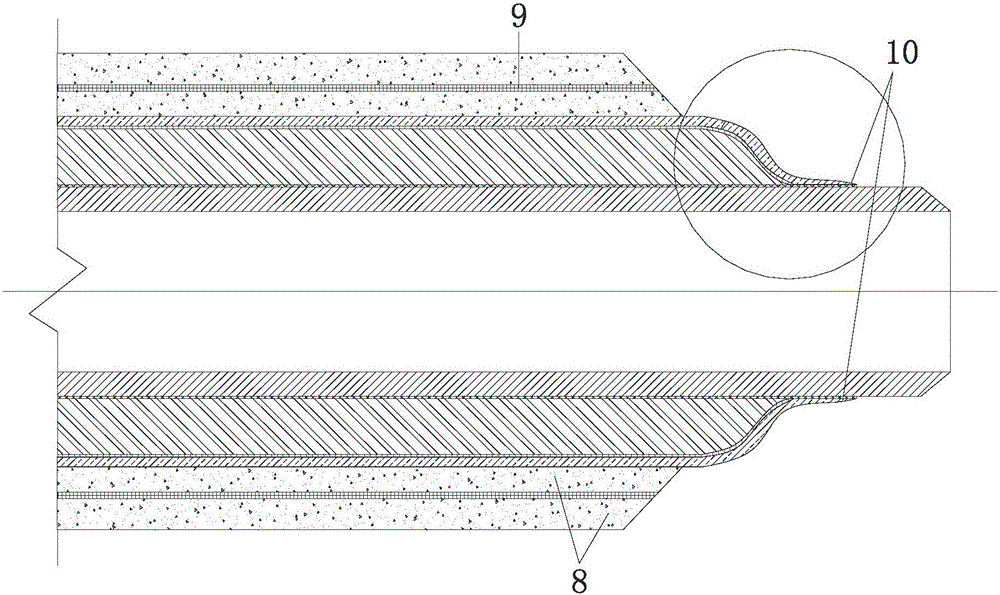

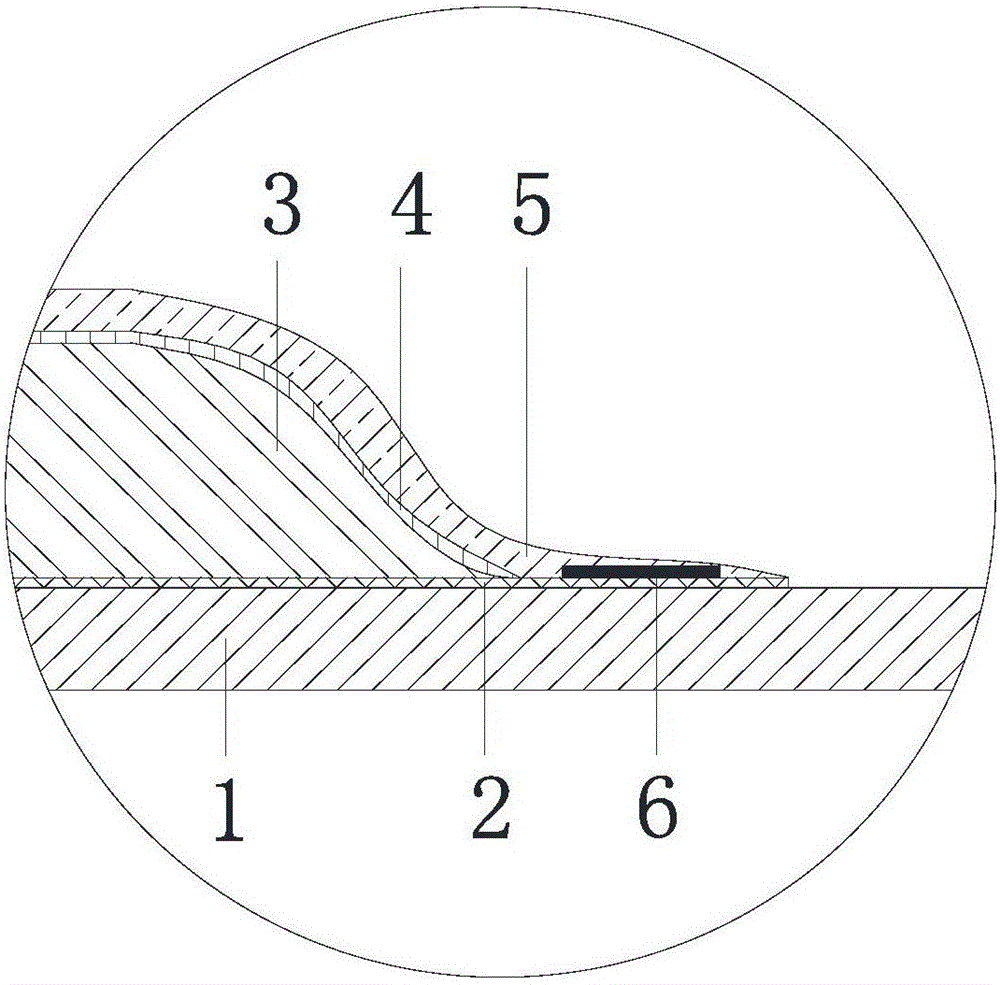

Marine polyurethane spraying prefabricated thermal insulation balance weight pipe and preparation method thereof

InactiveCN105909883AEnsure consistencyAvoid your own flawsThermal insulationPipe protection by thermal insulationPolyolefinAdhesive

Owner:CHINA NAT OFFSHORE OIL CORP +1

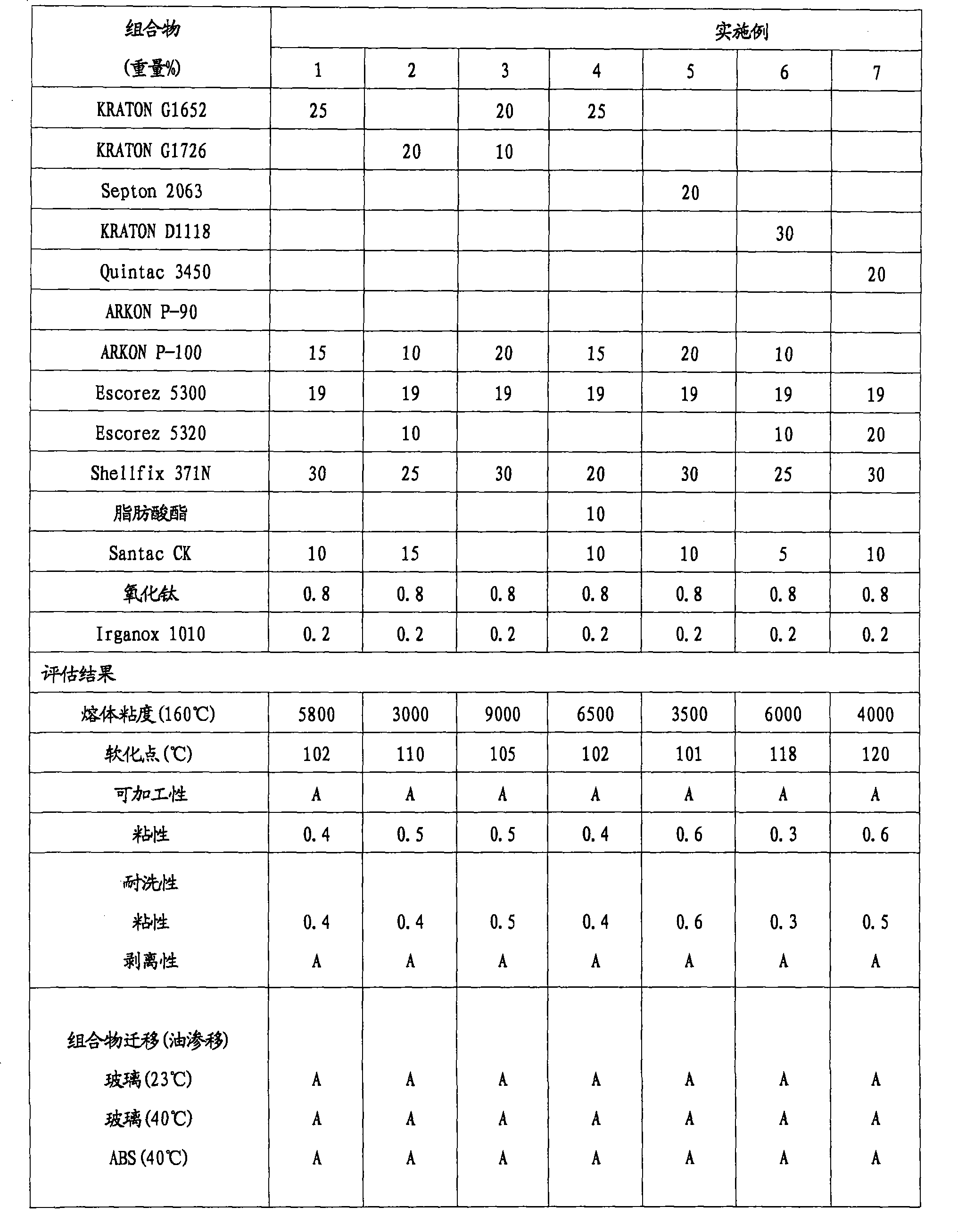

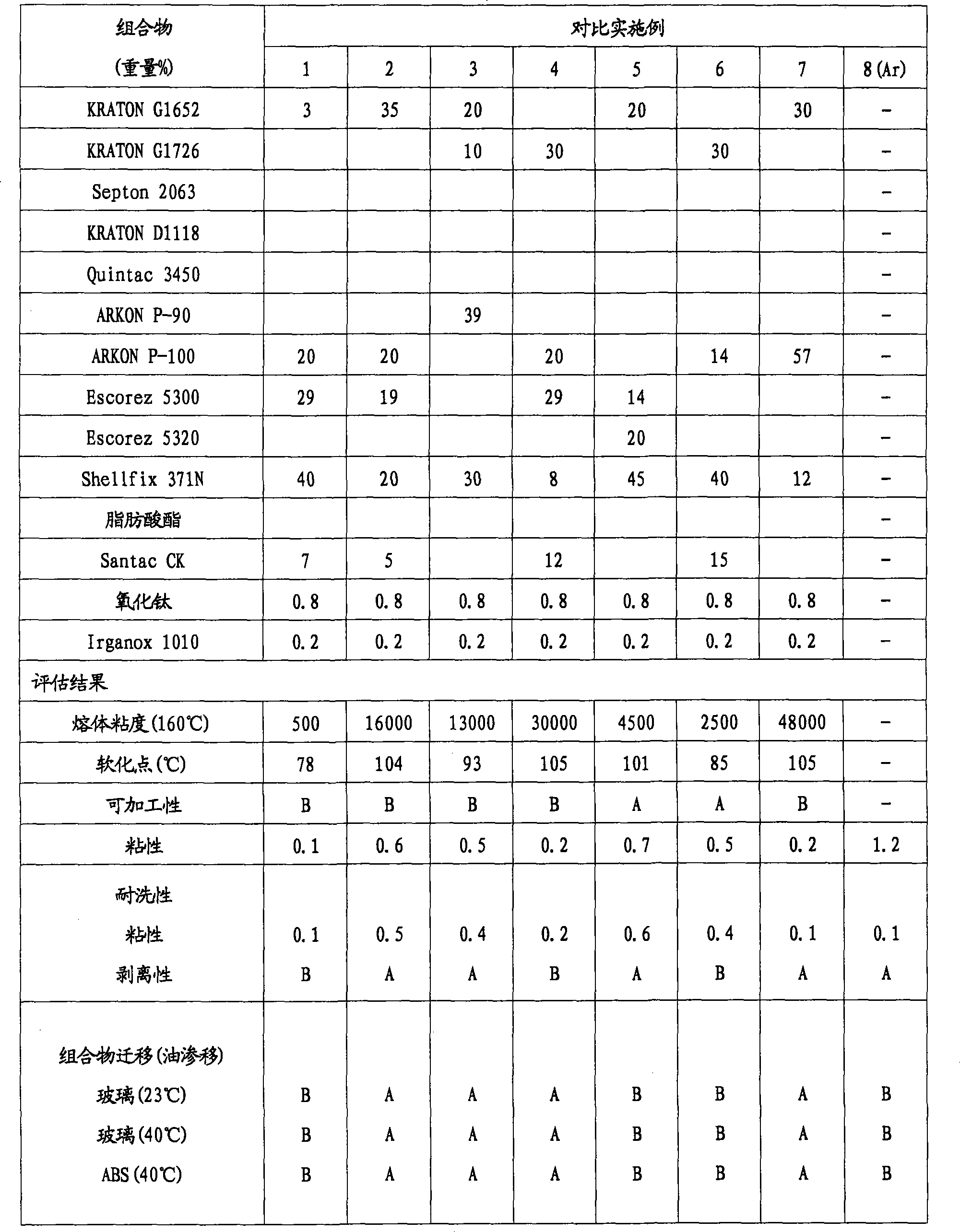

Hot melt composition for toilet seat sheet and toilet seat sheet

InactiveCN101381588AReduce manufacturing costIncrease productionBathroom coversAdhesivesPolyolefinEngineering

Owner:NISSHIN CHEM IND CO LTD

Master batch composition, polyolefin resin composiion comprising the same, and molded product thereof

Owner:IDEMITSU KOSAN CO LTD

TPO (thermoplastic polyolefin) waterproof roll material and preparation method thereof

ActiveCN104212066AImprove flame retardant performanceGood low temperature bending resistanceThermoplasticPolyolefin

Owner:河南蓝翎环科防水材料有限公司

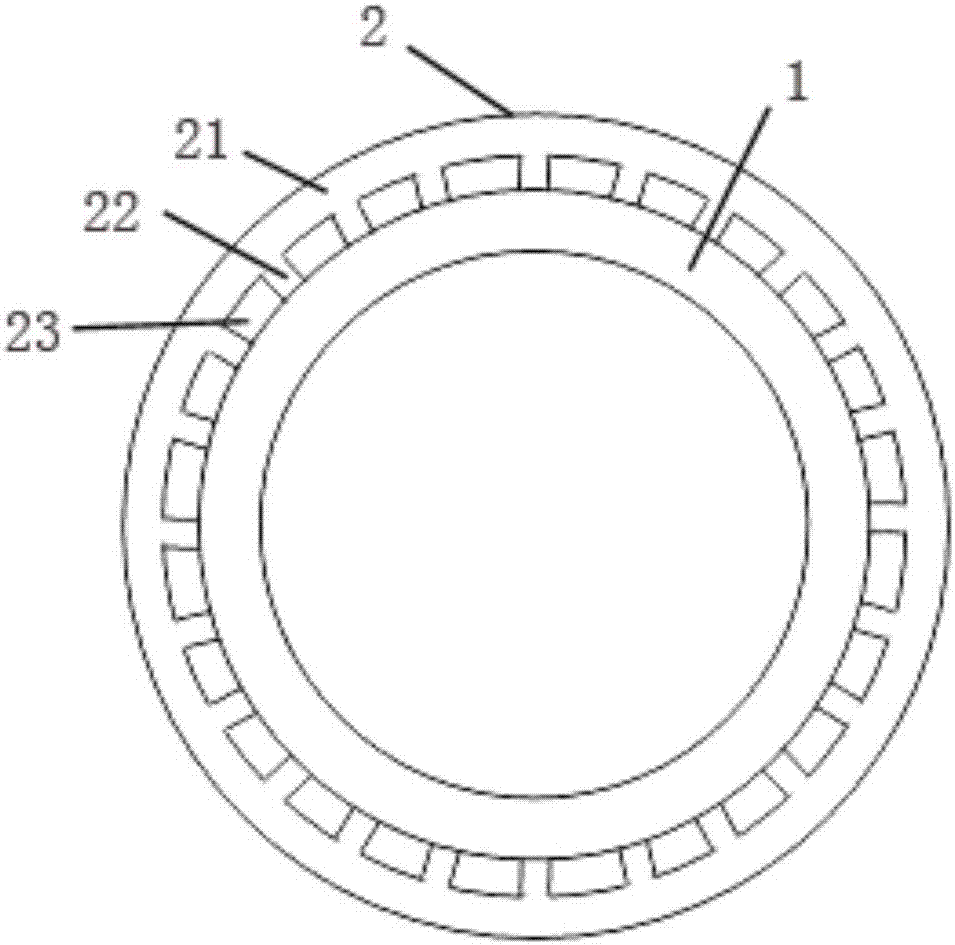

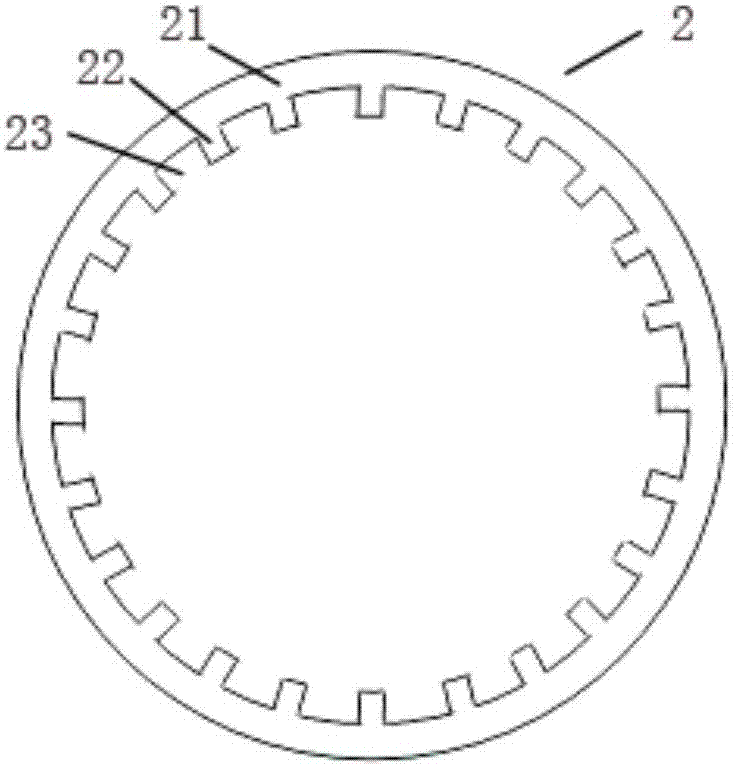

Shield haf type wire and cable protective sleeve

InactiveCN1858948AEasy to replaceEasy maintenanceCable installations in underground tubesNon-conductive material with dispersed conductive materialPolyolefinMetal powder

Owner:周宝茂 +2

Tinct olefinic hydrocarbon yarn and fabric using the same

Owner:AQUADYE FIBERS INC

Wafer processing method

ActiveUS20200286784A1Avoid quality lossAvoid problemsFilm/foil adhesivesSolid-state devicesPolyolefinWafering

A wafer processing method includes a polyolefin sheet providing step of positioning a wafer in an inside opening of a ring frame and providing a polyolefin sheet on a back side or a front side of the wafer and on a back side of the ring frame, a uniting step of heating the polyolefin sheet as applying a pressure to the polyolefin sheet to thereby unite the wafer and the ring frame through the polyolefin sheet by thermocompression bonding, a dividing step of applying a laser beam to the wafer to form modified layers in the wafer, thereby dividing the wafer into individual device chips, and a pickup step of picking up each device chip from the polyolefin sheet.

Owner:DISCO CORP

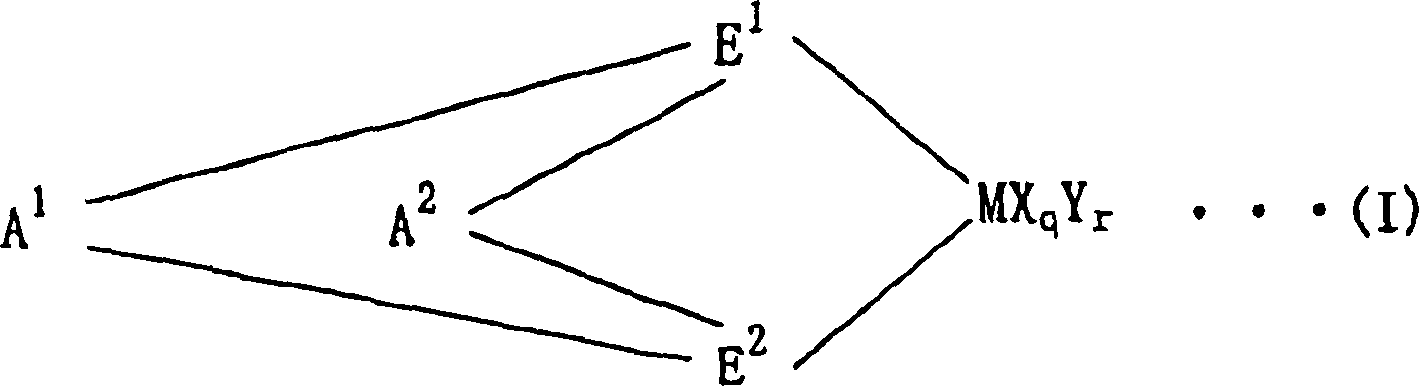

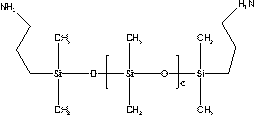

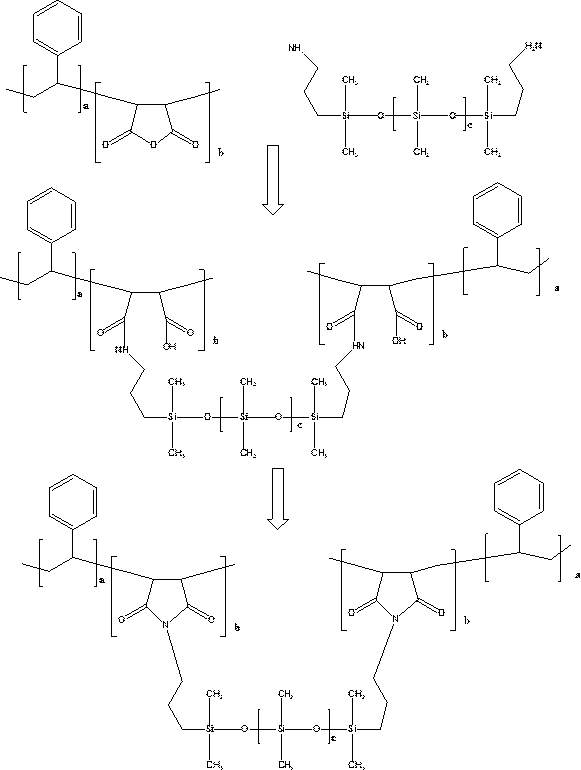

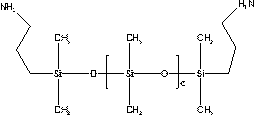

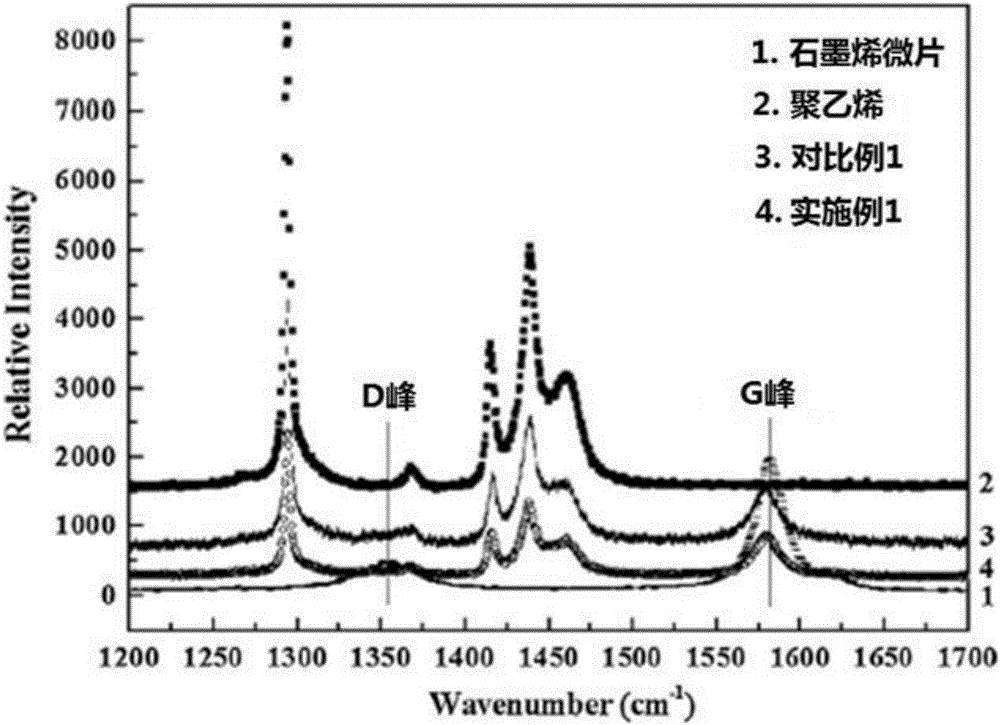

Synthesis of end amino silicone oil modified stryenemaleic anhydride copolymer

InactiveCN109337085AFlexible structure adjustmentControl Molecular Weight DistributionElastomerPolyolefin

Owner:YANTAI DARBOND TECH

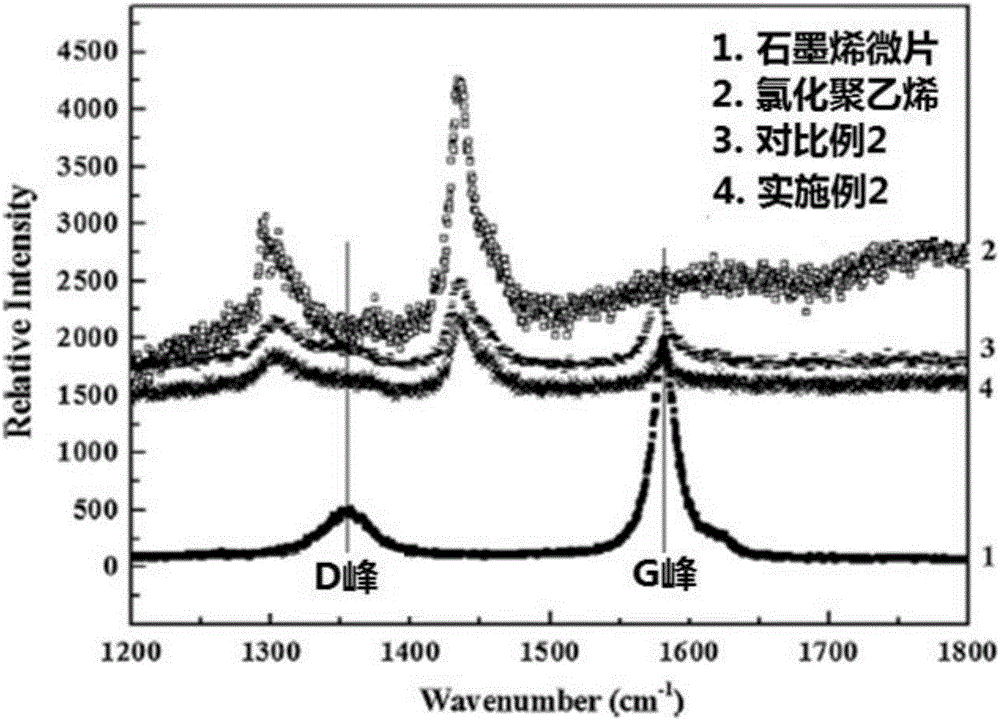

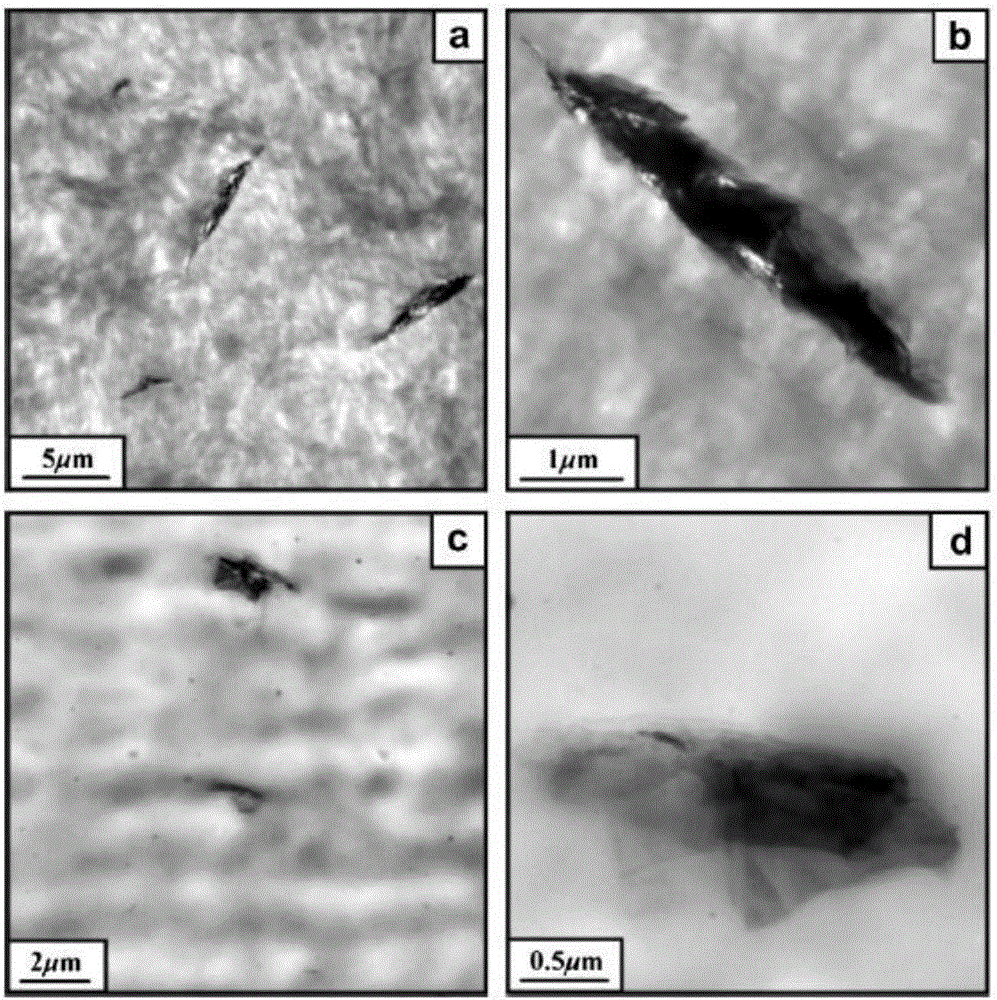

Polymer/carbon nano composite material and preparation method thereof

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG +1

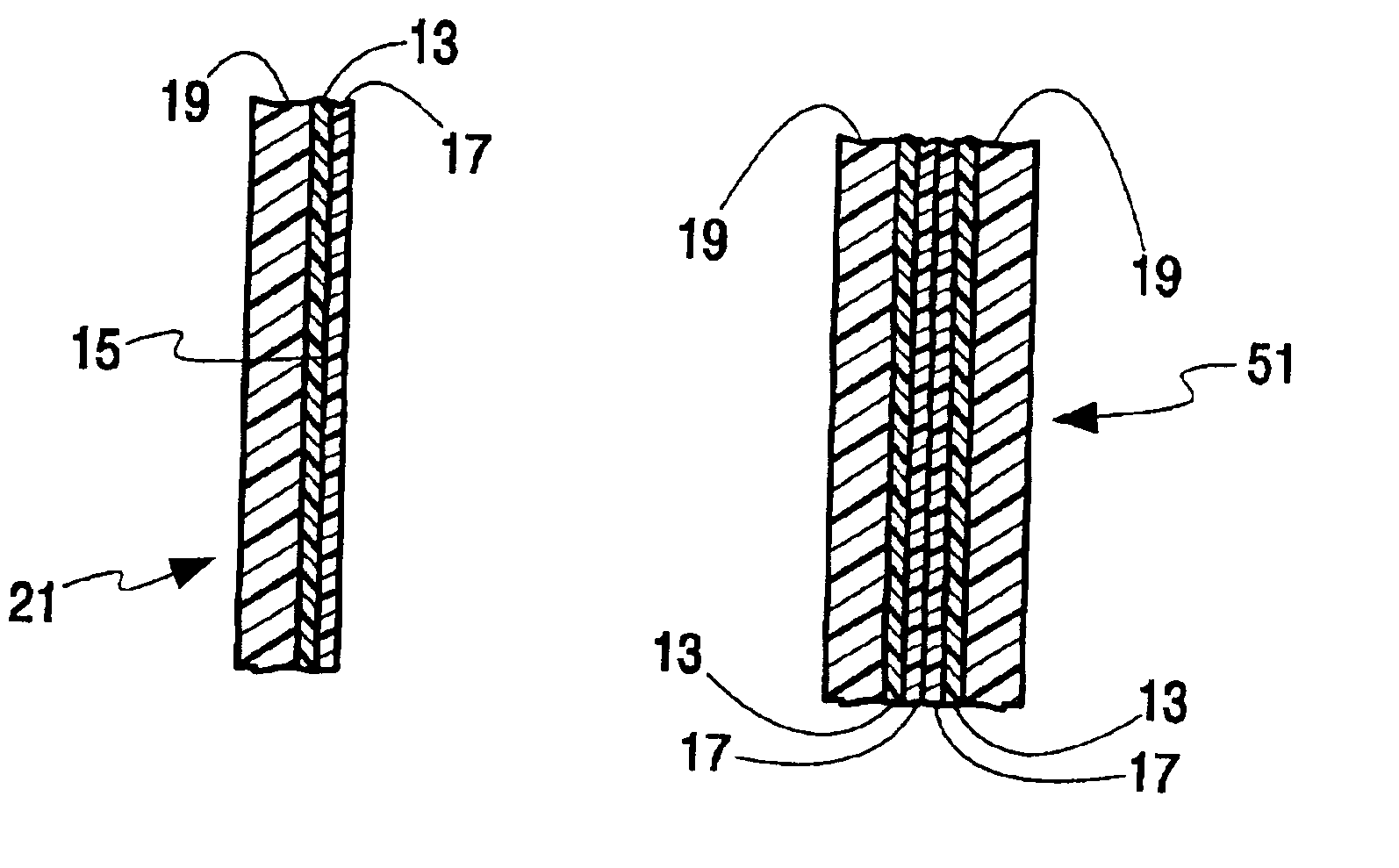

Identification card

InactiveUS6908527B2Increase awarenessPositive identificationOther printing matterLamination ancillary operationsPolyolefinEngineering

Owner:TRANSCENDIA INC

Method for the reduction of polar additives required for use in polyolefins

Owner:DOW GLOBAL TECH LLC

Composite wax with excellent cutting ability, and preparation method thereof

Owner:HANGZHOU ERRAN TECH

Halogen-free metal insulating tube and preparation method thereof

InactiveCN107573573AAchieve low smokeNot easy to catch fireThermal insulationCorrosion preventionCrack resistancePolyolefin

Owner:佛山市恒合信管业有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap