Halogen-free metal insulating tube and preparation method thereof

A technology of thermal insulation pipe and metal pipe body, which is applied in the direction of thermal insulation and protection of pipes and pipes through thermal insulation, can solve the problems of poor flame retardancy, release of harmful substances, complex structure and other problems of thermal insulation pipes, and achieves low cost, long service life, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] Correspondingly, the present invention also provides a preparation method of a halogen-free metal insulation pipe, comprising:

[0055] (1) Add polyethylene, ethylene vinyl acetate copolymer, flame retardant and silane coupling agent into the reactor, and copolymerize through coupling reaction to make polyolefin cable material;

[0056] (2) The polyolefin cable material is extruded through an extruder, and compounded on the outer surface of the metal pipe body.

[0057] Specifically, step (1) includes:

[0058] Add polyethylene, ethylene-vinyl acetate copolymer, flame retardant and silane coupling agent into the internal mixer for full rotation and mixing, and internal mixing. The temperature of the internal mixer is set at 105-120°C, and the time is 5-15min. The speed of the mill is 100-300r / min;

[0059] Send the mixed material mixed into the twin-screw extruder, and the twin-screw extruder shears, kneads and fully extrudes the mixed material;

[0060] The extruded mi

Embodiment 1

[0068] (1) Preparation of polyolefin cable material:

[0069] (1), take raw material by following formula:

[0070]

[0071] (2) Add the above-mentioned raw materials in the internal mixer to fully rotate and mix, internal mixer, the temperature of the internal mixer is set to 105 ℃, the time is 5min, and the rotating speed of the internal mixer is 100r / min;

[0072] (3) Send the mixed material mixed by banburying into the twin-screw extruder, and the twin-screw extruder shears, mixes and fully extrudes the mixed material;

[0073] (4) The extruded mixed material is extruded by the machine head, drawn, cooled, and pelletized to obtain polyolefin cable material;

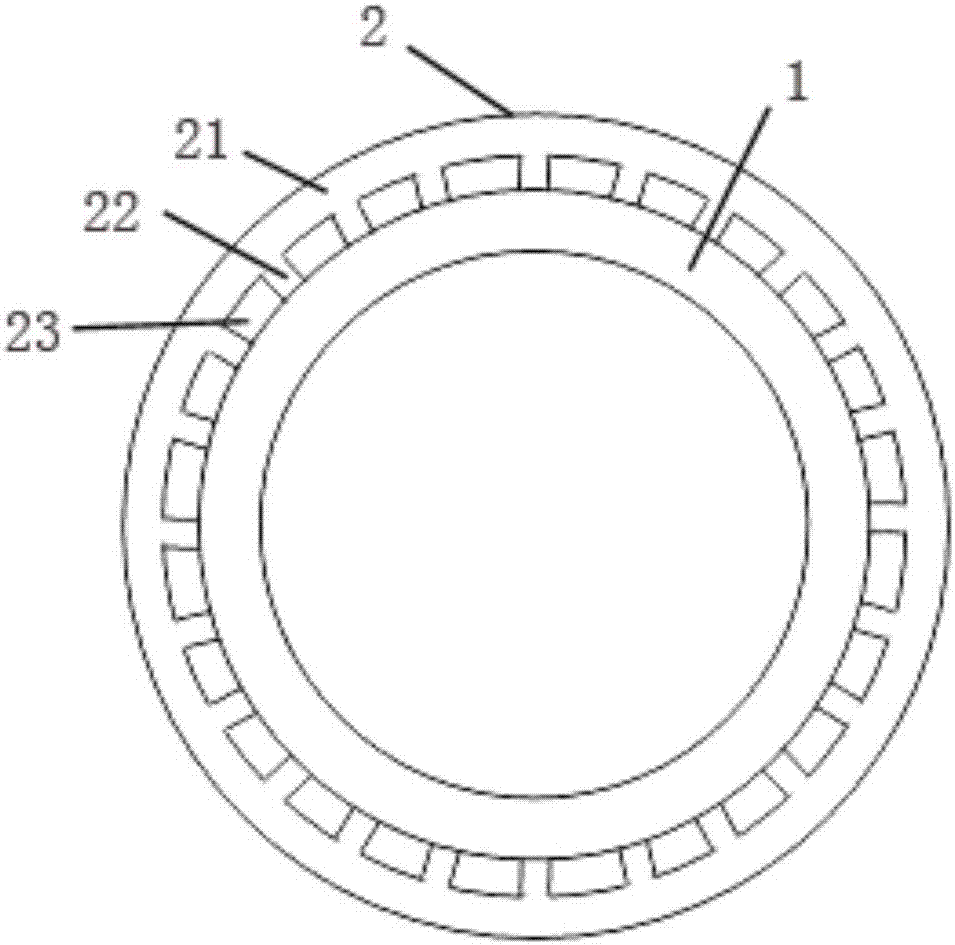

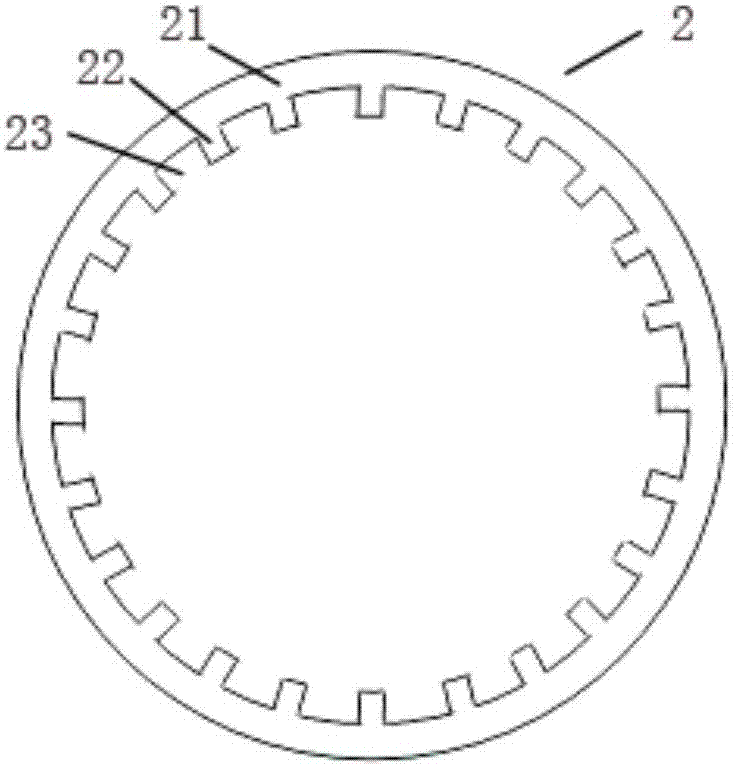

[0074] (2) The polyolefin cable material is extruded through an extruder, and compounded on the outer surface of the metal pipe body to obtain a halogen-free metal insulation pipe. Wherein, the metal pipe body is a stainless steel pipe, and the insulation layer includes a base and a plurality of protrusions arrang

Embodiment 2

[0076] (1) Preparation of polyolefin cable material:

[0077] (1), take raw material by following formula:

[0078]

[0079]

[0080] (2) Add the above-mentioned raw materials into the internal mixer to fully rotate and mix, internal mixer, the temperature of the internal mixer is set to 110 ℃, the time is 8min, and the rotating speed of the internal mixer is 150r / min;

[0081] (3) Send the mixed material mixed by banburying into the twin-screw extruder, and the twin-screw extruder shears, mixes and fully extrudes the mixed material;

[0082] (4) The extruded mixed material is extruded by the machine head, drawn, cooled, and pelletized to obtain polyolefin cable material;

[0083] (2) The polyolefin cable material is extruded through an extruder, and compounded on the outer surface of the metal pipe body to obtain a halogen-free metal insulation pipe. Wherein, the metal pipe body is a stainless steel pipe, and the insulation layer includes a base and a plurality of prot

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap