Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

16 results about "Power cable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A power cable is an electrical cable, an assembly of one or more electrical conductors, usually held together with an overall sheath. The assembly is used for transmission of electrical power. Power cables may be installed as permanent wiring within buildings, buried in the ground, run overhead, or exposed.

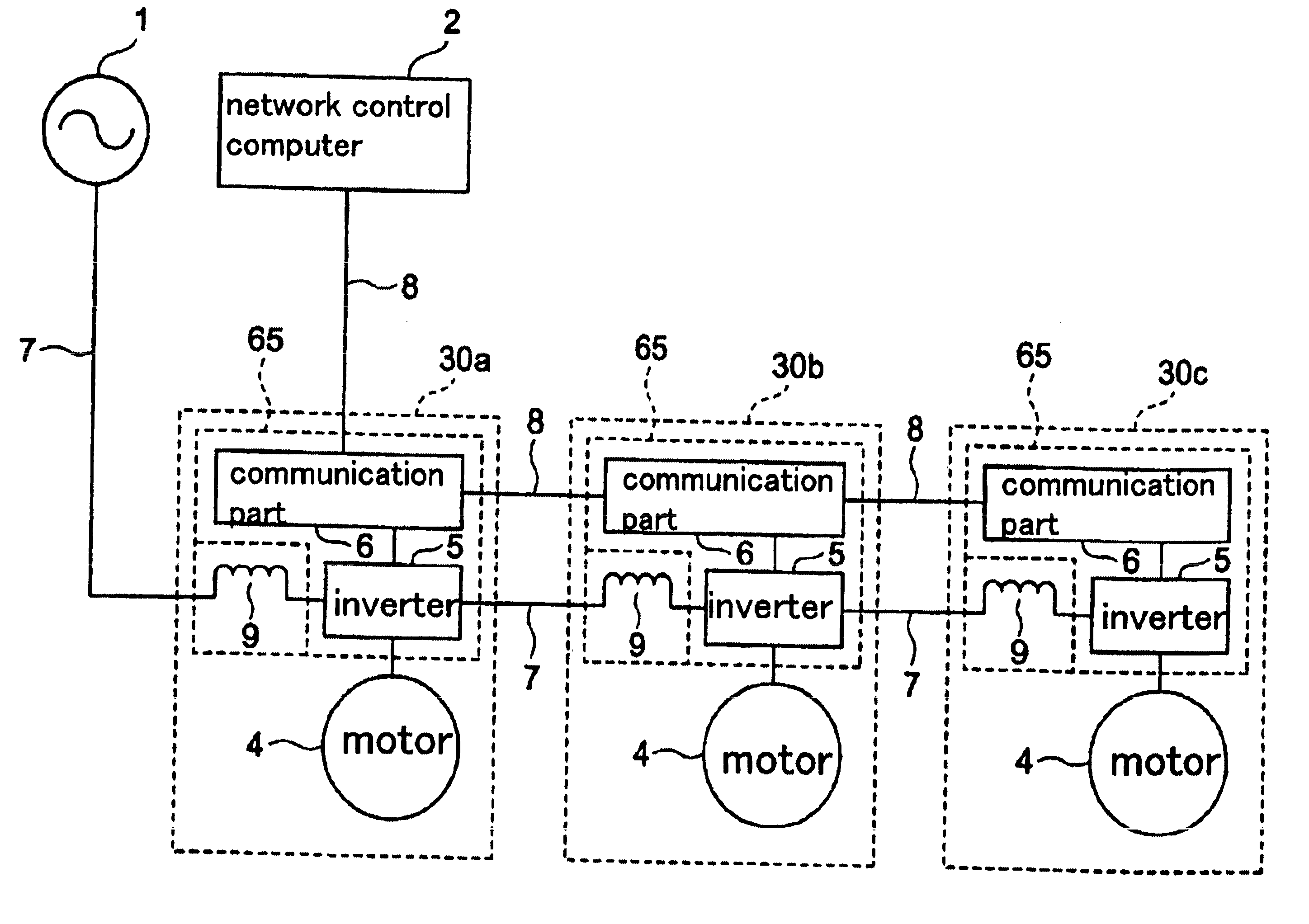

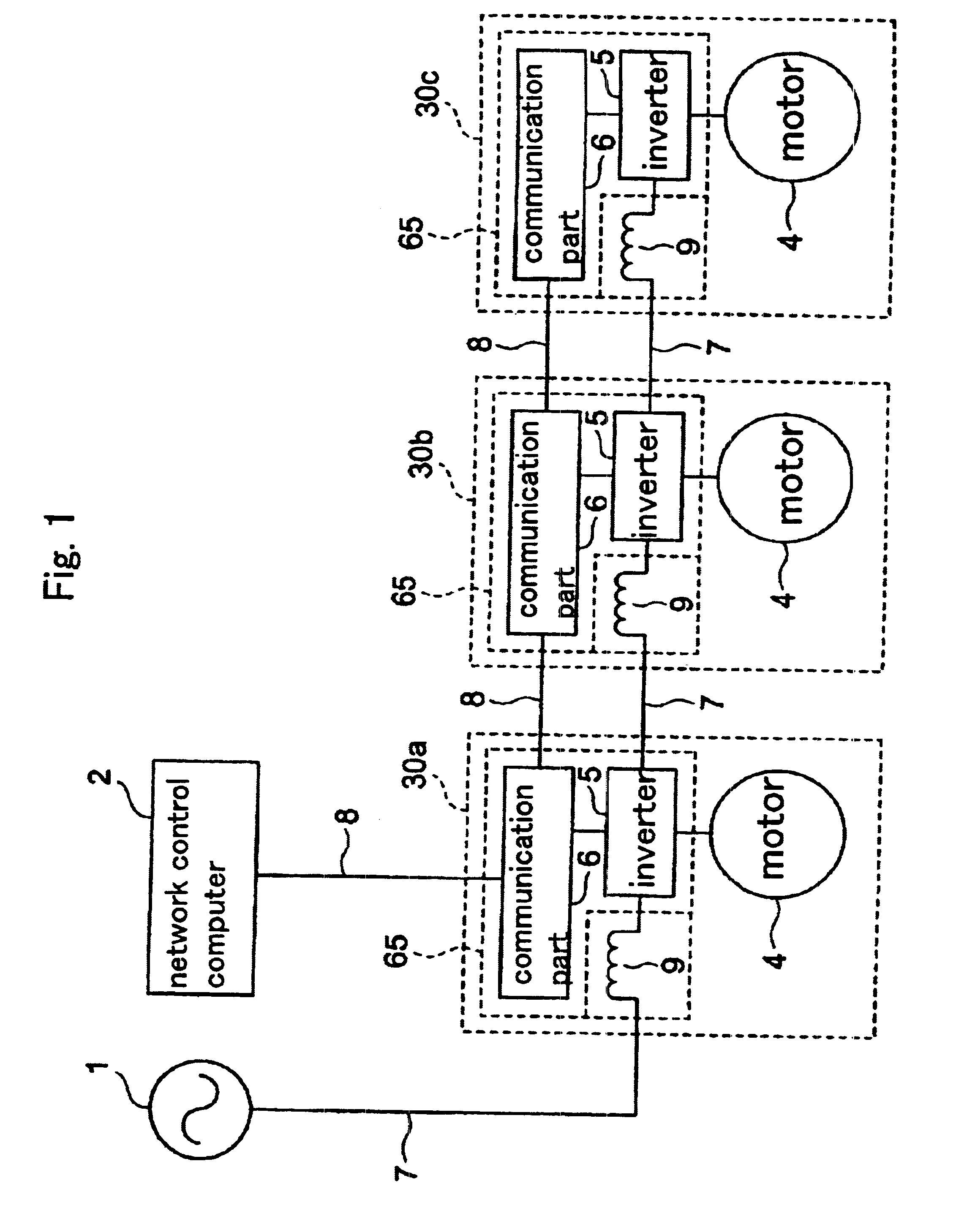

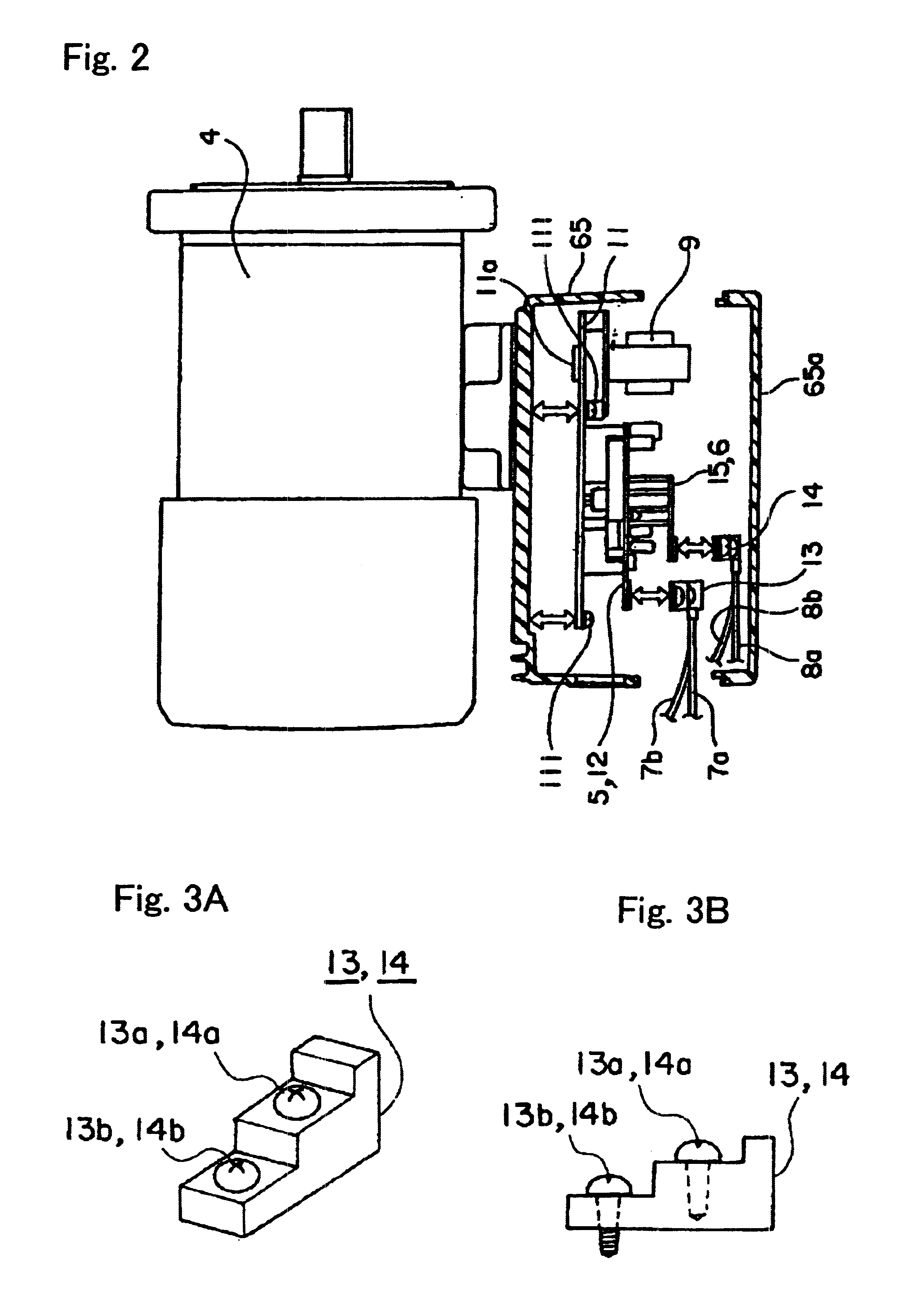

Motor network control system

InactiveUS6686712B2Shorten the line lengthEasy to carryElectrically conductive connectionsMultiple dynamo-motor startersPower cableControl system

Owner:MITSUBISHI ELECTRIC CORP

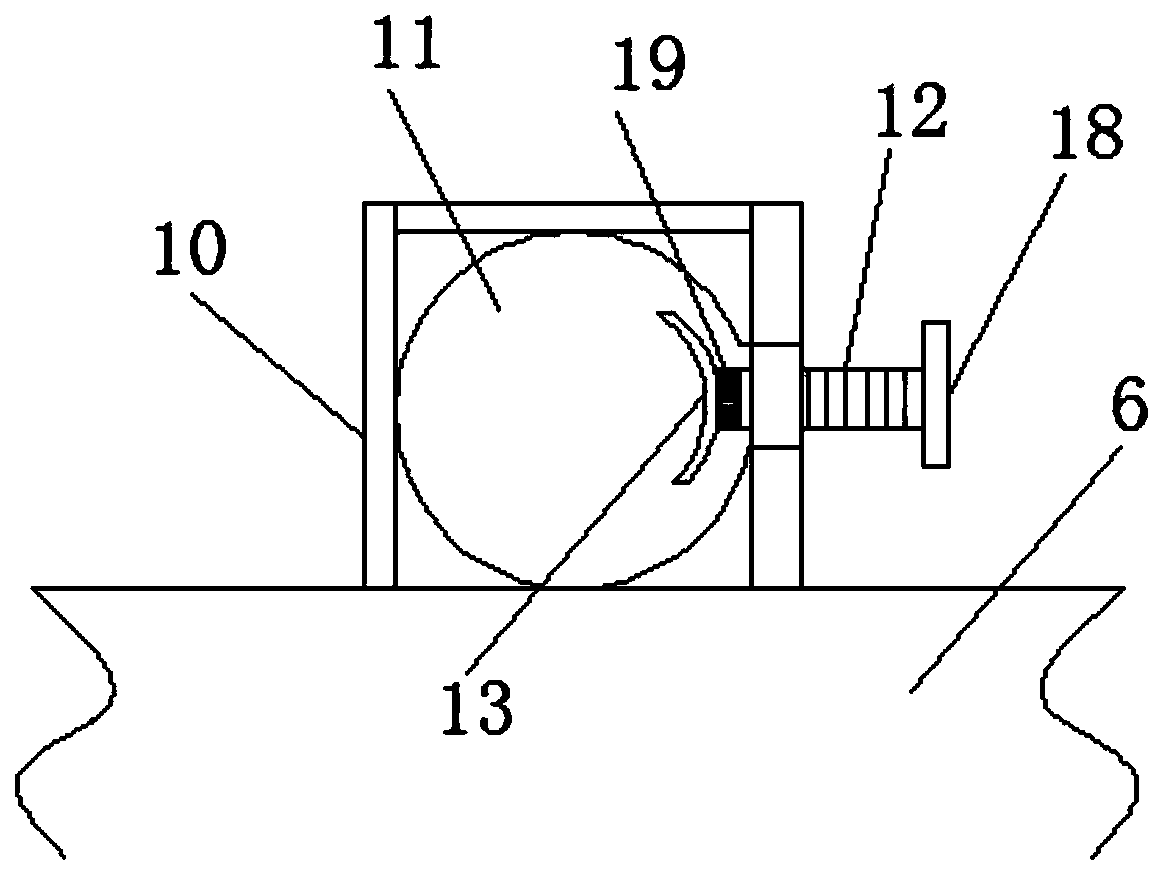

Power cable coiling device

Owner:陈佳敏

Low Dielectric Loss Power Cable Sheaths Comprising High Pressure Polyolefins Free of Silane Functionality

Power cables that comprise a sheath layer, e.g., an insulation layer, are produced from a mixture of a high pressure polyolefin free of silane functionality, e.g., high pressure low density polyethylene, and a polyether polyol of which at least 50 percent of its molecules comprise no more than a single hydroxyl functionality. Preferably, the power cable is a medium or high voltage power cable, and the polyolefin is crosslinked as the sheath layer is fabricated and / or subsequent to the fabrication of the sheath layer.

Owner:DOW GLOBAL TECH LLC

Preparation method of modified polyethylene terephthalate cable sheath tube

InactiveCN102604338AHigh strengthHigh compressive strengthCable installations in underground tubesDiethyl phosphatePolymer science

The invention relates to a preparation method of a modified polyethylene terephthalate cable sheath tube. The preparation method comprises the following steps of: with 62-73 parts by weight of polyethylene terephthalate as a raw material, adding 15-20 parts by weight of propylene-ethylene block copolymer, 5-8 parts by weight of ethylene-acrylic acid ethyl ester copolymer, 6.5-9.0 parts by weight of micro-encapsulation red phosphorus, 0.5-1.0 part by weight of 3, 5-di-tert-butyl-4 hydroxy benzyl diethyl phosphate, drying the mixture, stirring and mixing the mixture at a high speed, extruding and pelletizing the mixture by using a double screw, extruding and forming by using a single screw, and forming the cable sheath tube by using a cooling and setting technology. The cable sheath tube prepared by the method has the advantages that the vicat softening temperature is higher than 153 DEG C, the ring stiffness is greater than 25KN / m<2>, the volume resistivity is greater than 3.0*1011, the creep resistance and flame retardant property are good; and the cable sheath tube is suitable for the fields of buried power cable sheaths and the like.

Owner:FUJIAN NORMAL UNIV +4

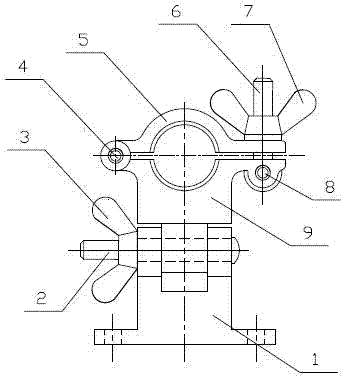

Fixing device of welding cable of welding robot

InactiveCN103498966ALarge clamping forceWork reliablyPipe supportsWelding/cutting auxillary devicesPower cableEngineering

Owner:JISHOU WOHUADE ROBOT SCI & TECH

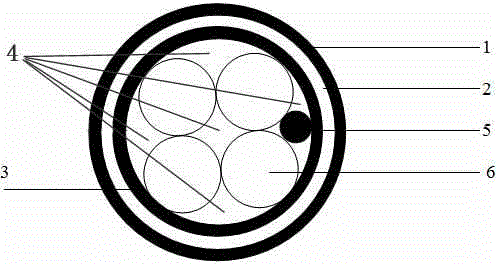

Optical fiber composite low-voltage power cable

PendingCN106876030AAvoid damageGuaranteed reliabilityInsulated cablesPower cables including optical transmission elementsCarbon fibersPower cable

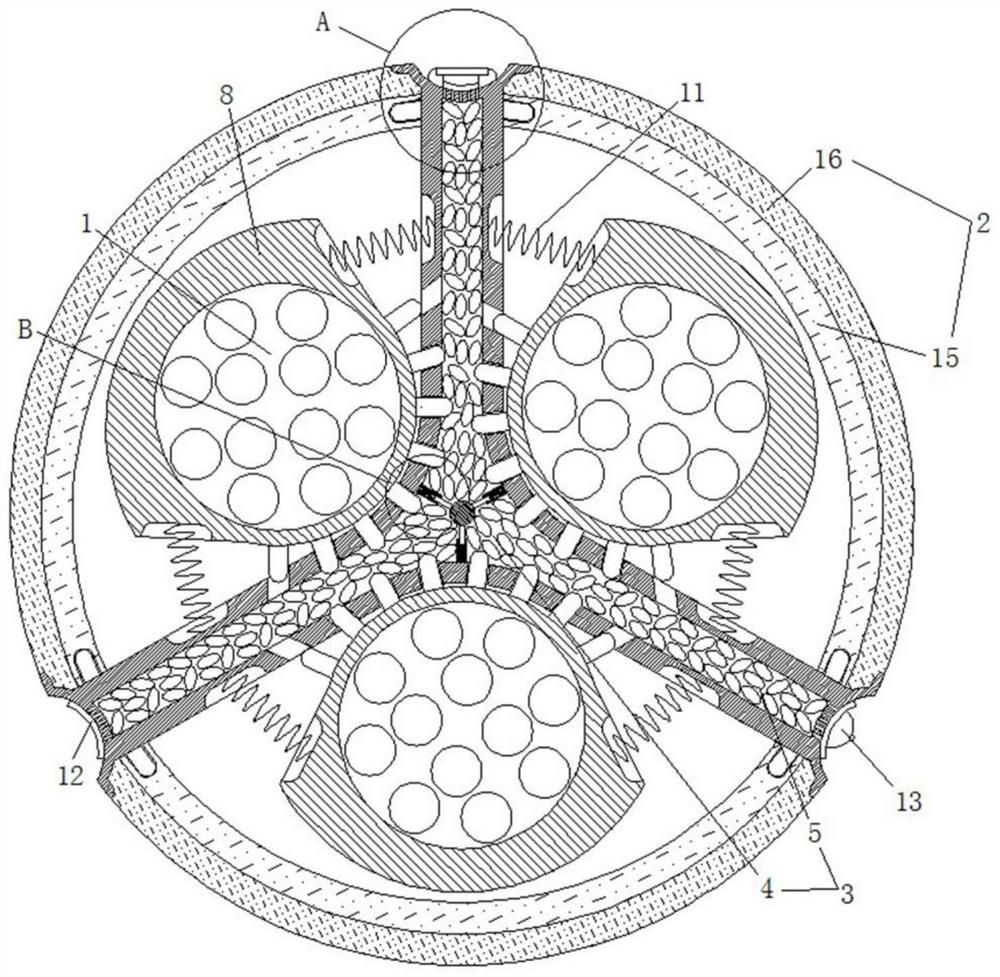

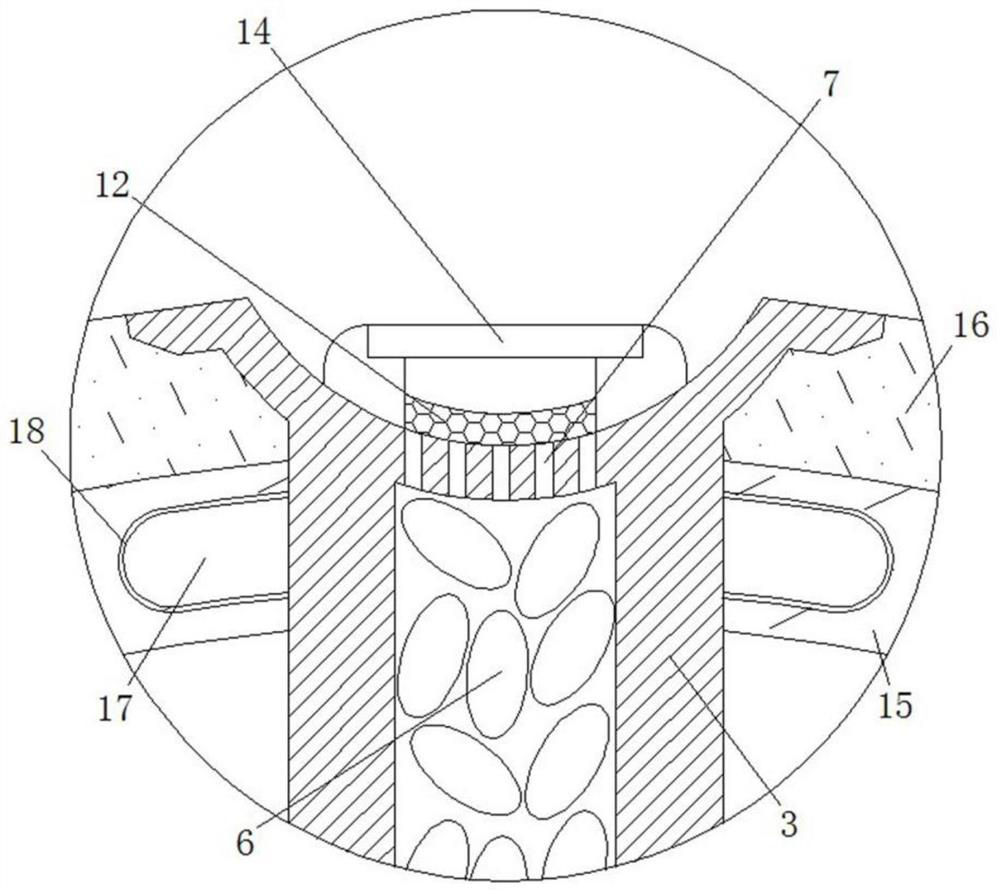

The invention is applicable to the technical field of a cable, and discloses an optical fiber composite low-voltage power cable. The optical fiber composite low-voltage power cable comprises an outer insulating composite sleeve, conductors and an optical unit, wherein the outer insulating composite sleeve comprises an outer sheath insulating layer, a metal armor layer, an inner lining insulating layer and a warping tape layer; each conductor comprises a metal core wire and a core wire insulating sleeve; the optical unit comprises a composite protection sleeve and optical fibers positioned in the composite protection sleeve; the optical fibers comprise 12 fiber cores; a cladding layer is arranged on the exterior of each fiber core; a polyacrylonitrile carbon fiber bundle is also arranged in the protection sleeve; the polyacrylonitrile carbon fiber bundle is sleeved with a shaping sleeve; the composite protection sleeve comprises a silica gel pipe and a coating layer on the inner side of the silica gel pipe; the thickness of the silica gel pipe is greater than or equal to 25% of the diameter of each conductor; and the interior of the warping tape layer is filled with a non-hygroscopic filler. The optical fiber composite low-voltage power cable provided by the invention can prevent the optical unit from being damaged caused by pulling and bending, so as to ensure communication reliability and continuity, so that the product has excellent reliability.

Owner:SHENZHEN BENDAKANG CABLE

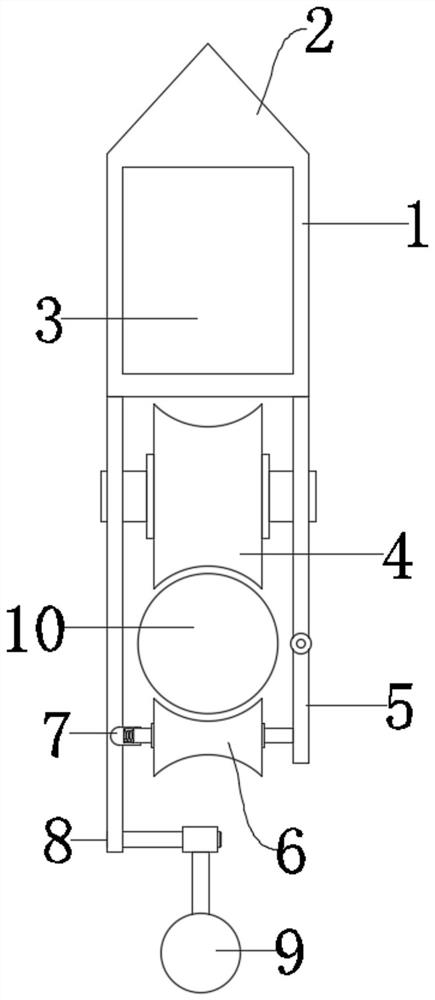

Electric power overhead cable sag adjusting device

InactiveCN114374182AAchieve regulationGuaranteed rateAdjusting/maintaining mechanical tensionPower cableElectric machine

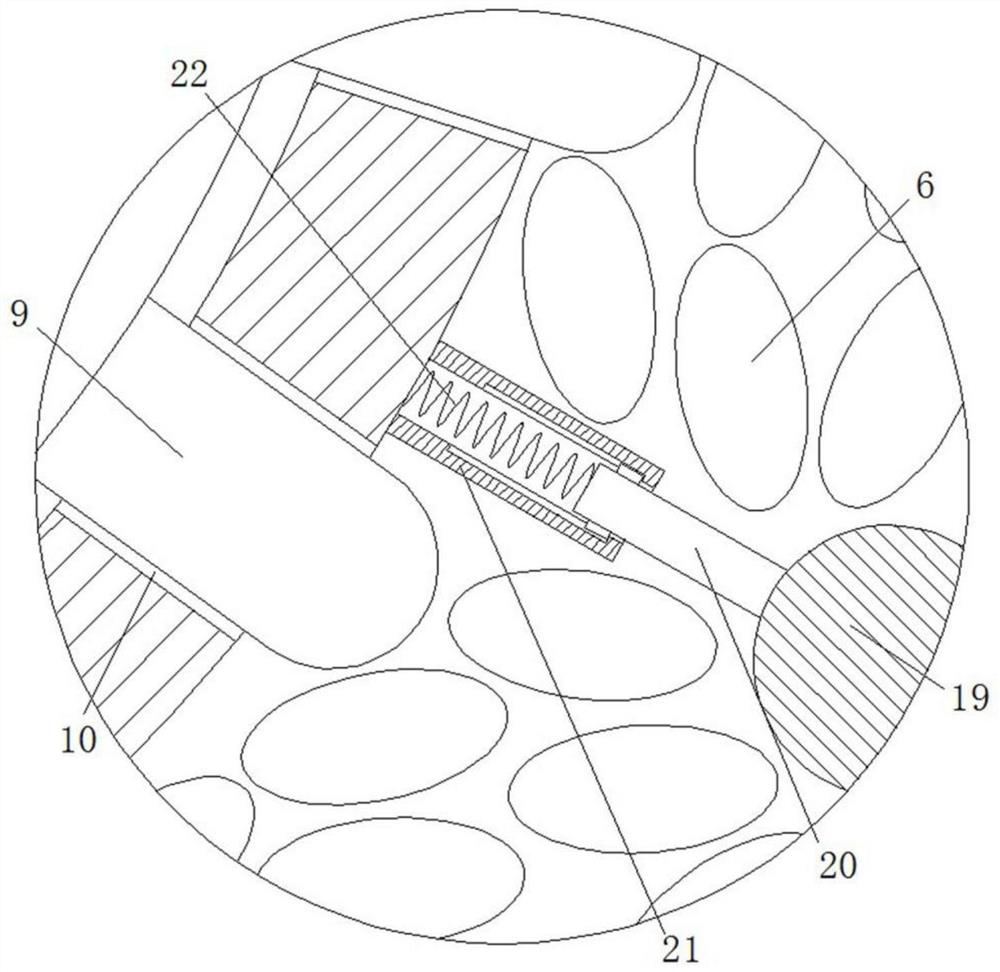

An electric power overhead cable sag adjusting device relates to the field of electric power cables. The invention aims to solve the problem that in the prior art, only sag detection can be carried out, sag processing cannot be carried out in time, and then the accident occurrence probability is increased. A power output shaft of a motor is coaxially connected with one end of a screw, the screw is in threaded connection with a nut, one end of an upper swing arm is hinged to one end of a lower swing arm, the other end of the upper swing arm is hinged to a motor shell, the other end of the lower swing arm is hinged to the outer circumferential face of the nut, and the upper swing arm, the lower swing arm and the screw are located on the same plane. An electromagnetic energy taking coil of the high-voltage cable induction power taking device is fixed to one end of the upper swing arm, the control part collects sag in real time through the sag monitoring device and compares the collected sag with a standard threshold value range, when the collected sag is larger than the upper limit of the standard threshold value range, the driving motor rotates forwards, and otherwise, the driving motor rotates backwards.

Owner:江志磊

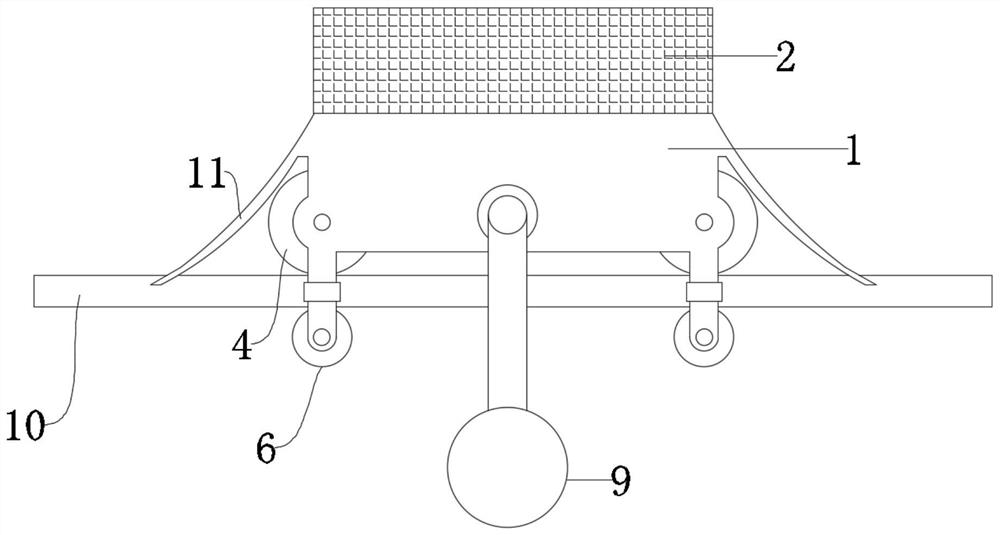

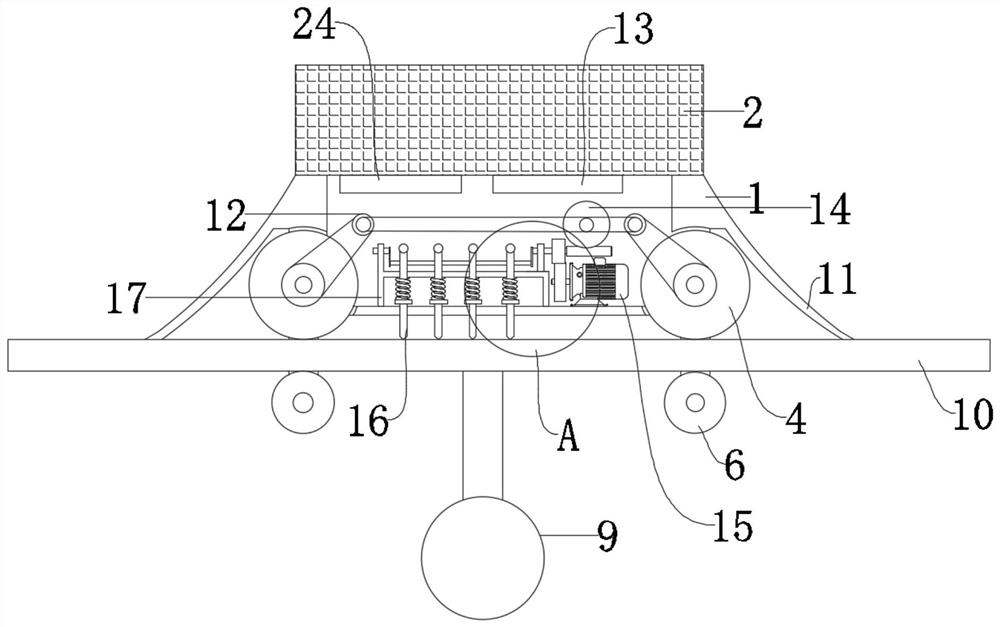

Deicing device for power cable

InactiveCN112202133AImprove efficiencySimple structureOverhead installationApparatus for overhead lines/cablesSnow removalPower cable

Owner:张希刚

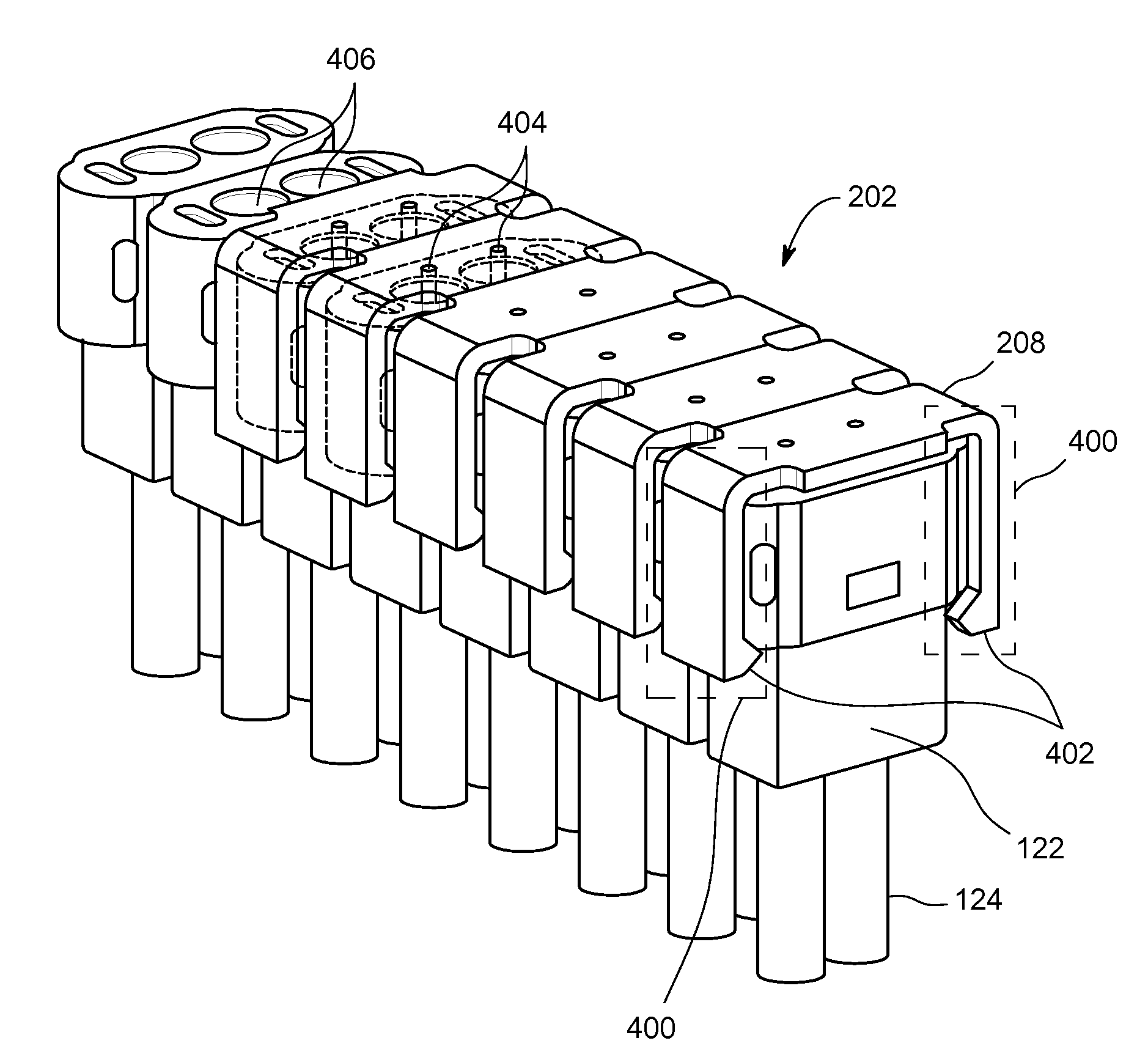

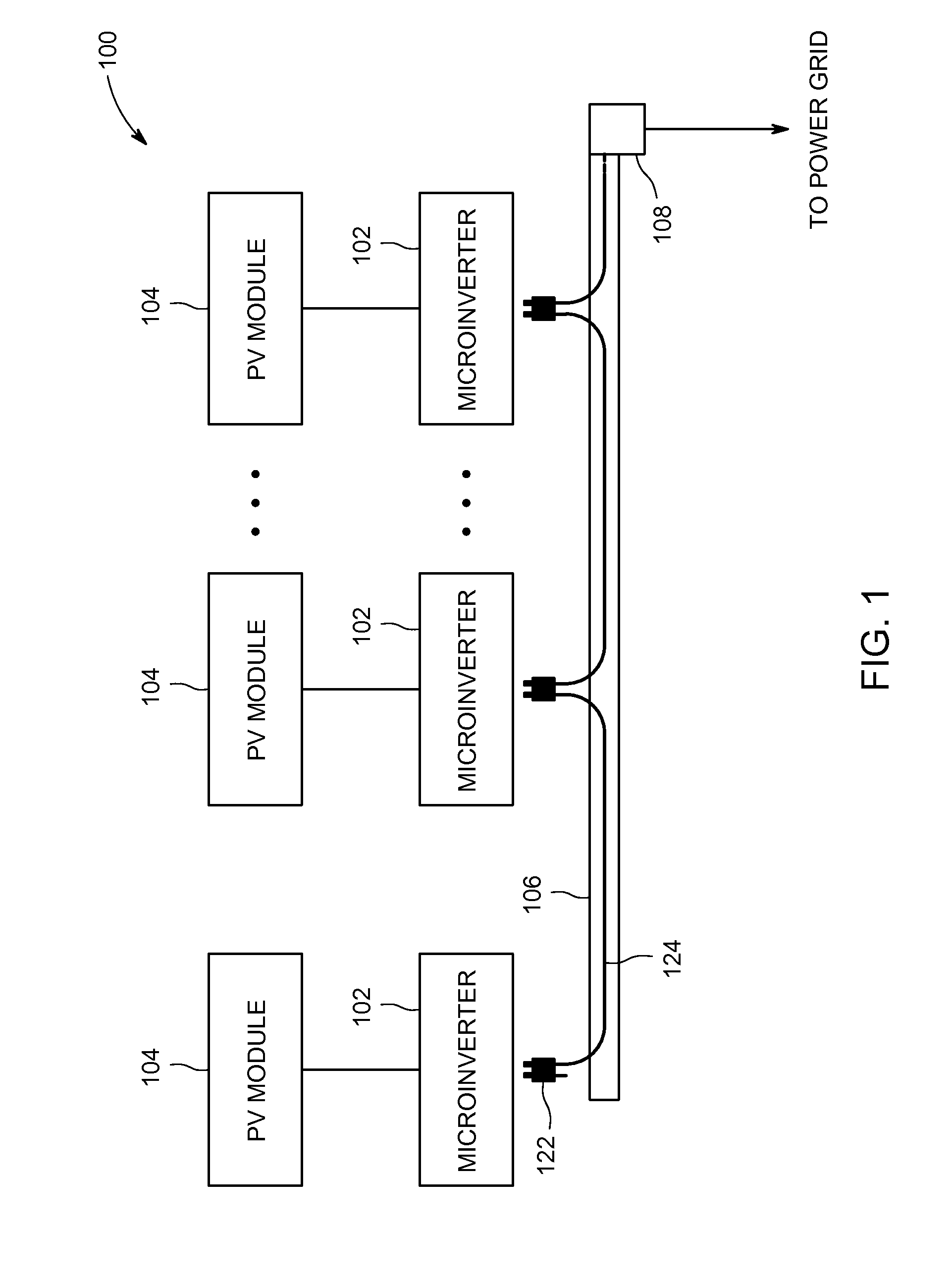

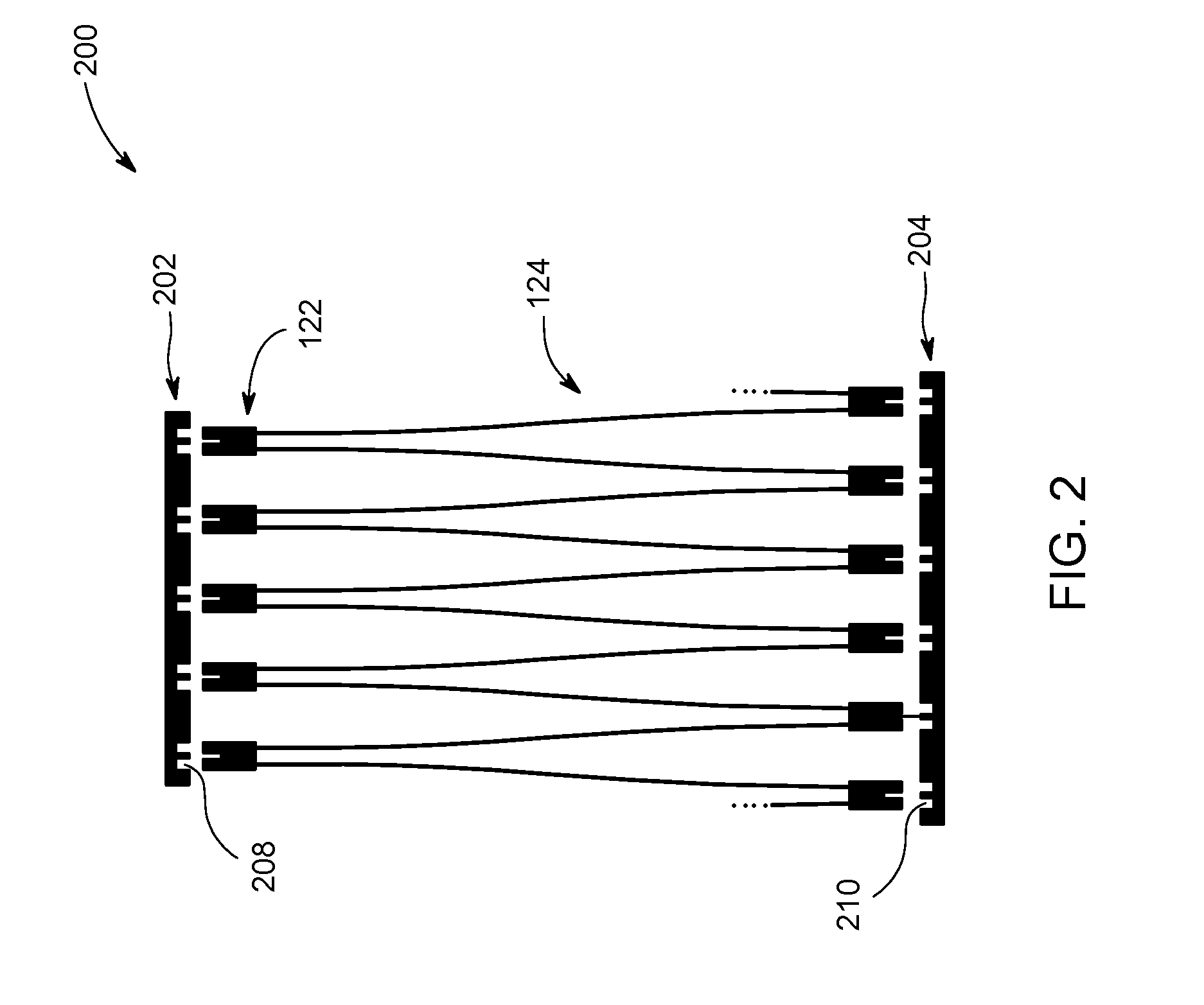

Method and apparatus for securing a segmented power cable for shipping and storage

Owner:ENPHASE ENERGY

Modified sheath for high-voltage power cable

InactiveCN105647082AImprove creep resistanceConsistent costPower cableChlorinated polyvinyl chloride

Owner:STATE GRID CORP OF CHINA +1

Pharmaceutical production site management method

InactiveCN110275491AReduce distractionsQuality adjustmentTotal factory controlProgramme total factory controlTime informationPower cable

Owner:NANJING COLLEGE OF INFORMATION TECH

Low-smoke halogen-free cable material

InactiveCN105906922ANot easy to producePlastic/resin/waxes insulatorsInsulated cablesLow voltageToxic material

The invention discloses a low-smoke halogen-free cable material, and relates to the technical field of cables. The low-smoke halogen-free cable material is prepared from the following raw materials in parts by weight: 100 parts of polyethylene, 5 parts of silicon carbide, 10-20 parts of aluminum hydroxide, 5-20 parts of magnesium hydroxide and 2-4 parts of an anti-ageing agent. The cable material has the performance of stopping combustion while being difficult to combust, and has flame retardant rating being V-0 level; during combustion, toxic substances containing halogen are not easily generated, and smoke is not easily generated, and therefore, the low-smoke halogen-free cable material can be suitable for a high-low-voltage power cable.

Owner:HEFEI OUBANG RUBBER TECH CO LTD

Novel optical fiber composite low-voltage cable

InactiveCN104952540ASave resourcesPrevent easy breakageInsulated cablesPower cablesElectric power transmissionLow voltage

Owner:WUXI SHUGUANG CABLE

Power cable with non-conductive armor

InactiveUS20200126686A1Insulated cablesCarbon-silicon compound conductorsPower cableStructural engineering

Owner:SAUDI ARABIAN OIL CO

Miniature flexible cable and production process thereof

InactiveCN111312436APowerfulSmall outer diameterClimate change adaptationFlexible cablesPower cableMiniaturization

The invention discloses a miniature flexible cable and a production process thereof. The miniature flexible cable sequentially comprises a wire core group, a first aluminum foil mylar tape wrapping layer, a metal shielding layer, a ceramic silicone rubber composite tape wrapping layer and a sheath from inside to outside. The wire core group comprises a standby wire core group positioned in the center of the cable, and a control wire core group, a signal wire core group and a power wire core group which surround the periphery of the standby wire core group and are tangent to the standby wire core group. The standby wire core group, the control wire core group and the signal wire core group are arranged in a pairwise tangent manner. A gap is formed between the periphery of the wire core group and the first aluminum foil mylar tape winding layer, and the gap is filled with a first flame-retardant rock wool rope. According to the invention, the power cable, the control cable, the signal cable and the standby cable are integrated together for reasonable structural arrangement, so that the outer diameter of the cable is reduced to a greater extent while the powerful function of the cableis ensured, the space occupancy of the cable is greatly reduced, and the miniaturization and microminiaturization process of equipment is facilitated.

Owner:FAR EAST CABLE +2

High-performance power cable for robot and production device thereof

ActiveCN113299434AGuaranteed cooling effectEasy to useInsulated cablesCable/conductor manufacturePower cableElectric cables

Owner:江西南远电缆有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap