Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31 results about "Pelletizing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pelletizing is the process of compressing or molding a material into the shape of a pellet. A wide range of different materials are pelletized including chemicals, iron ore, animal compound feed, plastics, and more.

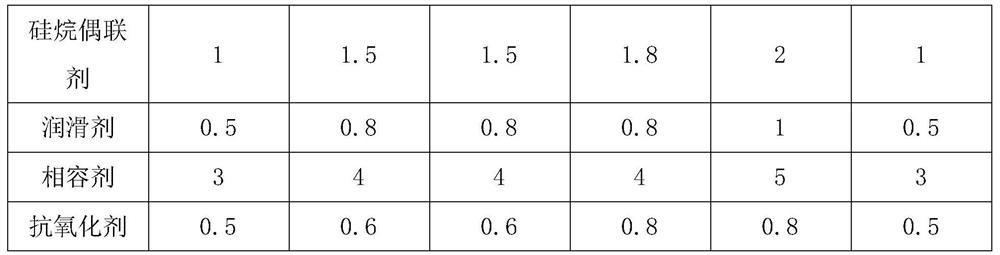

Polylactic acid/polyester alloy and preparation method thereof

The invention relates to a polylactic acid / polyester alloy and a preparation method thereof. The polylactic acid / polyester alloy comprises the following components in percentage by weight: polylactic acid, polyester, a compatilizer, a flexibilizer, an antioxidant and a lubricant. The preparation method comprises the following steps: firstly, proportioning the raw materials and mixing at a room temperature; and respectively carrying out melting extrusion, carrying out ultrasonic treatment at the first late stage, extruding at the second stage and pelletizing, so as to obtain degradable, high-impact-resistant and high-heat-resistant polylactic acid / polyester alloy. Compared with an existing method, the controllable ultrasonic treatment is utilized; and a similar polylactic acid-g-polyester structure is formed by in-situ reaction, so that the heat resistance of the polyester and the biodegradability of the polylactic acid are reserved; and meanwhile, a toughening system with a core-shell structure is formed in an alloy system through interface interaction of a special toughening compatilizer, so that the alloy product with high impact resistance, high heat resistance and high biodegradability can be obtained.

Owner:FINE BLEND POLYMER SHANGHAI CO LTD

Process for extracting both active embryonic peptide and natural corn oil from embryo bud of corn

Owner:徐昌洪

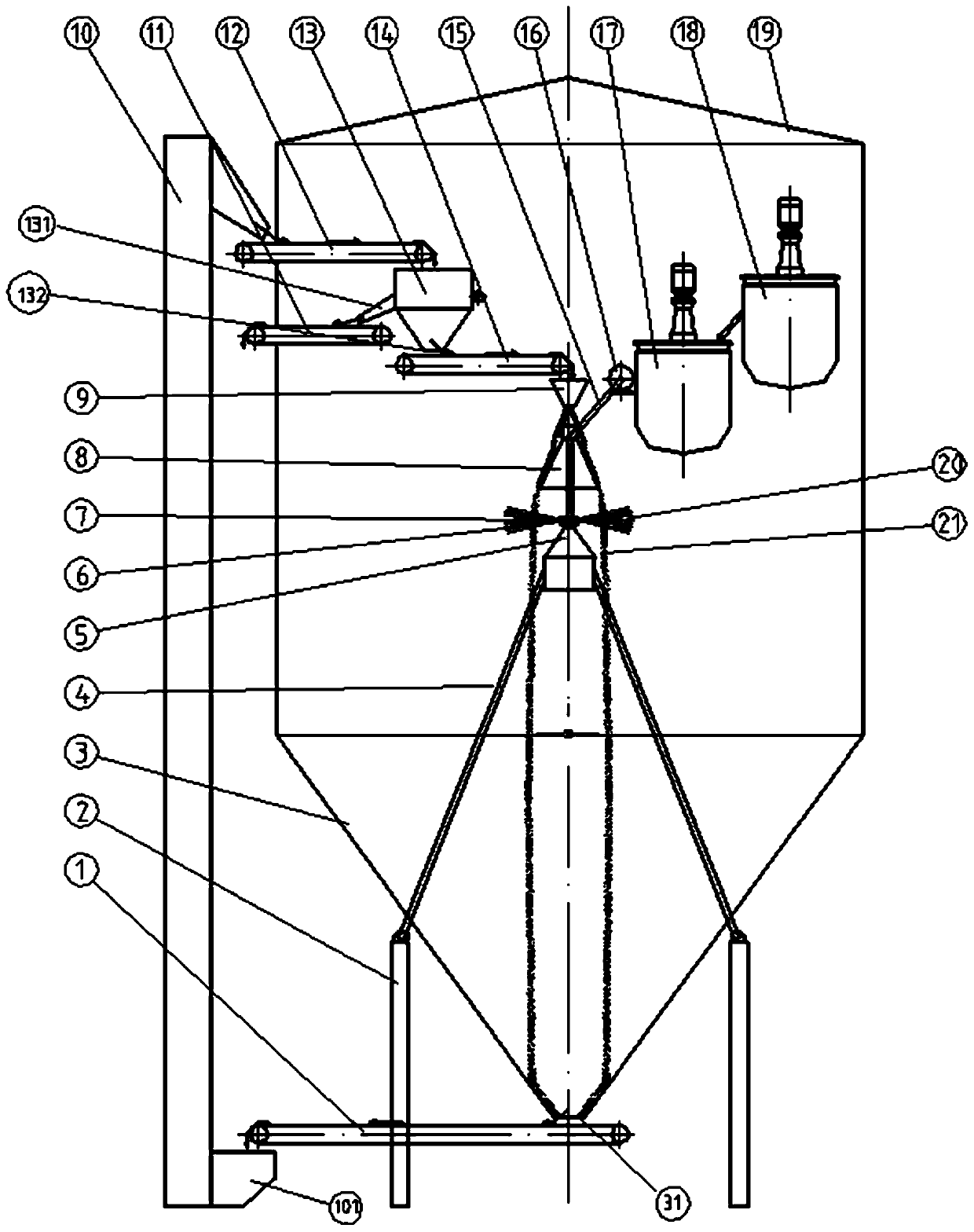

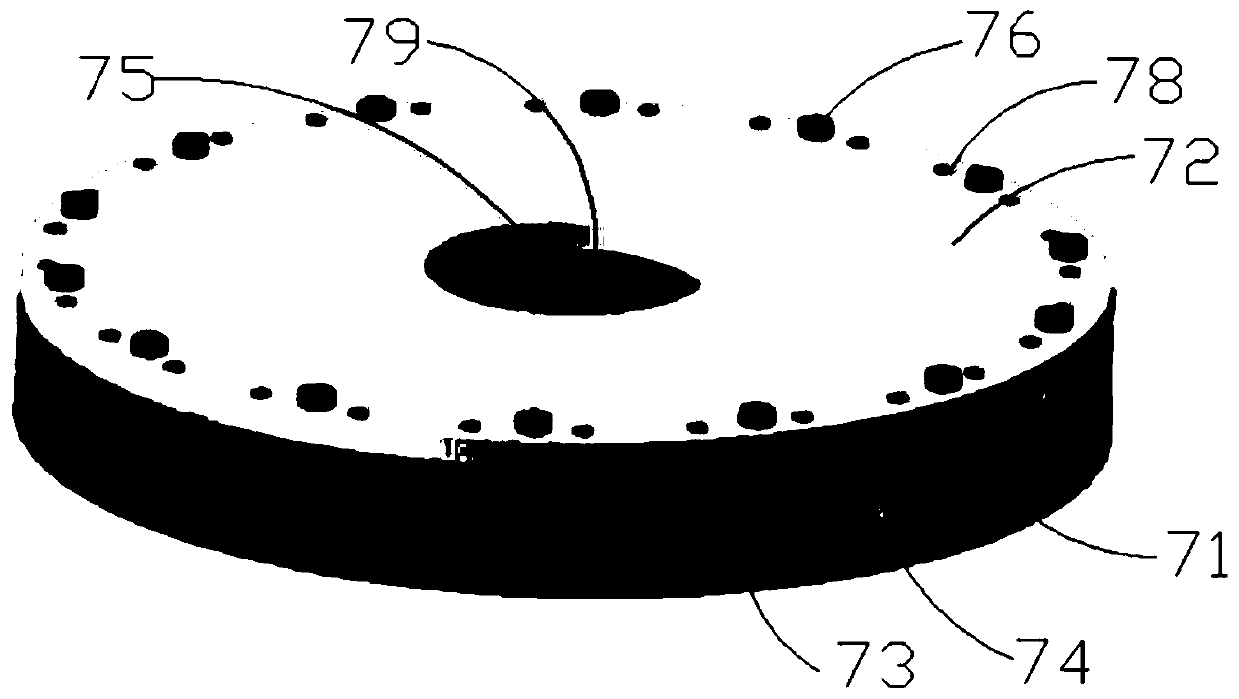

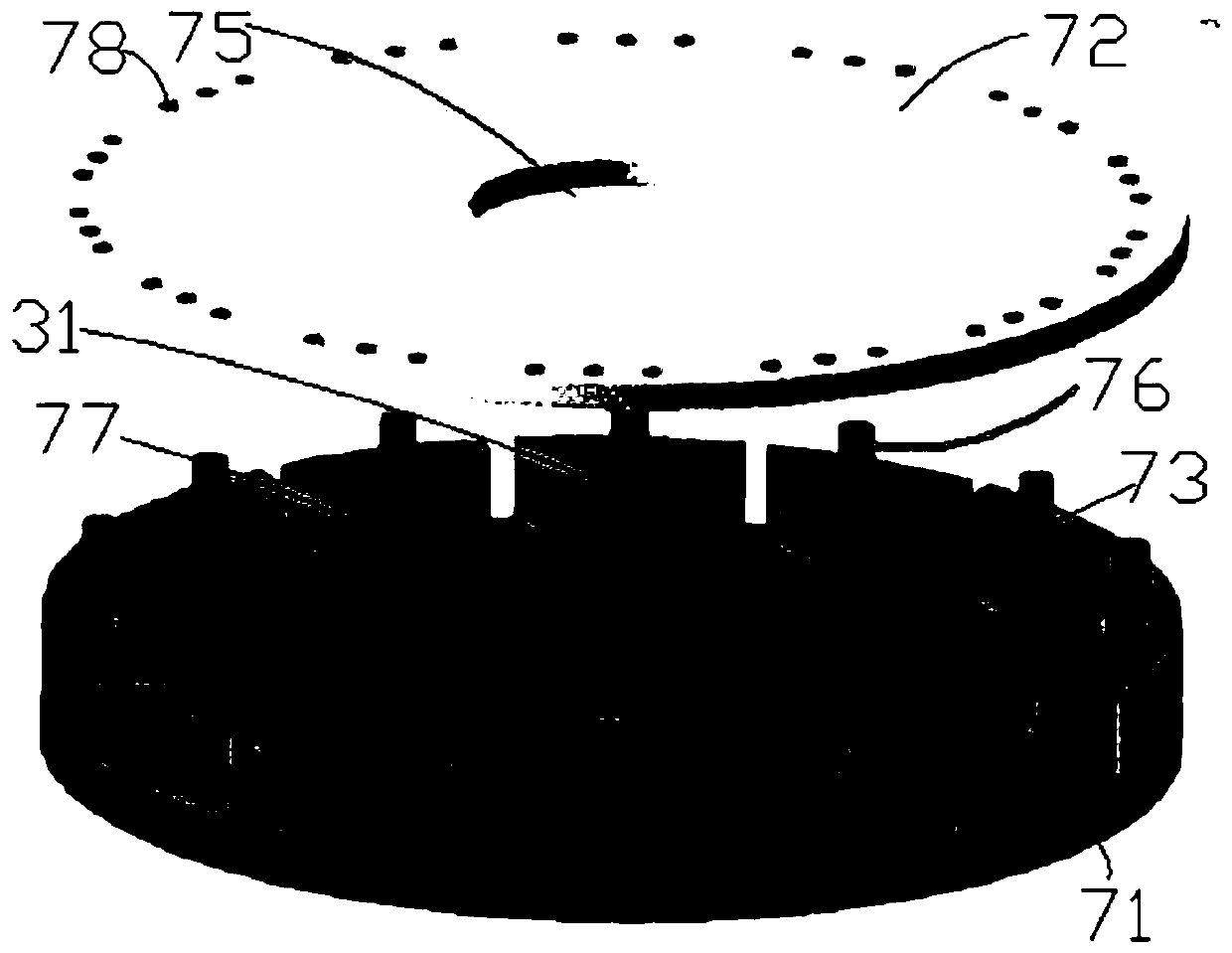

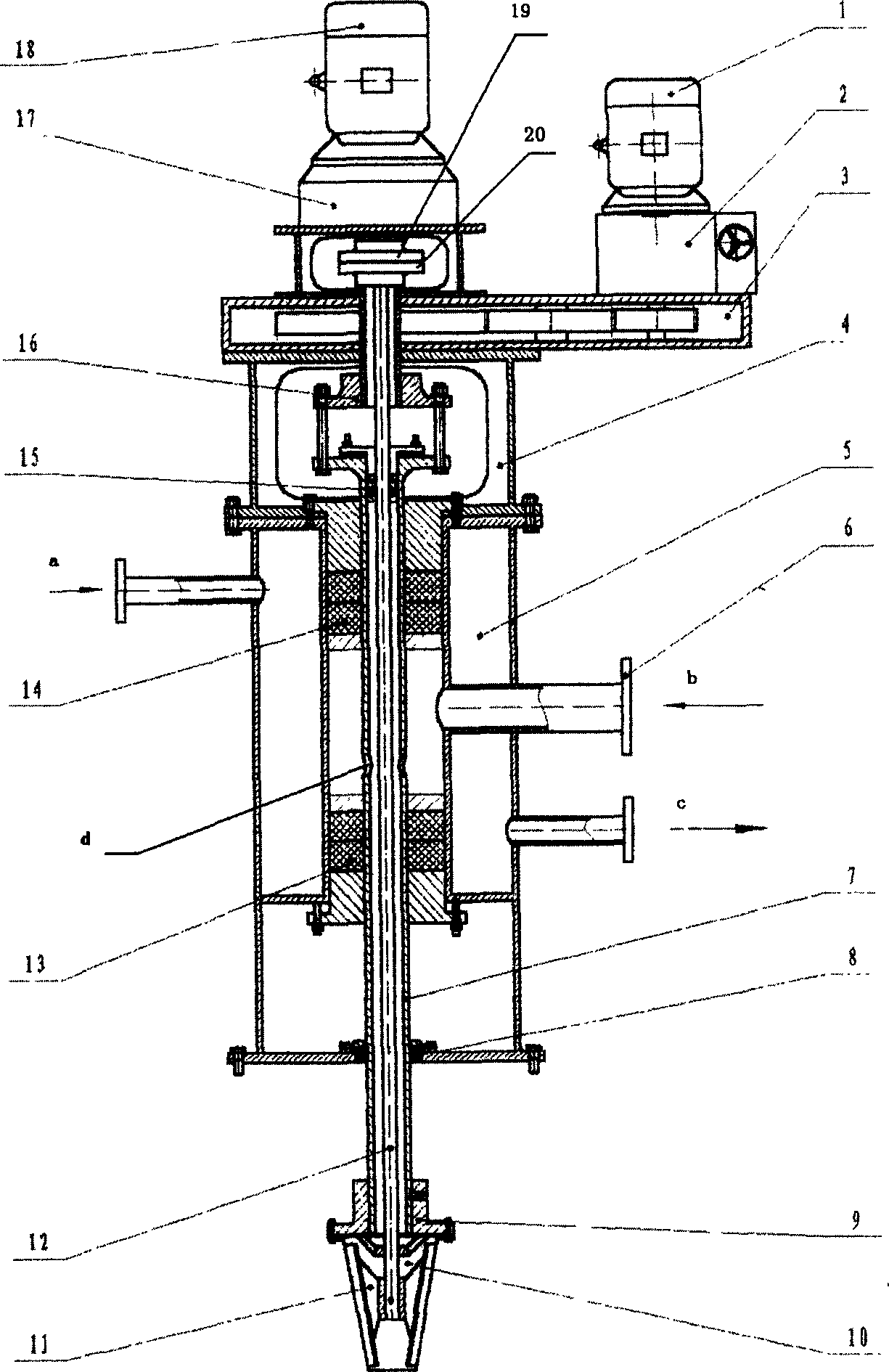

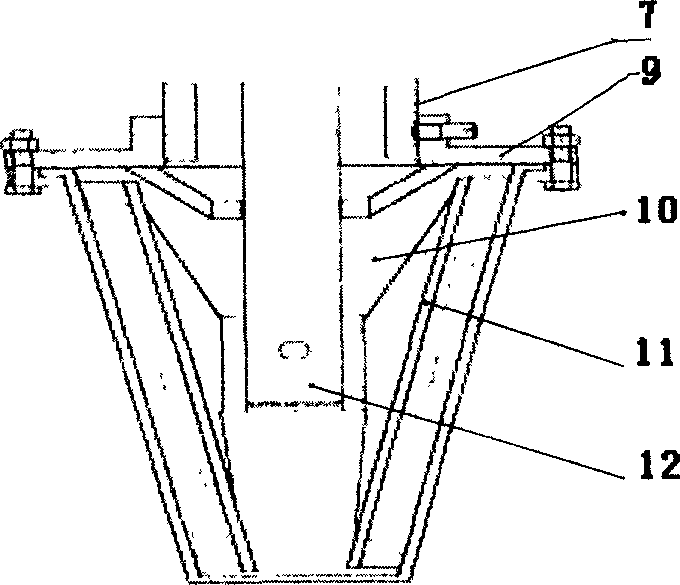

Annular coating granule chemical fertilizer pelletizing tower and process pelletizing method thereof

PendingCN110449090ASmall sizeAvoid easy cloggingGranulation by liquid drop formationGranulation by powder suspensionTowerProduct processing

Owner:SHENZHEN BATIAN ECOTYPIC ENG

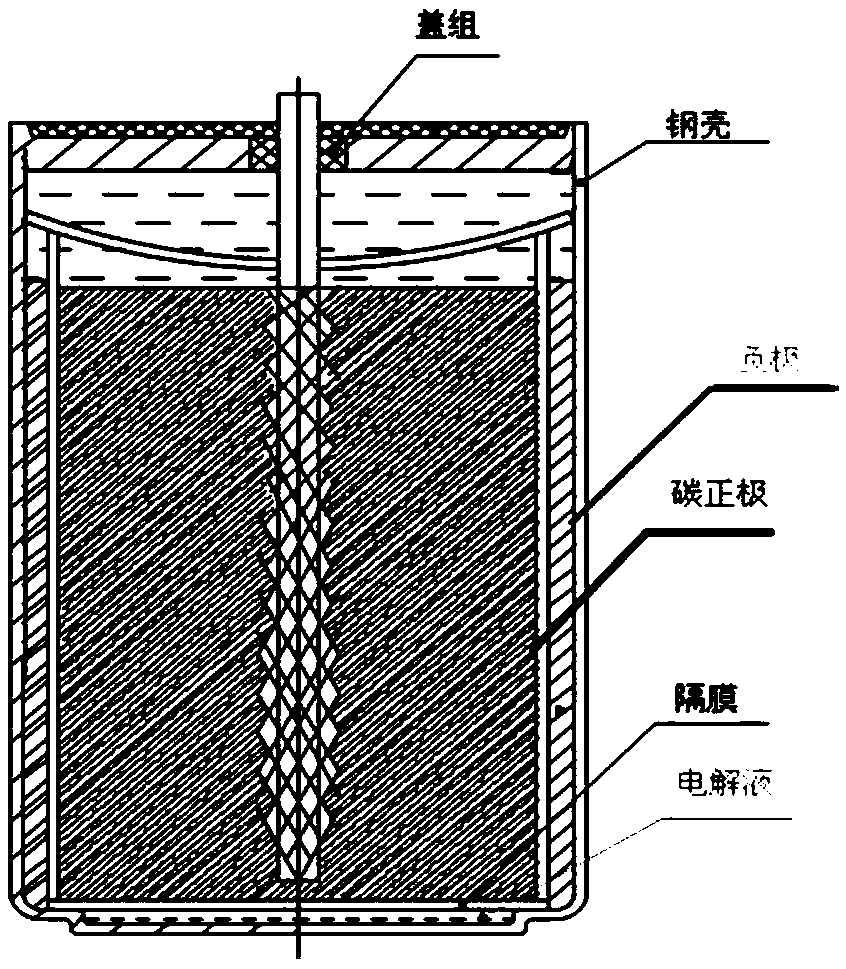

Positive electrode of lithium-thionyl chloride energy type battery and preparation method thereof and lithium-thionyl chloride energy type battery

Owner:武汉中原长江科技发展有限公司

Preparation method of special coating resin composition for polyethylene

ActiveCN102863670AImprove melt strengthLow shrinkageNon-macromolecular adhesive additivesFilm/foil adhesivesLow-density polyethylenePeroxide

Owner:PETROCHINA CO LTD

Processing method of ultrafine grinding wires

The invention discloses a processing method of ultrafine grinding wires. The processing method comprises the following steps of preparation of a treatment solution; preparation of a master batch; andmelt spinning. In the processing method, without using absolute alcohol, the risk that the absolute alcohol is inflammable and explosive is solved; the ultrafine grinding wires do not need to be laidand aired, so that the production space is greatly saved; without tedious programs including manual pelletizing, sieving and drying, the production efficiency is improved; and with a simple and convenient technology, the loss of diamond micropowder is reduced, and the cost is effectively lowered. In addition, for the ultrafine grinding wires produced by the processing method, the content of the diamond micropowder is full in content and uniform in distribution, so that the rigidity and the abrasion resistance of brush wires are improved, and the service life of the brush wires is prolonged; inthe use process, the fine polishing effect of the surface of a workpiece can be better; the diameter can be from 0.08mm to 0.149mm, and the blank of a product in the domestic and foreign markets is filled.

Owner:赵明余

Technique process of grainy calcium material for preventing and treating peanut blight

The inventive technique process of grainy calcium material for preventing and treating peanut blight primarily includes: adopting the shell powder and weathered coal as raw materials, machining into peanut blight prevention material through agglomeration granulation. The invention has innovative and reasonable design, which not only has simple process, easy implementing, but also has low cost of raw materials, product application convenience, remarkable peanut blight prevention effect, and capability of promoting high-efficient production pf peanut. In particular, the invention applies coastal oyster shell wastes for machining calcium materials for preventing and treating peanut blight, which not only reduces environmental pollution, but also promotes recycling of resources, has very significant economic, social and ecological benefits and greater promotional value.

Owner:INST OF SOIL & FERTILIZER FUJIAN ACADEMY OF AGRI SCI

Method for preparing green glaze ceramic cup artwork

Owner:ANHUI HONGFU CRAFTS

Polyester molded composition and production method and application thereof

InactiveCN109867923AMeet air tightness requirementsImprove bindingSemiconductor devicesArylPolymer science

The invention discloses a polyester molded composition. The polyester molded composition comprises the following components: 50-80 parts of PCT resin, 10-30 parts of white pigment, 10-30 parts of enhancing material and / or filler and 0.1-2 parts of phosphorous compound; and the phosphorous compound is of a structure as shown in the description, wherein R1 is aryl or OR2, R2 is aryl or alkyl containing 1-30 carbon atoms, R3 is alkyl containing 1-10 carbon atoms, and R4 and R5 are phenyl or alkyl containing 0-10 carbon atoms. A production method comprises the steps of mixing the polyester resin,the white pigment and the phosphorous compound in a high-speed mixer according to proportions, adding a mixture, the enhancing material and / or the filler into a twin-screw extruder, and conducting melt blending, extruding and granulating on a mixture to obtain the polyester molded composition. The polyester molded composition has high adhesion to a metal material strap and good air impermeability,reflectivity and light-resistant and heat-aging-resistant performance.

Owner:KINGFA SCI & TECH CO LTD +1

Air blowing and cooling system for hot cutting pelleting

Owner:KINGFA SCI & TECH CO LTD

Modified PVC (Polyvinyl Chloride) composite material and preparation method thereof

InactiveCN107474428AImprove creep resistanceImprove low temperature impact performancePlastic/resin/waxes insulatorsActive agentPolyvinyl chloride

The invention discloses a PVC (Polyvinyl Chloride) composite modified material and a preparation method thereof, relates to a PVC modified material and a preparation method thereof, and aims to solve the problems that a product surface is rough and lusterless as a conventional PVC modified material has a certain amount of unsaturated double bonds on a molecular chain, an active center can be formed and thus the ductility is low and a melt is easily crushed. The PVC composite modified material is prepared from the following components in parts by weight: a PVC resin, a low-temperature flexibilizer, an impact modifier, processing aids, a surfactant, a composite stabilizer, a covering agent, an initiator and a cross-linking agent. The preparation method comprises the following steps: I, weighing; II, premixing so as to obtain a premix; III, mixing at different steps so as to obtain mixtures of different steps; IV, performing final mixing so as to obtain a final mixture; and V, performing extrusion pelletizing, thereby obtaining the PVC composite modified material. The invention aims to prepare the PVC composite modified material.

Owner:WUHU PILOT NEW MATERIAL TECH CO LTD

Preparation method of granulated graphite for refractory castable material

Owner:马鞍山科润冶金材料有限公司

Scratch-resistant polypropylene material and preparation method thereof

ActiveCN111925591AImprove scratch resistanceEfficient deliveryPolypropylene compositesPolymer science

Owner:宁波精诚塑胶制品有限公司

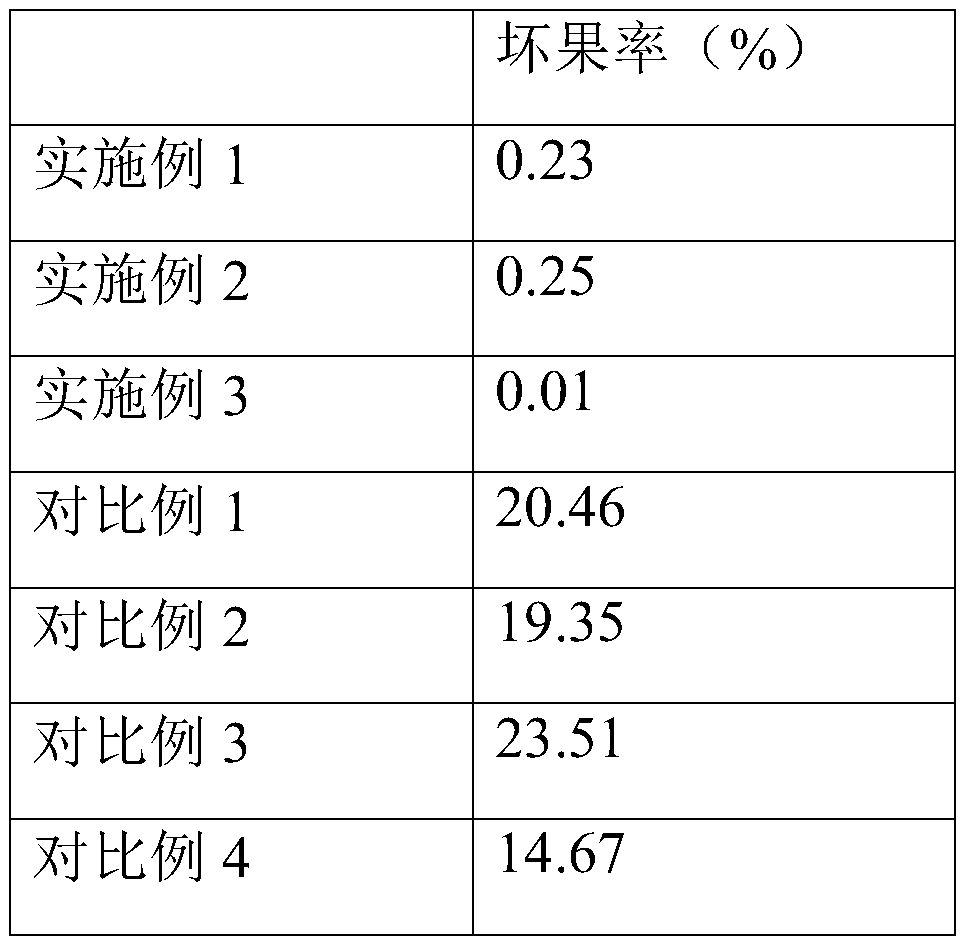

Laminated zirconia dental ceramic material and preparation method thereof

ActiveCN113461421AImprove product qualityImprove economic efficiencyImpression capsDentistry preparationsPelletizingOral problems

The invention belongs to the technical field of dental ceramic materials, and discloses a laminated zirconia dental ceramic material and a preparation method thereof. The preparation method mainly comprises the steps that before powder is formed, interfaces of different layers of powder are treated, first mixture screening powder and second mixture screening powder are prepared through granulation and sieving, the first mixture screening powder is paved on the lower-layer powder, the second mixture screening powder is paved on the first mixture screening powder, and then the upper-layer powder is stacked. The problem that the interface of the laminated zirconia dental ceramic is easy to crack is solved. The obtained product not only can be used for forming a disc-shaped blank, but also can be used for forming a blank of a personalized shape restoration on a preparation body.

Owner:PEKING UNIV SCHOOL OF STOMATOLOGY

Method for processing healthy and efficient bait

Owner:天门市兴发渔具厂

Special graphene heat-resisting master batch for hot water plastic pipe and preparation method

Owner:CHENDU NEW KELI CHEM SCI CO LTD

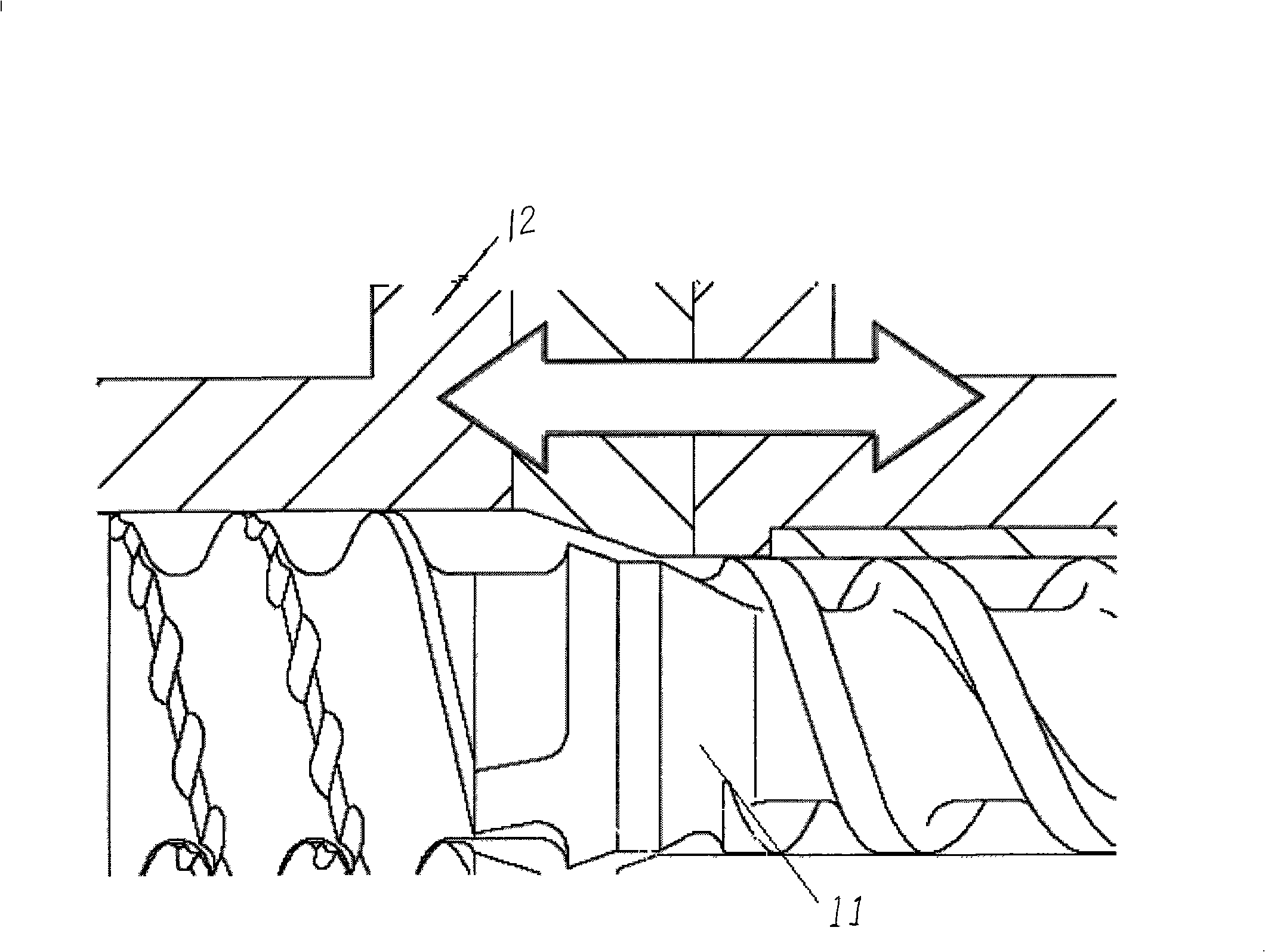

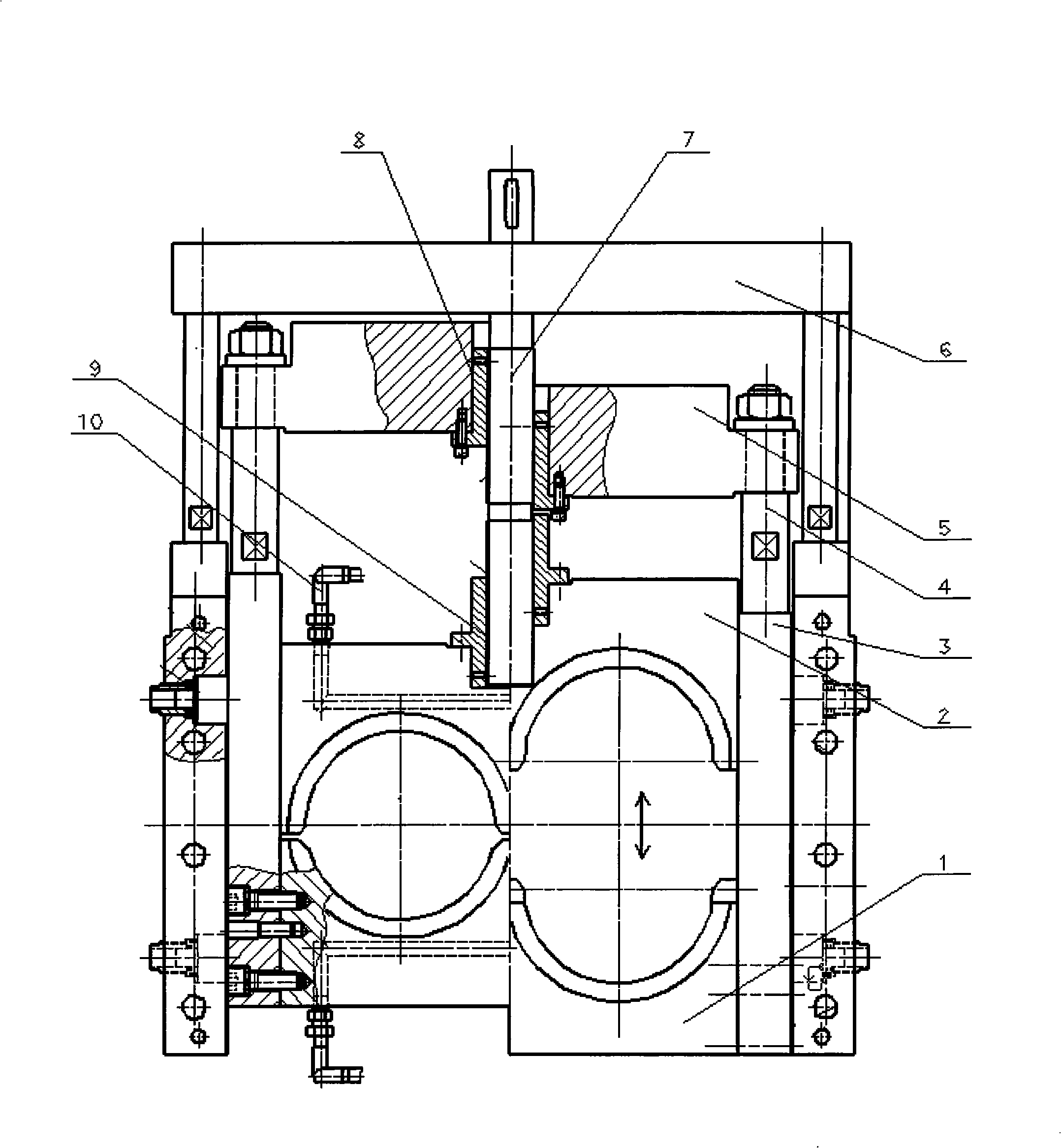

Door melt mass adjusting device of pugging and extruding pelletizer

Owner:大连橡胶塑料机械有限公司

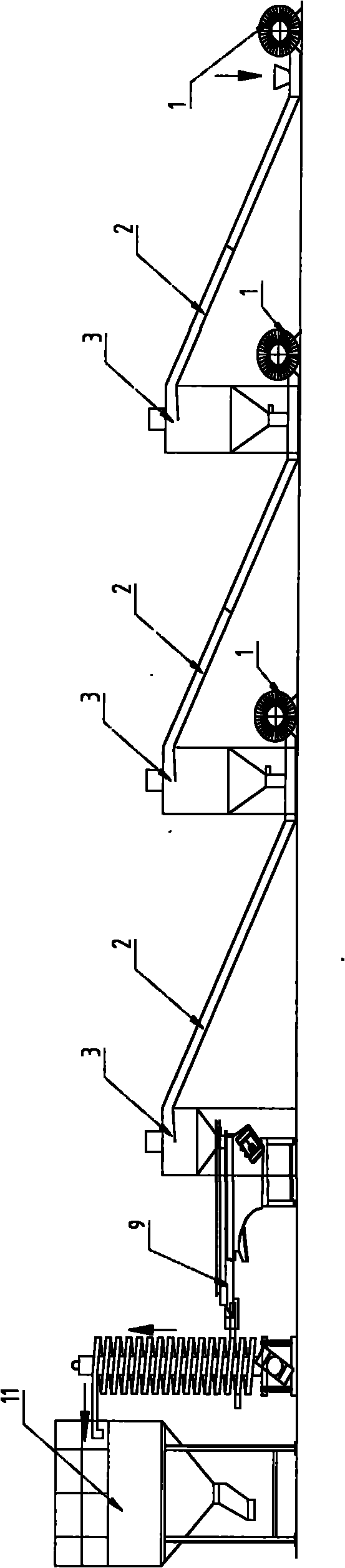

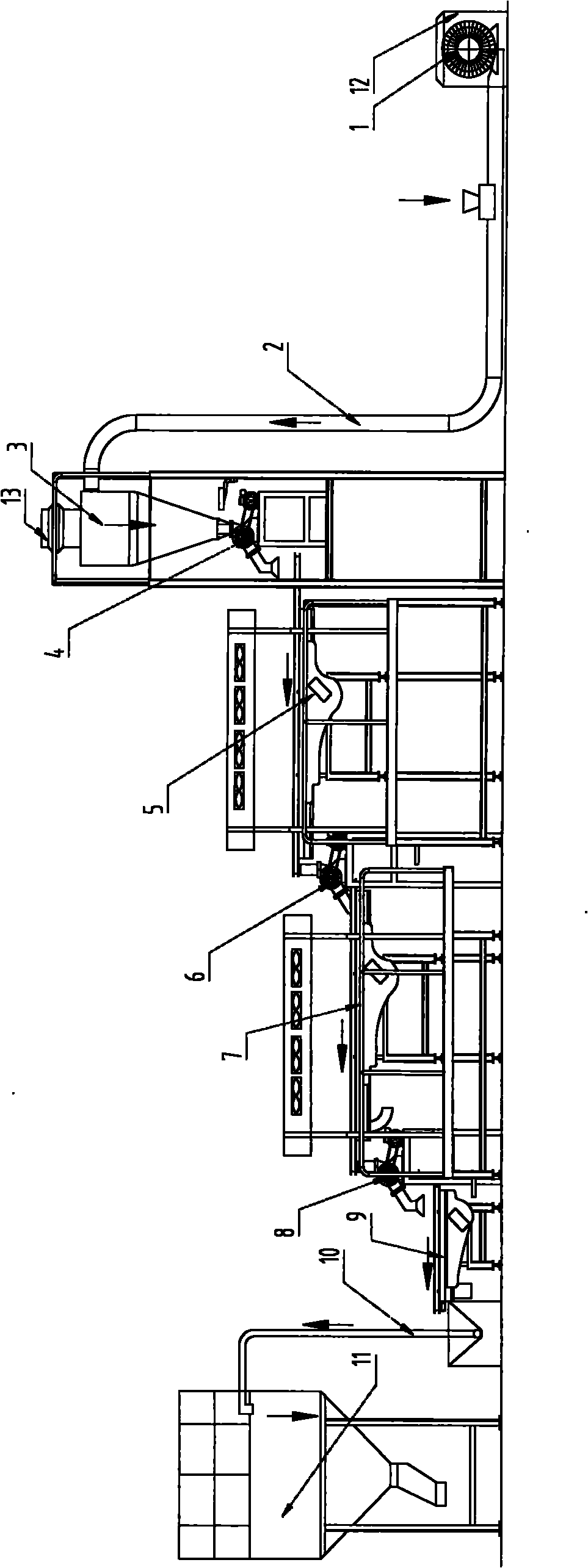

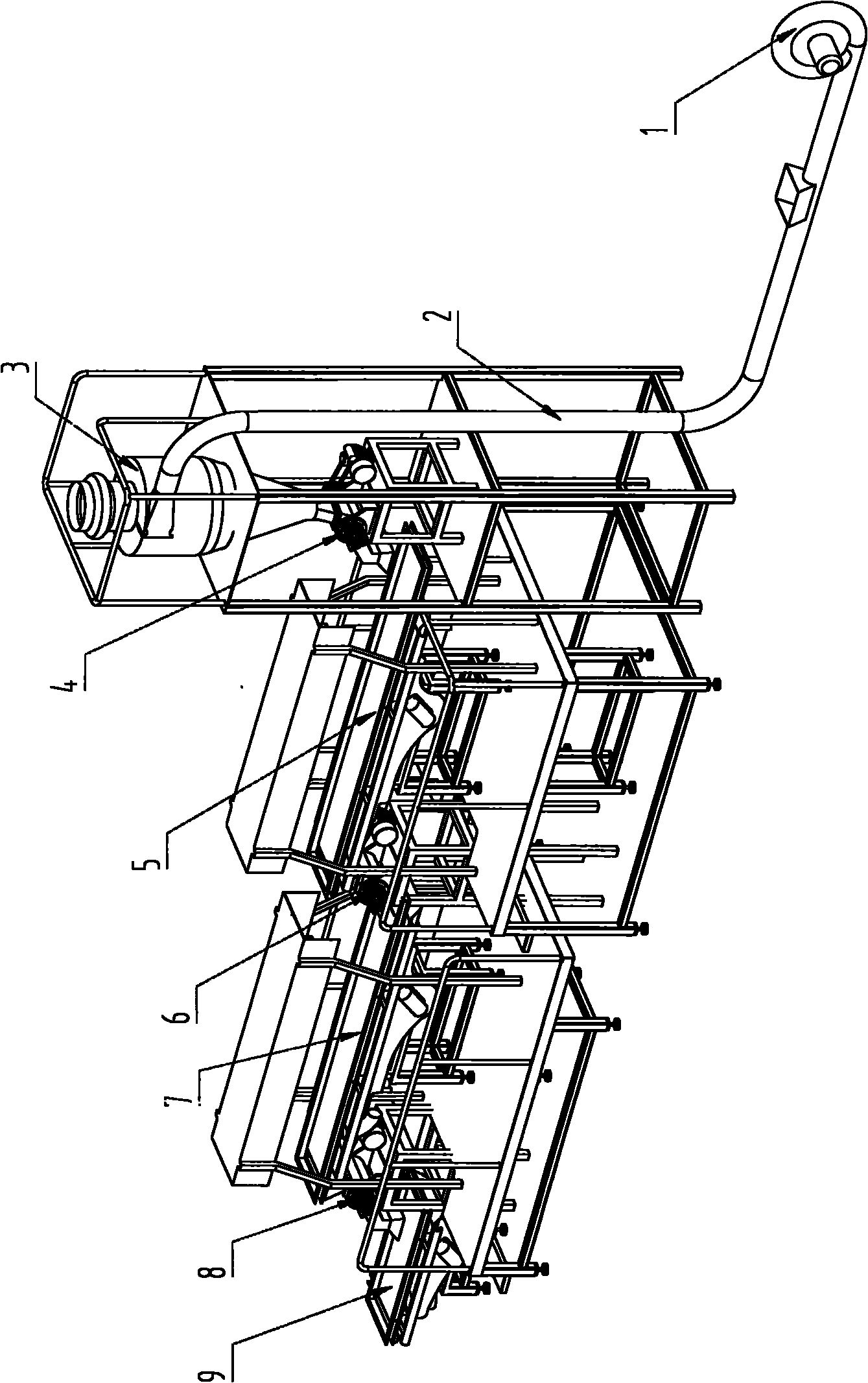

Continuous type solid liquid mixing granulation system

InactiveCN1562454AMeet different production requirementsGranulation by liquid drop formationMolten stateLiquid state

Owner:TIANJINSHI CHANGLUPRECISEBIOCHE MISTRY

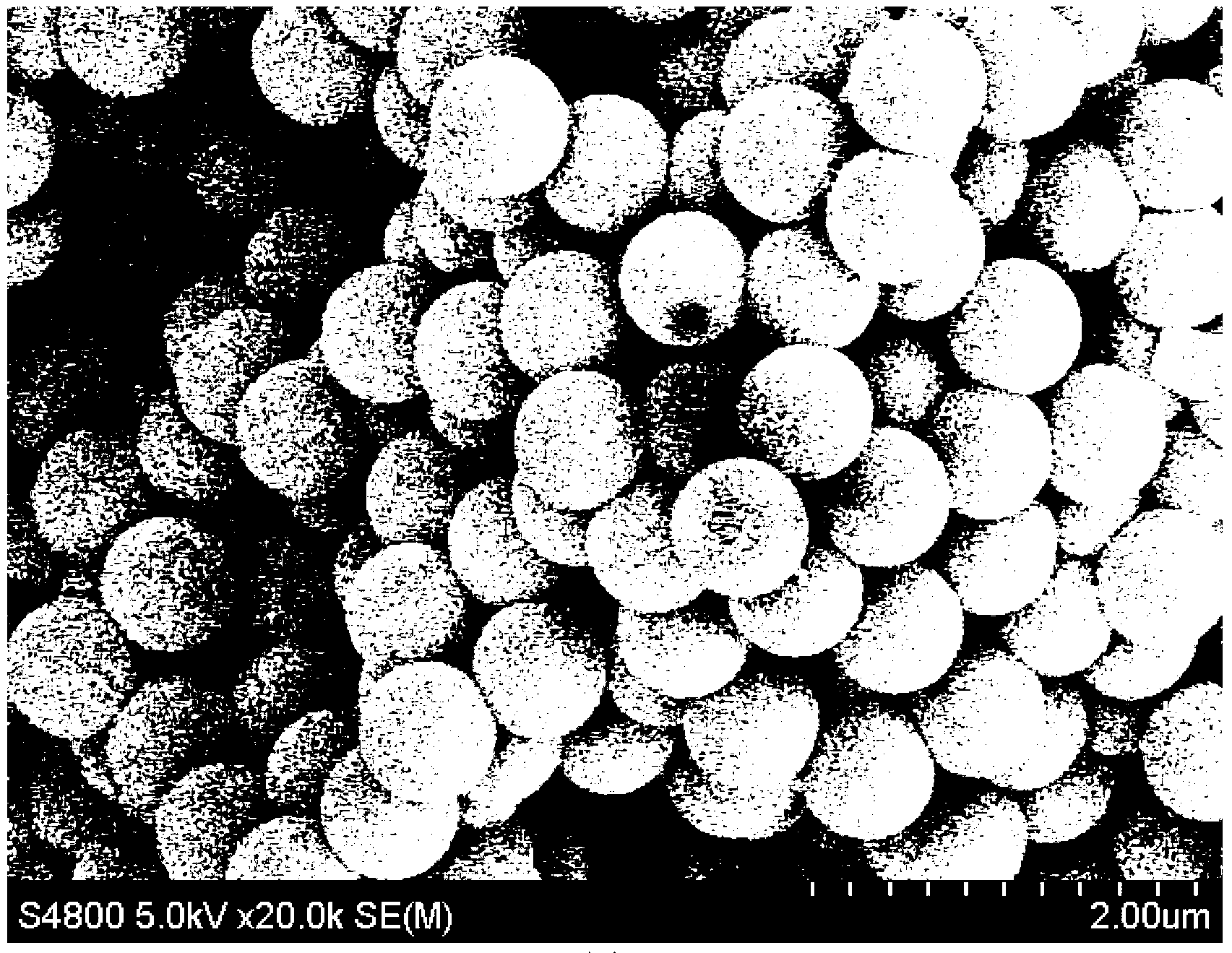

Preparation method of silicon dioxide microsphere/polyformaldehyde composite material

Owner:HEILONGJIANG UNIV

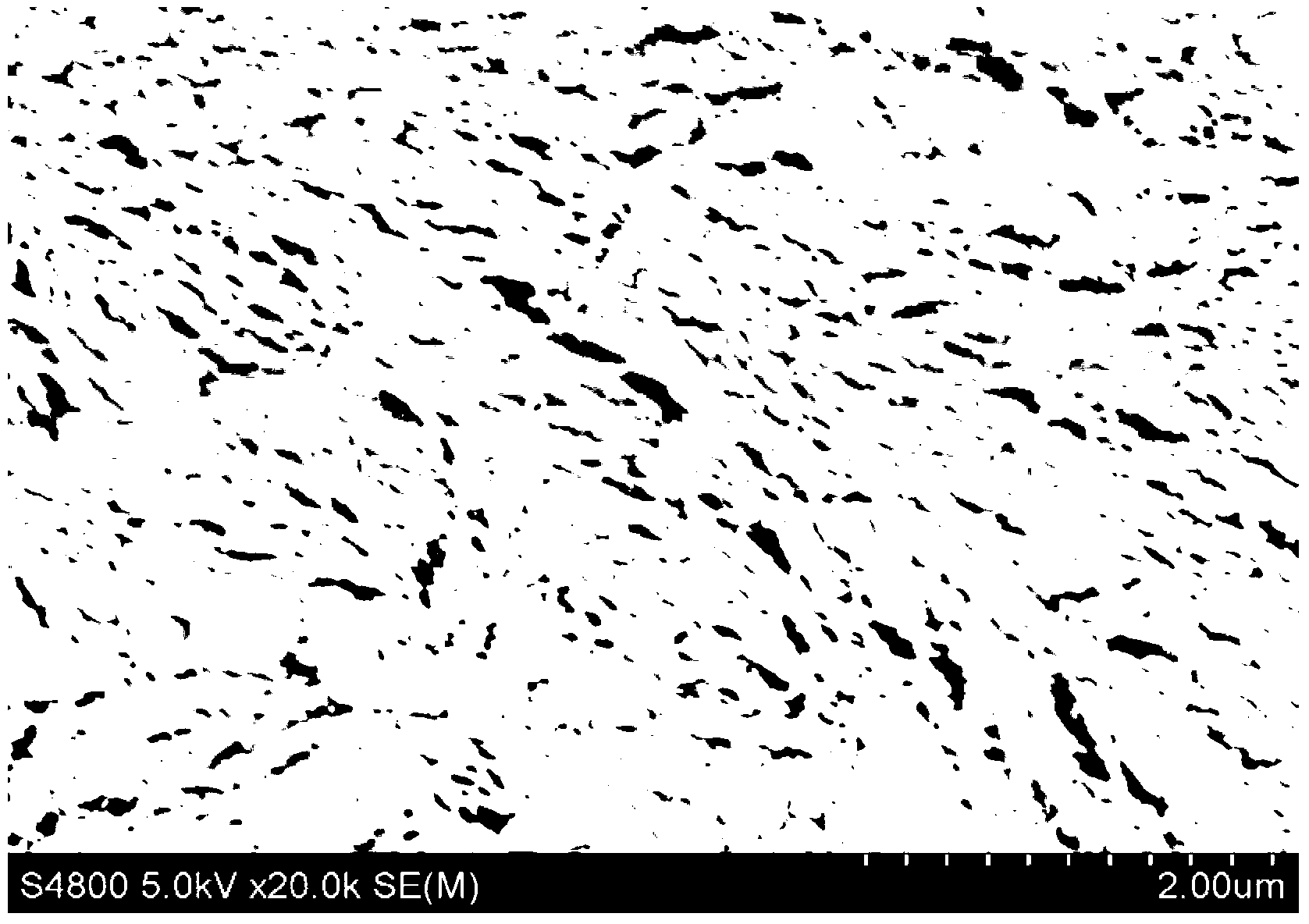

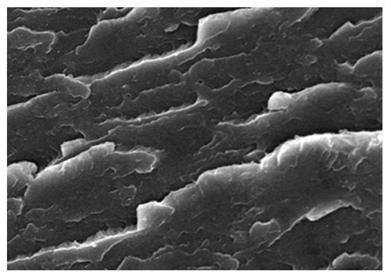

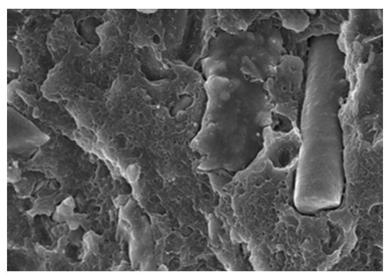

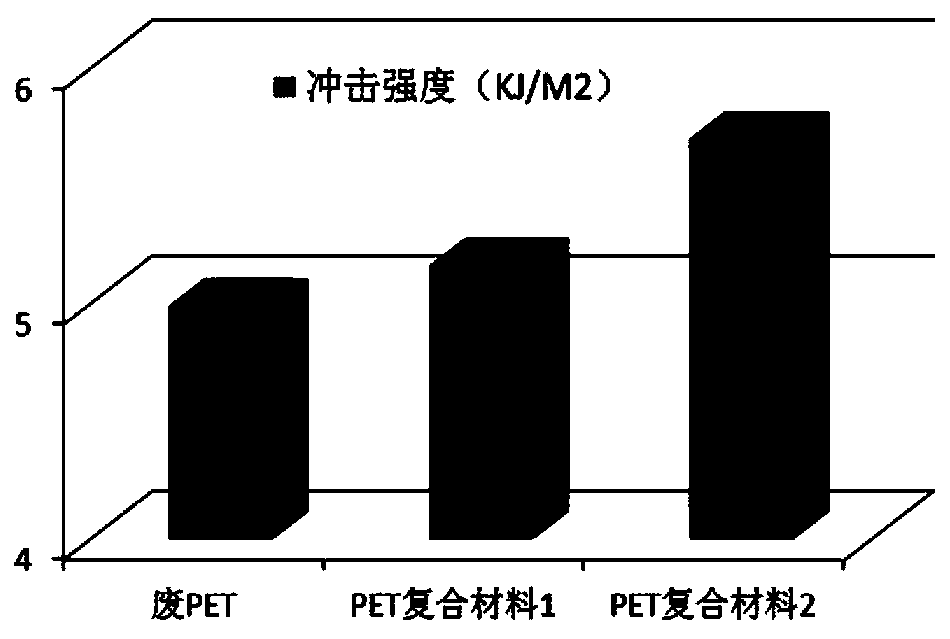

Waste PET composite material

ActiveCN109651776AOvercoming the problem of insufficient impact strengthImprove rigidityElastomerPolyolefin

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

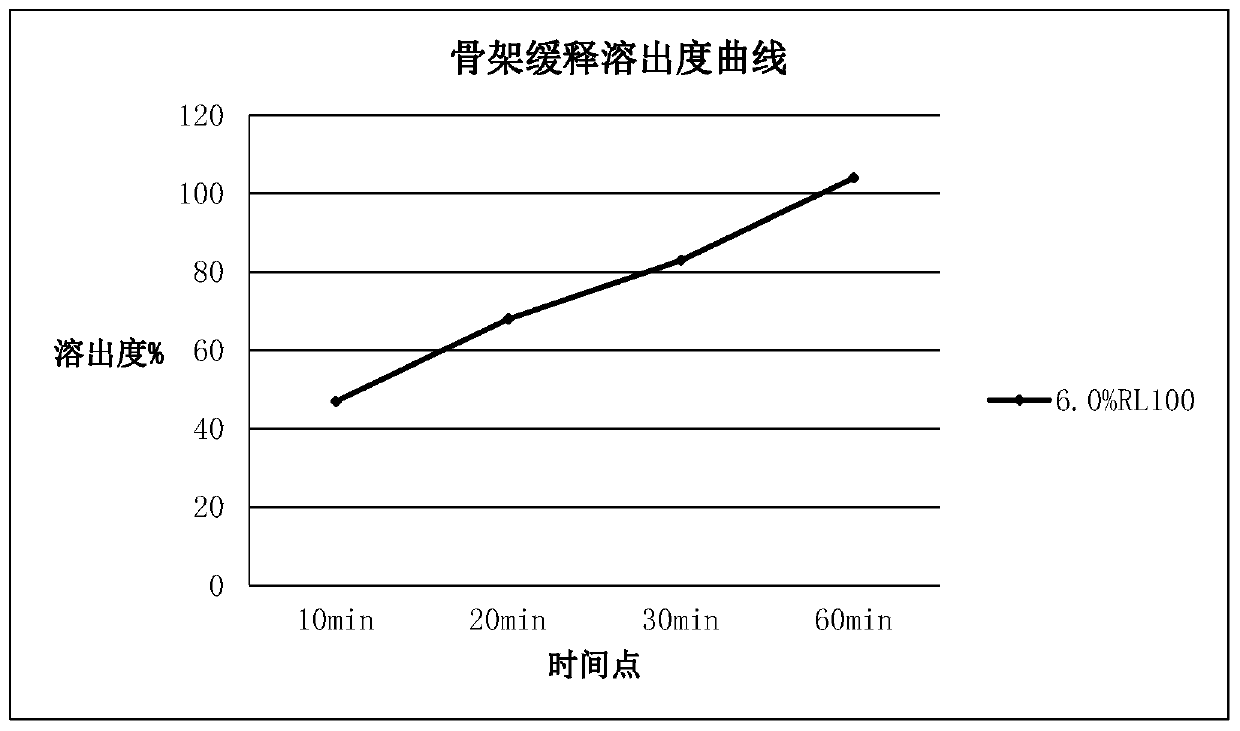

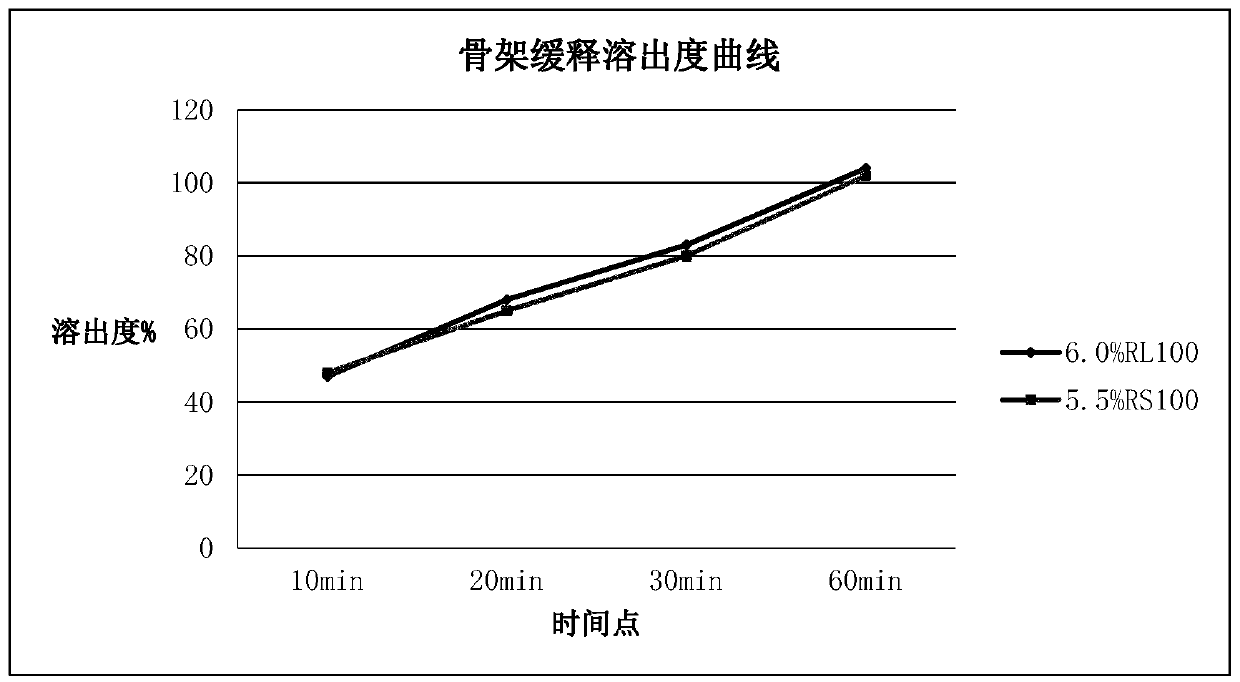

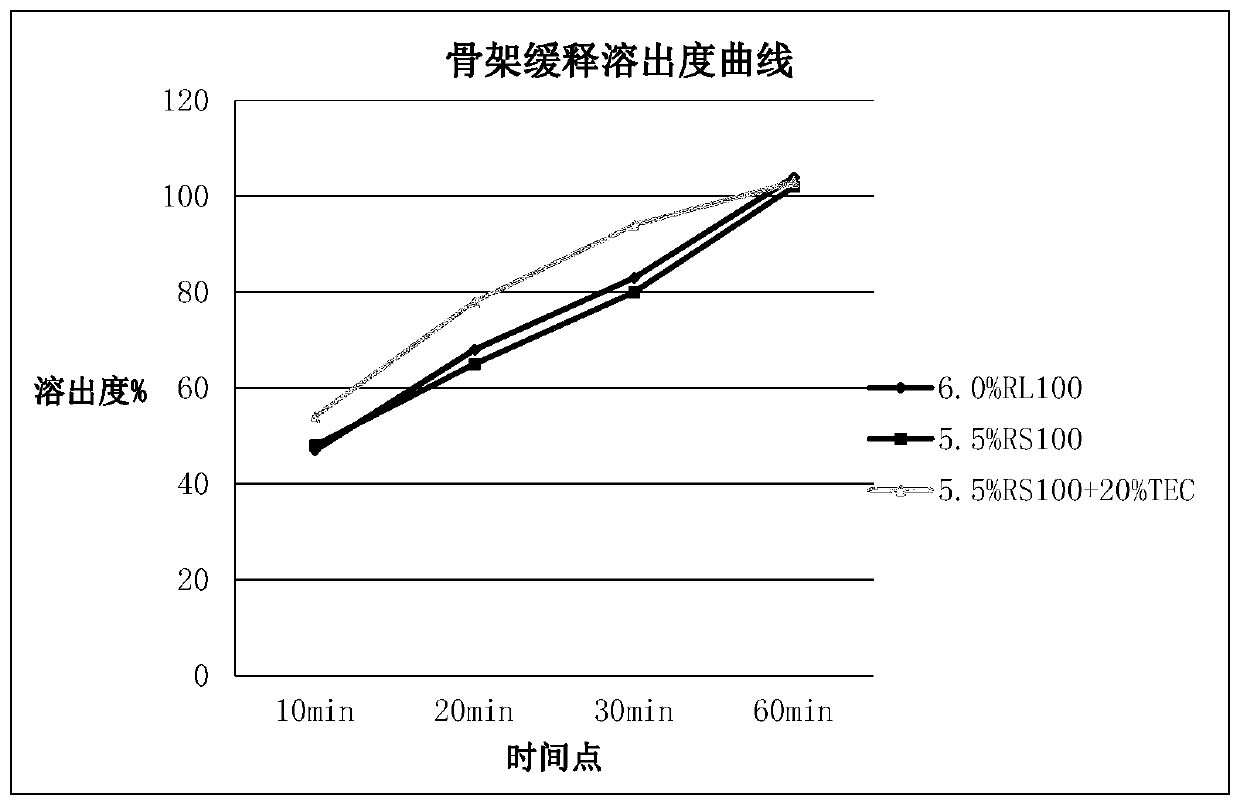

Method for making potassium chloride sustained release tablet controlled by framework and thin film

Owner:广州誉东健康制药有限公司

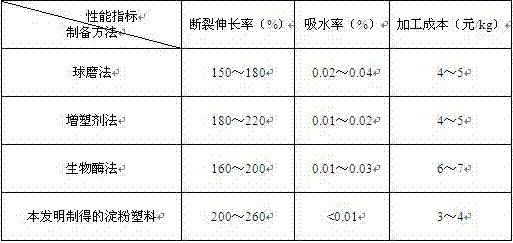

Low-cost method for preparing starch bioplastic

The invention belongs to the technical field of plastic preparation and provides a low-cost method for preparing starch bioplastic. The method comprises the following steps: preparing a precursor solution from butyl acrylate, methyl methacrylate, acrylic acid, an emulsifier and deionized water; adding starch superfine particles and performing ultrasonic dispersion; further adding an initiator to initiate a polymerization reaction to generate a hyperbranched polymer, and coating the starch superfine particles in a cavity; performing extrusion granulation with matrix resin and processing auxiliaries to obtain the starch bioplastic. Compared with traditional methods, the method provided by the invention has the advantages of simple preparation process, easily available raw materials, low energy consumption, low processing difficulty, relatively low cost and high environmental friendliness; moreover, the prepared starch bioplastic has relatively good water resistance, physical and mechanical properties and the like and can be applied to large-scale popularization and production.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

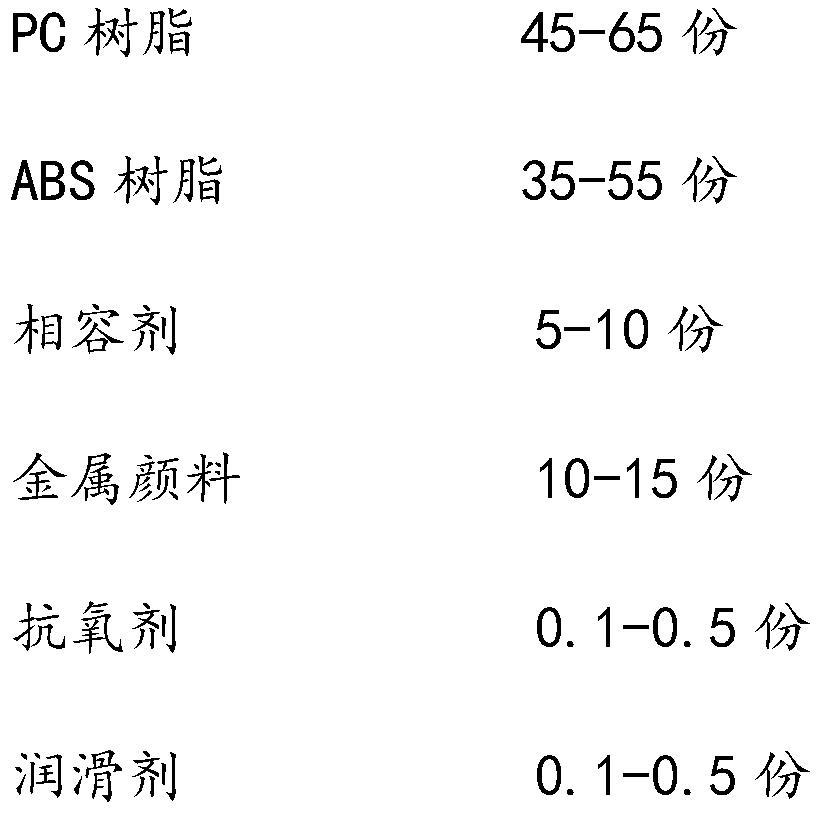

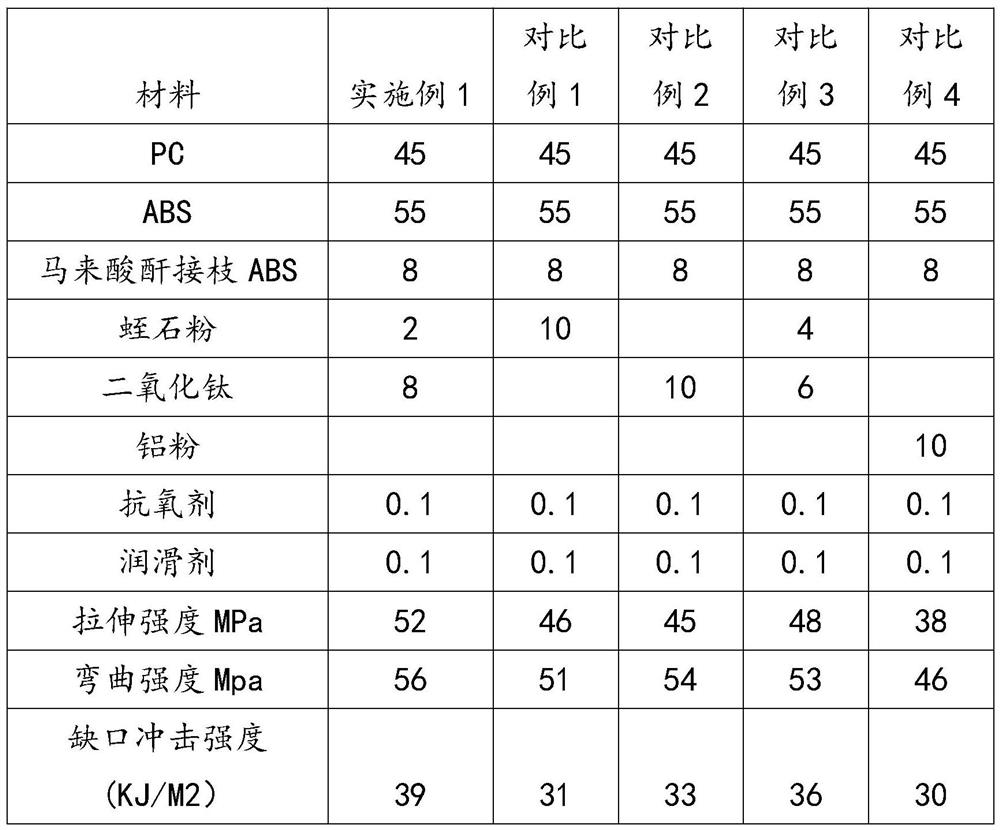

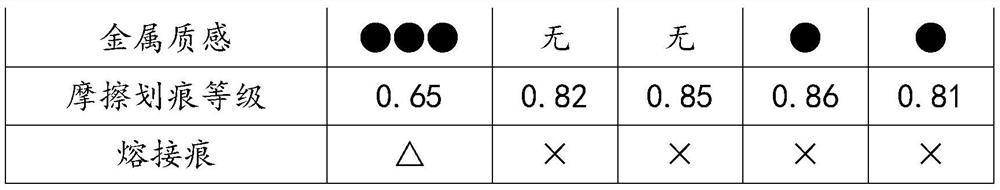

A kind of metallic texture, scratch-resistant PC/ABS composite material and preparation method thereof

Owner:CHUZHOU VOCATIONAL & TECHN COLLEGE

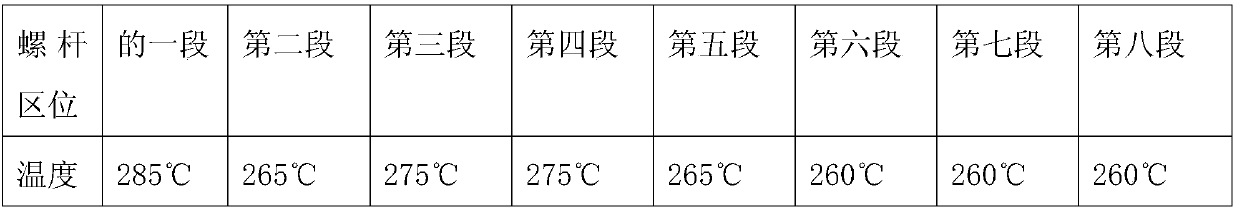

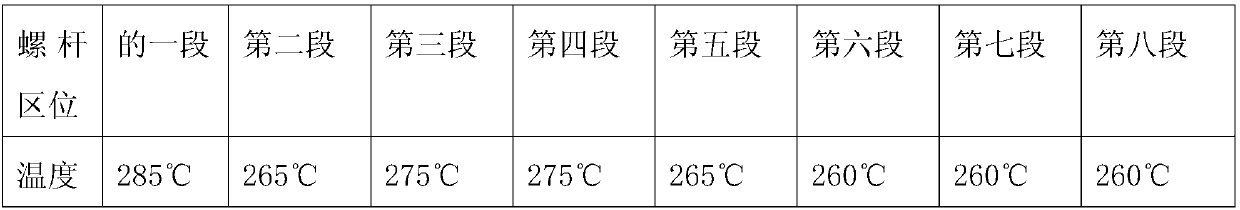

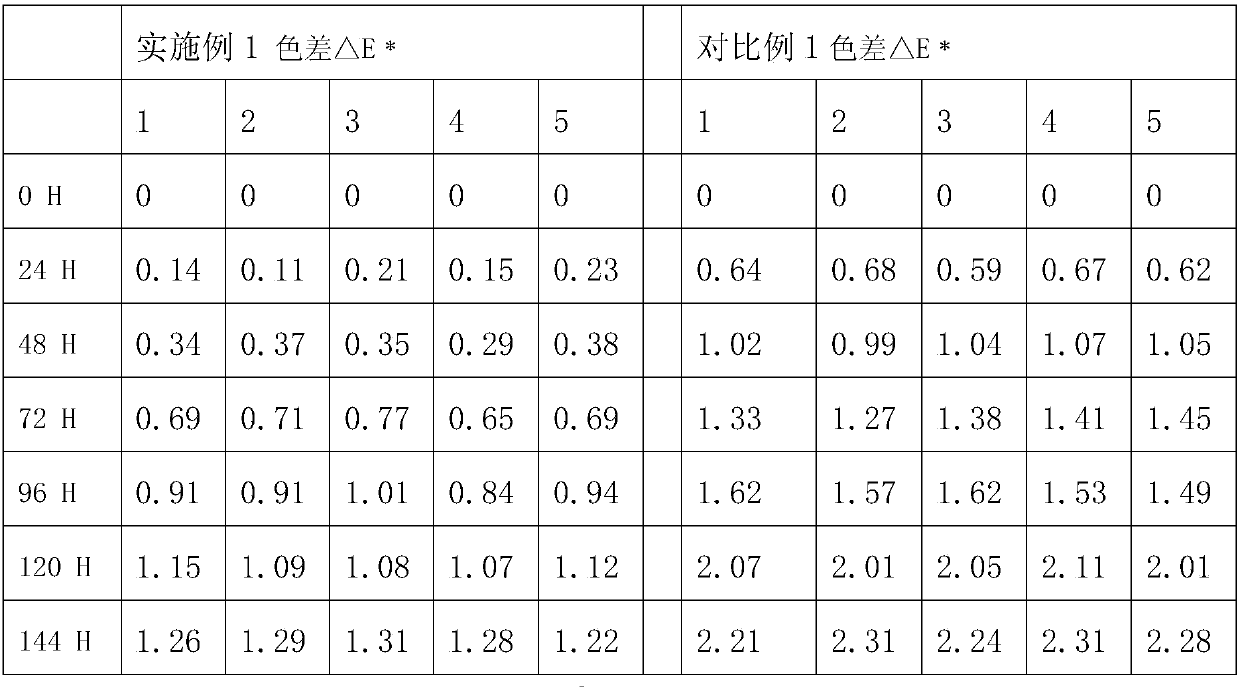

Method for controlling discoloration of nylon

Owner:NANJING HONGRUI PLASTIC PROD

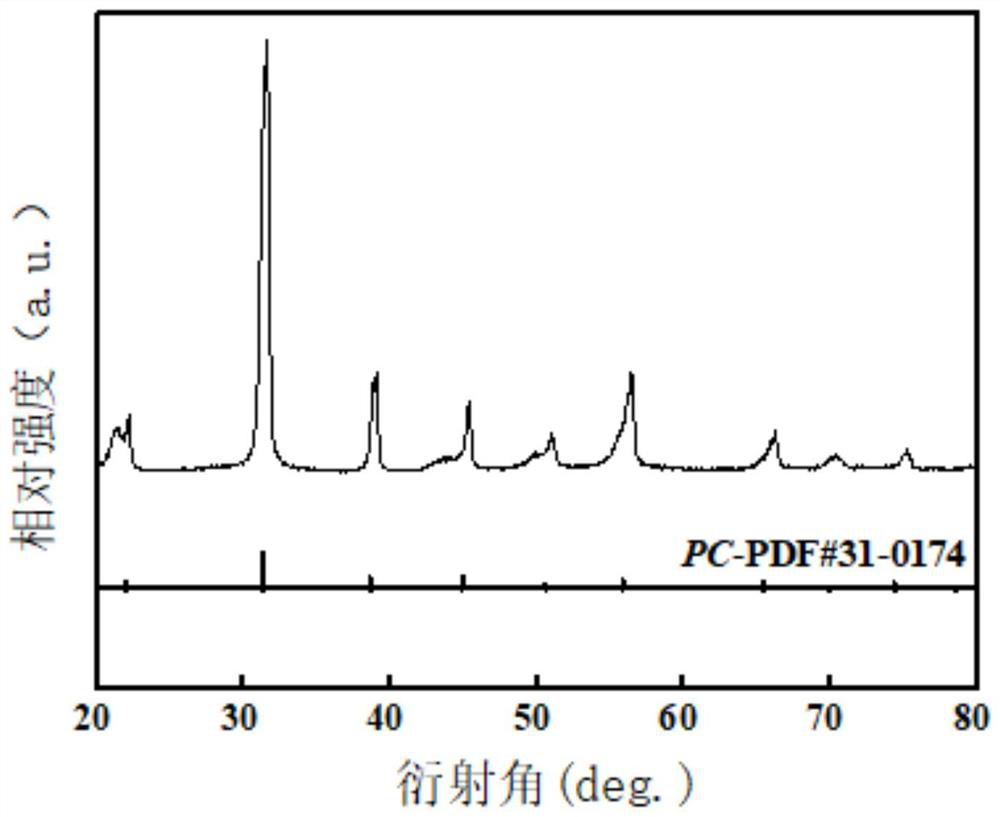

Preparation method of doped bismuth ferrite-barium titanate-based lead-free piezoelectric ceramic material

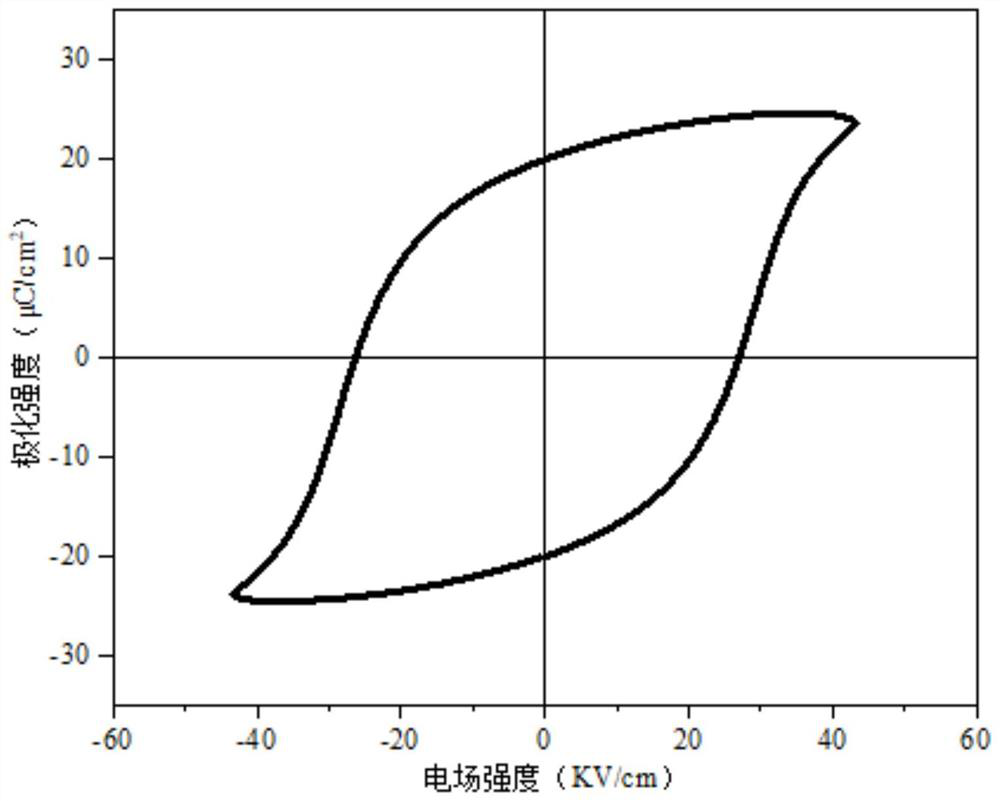

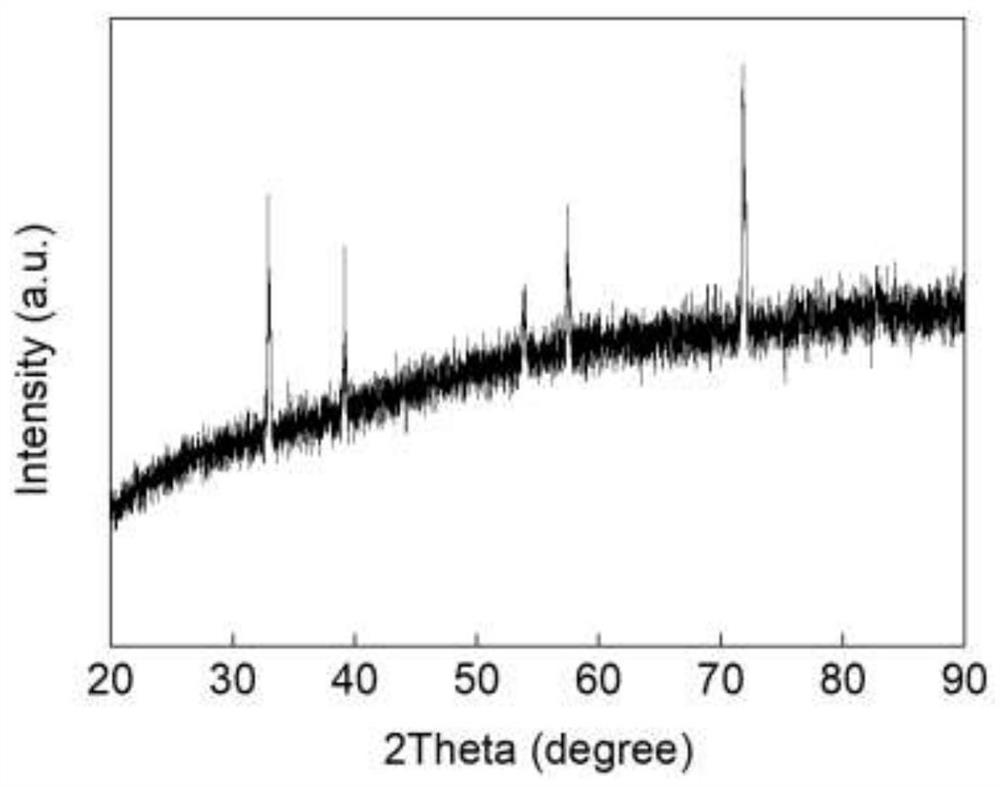

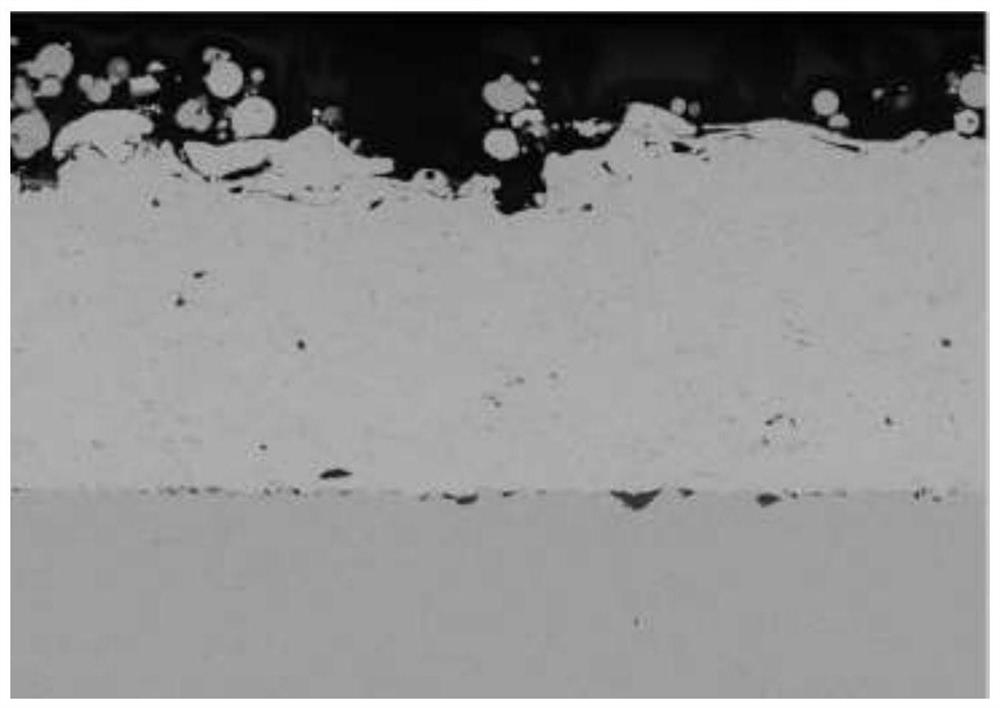

PendingCN114180952ASmall grain sizeHigh densityFixed capacitor dielectricAcceleration measurementBarium titanatePolyvinyl alcohol

Owner:UNIV OF SCI & TECH BEIJING

A high -performance soft magnetic non -crystal coating and preparation method

Owner:中国电子科技集团公司第九研究所

Method for fully recycling and reproducing waste drip irrigation belts and waste greenhouse films

PendingCN114211640AQuality improvementOutstanding reproduction effectPlastic recyclingMechanical material recoveryBlow moldingMasterbatch

The invention relates to a waste drip irrigation tape and waste greenhouse film total recovery and reproduction method, and relates to the technical field of waste drip irrigation tape and waste greenhouse film resource recovery and reutilization, and the method comprises the following steps: waste material cleaning: putting waste drip irrigation tapes and waste greenhouse films into a cleaning pool for full cleaning; waste material drying, wherein the cleaned waste drip irrigation tape and the cleaned waste greenhouse film are dried; the waste materials are cut up, wherein the dried waste drip irrigation belts and the dried waste greenhouse films are cut up; mixing the raw materials: fully mixing the chopped waste materials with the new plastic material and the dyeing master batch; granulation: adding the mixed raw materials into an extruder for extrusion granulation; and film forming: performing blow molding and film forming on the raw material particles to finish reproduction of the waste materials. The waste drip irrigation tape and the waste greenhouse film can be utilized to the maximum extent, and the produced product is good in performance and good in application effect.

Owner:NINGXIA YURUN AGRI WATER SAVING IRRIGATION MFG CO LTD

Manufacturing method of biodegradable cast film paper

PendingCN113956520ASolve non-degradable problemsImprove water vapor permeabilityFiberPolyethylene glycol

Owner:XIONGXIAN HENGTONG IND & TRADE CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap