Method for making potassium chloride sustained release tablet controlled by framework and thin film

A potassium chloride sustained-release tablet and a production method technology, applied in the field of potassium chloride sustained-release tablet production, can solve the problems of muscle necrosis, high gastrointestinal tract irritation, nausea, vomiting, loss of appetite and the like, and achieve a stable release curve, The effect of high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

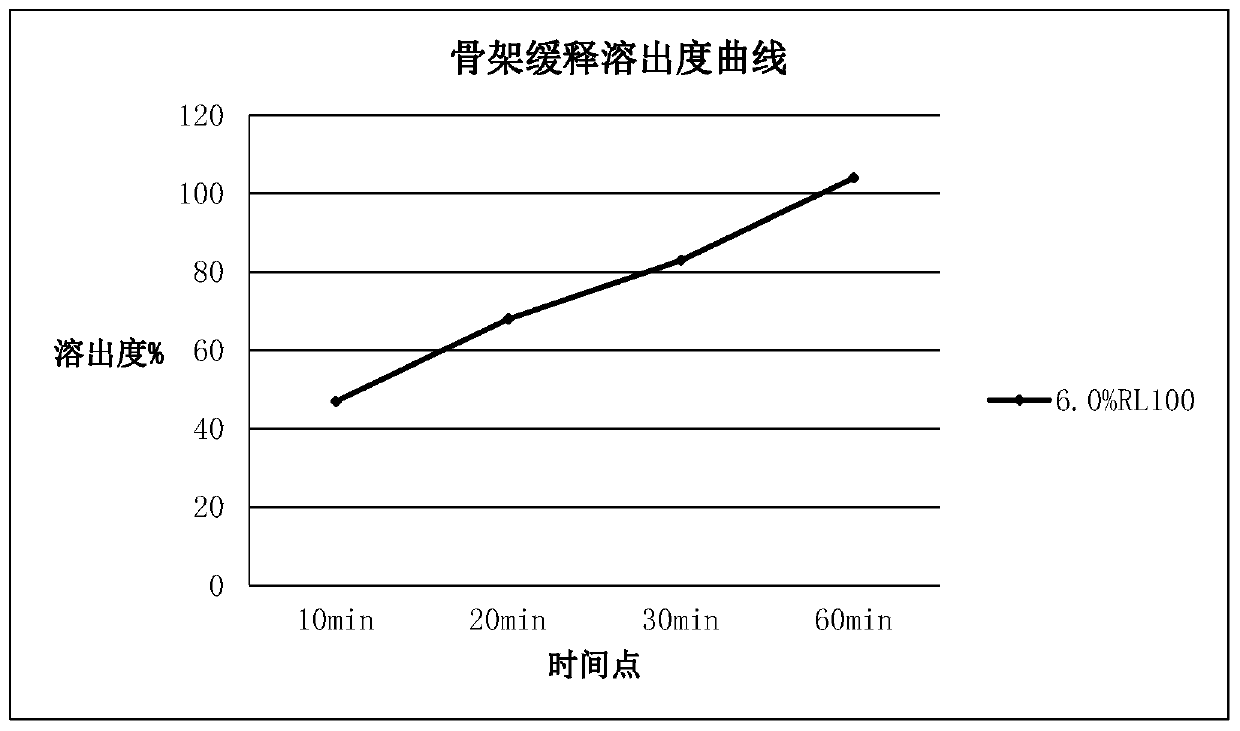

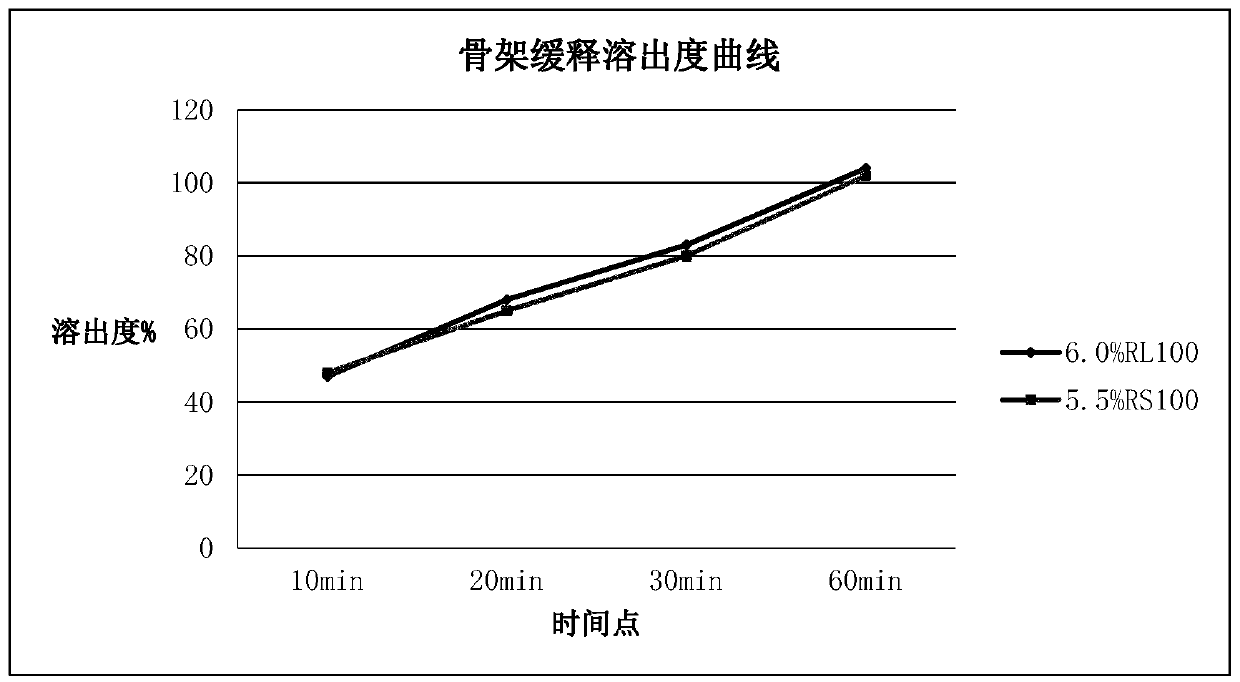

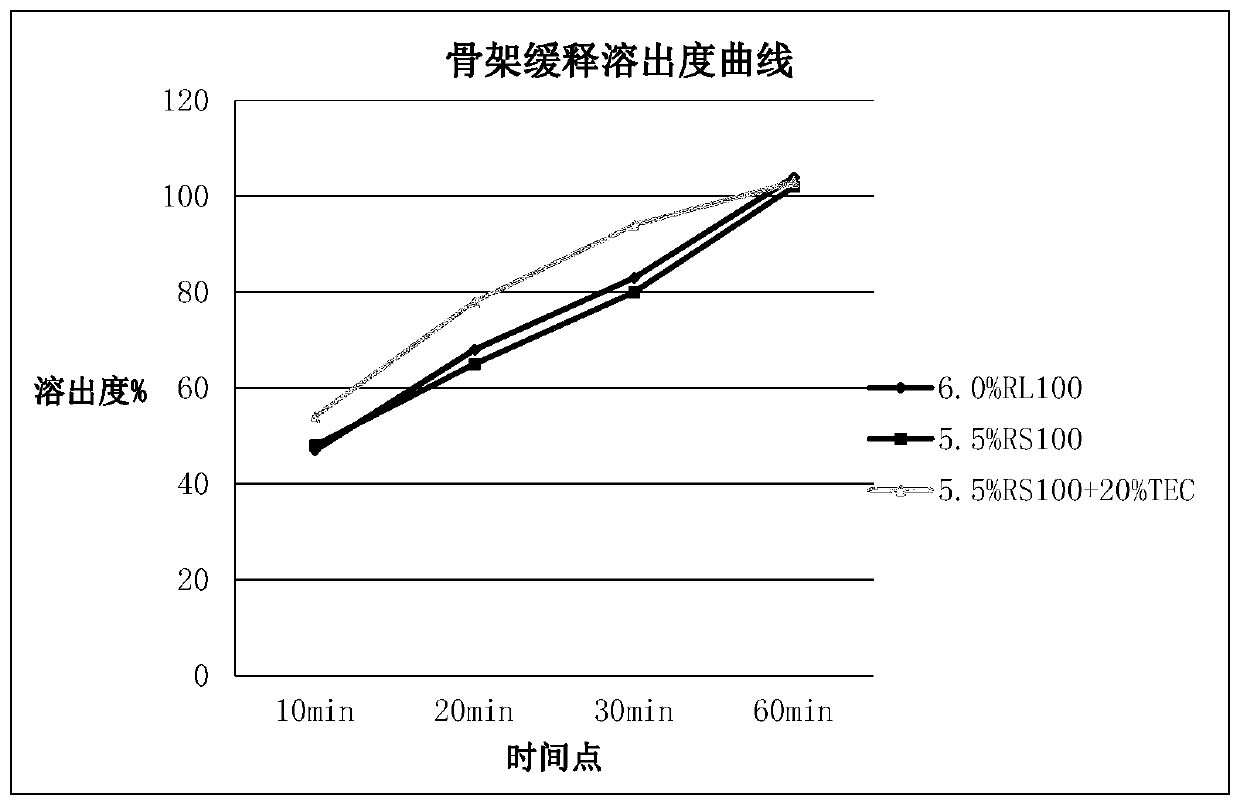

[0065] Example 1 Skeleton Structure Sustained Release Research Experiment

[0066] Experiment 1.1

[0067] Material:

[0068]RL100, 0.6g

[0069] Potassium chloride, 9.4g

[0070] process:

[0071] Use RL100 as the slow-release material to prepare a 33% mass aqueous solution; mix it with 80-mesh potassium chloride for wet granulation, pass through a 14-mesh sieve to obtain wet granules, dry 75% until the moisture content is ≤ 1%, granulate, and mix , Tablets. Dissolution testing was then performed.

[0072] results and analysis:

[0073] serial number 10min(%) 20min(%) 30min(%) 60min(%) 1 45.07 68.95 83.72 104.56 2 47.10 68.08 82.91 103.62 3 46.46 66.60 81.37 105.30 4 49.00 69.09 83.37 104.58 5 47.26 67.15 82.70 103.87 6 48.30 68.81 83.34 102.14 min 45.07 66.60 81.37 102.14 max 49.00 69.09 83.72 105.30 average 47 68 83 104

[0074] The friability is unqualified, the dissolution

Embodiment 2

[0112] Example 2 Membrane Controlled Release Research Experiment

[0113] On the basis of the skeleton structure sustained release research experiment, the next step experiment is carried out.

[0114] Experiment 2.1

[0115] In this experiment, water chestnut pot was used for spray coating

[0116]

[0117] Experimental procedure:

[0118] Before the coating solution is sprayed to the tablet by the spray gun, it has dried into white powder and cannot be wetted, flattened and dried on the surface of the tablet. It may be that the controlled release solution is an organic solvent, and the distance from the spray gun to the tablet bed is too far. Adjust the tablet. The bed distance and the exhaust air volume are adjusted from 4 gears to 2 gears, and the pump speed is increased from 15r / min to 25r / min. The amount of release liquid is not much, and the film coating fails to form a complete film on the sheet, and the test fails.

[0119] Experiment 2.2

[0120] On the basi

Embodiment 3

[0157] Embodiment three sugar coating experiment

[0158] The sugar coating takes the appearance quality as the standard;

[0159] Preparation of simple syrup: Prepare simple syrup according to sucrose:water ratio of 2-3:1 (mass ratio), and stir evenly.

[0160] Preparation of mixed slurry: Prepare mixed slurry according to simple syrup: talc powder at a ratio of 1.5-2:1 (mass ratio), and stir evenly.

[0161] The sugar coating process is as follows:

[0162] 1. Put the film-coated tablet into the coating pan;

[0163] 2. Start the coating pot, dust remover and pot electric heating plate; set the inlet air temperature to 55-75°C, and the pot speed to 18-22r / min;

[0164] 3. Sprinkle simple syrup into the pot, sprinkle talcum powder after one side is evenly moistened, turn on the hot air inlet after the rotation is not sticky, and turn off the air inlet after the coating layer is dry;

[0165] 4. Repeat step 3 two to three times;

[0166] 5. Sprinkle the mixed slurry, sprin

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap