Polypropylene grass and cold prevention fabric, preparation method thereof and application of fabric

A technology of polypropylene and cold-proof cloth, which is applied in the manufacture of fire-resistant and flame-retardant filaments, single-component polyolefin artificial filaments, non-woven fabrics, etc., and can solve soil and crop hazards, chemical components that cannot be eradicated, and hazards that cannot be treated, etc. problems, to achieve good ventilation and air permeability, which is conducive to flowering and fruiting, and reduces the chance of freezing in the shed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

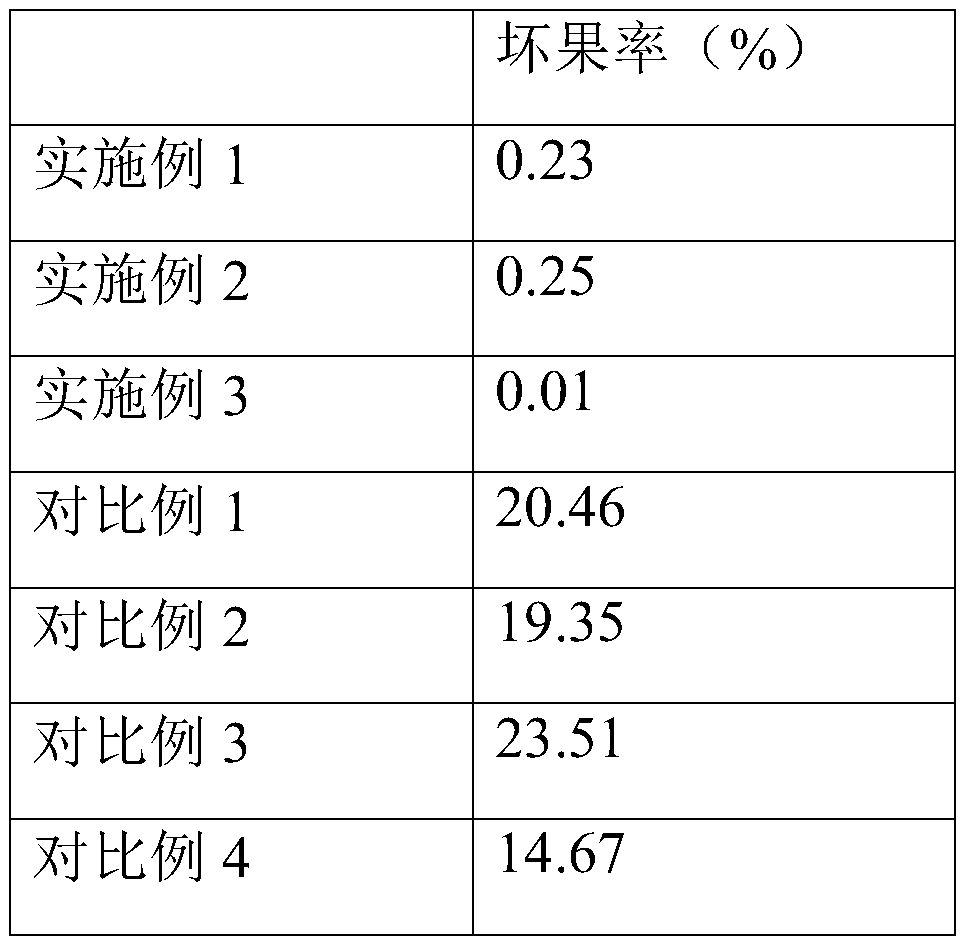

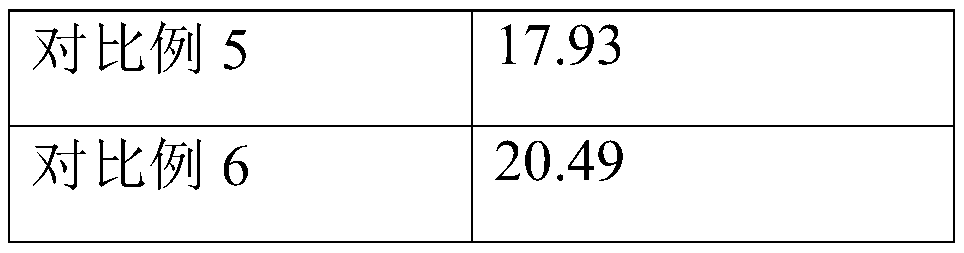

Examples

Embodiment 1

[0019] Embodiment 1 proposes a kind of preparation method of polypropylene grass-proof, cold-proof cloth, comprises the steps:

[0020] (1) Mix mica and urea according to the weight ratio of 2:0.8, then add deionized water and ultrasonically disperse for 3 hours, then add sodium stannate, and ultrasonically disperse for 2 hours, then add zinc sulfate aqueous solution and ultrasonically disperse for 6 hours, then filter and dry , and then calcined at 420° C. for 30 minutes to obtain a zinc sulfide-mica-based flame retardant. The weight ratio of described mica and described deionized water is 1:8, and the mass ratio of described urea and described sodium stannate is 2:1.2, and the concentration of described zinc sulfate aqueous solution is 0.5mol / L; The sulfuric acid The weight ratio of the zinc aqueous solution to the deionized water is 1:6. The drying temperature is 40° C., and the drying time is 4 hours.

[0021] (2) Mix polypropylene with nucleating agent, antioxidant, dis...

Embodiment 2

[0026] Embodiment 2 proposes a kind of preparation method of polypropylene grass-proof, cold-proof cloth, comprises the steps:

[0027] (1) Mix mica and urea according to the weight ratio of 2:1.2, then add deionized water and ultrasonically disperse for 2 hours, then add sodium stannate and ultrasonically disperse for 3 hours, then add zinc sulfate aqueous solution and ultrasonically disperse for 4 hours, then filter and dry , and then calcined at 450° C. for 15 minutes to obtain a zinc sulfide-mica-based flame retardant. The weight ratio of the mica and the deionized water is 1:10, the mass ratio of the urea and the sodium stannate is 2:0.8, and the concentration of the zinc sulfate aqueous solution is 0.75mol / L; the sulfuric acid The weight ratio of the zinc aqueous solution to the deionized water is 1:5. The drying temperature is 60° C., and the drying time is 2 hours.

[0028] (2) Mix polypropylene with nucleating agent, antioxidant, dispersant and zinc sulfide-mica-bas...

Embodiment 3

[0033] Embodiment 3 proposes a kind of preparation method of polypropylene grass-proof, cold-proof cloth, comprises the steps:

[0034](1) Mix mica and urea according to the weight ratio of 2:1, then add deionized water and ultrasonically disperse for 2.5h, then add sodium stannate, and ultrasonically disperse for 2.5h, then add zinc sulfate aqueous solution and ultrasonically disperse for 5h, then filter and dried, and then calcined at 435° C. for 23 minutes to obtain a zinc sulfide-mica-based flame retardant. The weight ratio of described mica and described deionized water is 1:9, and the mass ratio of described urea and described sodium stannate is 2:1, and the concentration of described zinc sulfate aqueous solution is 0.62mol / L; The sulfuric acid The weight ratio of the zinc aqueous solution to the deionized water is 1:5.5. The drying temperature is 50° C., and the drying time is 3 hours.

[0035] (2) Mix polypropylene with nucleating agent, antioxidant, dispersant and ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap