Waste PET composite material

A composite material and mixed material technology, which is applied in the field of plastic material recycling, can solve the problems of poor impact performance of waste PET, and achieve the effects of improving toughness, saving resources and energy, and reducing pollution emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

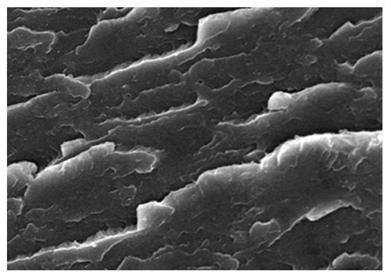

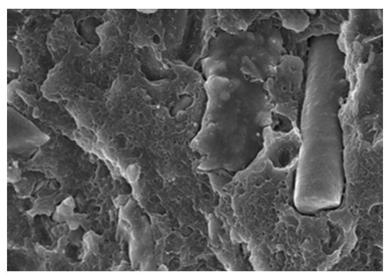

Image

Examples

Embodiment 1

[0035] A waste PET composite material, raw materials include: waste PET with a crushing particle size of 1-10 cm, waste resin powder of 40-100 mesh, silane coupling agent and polyolefin elastomer (POE), the preparation process is as follows:

[0036] 1) Mix the silane coupling agent and waste resin powder at a mass ratio of 1 to 10:100, and dry to obtain silanized waste resin powder;

[0037] 2) Weigh the waste PET and dry it, and mix the waste PET with the silanized waste resin powder and polyolefin elastomer obtained in step 1) to obtain a mixture, wherein the mass ratio of PET to waste resin powder is 5-9:1 -5, the amount of polyolefin elastomer added accounts for 1% to 20% of the mass of the mixture;

[0038] 3) The mixture is extruded and granulated through a twin-screw extruder. The temperature of the barrel of the extruder is 235-260°C, the temperature of the die head is 240-265°C, the speed of the main engine is 150-180r / min, and the feeding speed is about 10-25 r / mi

Embodiment 2

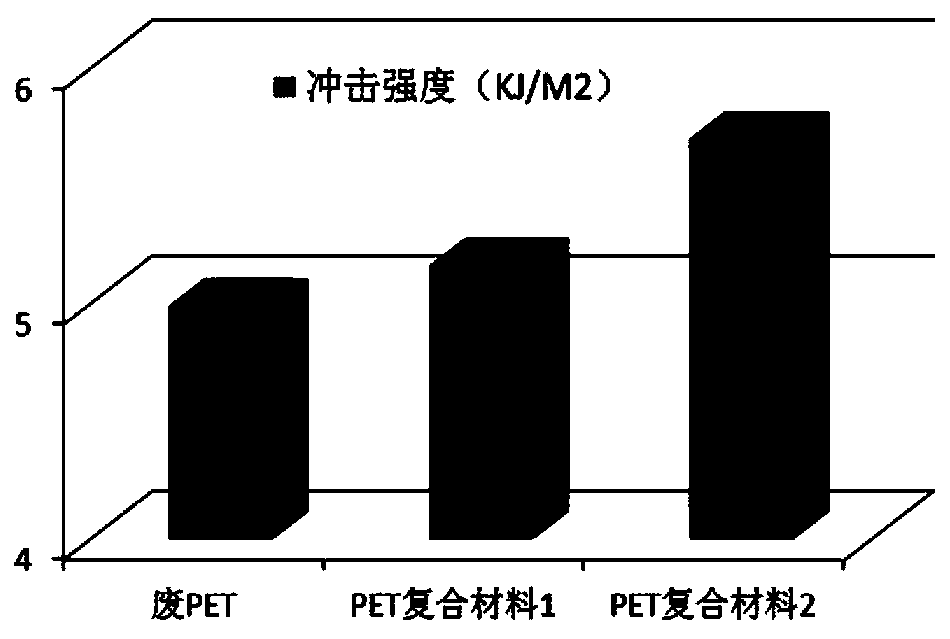

[0049] Improvements were made on the basis of Example 1, wherein the mass ratio of waste resin powder: POE: waste PET was limited to 1:1:8, and composite material 1 was obtained. After testing, the impact strength of composite material 1 increased by 3.4% compared with waste PET, see image 3 . Its elongation at break, flexural strength, tensile strength see Figure 4 , 5 6.

Embodiment 3

[0051] Improvements were made on the basis of Example 2, wherein the mass ratio of waste resin powder: POE: waste PET was limited to 1:1.5:7.5, and composite material 2 was obtained. After testing, the impact strength of composite material 2 increased by 14% compared with waste PET, see image 3 . After testing, the elongation at break, bending strength, and tensile strength of this embodiment are also within reasonable ranges, and this embodiment is the most preferred embodiment after comprehensive evaluation. Its elongation at break, flexural strength, tensile strength see Figure 4 , 5 6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Broken particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap