Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

14 results about "Toughening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Toughening refers to improving the fracture resistance of a given material. The material's toughness is described by irreversible work accompanying crack propagation. Designing against this crack propagation leads to toughening the material.

3D printing modified polyamino acid material and preparation method thereof

Owner:INST OF CHEM CHINESE ACAD OF SCI

Polylactic acid/polyester alloy and preparation method thereof

The invention relates to a polylactic acid / polyester alloy and a preparation method thereof. The polylactic acid / polyester alloy comprises the following components in percentage by weight: polylactic acid, polyester, a compatilizer, a flexibilizer, an antioxidant and a lubricant. The preparation method comprises the following steps: firstly, proportioning the raw materials and mixing at a room temperature; and respectively carrying out melting extrusion, carrying out ultrasonic treatment at the first late stage, extruding at the second stage and pelletizing, so as to obtain degradable, high-impact-resistant and high-heat-resistant polylactic acid / polyester alloy. Compared with an existing method, the controllable ultrasonic treatment is utilized; and a similar polylactic acid-g-polyester structure is formed by in-situ reaction, so that the heat resistance of the polyester and the biodegradability of the polylactic acid are reserved; and meanwhile, a toughening system with a core-shell structure is formed in an alloy system through interface interaction of a special toughening compatilizer, so that the alloy product with high impact resistance, high heat resistance and high biodegradability can be obtained.

Owner:FINE BLEND POLYMER SHANGHAI CO LTD

Polyamide toughening agent as well as preparation method and use thereof

InactiveCN104177825AImprove impact resistanceImprove low temperature impact resistanceElastomerPolyolefin

The invention provides a polyamide toughening agent as well as a preparation method and use thereof. The polyamide toughening agent is mainly prepared from the following raw materials in parts by weight: 50-95 parts of an ethylene-octene copolymer elastomer, 0.5-2.5 parts of a grafting monomer, 5-50 parts of polyolefin, 0.05-0.5 part of an initiator and 5-20 parts of polyamide. The toughening agent provided by the invention is simple in preparation method, have good mechanical property and low-temperature impact toughness when being used for toughening the polyamide, and can be widely applied to modification of polyamide materials in the fields of inner and outer decorative parts of automobiles, electric tools, rail bases, transformers, oil tubes and the like.

Owner:DONGGUAN CALVIN PLASTIC & TECH

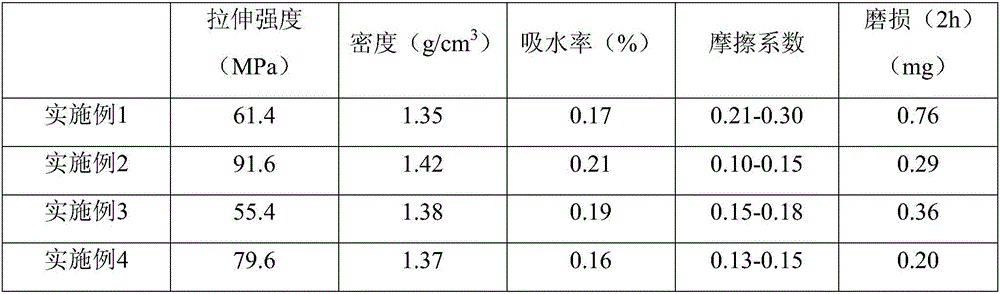

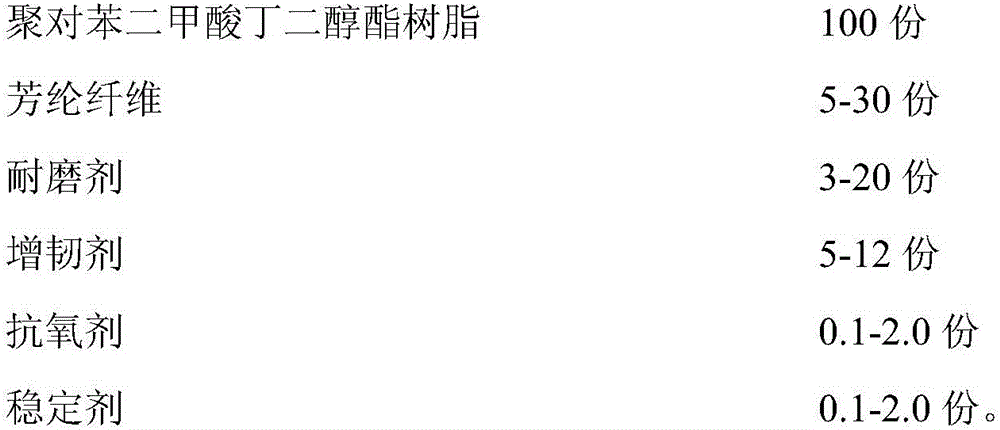

High-molecular self-lubricating material, preparation method of high-molecular self-lubricating material, and plate spring flanged bushing made of high-molecular self-lubricating material

InactiveCN106633695AWith wear resistanceGood dimensional stabilityResilient suspensionsVehicle springsPolytetramethylene terephthalateAntioxidant

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

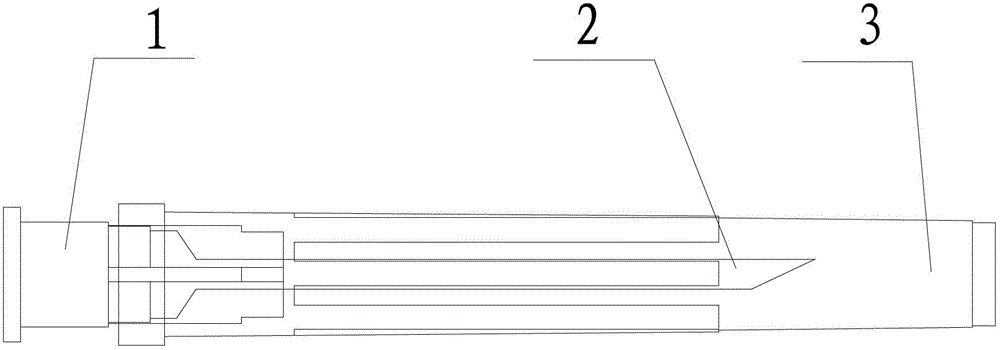

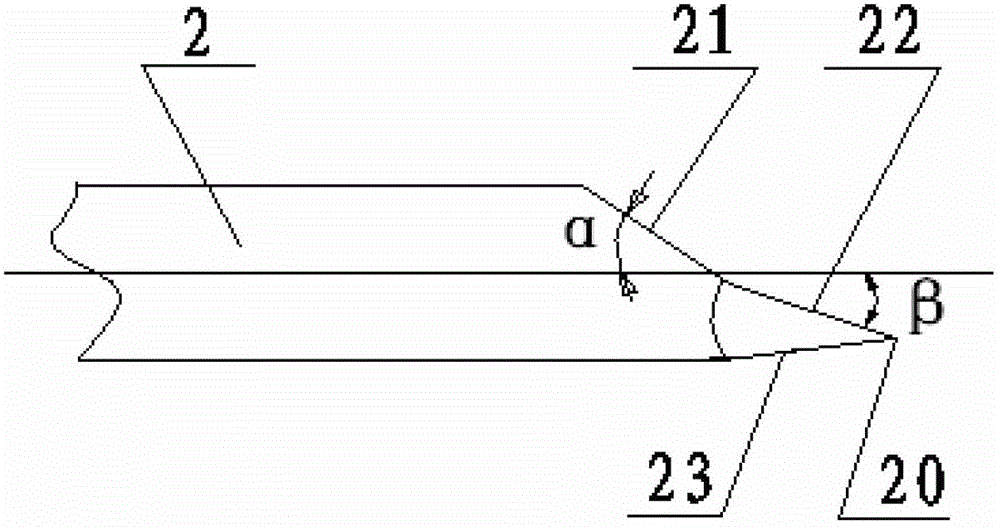

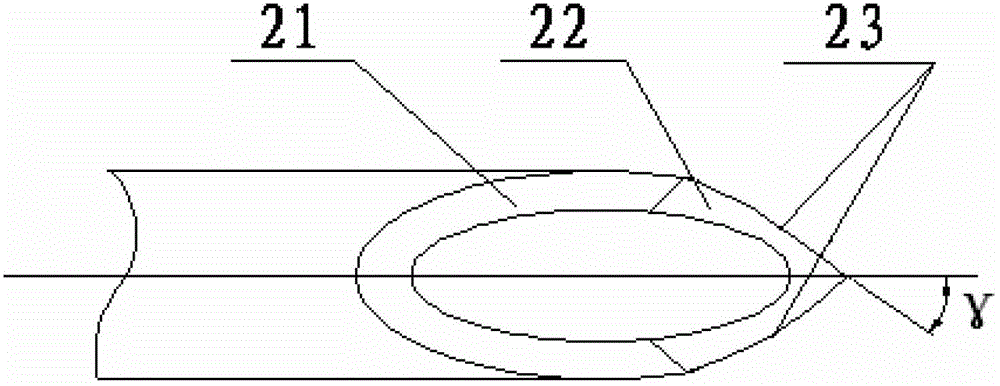

Disposable medical syringe needle

InactiveCN102716531AMeet production requirementsEasy to processInfusion needlesDiseaseInjection moulding

Owner:侯李明

Biodegradable 3D printing toughened material and preparation method thereof

InactiveCN106893279AImprove the shortcomings of low impact performanceHigh impact strengthAdditive manufacturing apparatusPolymer scienceGlycidyl methacrylate

Owner:四川鑫达企业集团有限公司

Preparation method of low-density low-VOC scraping-resistant modified polypropylene composite material

The invention discloses a low-density low-VOC scraping-resistant modified polypropylene composite material and a preparation method thereof. The composite material consists of the following raw materials in parts by weight: 60-80 parts of polypropylene, 15.5-31 parts of a toughening-VOC adsorption compound additive, 1-2 parts of a scraping agent, 0.02-0.05 part of an antioxidant and 2-4 parts of pure water. The toughening-VOC adsorption compound additive consists of the following raw materials in parts by weight: 3-8 parts of ethylene-octene copolymer (POE), 1 part of a compatilizer, 1 part ofa coupling agent, 0.5-1 part of nano vermiculite and 10-20 parts of diatomite with micropores in the surface. The composite material has low density, low VOC and high scraping resistance, and is suitable for automotive trim.

Owner:QINGDAO DONG PLASTIC CO LTD

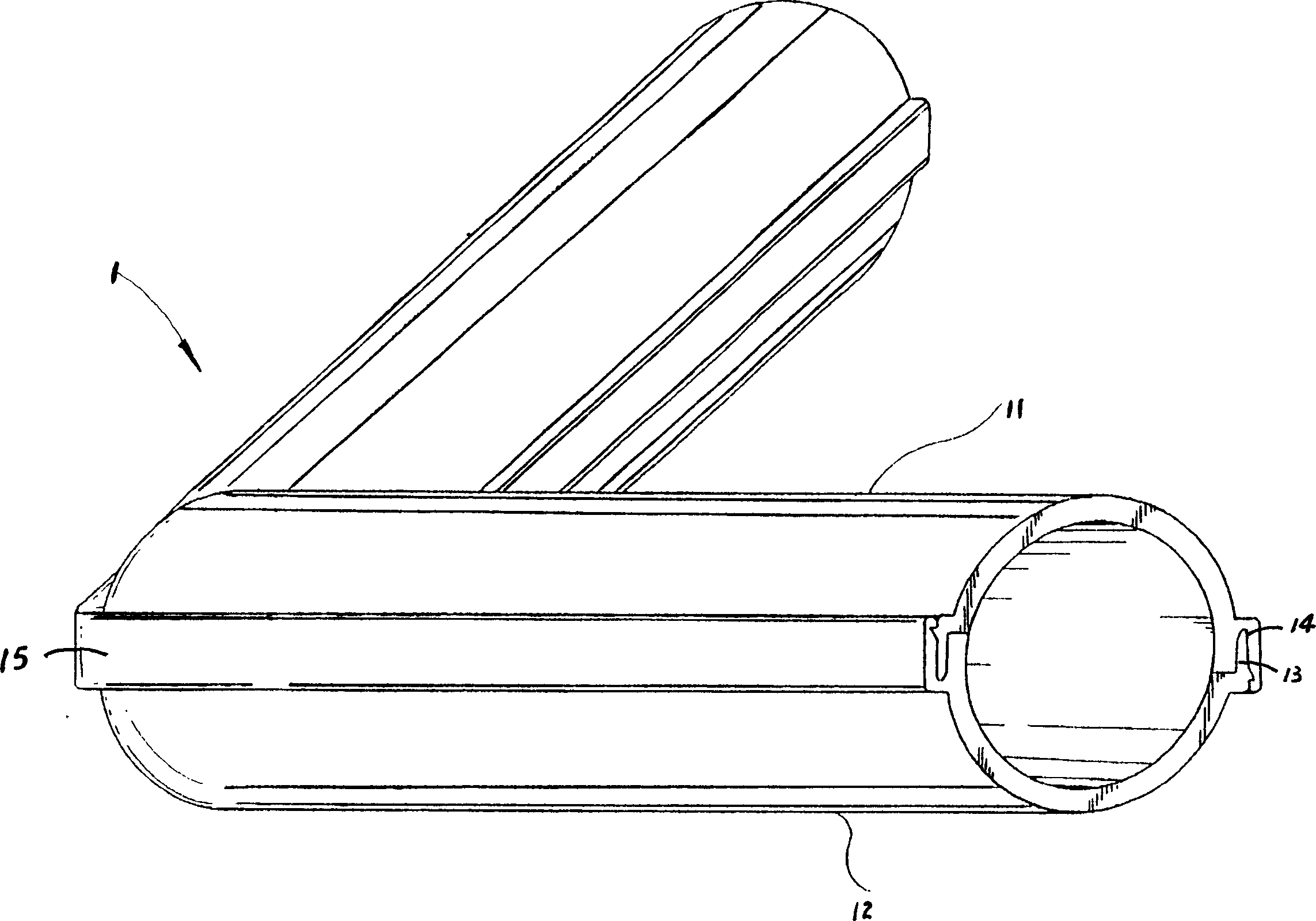

Shield haf type wire and cable protective sleeve

InactiveCN1858948AEasy to replaceEasy maintenanceCable installations in underground tubesNon-conductive material with dispersed conductive materialPolyolefinMetal powder

Owner:周宝茂 +2

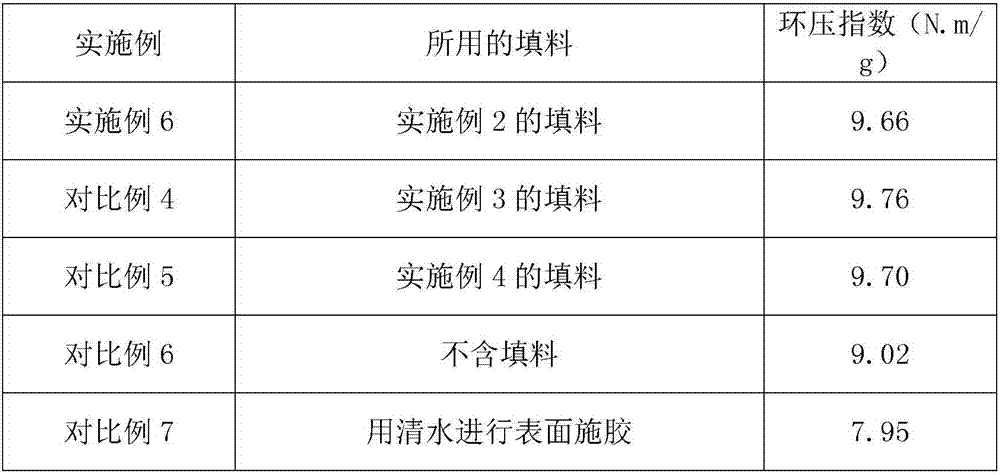

Straw-based composite filler and preparation method of straw-based composite filler as well as paper sheet containing straw-based composite filler

InactiveCN106866897AHydrophilicCationicReinforcing agents additionPaper/cardboardCore shellToughening

Owner:GUANGDONG IND TECHN COLLEGE

Impact-resistant conductive polyphenylene sulfide material and preparation method thereof

The invention belongs to the technical field of high polymer materials, and relates to an impact-resistant conductive polyphenylene sulfide material and a preparation method thereof. The impact resistant conductive polyphenylene sulfide material is prepared from the following components in parts by weight: 60-75 parts of PPS, 0.5-1 part of a lubricant, 0.5-0.8 part of epoxy resin, 8-15 parts of a toughening agent, 17-25 parts of carbon black and 0.5-2 parts of a coupling agent. The impact-resistant conductive polyphenylene sulfide material is prepared by using a high-speed pre-mixing dispersion one-step extrusion process. The impact-resistant conductive polyphenylene sulfide material provided by the invention has the characteristics of being good in mechanical property, good in flame retardancy, good in stability, easy to process, good in impact resistance and the like, and is applicable to packages of precise and advanced products of the electronic industry, the war industry and the like.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Heat-resisting and high-breathability composite modified water glass sand used for pump valve casting and manufacturing method of heat-resisting and high-breathability composite modified water glass sand

InactiveCN105436394AExcellent normal temperature wet strengthImprove thixotropyFoundry mouldsFoundry coresSodium BentoniteRoom temperature

Owner:TONGLING JINGWEI FLUID SCI & TECH

Nano lanthanum oxide modified talcum powder enhanced polyphenylene sulfide-based heat dissipating material for LED and preparation method of nano lanthanum oxide modified talcum powder enhanced polyphenylene sulfide-based heat dissipating material

Owner:BENGBU GAOHUA ELECTRONICS

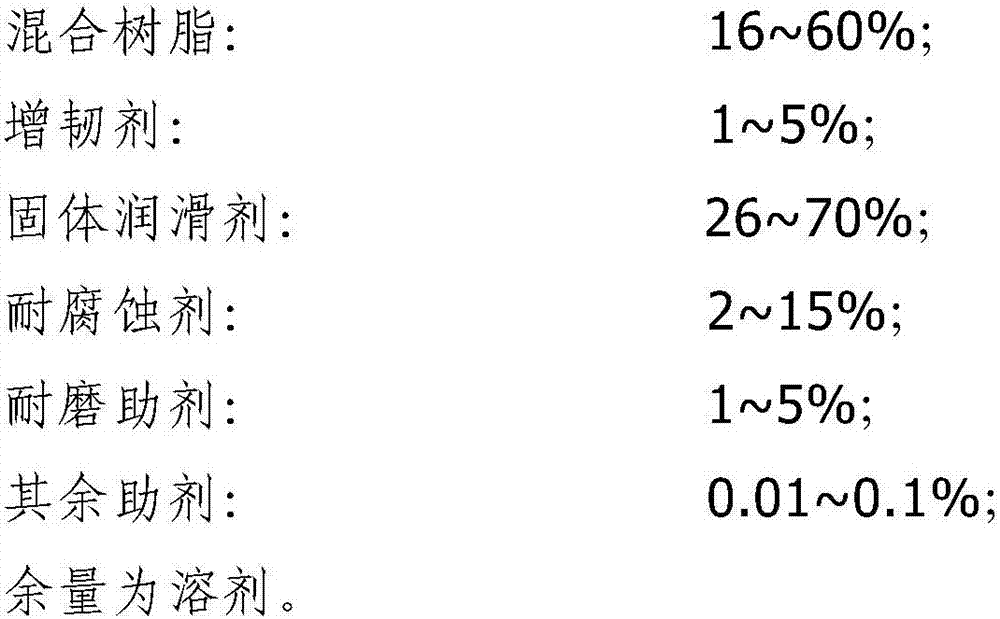

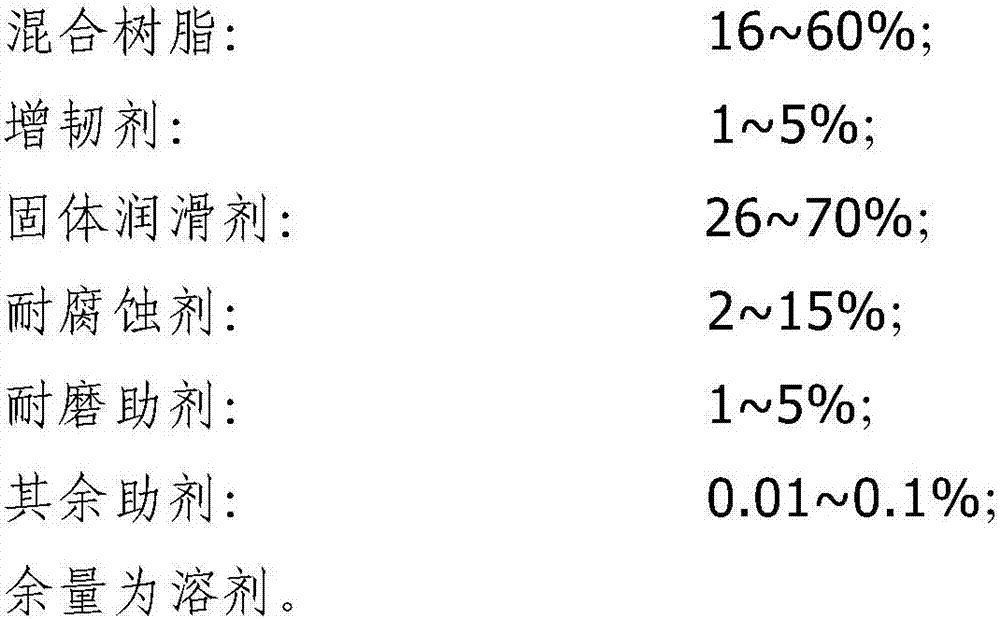

Anti-gluing solid lubricating paint as well as preparation method and applying method thereof

ActiveCN107286839AHigh bonding strengthGood anti-sticking propertiesSpecial surfacesEpoxy resin coatingsSolventToughening

Owner:BAOSHAN IRON & STEEL CO LTD

Reinforced and toughened polypropylene composite material and preparation method thereof

Owner:JIANGSU UNIV OF TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap