Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

75results about "Epoxy resin coatings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyaniline-graphene composite based anticorrosive paint and preparation method thereof

Owner:HARBIN ENG UNIV

Organometallic compositions and coating compositions

InactiveUS20060036007A1Reduce yellowingImprove moisture resistanceOrganic-compounds/hydrides/coordination-complexes catalystsPolyurea/polyurethane coatingsCarbamateZinc

Owner:KING INDUSTRIES INC

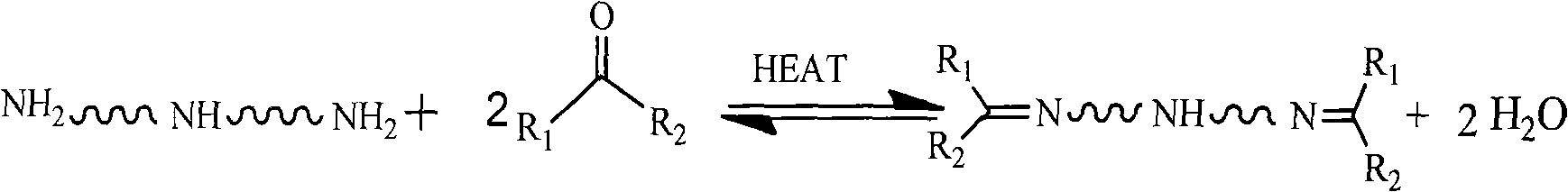

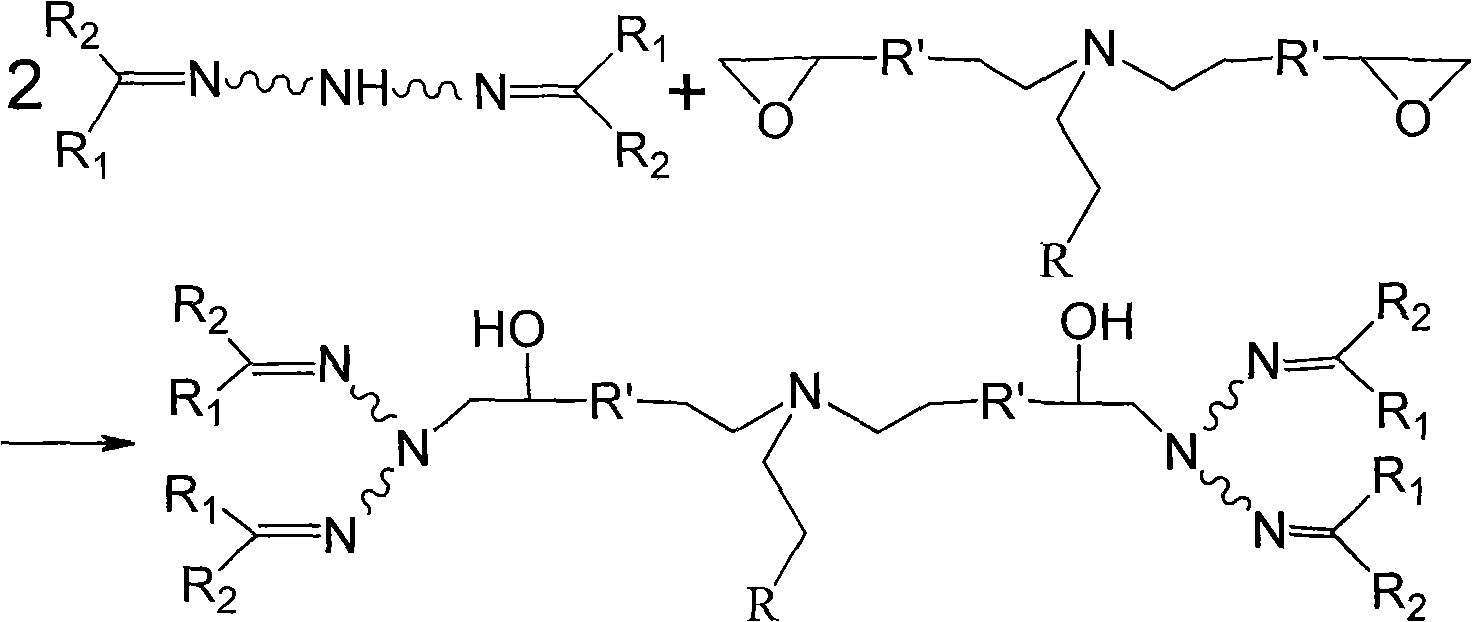

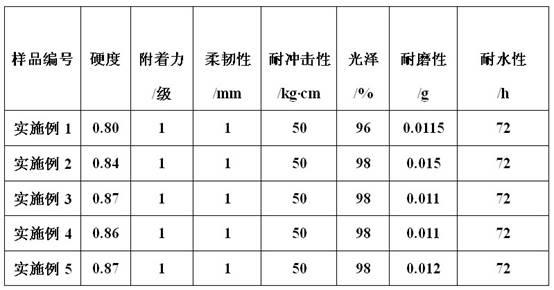

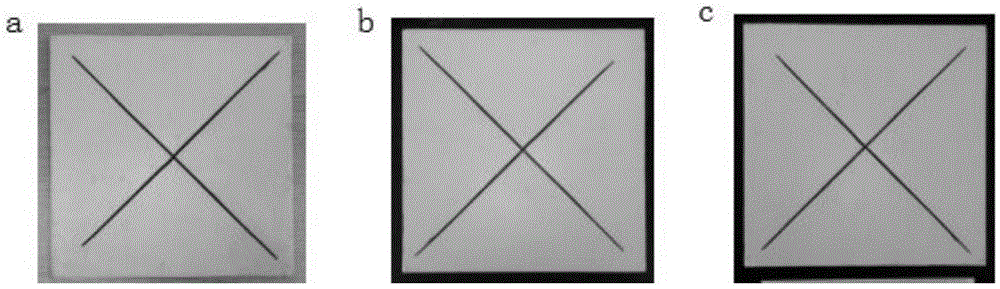

Preparation and application of latent nonionic self-emulsifying epoxy curing agent

Owner:GUANGZHOU CHEM GROUTING CO LTD CAS

Preparation method for light-heat dual-cured woodware UV varnish coating

InactiveCN102321424AOvercome depthOvercoming the difficulty in application in colored systemsEpoxy resin coatingsEpoxyPtru catalyst

Owner:SOUTH CHINA UNIV OF TECH

Transparent thermal insulation coating material system for glass substrate

InactiveCN102942841AInstant cureReduce energy consumptionPolyurea/polyurethane coatingsEpoxy resin coatingsThermal insulationUltraviolet lights

The present invention discloses a transparent thermal insulation coating material system for a glass substrate. The coating material system is a double layer coating material system formed by a separately-prepared primary coating and a separately-prepared surface coating, wherein the surface coating is coated on the primary coating, the primary coating comprises the following components, by mass, 0.05-3 parts of a silicane coupling agent or a titanate coupling agent, 0.2-5 parts of a hydrolysis catalyst, and 95-99 parts of a solvent, and the surface coating comprises the following components, by mass, 50-80 parts of a light curable resin, 5-35 parts of an active diluent, 1-8 parts of a photoinitiator, 5-35 parts of an antimony tin oxide nanometer thermal insulation powder slurry or an indium tin oxide nanometer thermal insulation powder slurry, 100-140 parts of an inert diluent, and 0.01-0.15 part of a leveling agent. With the coating material system, a film can be formed through a conventional film forming method, and the film layer can be cured within a few seconds after ultraviolet light irradiation. In addition, the coating material system has characteristics of high hardness, excellent adhesion and excellent water resistance.

Owner:刘志钊 +1

Functional composite coating and preparing method thereof

ActiveCN105623341AOn-site construction is simpleImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyFluoropolymer

Owner:CHANGCHUN A&Z SCI CO LTD

Photochromic glass paint and preparation method thereof

Owner:北京首创纳米科技有限公司

High heat resistant non-skid coatings

InactiveUS20110224327A1Efficient use ofAcceptable mechanicalFireproof paintsOther chemical processesMechanical propertyHigh heat

Owner:AKZO NOBEL COATINGS INT BV

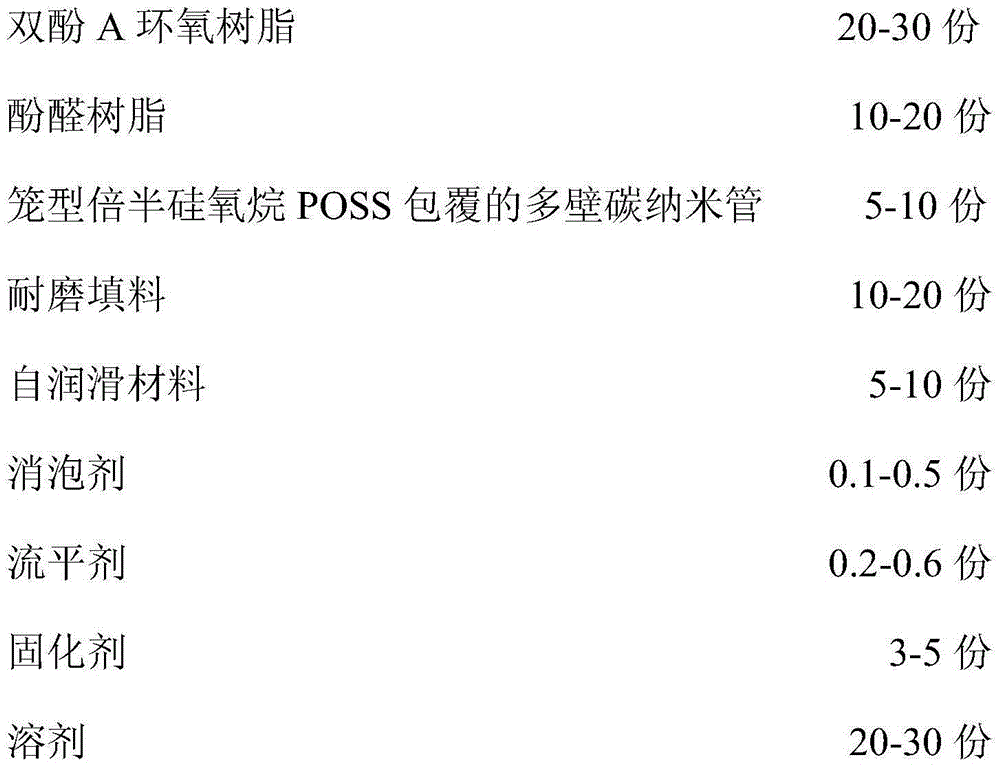

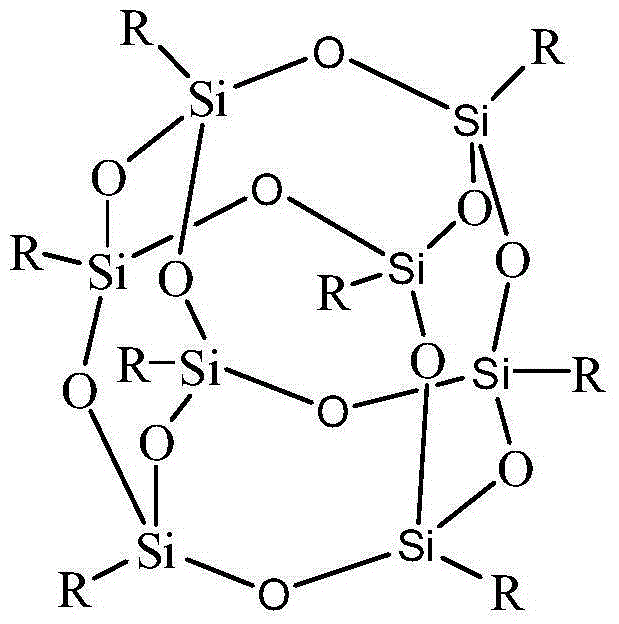

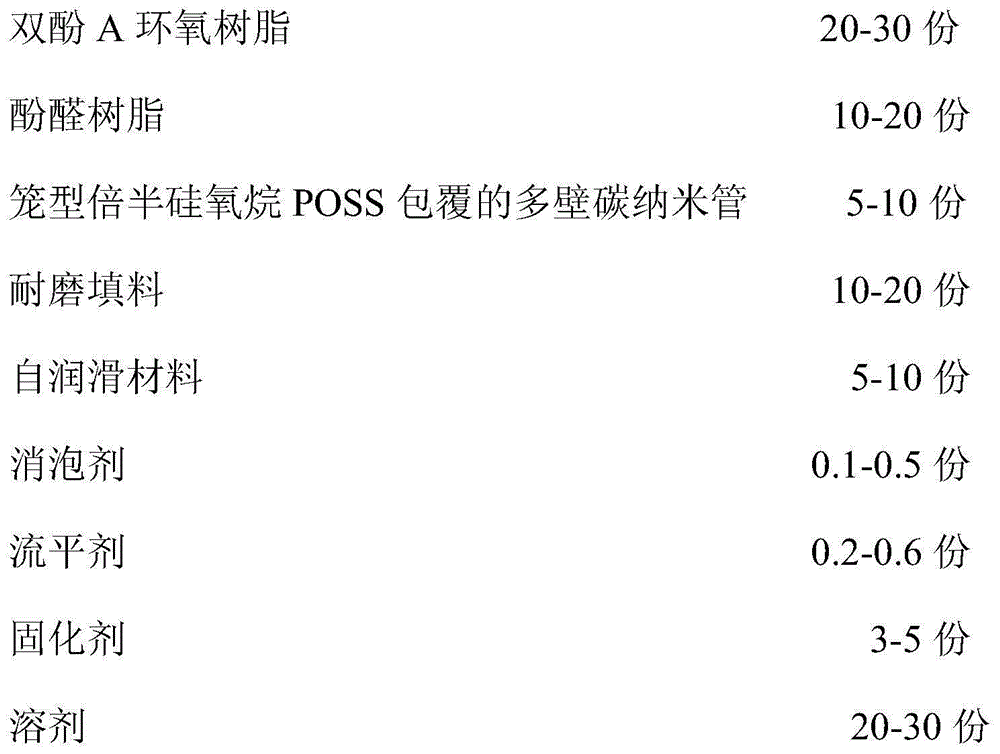

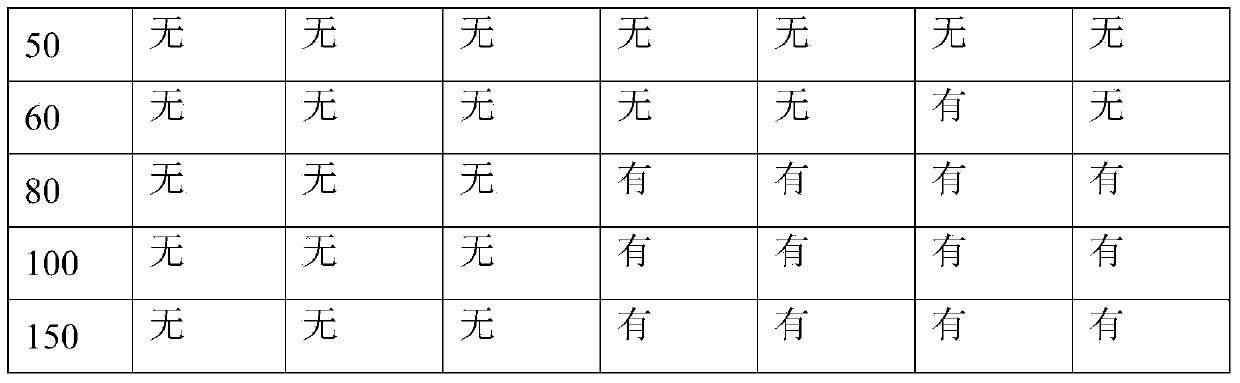

Anti-corrosion and wear-resisting coating for throwing disc of pneumatic type feeder and preparation method of coating

InactiveCN105062300AImprove corrosion resistanceImprove high temperature resistanceAnti-corrosive paintsEpoxy resin coatingsMultiwalled carbonRoom temperature

Owner:JINHU JIEDA MACHINERY MFR

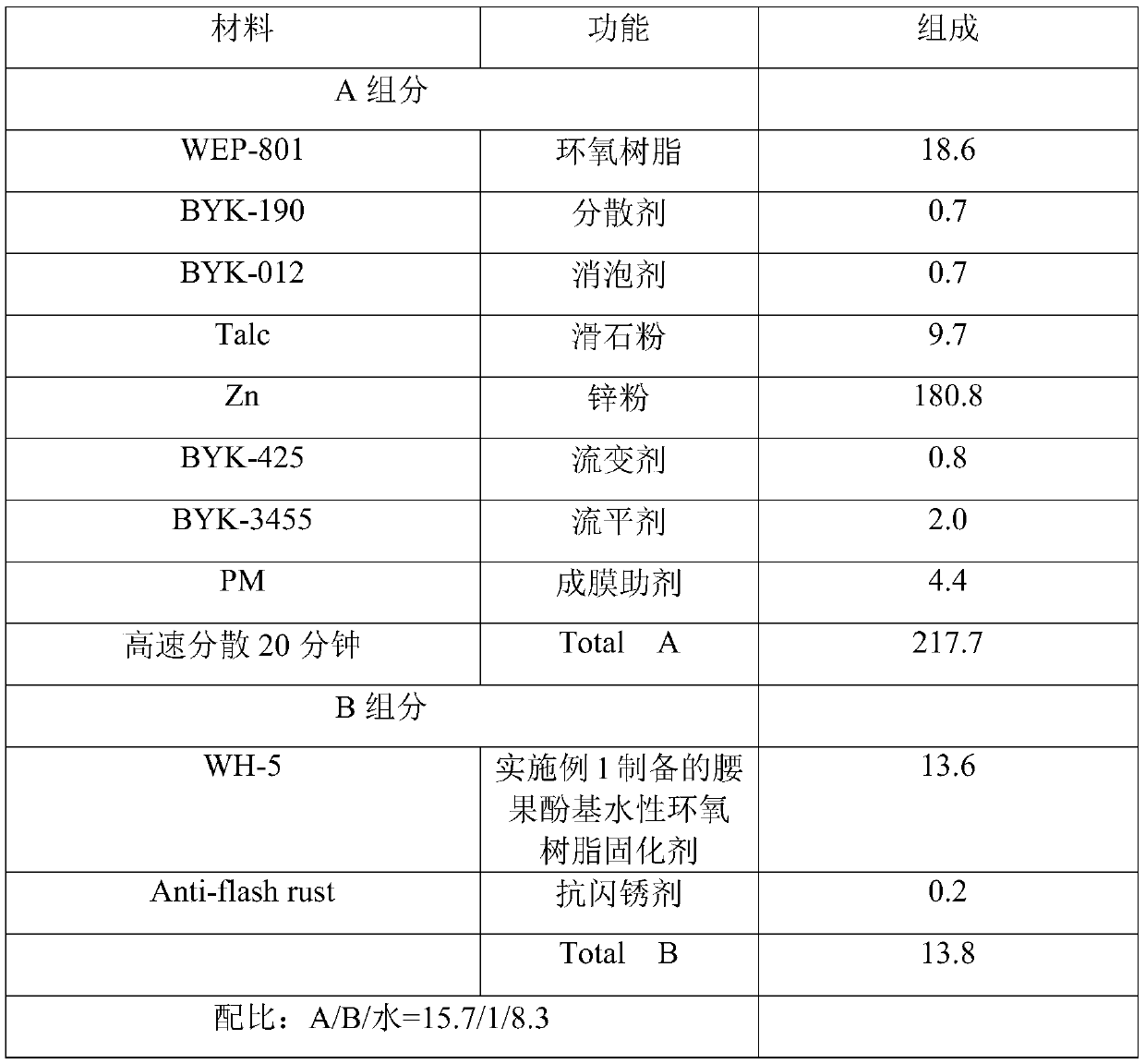

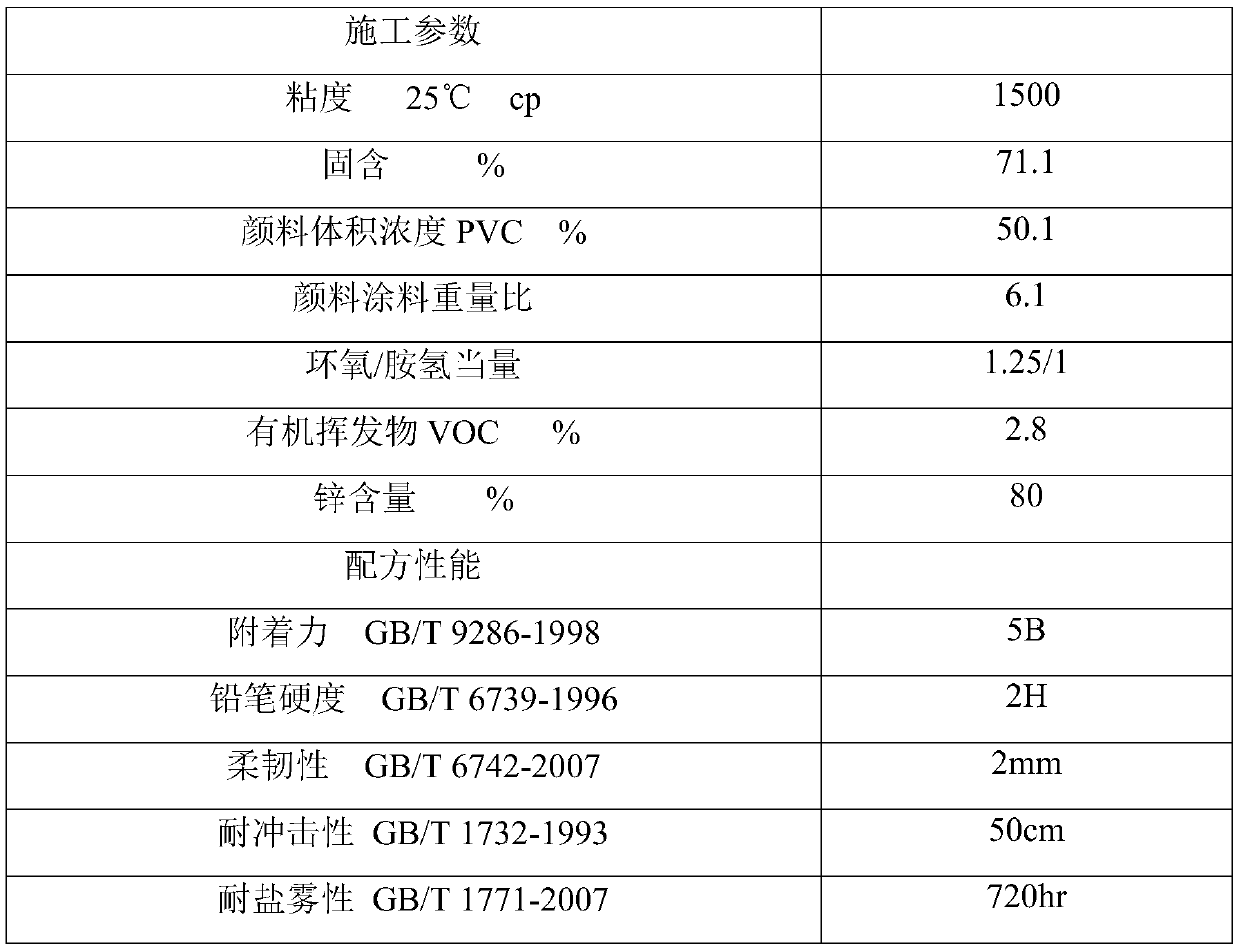

High-performance water-based bicomponent epoxy zinc rich primer and preparation method thereof

ActiveCN107573816AReduce usageImprove protectionAnti-corrosive paintsEpoxy resin coatingsEpoxyCollocation

The invention relates to a high-performance water-based bicomponent epoxy zinc rich primer and a preparation method thereof. A water-based bicomponent epoxy zinc rich coating A in the high-performancewater-based bicomponent epoxy zinc rich primer comprises a water-based epoxy curing agent, an additive A, a complex solubilizer, zinc powder, zinc and an anti-settling agent; a water-based bicomponent epoxy zinc rich coating B comprises a water-based epoxy emulsion and an additive B; the weight ratio of the coating A to the coating B is at 100 to (10-30). The preparation method comprises the following steps: (1) uniformly mixing the components in the coating A at ratio and using a 100-mesh screen for filtering; (2) uniformly mixing the components in the coating B at ratio; and uniformly mixing the coating A with the coating B at the weight ratio in a use process and regulating the construction viscosity. When the high-performance water-based bicomponent epoxy zinc rich primer is used, water is taken as a solvent, so that the use of the organic solvent is greatly reduced and the environmental protection is benefited. The collocation of the anti-settling agent is utilized to solve the problems of storage and construction.

Owner:SHANDONG QIWEI NEW MATERIALS CO LTD

Ultraviolet (UV) gloss oil and preparation method thereof

Owner:上海奇想青晨新材料科技股份有限公司

Bicomponent epoxy zinc enriched base paint and its manufacturing method

ActiveCN1912032ALong application periodStrong adhesionAnti-corrosive paintsEpoxy resin coatingsEpoxySilanes

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Permeation consolidation type solvent-free epoxy anticorrosive coating, and preparation method and application thereof

ActiveCN105238217AImprove wetting abilityImprove bonding abilityAnti-corrosive paintsEpoxy resin coatingsSolventSurface corrosion

The invention belongs to the technical field of anticorrosive coatings, and discloses a permeation consolidation type solvent-free epoxy anticorrosive coating, and a preparation method and an application thereof. The anticorrosive coating consists of a component A and a component B. The component A consists of the following components in parts by weight: 18-89 parts of epoxy resin, 5-50 parts of enhanced type reactive solvents, 5-60 parts of permeation type reactive solvents, 0-5 parts of interfacial modifiers and 0-3 parts of permeation enhancers. The component B consists of the following components in parts by weight: 5-95 parts of functional curing agents, 0-30 parts of curing regulators, 0-50 parts of double-function regulators, 0-40 parts of curing accelerators and 0-5 parts of condensation catalysts. The coating is low in viscosity and excellent in permeability, and has an excellent mechanical property after being cured. In addition, the permeation consolidation type solvent-free epoxy anticorrosive coating disclosed by the present invention has good wettability and viscocity with concrete, and strength of the concrete can be improved, water on the surface of the concrete can be removed, and surface corrosion factors of the concrete are reduced.

Owner:SOUTH CHINA UNIV OF TECH

Hardware surface coating process

Owner:深圳市旺鑫精密工业有限公司

Seam binding agent with modified fatty amine as epoxy curing agent resin

ActiveCN102816501AFast shapingEasy constructionNon-macromolecular adhesive additivesEpoxy resin adhesivesCalcium silicateFiber

The invention relates to a seam binding agent with modified fatty amine as epoxy curing agent resin. The agent is suitable for easy-cracking positions in indoor and outdoor decorations. The agent is filled into seams of same or different materials such as wood, brick and stone, gypsum board, calcium silicate, and the like, for providing an excellent anti-cracking effect. The agent can also be used as a binding agent for roof leakage repairing, wood, and plastic. The agent can be used in crack sealing and water proofing of various grouting projects, bridges, and tunnels. According to the invention, a novel nano fiber binding technology is adopted. When the product is cured, nano fibers in the product form a high-molecular high-density net-shaped film at a seam position, wherein the physical density of the film is close to that of wood board or gypsum board. The film can expand or contract synchronically with the board when weather is changed, and has good cracking resistance, adhesive force, and flexibility. The seam binding agent is advantaged in fast shaping, easy construction, and low sagging.

Owner:SKSHU PAINT

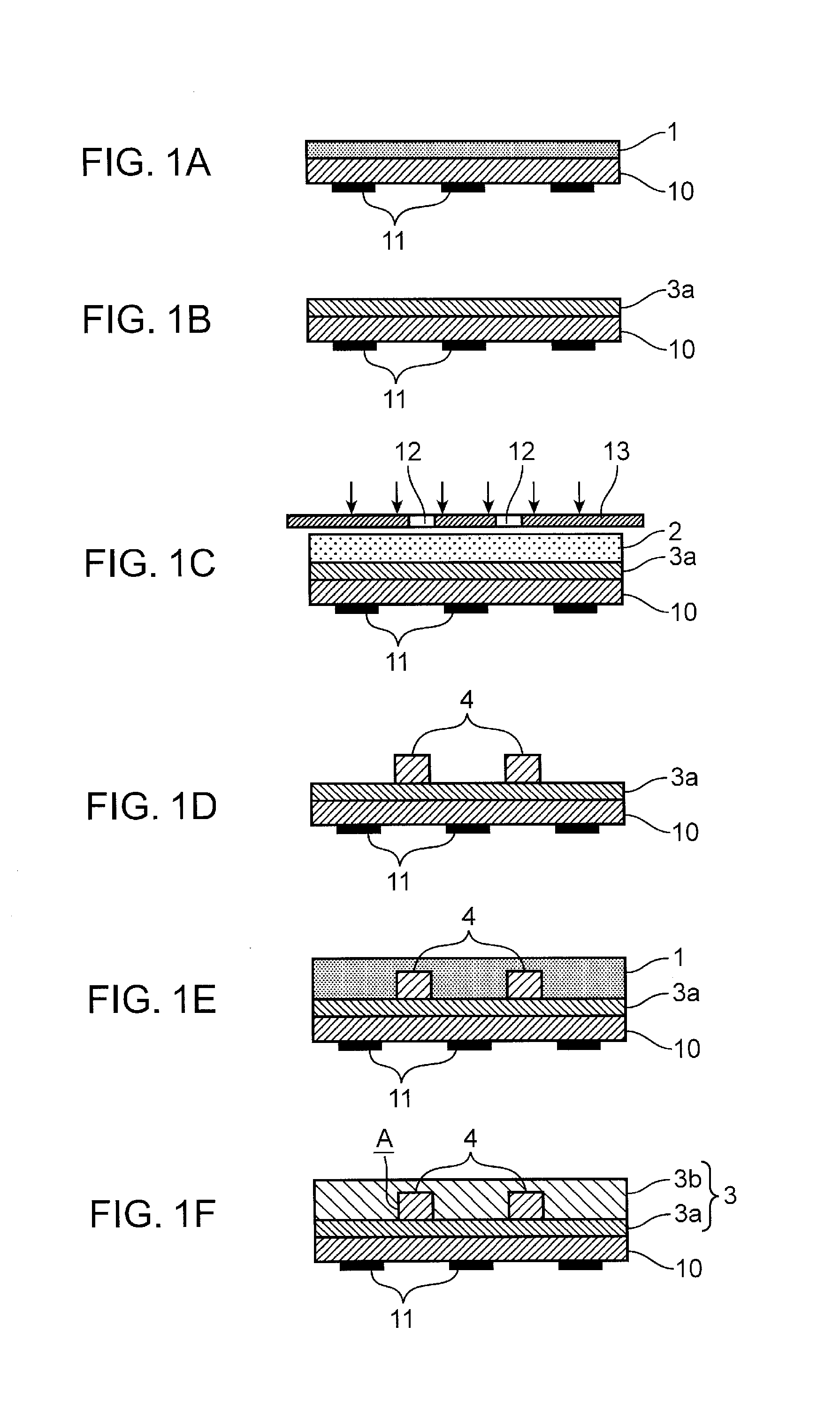

Resin composition for optical waveguide, dry film, optical waveguide, and photoelectric composite wiring board using same

ActiveUS20140004321A1High transparencyLow coefficient of linear expansionDuplicating/marking methodsDecorative surface effectsEpoxyPolymer science

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Water-based epoxy thick slurry anticorrosive paint as well as preparation method and application thereof

Owner:SHANGHAI ZHENHUA HEAVY IND CHANGZHOU COATINGS CO LTD

Super heat insulation coating loaded with nano titanium dioxide and preparation method of super heat insulation coating

InactiveCN104610847ADelay the aging processImprove hydrophilicityEpoxy resin coatingsBulk chemical productionEpoxySilicon dioxide

Owner:WUHU BAOYI AMUSEMENT EQUIP

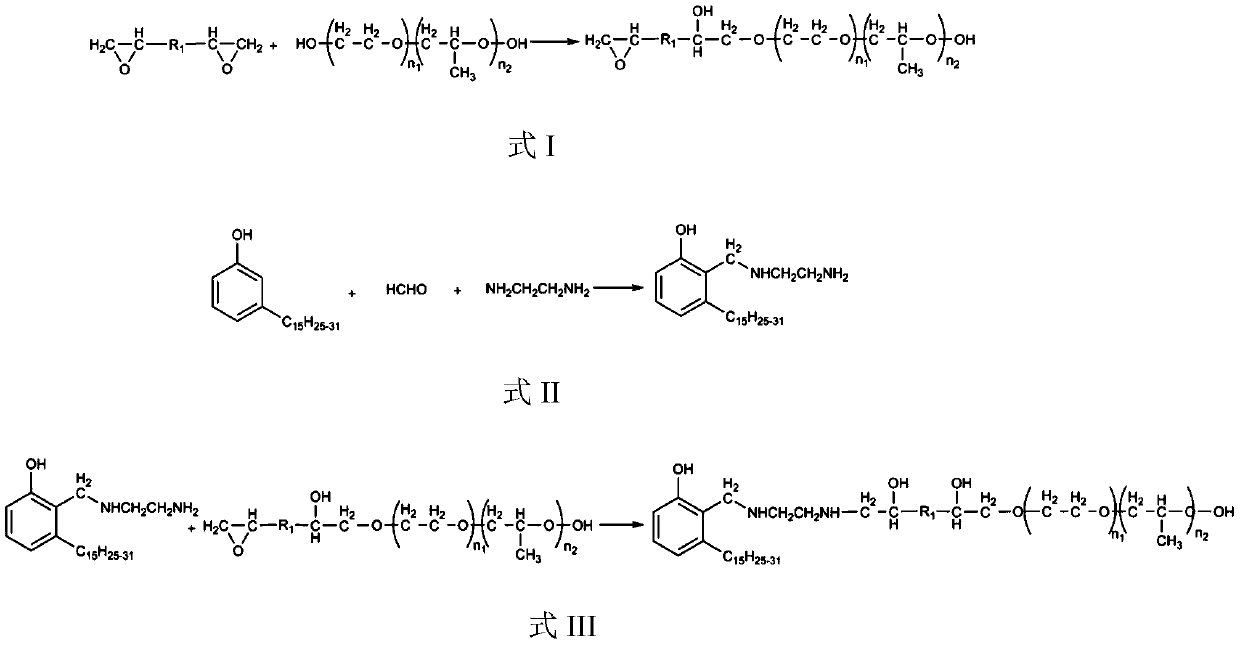

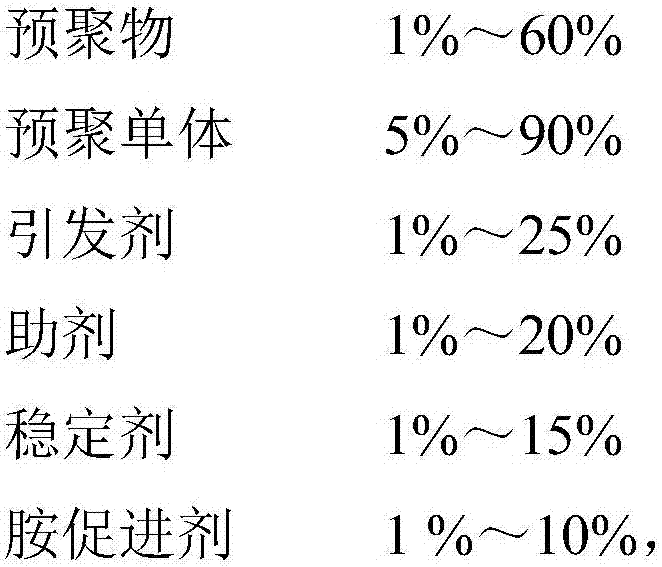

Preparation method and application of cardanol-based waterborne epoxy resin curing agent

The invention discloses a preparation method and application of a cardanol-based waterborne epoxy resin curing agent. The preparation method comprises the following steps: (1) mixing an epoxy resin and a polyether polyol, heating for melting, adding a catalyst at 50-100 DEG C, and carrying out condensation reaction to obtain an epoxy functional group emulsifier after the reaction is finished; (2)carrying out Mannich reaction on cardanol, a polyamine and formaldehyde to obtain a cardanol modified curing agent; and (3) adding the epoxy functional group emulsifier obtained in the step (1) into the cardanol modified curing agent obtained in the step (2), heating to 60-80 DEG C, and reacting to obtain the cardanol-based waterborne epoxy resin curing agent. The cardanol-based waterborne epoxy resin curing agent prepared by the preparation method disclosed by the invention is insensitive to the pH value and good in stability; the process is simple, amine does not need to be excessive, no organic solvent is added, and energy conservation and environmental protection are achieved.

Owner:岳阳中展科技有限公司

High-fidelity durable lightfast UV/UVLED curing coating for note and preparation method thereof

InactiveCN107325691ALow VOC/NOVOCWith transparentWax coatingsPaper coatingMethacrylateVinyl ether

Owner:XIAN BANKNOTE PRINTING +1

Static-conducting and anti-corrosive coating on inner wall of oil tank, and preparation method of static-conducting and anti-corrosive coating

InactiveCN104098989ALight colorEasy for visual inspectionAnti-corrosive paintsEpoxy resin coatingsPetrochemicalReactive diluent

The invention discloses a static-conducting and anti-corrosive coating and a preparation method thereof. The static-conducting and anti-corrosive coating comprises bisphenol A epoxy resin, a reactive diluent, rutile titanium dioxide, conductive mica powder, a coupling agent and a flexibilizer. The bisphenol A epoxy resin is ground; the reactive diluent, the flexibilizer, the coupling agent and a light-colored static-conducting material are added; and the coating free of an inertial and volatile solvent is prepared. The coating has the characteristics of high cohesion, good closure and stable static conductivity, is suitable for internal anti-corrosive and static-conducting protection of oil storage and transport equipment such as an oil storage tank, an oil transport pipeline and an oil transport tank in the petrochemical industry, and is also suitable for anti-corrosive and anti-static protection of a gas tank, a water gate and an underground pipeline.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

True copper metallic combination paint as well as preparation method and construction process thereof

InactiveCN102533056AImprove anti-corrosion performanceExcellent anti-rustPretreated surfacesAnti-corrosive paintsEpoxyProduction line

Owner:江苏佳尔利装饰材料有限公司 +1

High-temperature-resistant powder paint and preparation method thereof

InactiveCN105860765ALow curing temperatureShort curing timeFireproof paintsPowdery paintsPolyester resinTemperature resistance

Owner:合肥燕美新材料科技有限公司

Full-frequency wave-absorbing high-temperature heat-insulating stealth integrated paint and preparation method thereof

InactiveCN111393989AImprove reflective absorption performanceIncrease autonomyFireproof paintsRadiation-absorbing paintsFiberFrequency wave

Owner:QINGDAO AIR NEW MATERIALS

High-strength powder paint

ActiveCN104119772AHigh strengthImprove the level ofPowdery paintsEpoxy resin coatingsEpoxyAcrylic resin

The invention discloses a high-strength powder paint which is composed of the following components in percentage by weight: 33-41% of epoxy resin, 8-10% of acrylic resin, 3-6% of EVA (ethylene-vinyl acetate) resin, 15-22% of titanium white, 20-24% of barium sulfate, 3-6% of curing agent, 0.5-1.5% of leveling agent, 0.5-1.5% of brightening agent and 1% of pigment and filler. On the premise of ensuring favorable leveling property of the paint, the coating strength of the paint is enhanced, and the cost is lowered. The product adopts the existing production equipment, is simple in operational procedure, and is widely suitable for anticorrosion coatings of household appliances, home appliances, vehicles and hardware machines.

Owner:FOSHAN TUYI DECORATIVE MATERIAL TECH CO LTD

UV wax oil and preparation method thereof

InactiveCN110079198AIncrease productivityHigh coating hardnessWax coatingsAntifouling/underwater paintsVegetable oilUltraviolet

The invention discloses UV (ultraviolet) wax oil which comprises the following raw materials in percentage by mass: 40-60% of vegetable oil modified epoxy acrylate, 10-20% of Chinese wood oil, 5-10% of rosin, 5-10% of paraffin, 2-6% of beewax, 3-7% of palm wax, 3-6% of photoinitiator, 0.5-2% of assistant and 10-20% of wear-proof powder. The raw materials are combined together organically, so thatthe UV wax oil can be used for roller coating or rubbing coating and produced on a production line; and the production efficiency is greatly improved. The UV wax oil is free from VOC (volatile organiccompound) emission, belongs to an environment-friendly product, is high in film hardness, good in wear resistance, water resistance and fouling resistance, high in adaptability and low in productioncost, and can completely substitute the traditional common wax oil; the high-quality UV wax oil can be prepared through a series of operation of material preparation, ester addition, addition of the oil, the wax, the rosin and the like, re-charging, inspection and packaging; intensive mixing of the raw materials is facilitated; the raw materials are made full use of; and the production quality ofthe UV wax oil is improved.

Owner:YOUCAI (SHANDONG) ENVIRONMENTAL PROTECTION TECH CO LTD

UV (ultraviolet)-highly-clear curtaining finish

Owner:JIANGSU HIMONIA TECH

Moisture-proof agent for storage of powder coating for film forming by electrostatic spraying

InactiveCN107337955AReduced hygroscopicityGood moisture resistancePowdery paintsEpoxy resin coatingsPolyglutamic acidPolytetrafluoroethylene

The invention discloses a moisture-proof agent for storage of a powder coating for film forming by electrostatic spraying, and relates to the technical field of powder coatings. The moisture-proof agent is prepared from the raw materials in parts by weight as follows: 10-15 parts of hydrophobic fine silica aerogel, 5-10 parts of glycerol monostearate-polyglutamic acid-dodecanol, 5-10 parts of N-(hydroxymethyl)acrylamide, 1-5 parts of chlorinated polyvinyl chloride, 1-5 parts of ultrafine magnesium oxide, 0.5-2 parts of polytetrafluoroethylene ultrafine powder, 0.5-2 parts of carnauba wax and 50-100 parts of absolute ethanol. After 3%-5% by mass of the moisture-proof agent is added to the powder coating, excellent moisture-proof performance can be developed, the resistivity and dielectric constant of the powder coating are prevented from being affected by agglomeration due to moisture absorption during storage and use, and accordingly, smooth implementation of electrostatic spraying of the powder coating and quality of a formed film are ensured.

Owner:ANHUI ZHIBO NEW MATERIAL TECH CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap