Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4 results about "Rutile" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rutile is a mineral composed primarily of titanium dioxide (TiO₂), and is the most common natural form of TiO₂. Other rarer polymorphs of TiO₂ are known including anatase, akaogiite, and brookite. Rutile has one of the highest refractive indices at visible wavelengths of any known crystal and also exhibits a particularly large birefringence and high dispersion. Owing to these properties, it is useful for the manufacture of certain optical elements, especially polarization optics, for longer visible and infrared wavelengths up to about 4.5 μm.

Static-conducting and anti-corrosive coating on inner wall of oil tank, and preparation method of static-conducting and anti-corrosive coating

InactiveCN104098989ALight colorEasy for visual inspectionAnti-corrosive paintsEpoxy resin coatingsPetrochemicalReactive diluent

The invention discloses a static-conducting and anti-corrosive coating and a preparation method thereof. The static-conducting and anti-corrosive coating comprises bisphenol A epoxy resin, a reactive diluent, rutile titanium dioxide, conductive mica powder, a coupling agent and a flexibilizer. The bisphenol A epoxy resin is ground; the reactive diluent, the flexibilizer, the coupling agent and a light-colored static-conducting material are added; and the coating free of an inertial and volatile solvent is prepared. The coating has the characteristics of high cohesion, good closure and stable static conductivity, is suitable for internal anti-corrosive and static-conducting protection of oil storage and transport equipment such as an oil storage tank, an oil transport pipeline and an oil transport tank in the petrochemical industry, and is also suitable for anti-corrosive and anti-static protection of a gas tank, a water gate and an underground pipeline.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

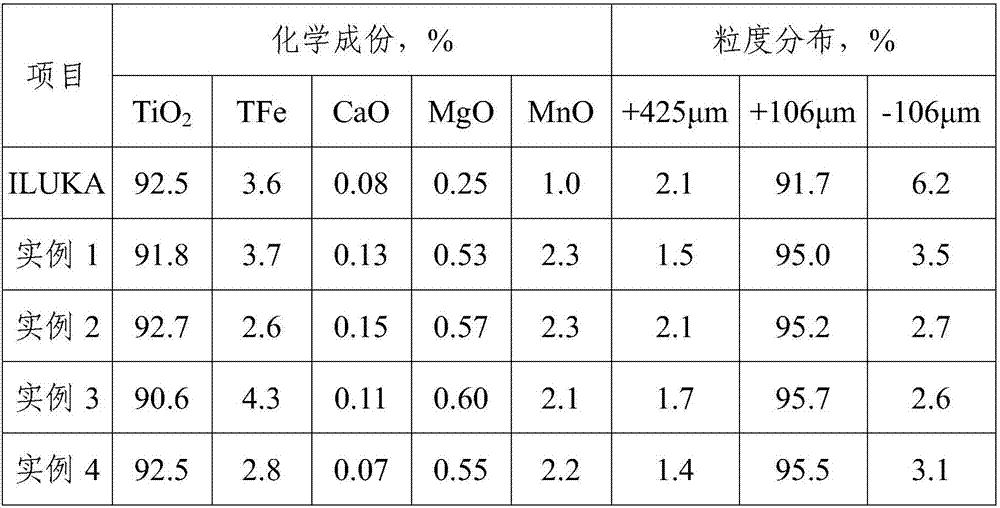

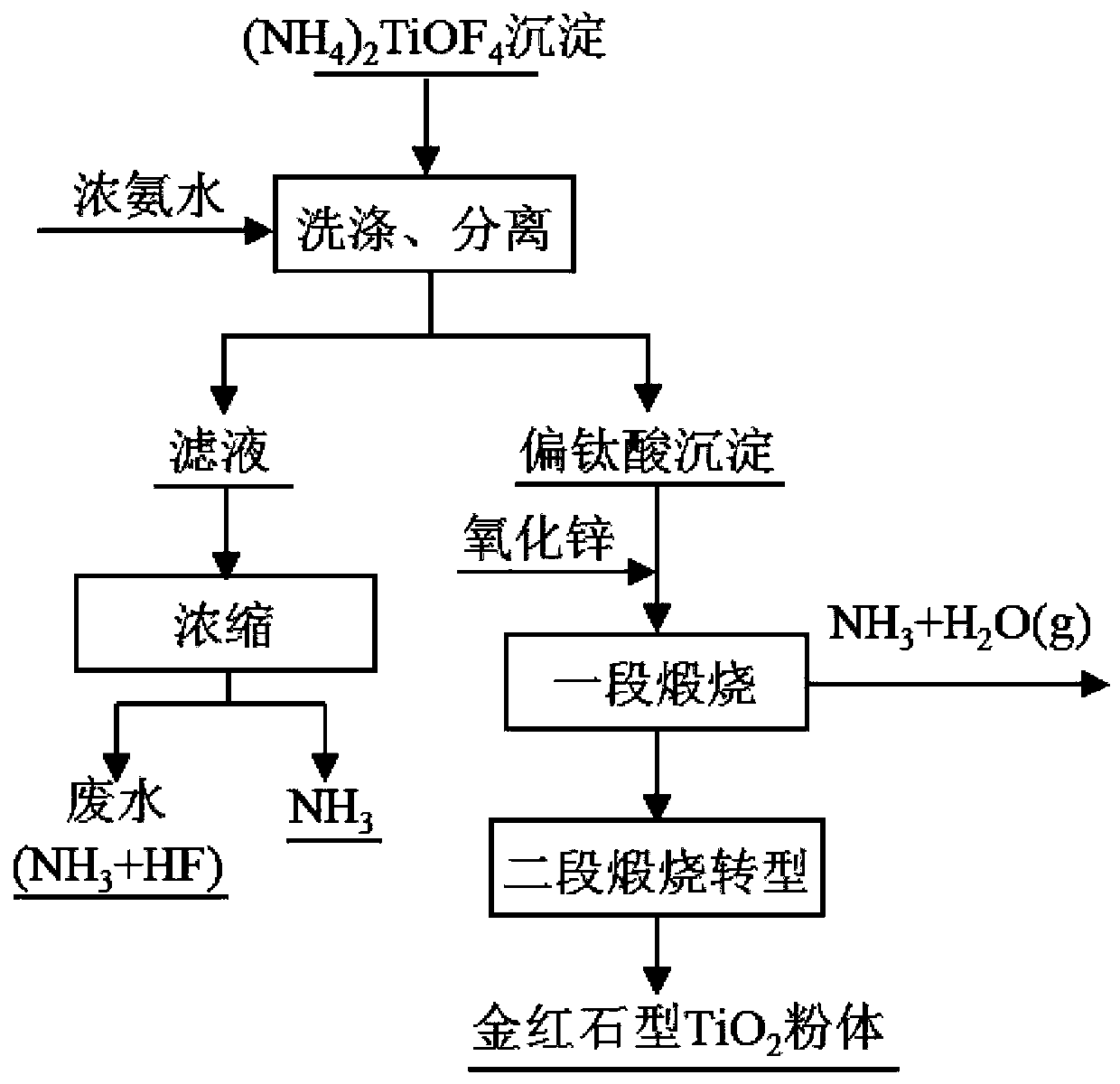

Method of preparing artificial rutile with ferric salt solution leaching method

InactiveCN107043128ASpeed up the leaching reactionAvoid chalkingIron oxides/hydroxidesIron sulfatesHigh energyTitanium tetrachloride

Owner:郑祥发

Waterborne polyurethane super wear-resistant finish paint and preparation process thereof

ActiveCN109456690ASmall particle diameterGood dispersionPolyurea/polyurethane coatingsWear resistantWear resistance

The invention discloses waterborne polyurethane super wear-resistant finish paint and a preparation process thereof, and relates to the technical field of preparation of finish paint, aiming at solving the problem that the finish paint is poorer in wear resistance, so that local damage is easily caused in a using process. The finish paint is prepared from a component A and a component B, wherein the component A is prepared from the following raw materials: 50-60 parts of waterborne polyurethane resin AH-1618, 12-18 parts of polyurethane color paste, 0.8-1.2 parts of a leveling agent BYK346, 0.3-0.5 part of an aqueous leveling agent BYK333, 0.3-0.6 part of a polyurethane rheological agent SN612NC, 0.3-0.5 part of a defoaming agent BYK024, 0.08-0.1 part of a defoaming agent Tego901W, 0.8-1.5parts of rutile titanium dioxide, 8-10 parts of wear-resistant ball powder, 0.8-1.5 parts of an aqueous scratch-resistant agent, 1.2-1.6 parts of propylene glycol methyl ether and 12-18 parts of deionized water; the component B is prepared from 95-100 parts of a polyurethane curing agent; the ratio of parts by weight of the component A to parts by weight of the components B is equal to (4-6) to 1. The waterborne polyurethane super wear-resistant finish paint has good wear resistance after being cured.

Owner:SHANGHAI BOGE BUILDING MATERIALS CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap