Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

70 results about "Titanium dioxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Titanium dioxide, also known as titanium(IV) oxide or titania, is the naturally occurring oxide of titanium, chemical formula TiO₂. When used as a pigment, it is called titanium white, Pigment White 6 (PW6), or CI 77891. Generally, it is sourced from ilmenite, rutile and anatase. It has a wide range of applications, including paint, sunscreen and food coloring. When used as a food coloring, it has E number E171. World production in 2014 exceeded 9 million metric tons. It has been estimated that titanium dioxide is used in two-thirds of all pigments, and pigments based on the oxide have been valued at $13.2 billion.

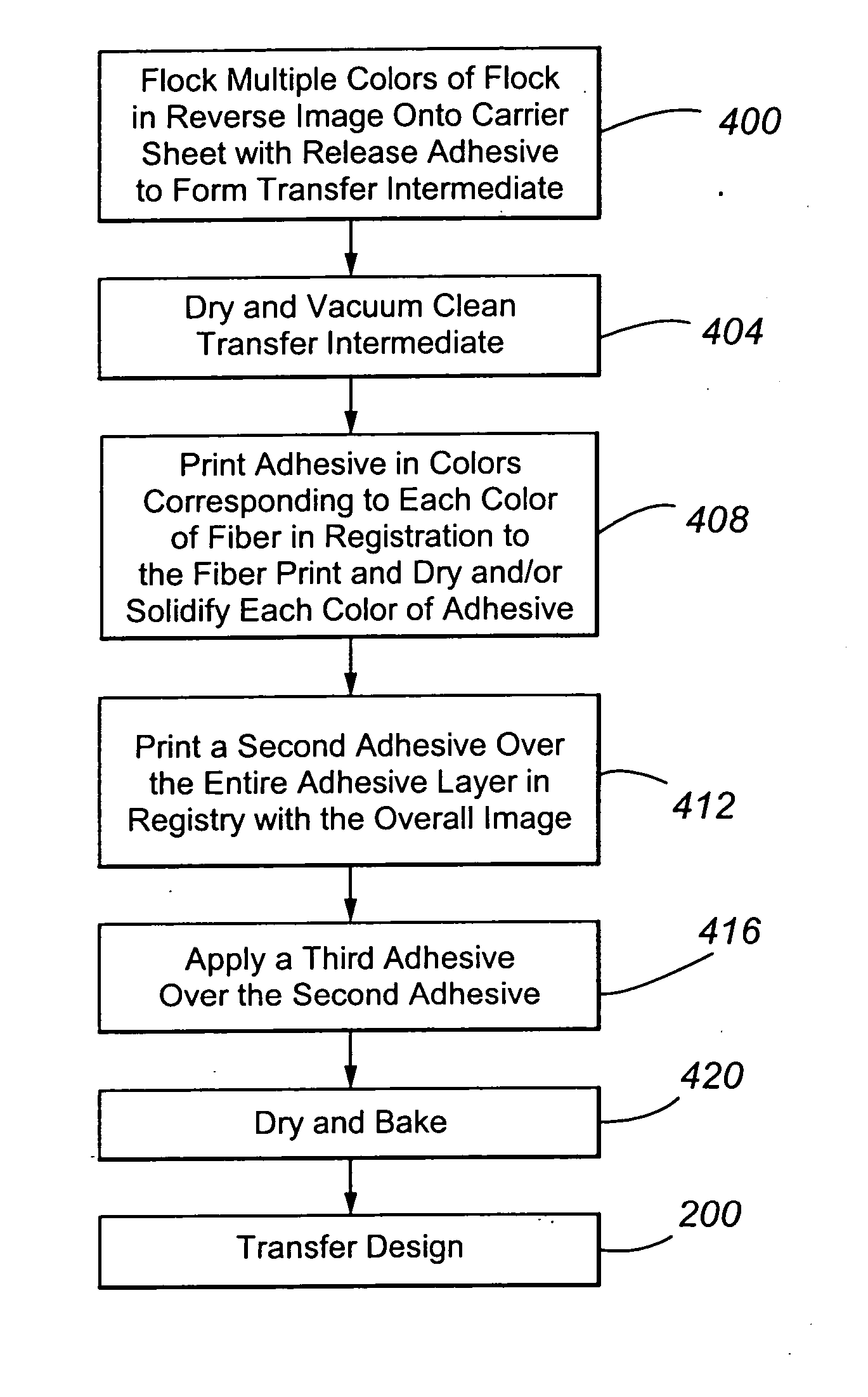

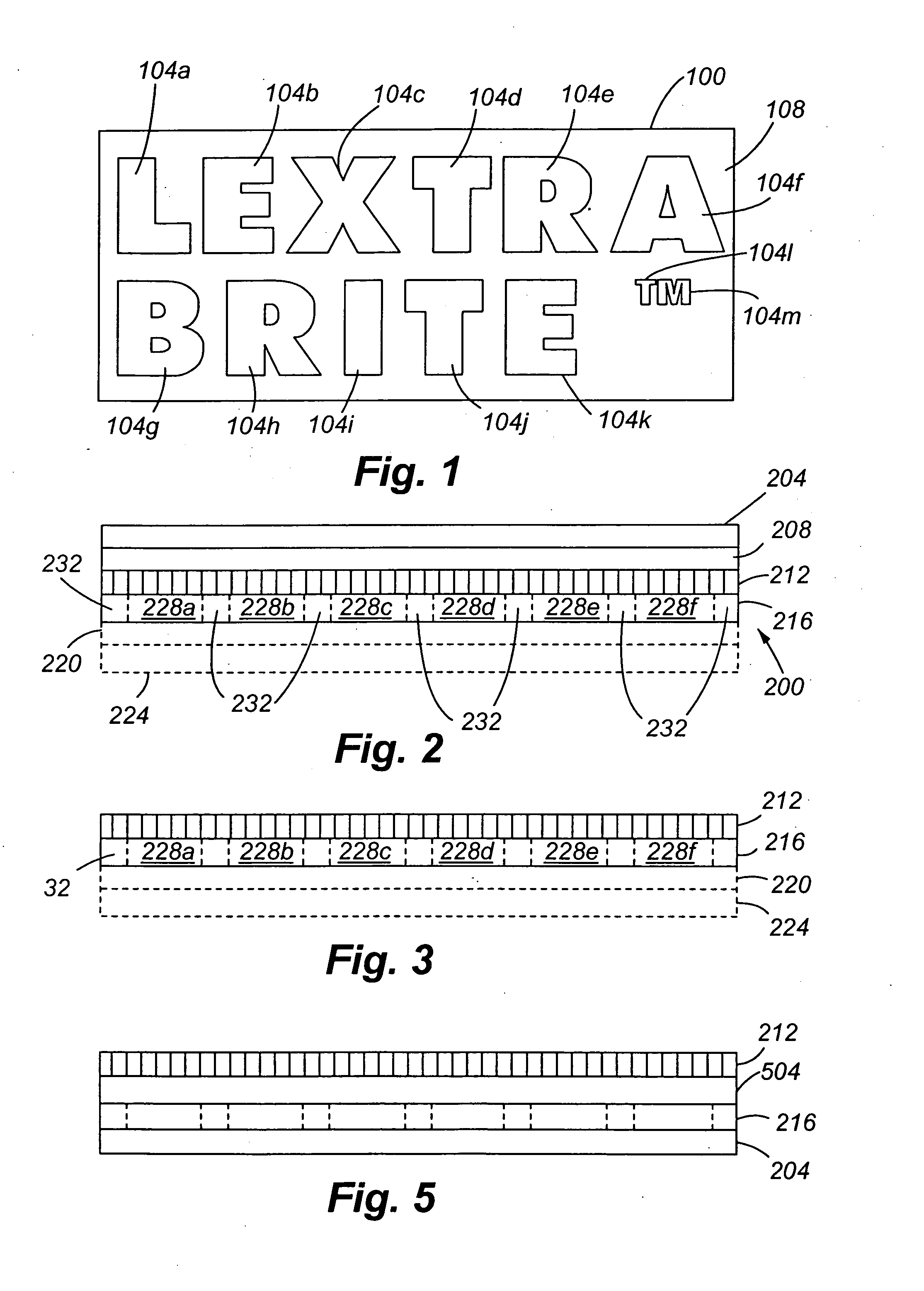

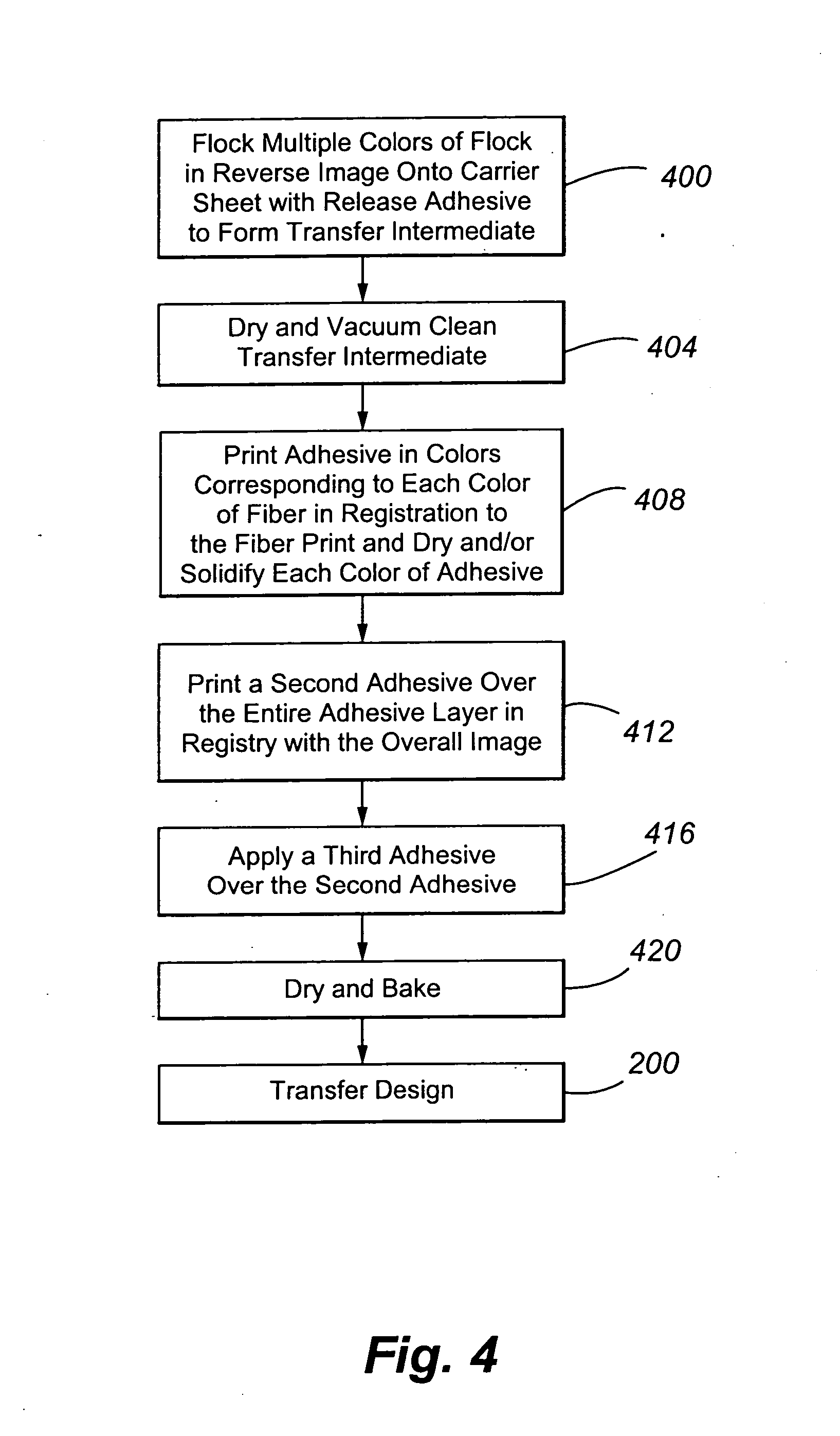

Flocked multi-colored adhesive article with bright lustered flock and methods for making the same

InactiveUS20060251852A1Reduce shadowing effectFlock densityLayered productsOrnamental structuresFiberEngineering

Owner:HIGH VOLTAGE GRAPHICS

Aqueous texture wallpaper paint and method for making same

The invention relates to a watercraft texture wallpaper paint, characterized in that the invention comprises the following components: 31 percent to 35 percent of styrene-acrylic emulsion, 23.94 percent of superfine weight calcium, 1 percent to 2 percent of nano-titanium dioxide, 10 percent to 18 percent of titanium pigment, 8 percent to 9.8 percent of calcined kaolin, 1.2 percent to 1.8 percent of ethylene glycol, 0.2 percent to 0.5 percent of hydroxyethylcellulose, 0.8 percent to 1.5 percent of film forming additive, 0.15 percent to 0.25 percent of multi-functional additive, 0.3 percent to 0.5 percent of dispersant, 0.1 percent to 0.2 percent of wetting agent, 0.15 percent to 0.21 percent of defoamer, 0.08 percent of anticorrosion and insecticide, 0.8 percent to 2 percent of thickener and 20 percent to 22 percent of water. The invention is the watercraft texture wallpaper paint, is environment-friendly, has strong elastic tension, has good covering and anti-cracking effect on the fine cracking of wall, and has good scrape resistance performance, greatly enhancing the degree of wall surface protection; meanwhile, the invention still has strong waterproof performance, without color-changing and decortication and mildew and can fully solve the common problems existing in wall decoration.

Owner:FOSHAN SHUNDE QINGDA RUNCAI COATING CO LTD

Multifunctional textile lining

InactiveCN101173487AStrong reductionStrong oxidation abilityFibre treatmentMagnetic/electric field screeningNanometreHot-melt adhesive

Owner:SHENGHONG GRP CO LTD

One-step treatment process of sol filming for preparing toughening self-cleaning glass with film of titanium dioxide

Owner:WUHAN UNIV OF TECH

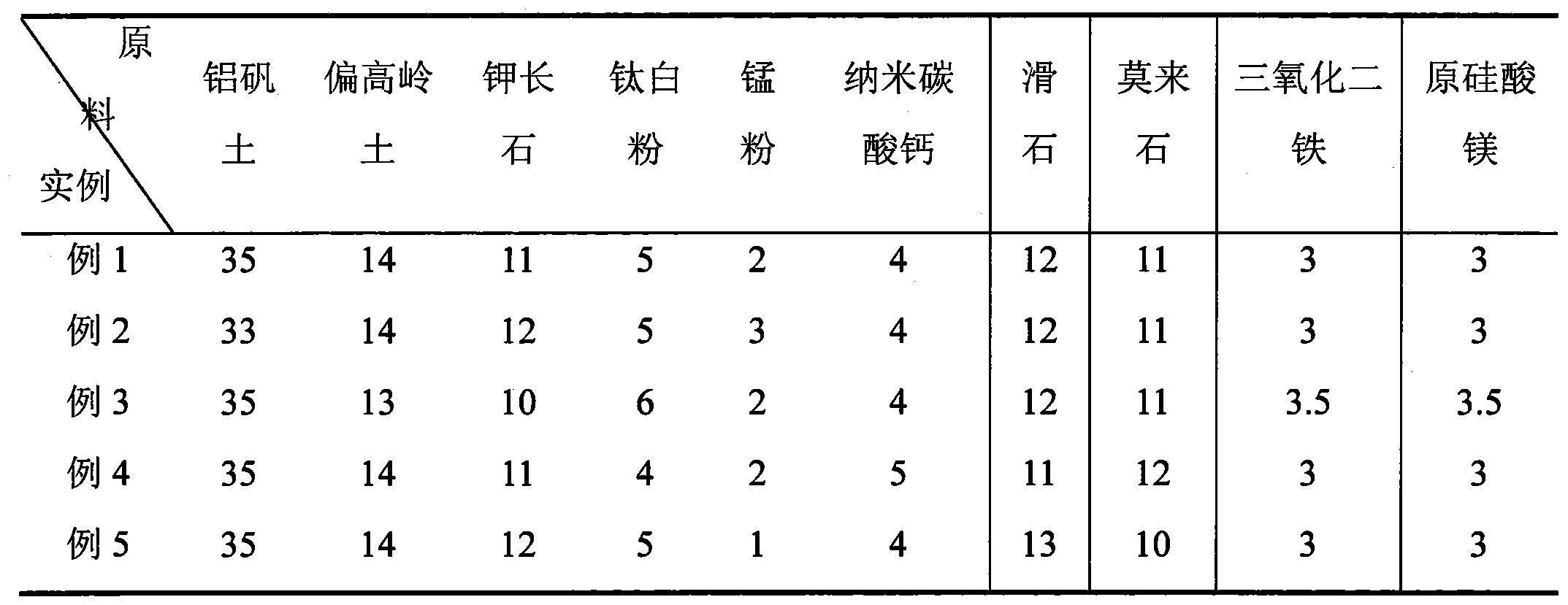

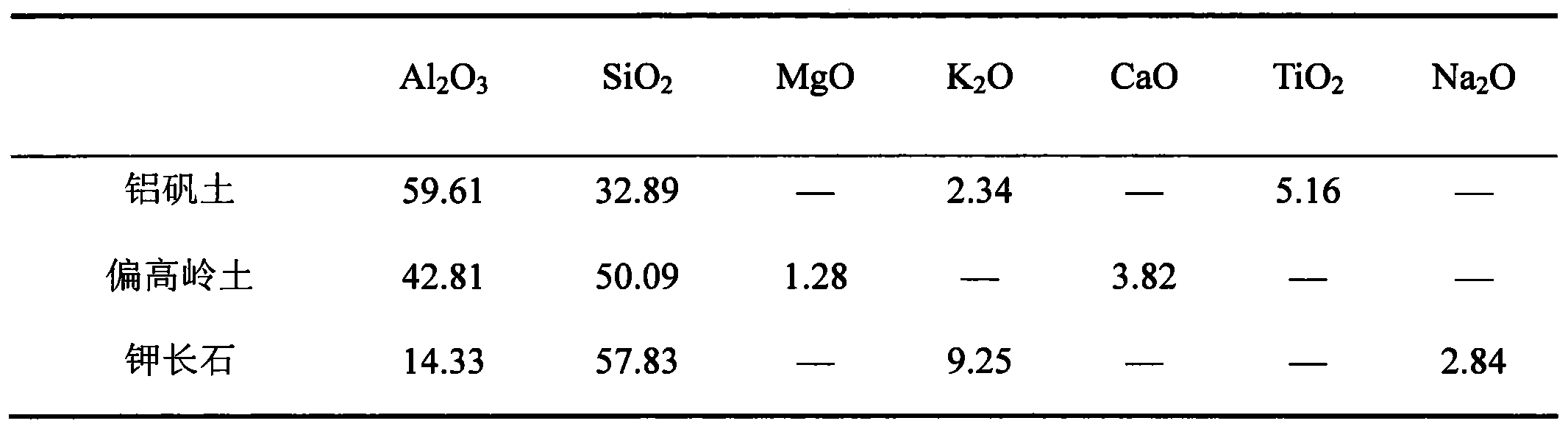

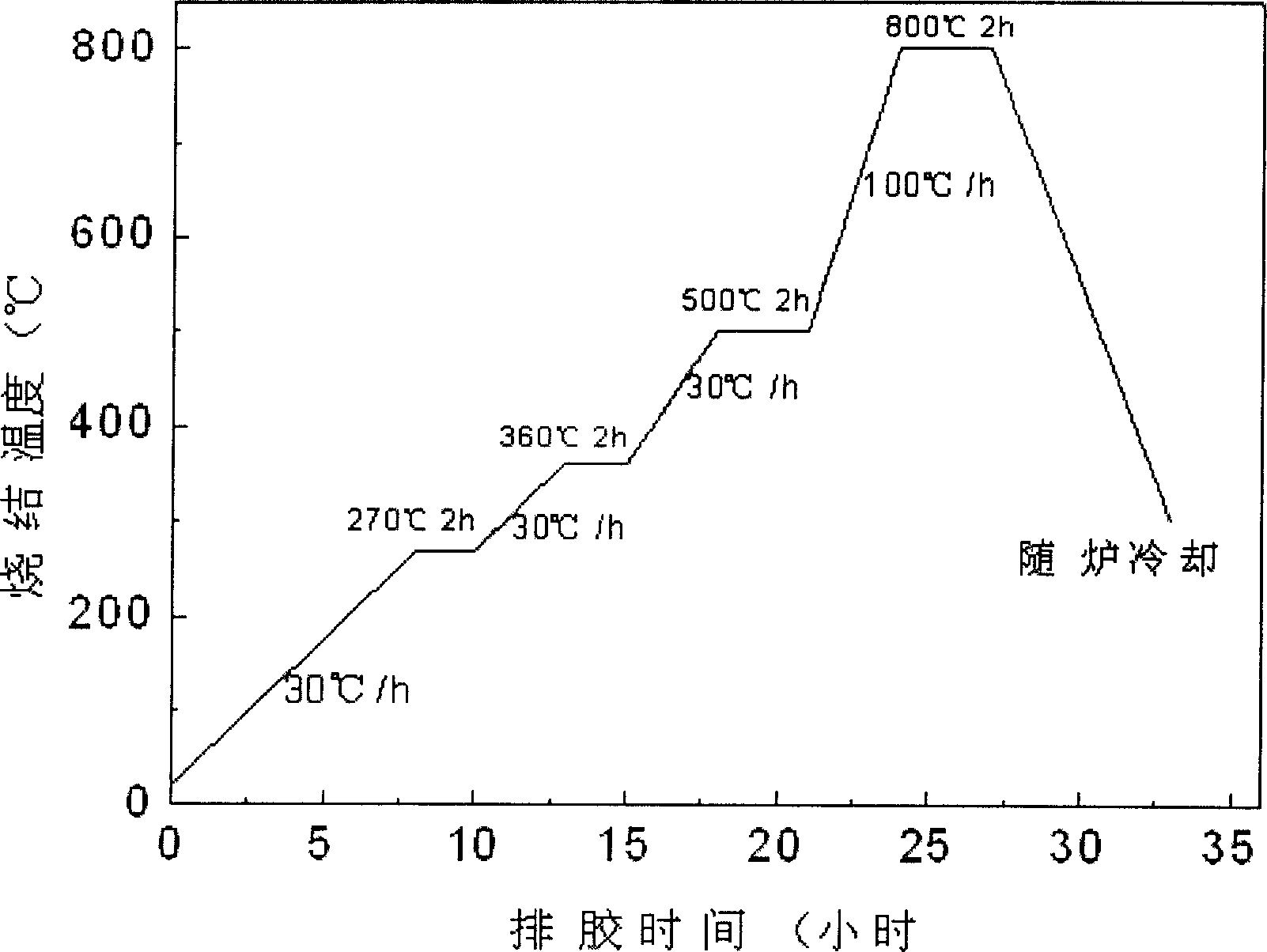

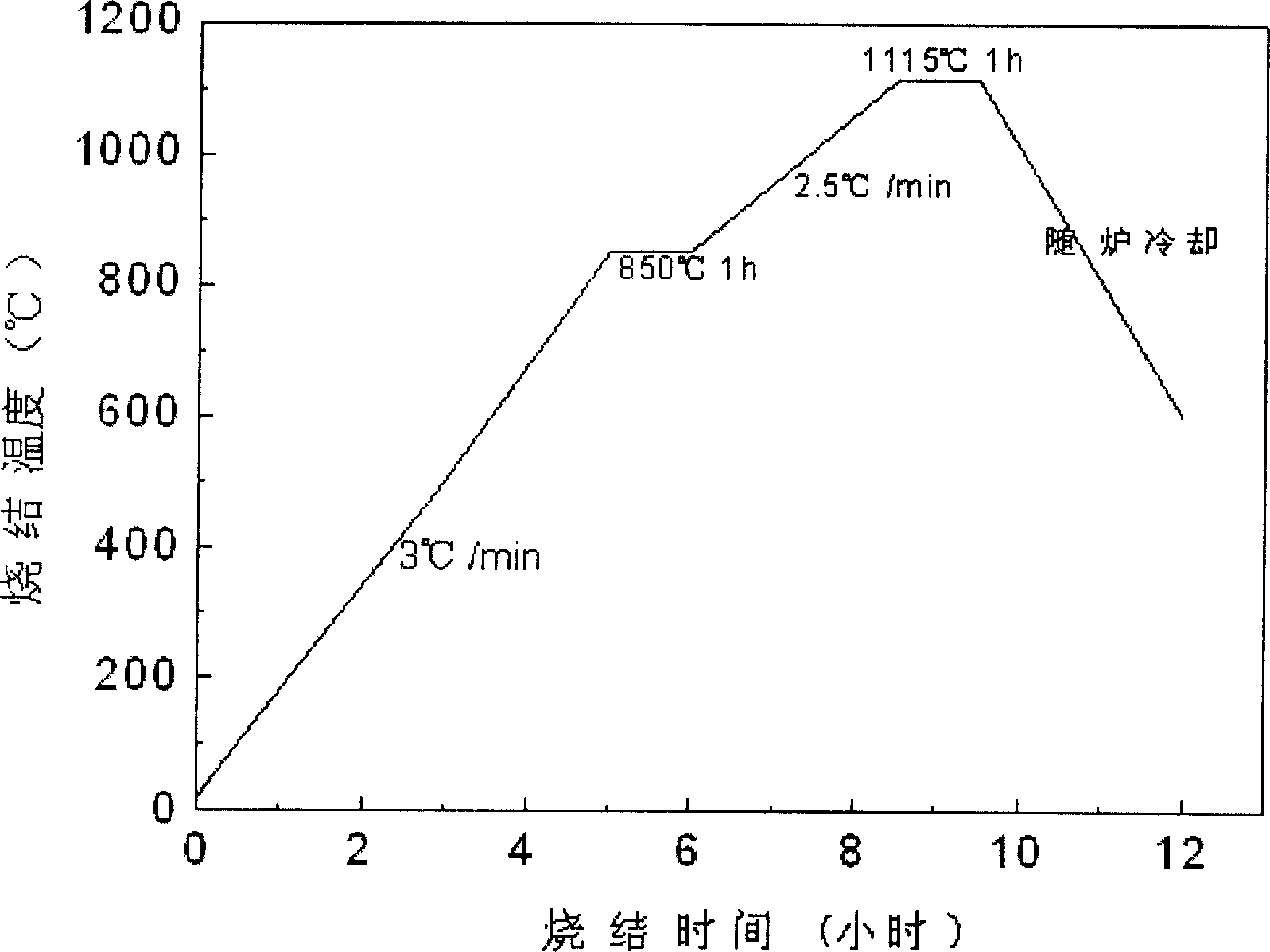

New low-density high-intensity ceramsite fracturing propping agent and preparation method thereof

ActiveCN104099082AAppropriate dispersionEnhancement effect is goodFluid removalDrilling compositionMagnesium orthosilicateExpanded clay aggregate

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Coating having heat-insulation and reflection functions, and preparation method thereof

InactiveCN107267011AWith heat insulation reflective functionImprove economyReflecting/signal paintsCelluloseMicrosphere

Owner:HEFEI ZEJUN ELECTRICAL EQUIP CO LTD

Bismuth sodium titanate-barium titanate base piezoelectric ceramic and its prepn process

InactiveCN1673178ALower coercive fieldLow resistivityPiezoelectric/electrostrictive/magnetostrictive devicesBarium titanateAdhesive

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Preparation method of titanium dioxide photocatalytic adsorbing material

ActiveCN105727901AImprove adsorption capacityEasy to recycleWater/sewage treatment by irradiationOther chemical processesPhysical chemistryMolecular materials

The invention discloses a preparation method of a titanium dioxide photocatalytic adsorbing material. The titanium dioxide photocatalytic adsorbing material obtained by the preparation method can be used for not only effectively improving the photocatalytic performance of TiO2 and simultaneously solving the problem that the photocatalytic material is difficultly separated and recovered. According to the preparation method disclosed by the invention, a photo-reduction method is firstly adopted for preparing an Ag elementary substance, the Ag elementary substance is loaded on the surface of TiO2 to form an Ag-loaded TiO2 photocatalyst, and then the purpose of inhibiting electron and hole recombination is achieved, so that the photocatalytic efficiency of the catalyst is improved; then the chitosan made of high-molecular materials is adopted as an immobilized base material to immobilize Ag-loaded TiO2; the obtained novel titanium dioxide photocatalytic adsorbing material not only has a good adsorbing effect, but also is easily recovered and separated, can be applied to treatment of emerging pollutants PPCPs; and known from an experimental result, the effect of removing carbamazepine and ibuprofen in PPCPs is good.

Owner:HOHAI UNIV

High-toughness high temperature-resistant modified PVC pipe

InactiveCN105440481AImprove toughnessImprove high temperature resistanceAcrylonitrileMaterials science

The invention discloses a high-toughness high temperature-resistant modified PVC pipe. The high-toughness high temperature-resistant modified PVC pipe comprises the following raw materials by weight: 80 to 120 parts of PVC resin, 30 to 60 parts of chlorinated polyethylene, 40 to 80 parts of liquid butadiene-acrylonitrile rubber, 10 to 30 parts of polyurethane elastomer, 2 to 8 parts of modified nanometer calcium carbonate, 1 to 5 parts of kaolin, 2 to 6 parts of fly ash, 4 to 8 parts of glass beads, 4 to 8 parts of glass fiber, 1 to 6 parts of titanium dioxide, 3 to 9 parts of PE wax, 2 to 5 parts of methyl methacrylate, 4 to 8 parts of acrylate, 1 to 5 parts of a heatproof modifier and 2 to 6 parts of a coupling agent. The PVC pipe provided by the invention has excellent toughness and high temperature resistance.

Owner:NINGGUO CITY GAOXIN PIPE CO LTD

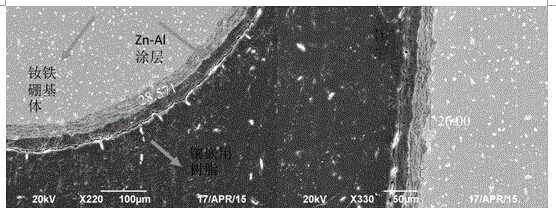

Zinc-aluminum coating enhanced with particles in micro-nano sizes and production method of zinc-aluminum coating

InactiveCN104984889AImprove mechanical propertiesImprove scratch resistancePretreated surfacesSpecial surfacesMicro nanoSilicon oxide

Owner:EARTH PANDA ADVANCE MAGNETIC MATERIAL

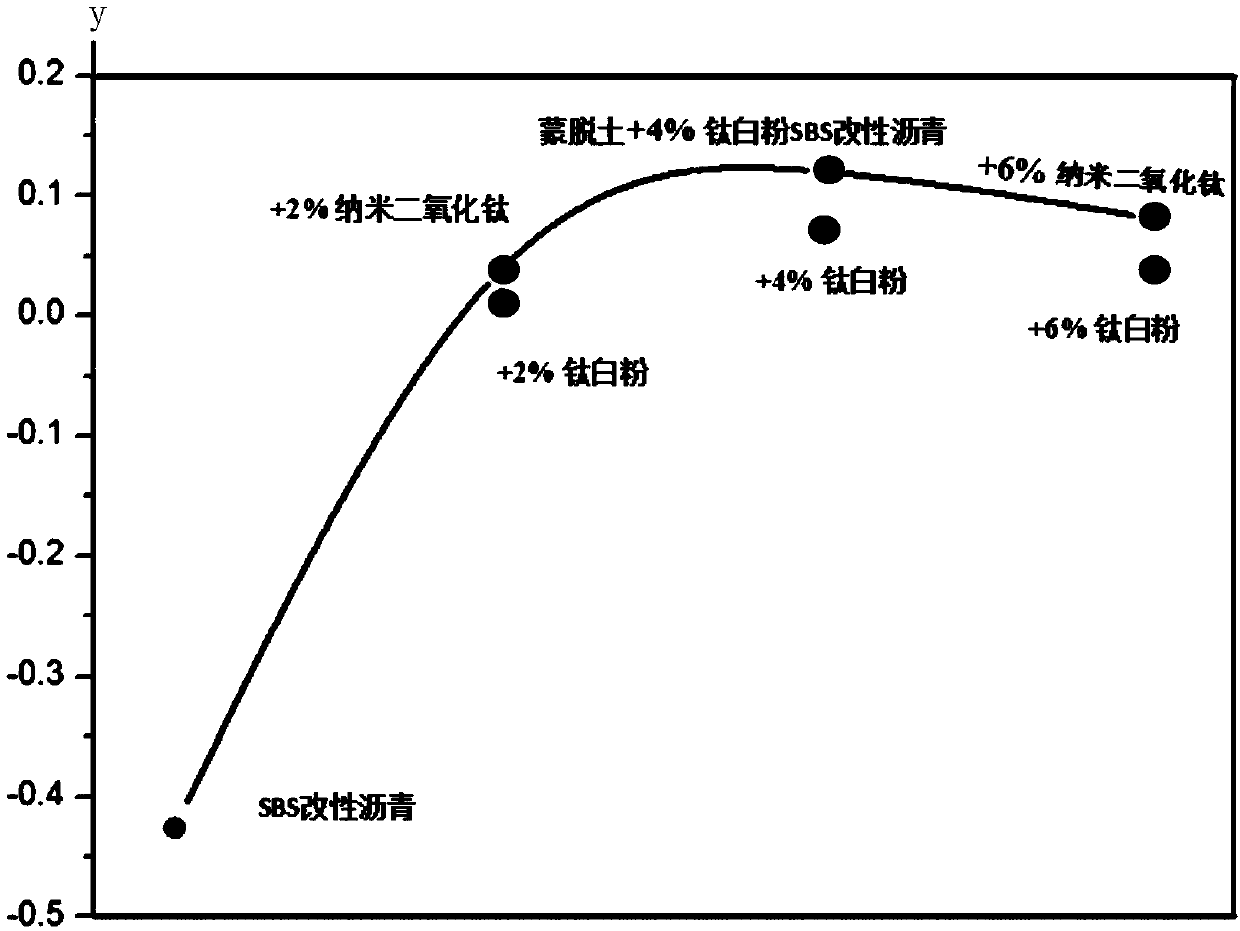

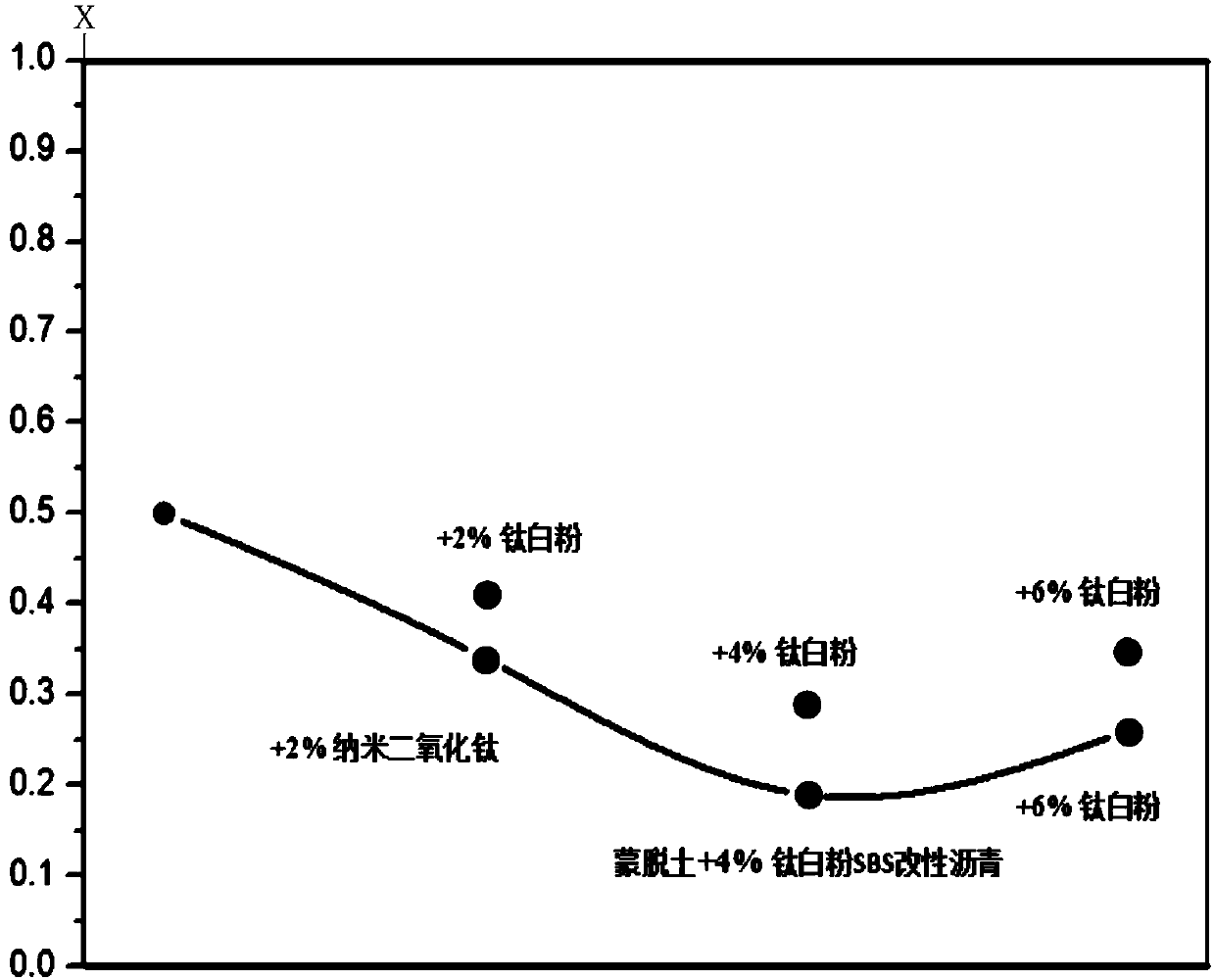

Preparation method of durable modified asphalt

Owner:宁夏路桥工程股份有限公司

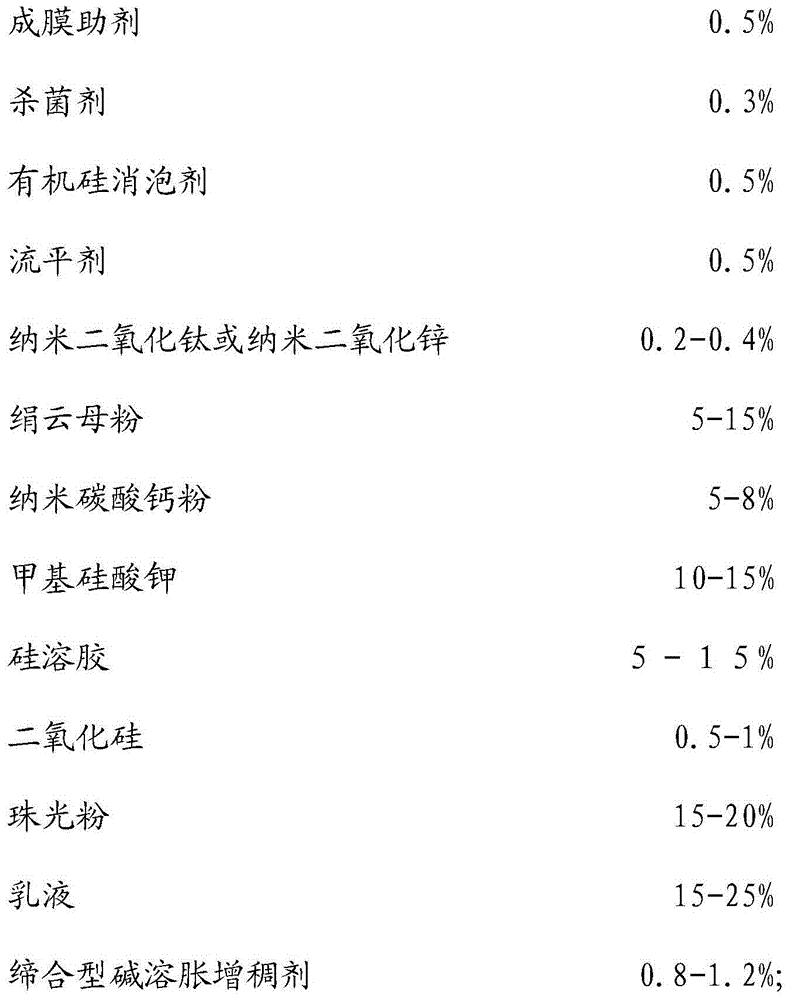

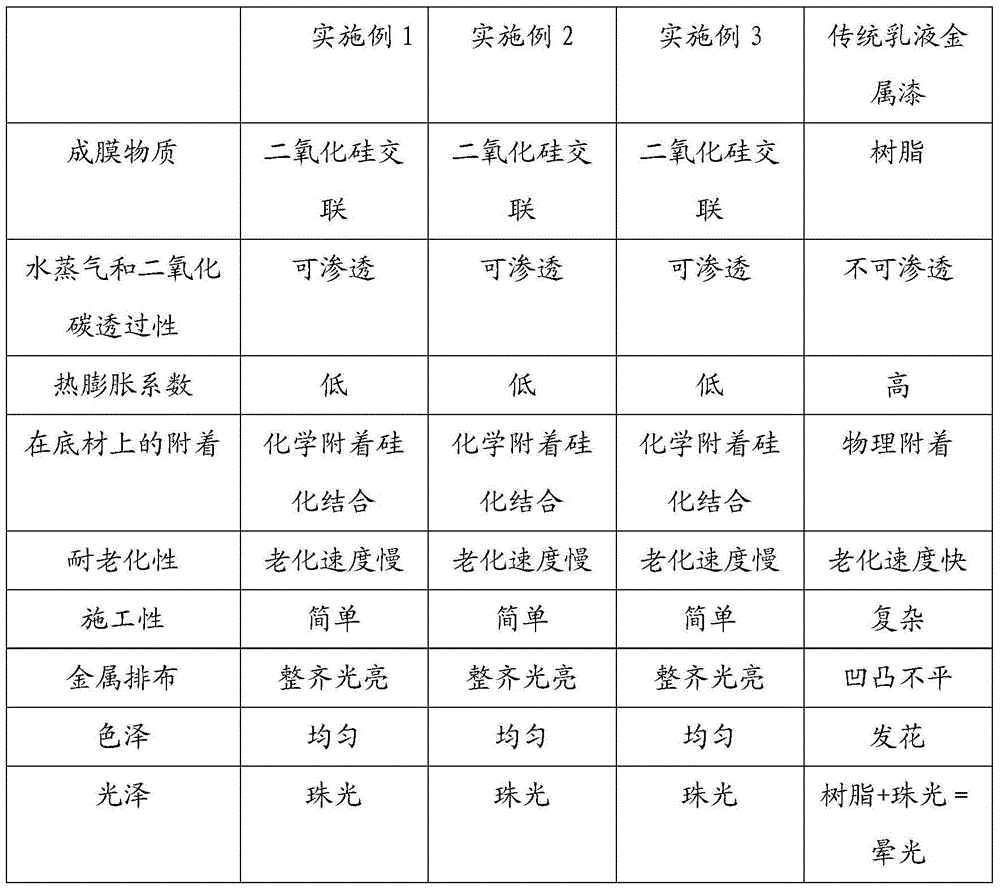

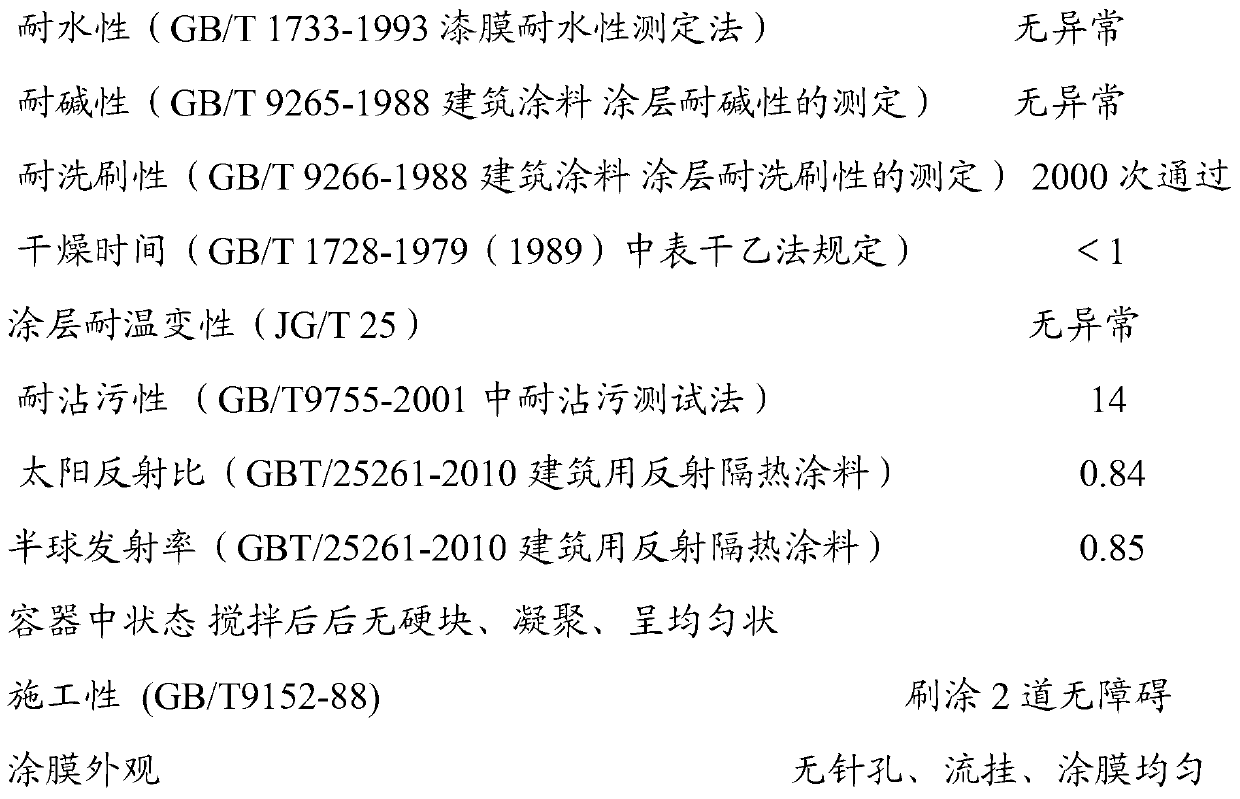

Inorganic water-based metallic paint and preparation method thereof

Owner:佛山市南海万磊建筑涂料有限公司

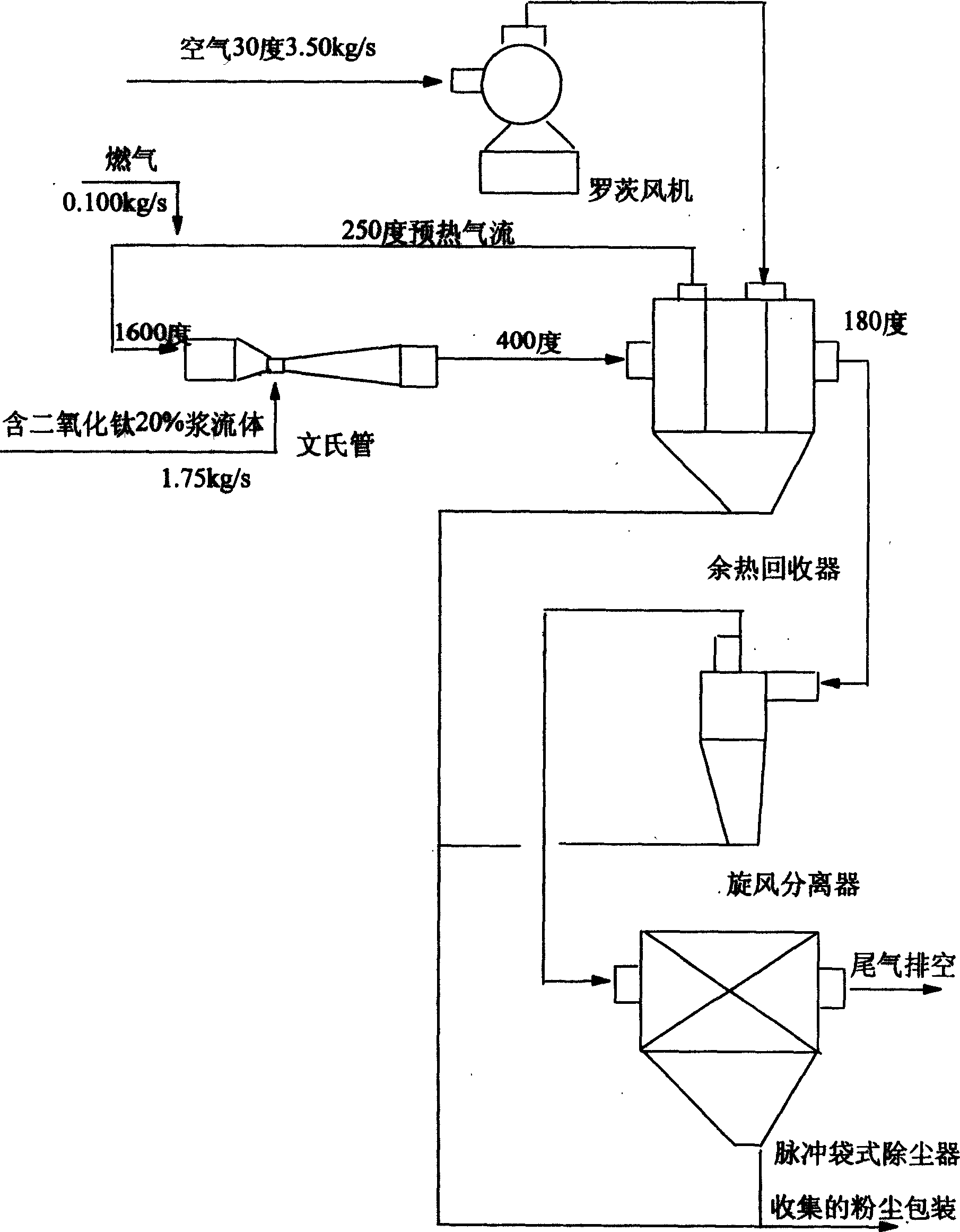

Drying and pulverizing process for preparing powder material with high dispersibility

InactiveCN1605824AIncrease temperatureConvenient heat treatmentDrying solid materials with heatHearth type furnacesPolymer scienceIron oxide

Owner:曾维兴

Elastic thermal insulating coating

InactiveCN103342936ABroad market spaceImprove environmental friendlinessReflecting/signal paintsWeather resistanceTitanium dioxide

The invention belongs to the technical field of architectural coating and particularly relates to an elastic thermal insulating coating. The elastic thermal insulating coating comprises the following components by weight percent: 40-50% of film forming agent, 10-20% of titanium dioxide, 4-10% of hollow glass bead, 5-7.5% of filler, 3-6% of dispersing agent, 1-3% of wetting agent, 1.6-4.0% of coalescing agent, 0.1-0.2% of cellulose, 0.1-0.5% of thickening agent, 0.2-0.5% of antifoaming agent and the balance of water. According to the technical scheme, all the materials are environment-friendly, and excellent thermal insulating effect and weather resistance are achieved due to the adoption of the hollow glass bead and rutile-type nanometer titanium dioxide. The hollow glass bead coating has a broad market space.

Owner:KUNSHAN DACHUAN COLORANT MATERIAL

Environmental-friendly foaming plastic and preparing method thereof

Owner:ANHUI GUANGYUAN TECH DEV

Water-based alkyd-acrylate dispersion as well as preparation method and application thereof

ActiveCN111138603AImprove compactnessImprove the level ofAnti-corrosive paintsPolymer sciencePtru catalyst

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Water treating module and water treater

InactiveCN1847159AHigh degree of industrializationWater/sewage treatment by irradiationCatalyst activation/preparationPhotocatalytic reactionWastewater

The present invention discloses one kind of water treating module and water treater. The water treating module is designed as one water treating packed bed, which is frame structure with cavity holding ultraviolet ray source. The water treater is one modular structure including one cavity with water inlet and water outlet and holding water treating modules arranged inside. The present invention is superior to available suspended photocatalytic water treater and fixed photocatalytic water treater.

Owner:72G GROUP

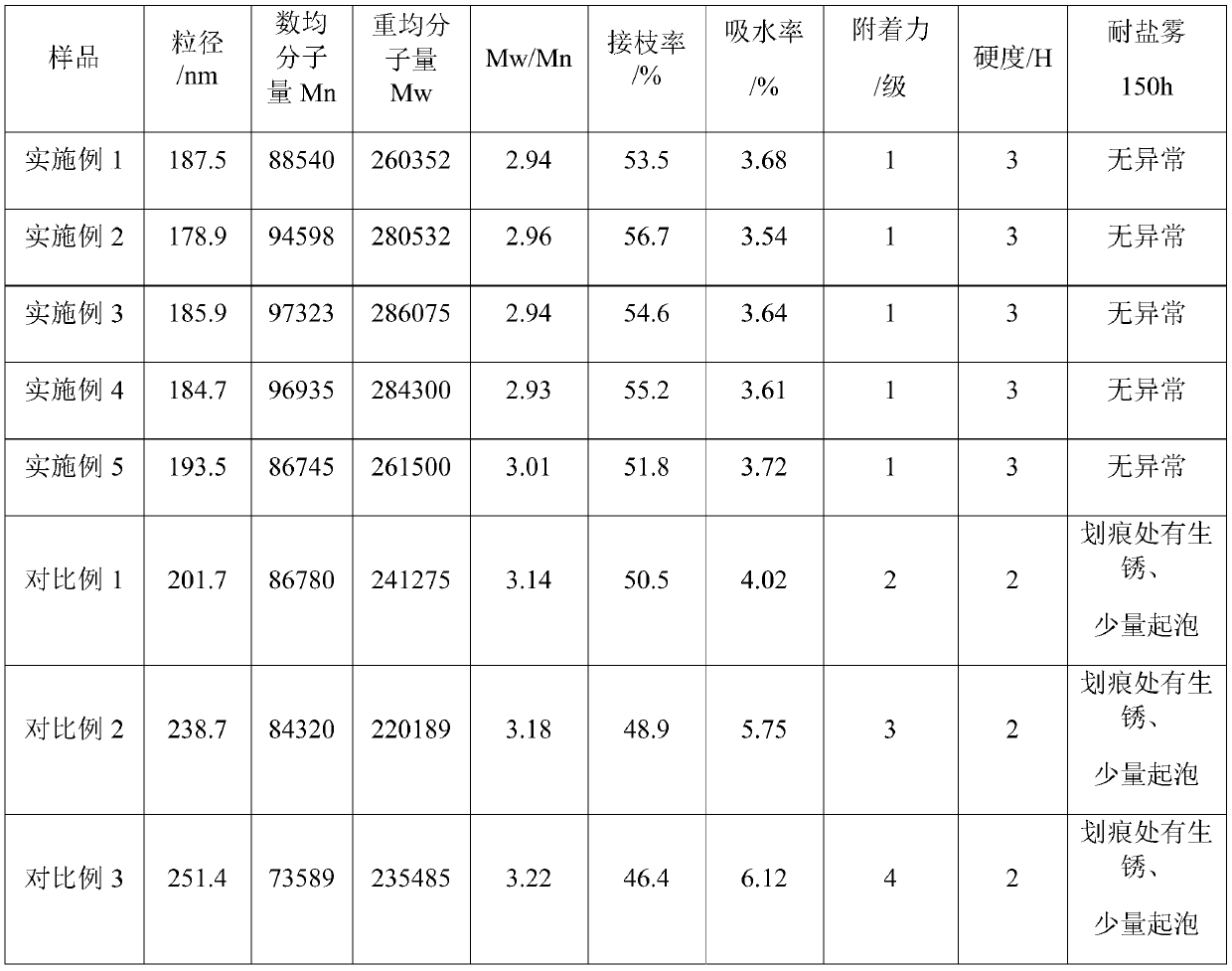

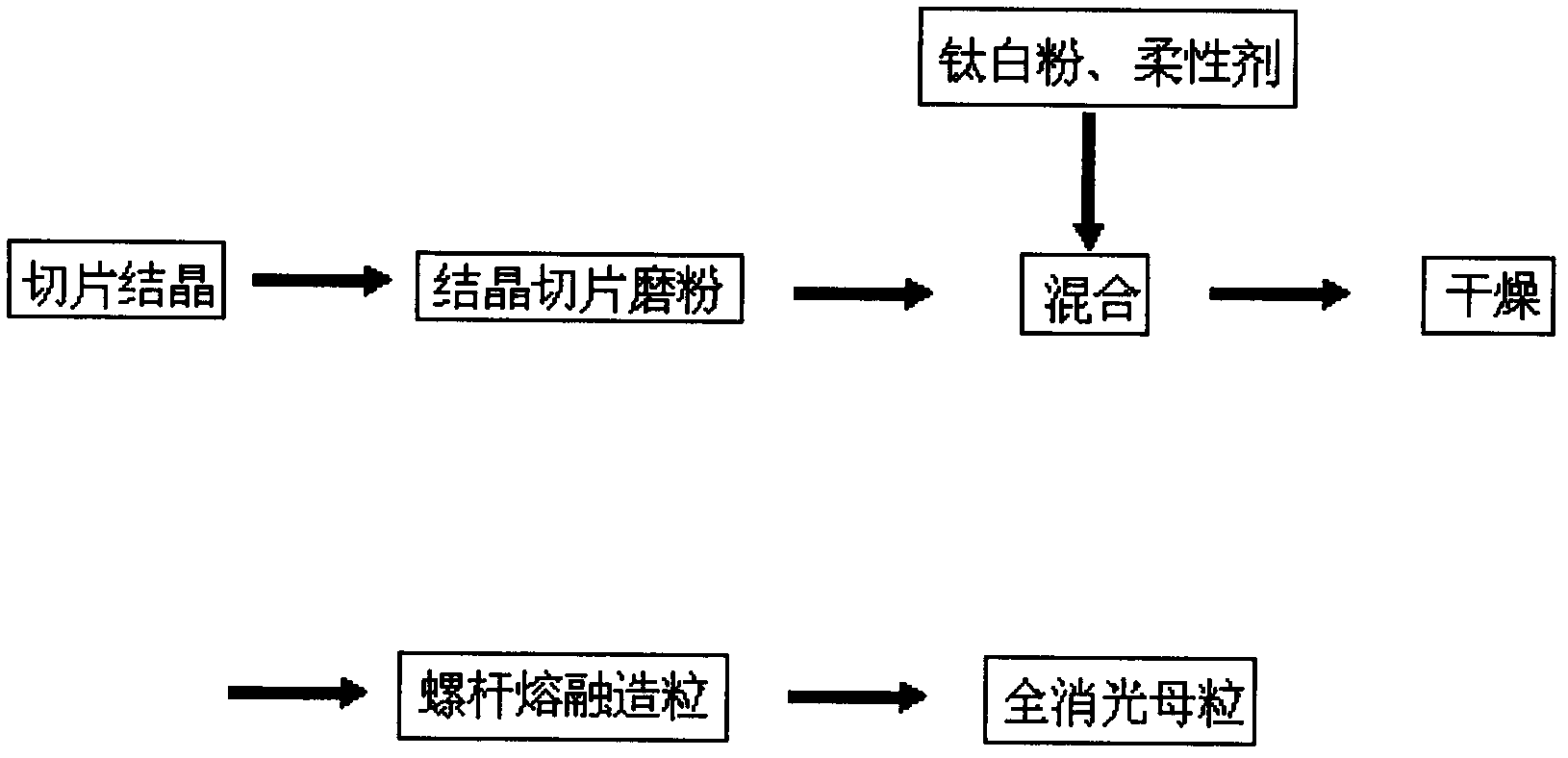

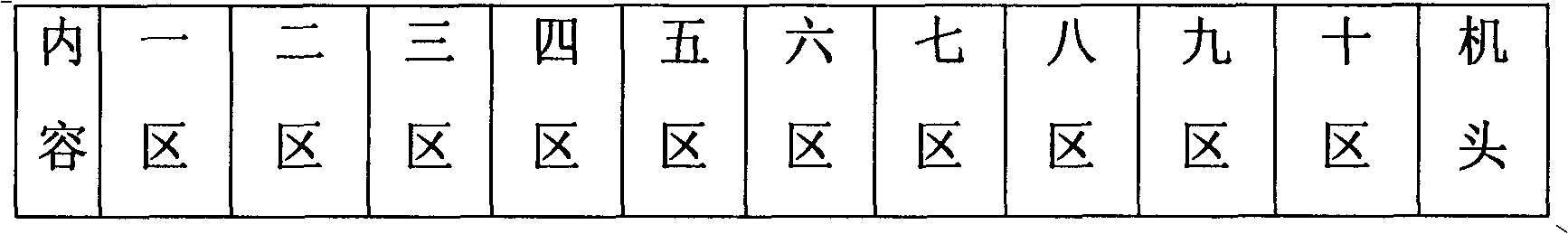

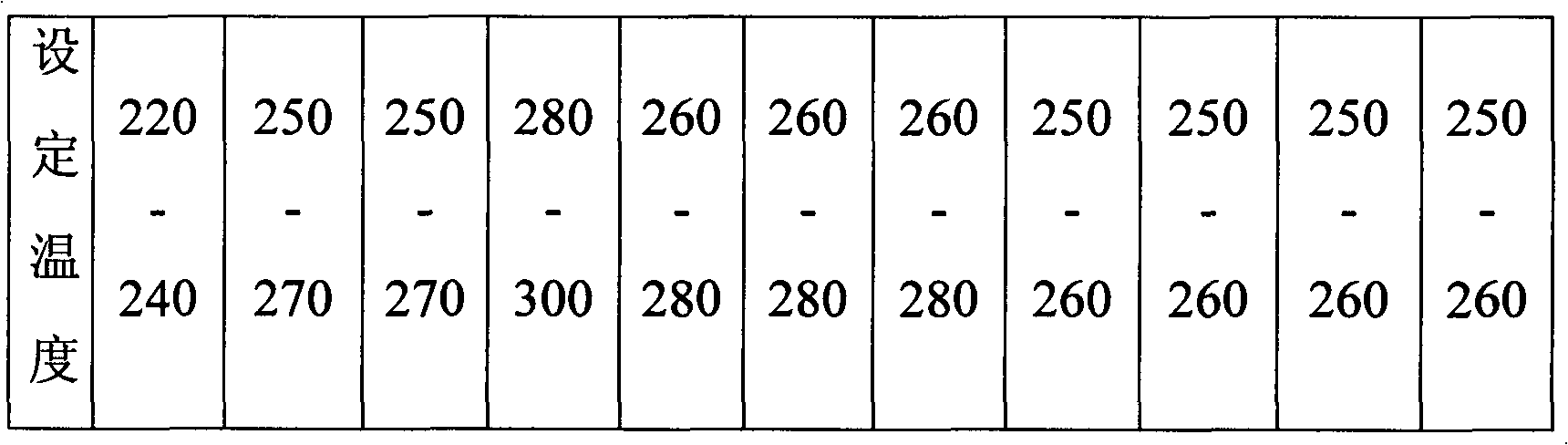

Formula of full-dull master batch and preparation method thereof

Owner:TAICANG ZHENHUI CHEM FIBER

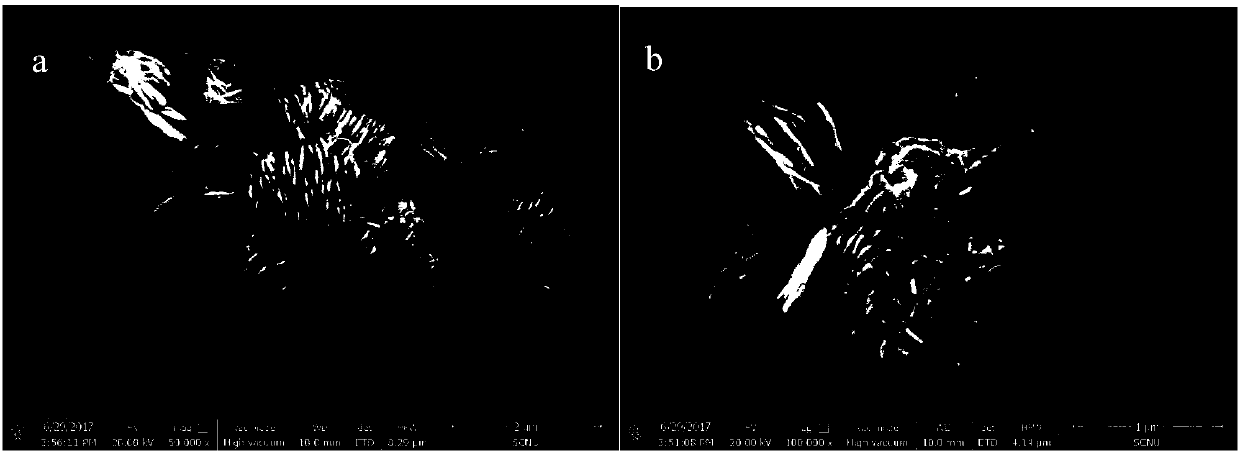

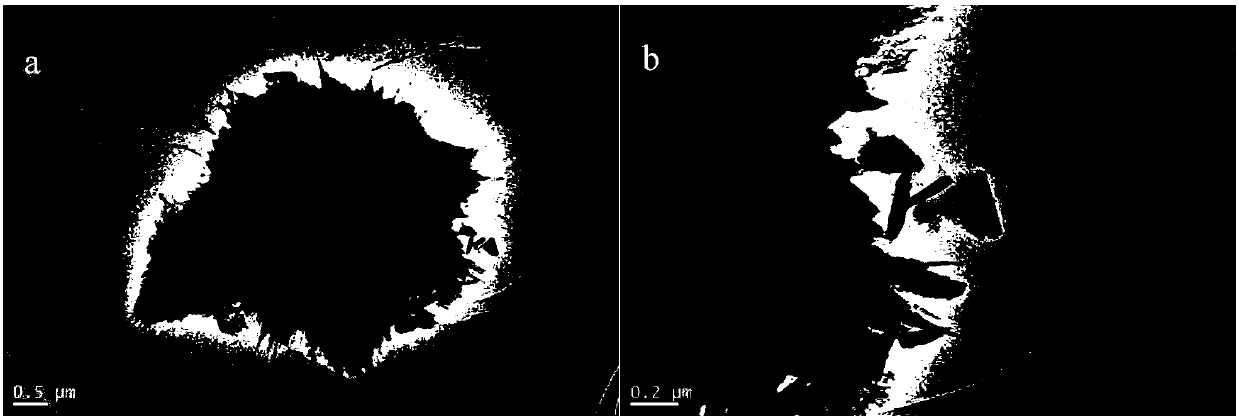

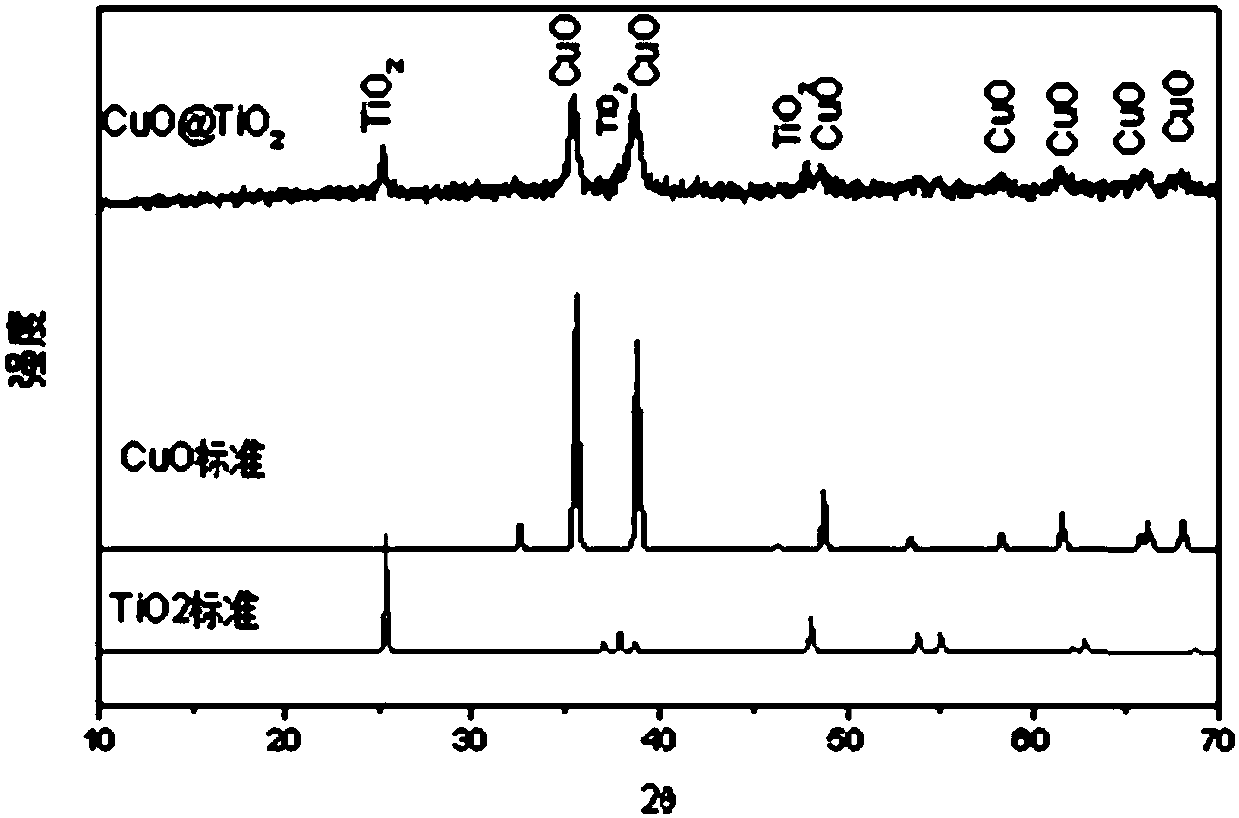

Titanium dioxide-copper oxide nano compound and preparation method and application thereof

ActiveCN107799744ARaw materials are easy to obtainSimple processMaterial nanotechnologyCell electrodesAir atmosphereFree cooling

Owner:SOUTH CHINA NORMAL UNIVERSITY

Super heat insulation coating loaded with nano titanium dioxide and preparation method of super heat insulation coating

InactiveCN104610847ADelay the aging processImprove hydrophilicityEpoxy resin coatingsBulk chemical productionEpoxySilicon dioxide

Owner:WUHU BAOYI AMUSEMENT EQUIP

Static-conducting and anti-corrosive coating on inner wall of oil tank, and preparation method of static-conducting and anti-corrosive coating

InactiveCN104098989ALight colorEasy for visual inspectionAnti-corrosive paintsEpoxy resin coatingsPetrochemicalReactive diluent

The invention discloses a static-conducting and anti-corrosive coating and a preparation method thereof. The static-conducting and anti-corrosive coating comprises bisphenol A epoxy resin, a reactive diluent, rutile titanium dioxide, conductive mica powder, a coupling agent and a flexibilizer. The bisphenol A epoxy resin is ground; the reactive diluent, the flexibilizer, the coupling agent and a light-colored static-conducting material are added; and the coating free of an inertial and volatile solvent is prepared. The coating has the characteristics of high cohesion, good closure and stable static conductivity, is suitable for internal anti-corrosive and static-conducting protection of oil storage and transport equipment such as an oil storage tank, an oil transport pipeline and an oil transport tank in the petrochemical industry, and is also suitable for anti-corrosive and anti-static protection of a gas tank, a water gate and an underground pipeline.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

Preparation method for mesoporous titanium dioxide material

InactiveCN102139917AImprove performanceReduce consumptionNanotechnologyTitanium dioxideAlcoholPhysical chemistry

The invention discloses a preparation method for a mesoporous titanium dioxide material. Tween-80, Span-80 and titanate are evenly mixed to be used as precursor; and a sol is prepared after the precursor is dissolved and violently stirred and the pH value of the precursor is adjusted. A xerogel is obtained after the sol is aged, scrubbed by absolute ethyl alcohol and dried in vacuum. Pulse voltage is applied to the xerogel under the constant pressure condition so as to generate plasmas which activate the surface of the xerogel; after being activated, the xerogel is heated by direct current; and after the xerogel is cooled, the mesoporous titanium dioxide material is obtained. The plasma activated sintering method is innovatively adopted for preparing the mesoporous titanium dioxide material. The complex matching of two template agents leads solubilization ability to be greatly improved. The method can effectively inhibit the occurrence of situations such as excessive growing of crystal particles, pore space collapse and difficult pore diameter distribution control and the like, and improves performances of sintering materials in essence. The sintering time is greatly shortened; and the temperature is greatly reduced. Compared with the traditional sintering process, the preparation method not only reduces the power consumption, but also reduces the loss of a device.

Owner:KUNMING METALLURGY COLLEGE

Heat-resistant modified asphalt

Owner:WUJIANG HUAWEI SPECIAL OIL

Self-peelable protective coating for cogging and forging process of pure titanium or titanium alloy and production process of self-peelable protective coating

InactiveCN104371385ASimple coating processGood molding effectAlkali metal silicate coatingsProduction rateTitanium

Owner:BEIJING TIAN LICHUANG SCI & TECH OF GLASS DEV

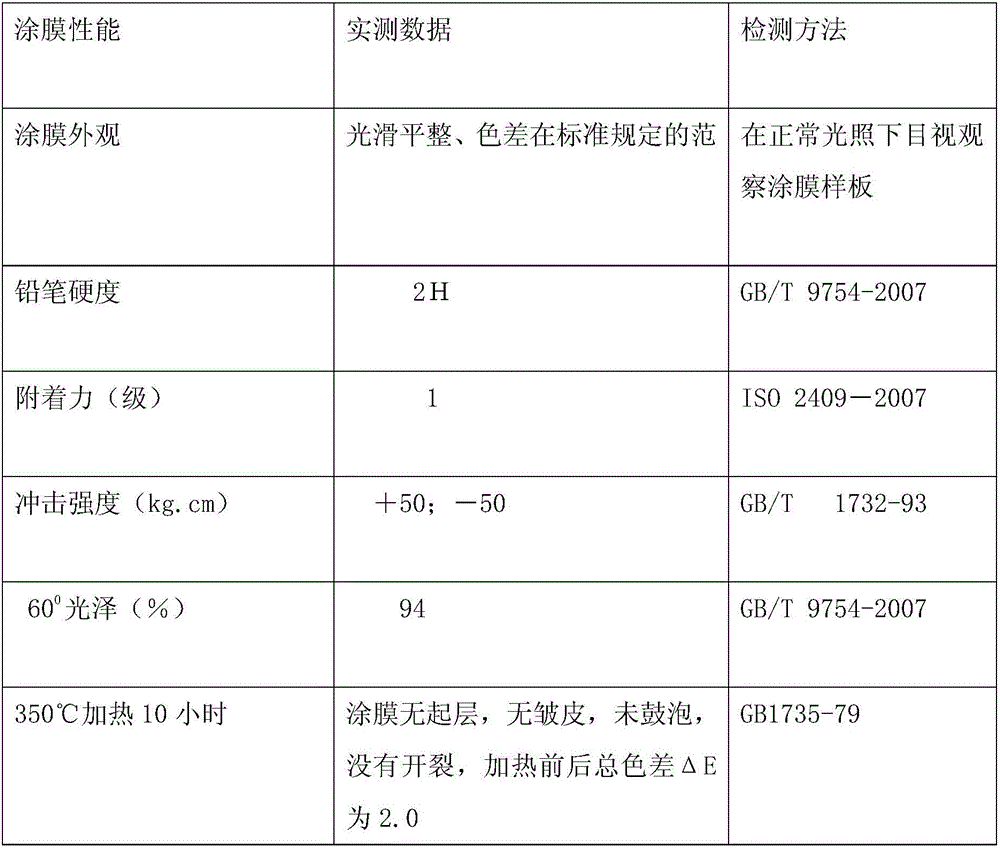

High-temperature-resistant powder paint and preparation method thereof

InactiveCN105860765ALow curing temperatureShort curing timeFireproof paintsPowdery paintsPolyester resinTemperature resistance

Owner:合肥燕美新材料科技有限公司

Hydrophobicity-enhanced heat-vulcanized silicone rubber and preparation method thereof

InactiveCN107286671AEnhance internal bondingImprove mechanical propertiesVulcanizationPolymer science

The invention provides hydrophobicity-enhanced heat-vulcanized silicone rubber and a preparation method thereof. The specific preparation method of the silicone rubber comprises steps as follows: divinyltetramethyldisiloxane is mixed with a mixed solution of concentrated hydrochloric acid, deionized water and ethanol, the mixture is mechanically stirred, ethyl orthosilicate is dropwise added, the mixture is subjected to hydrolytic condensation, methylbenzene is added for extraction and layering, methyl vinyl silicone resin is obtained, crosslinked polyethylene particles are added to the methyl vinyl silicone resin, the mixture is stirred uniformly and subjected to molding curing and vacuum heat treatment, and the polyethylene particle crosslinked methyl vinyl silicone resin is obtained; nano-montmorillonite, amorphous alumina and titanium dioxide are added to a polydimethylsiloxane prepolymer, the mixture is mixed and subjected to crosslinking and curing, and a reinforced material coated with organic silicone rubber is obtained; the polyethylene particle crosslinked methyl vinyl silicone resin, the reinforced material coated with organic silicone rubber, 2,4-dichlorobenzoyl peroxide, diphenyl silanediol and octamethylcyclotetrasiloxane are mixed uniformly, left to stand, subjected to open milling and secondary vulcanization, and the hydrophobicity-enhanced heat-vulcanized silicone rubber is obtained.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

Aging-resistant polyvinyl chloride plastic

Owner:湖南凯誉电气科技有限公司

Insulated fireproof coating for optical cables

InactiveCN105567024AExcellent physical and chemical propertiesDry fastFireproof paintsEpoxy resin coatingsFiberEpoxy

Owner:FUXIN POWER SUPPLY COMPANY STATE GRID LIAONING ELECTRIC POWER +1

Waterborne polyurethane super wear-resistant finish paint and preparation process thereof

ActiveCN109456690ASmall particle diameterGood dispersionPolyurea/polyurethane coatingsWear resistantWear resistance

The invention discloses waterborne polyurethane super wear-resistant finish paint and a preparation process thereof, and relates to the technical field of preparation of finish paint, aiming at solving the problem that the finish paint is poorer in wear resistance, so that local damage is easily caused in a using process. The finish paint is prepared from a component A and a component B, wherein the component A is prepared from the following raw materials: 50-60 parts of waterborne polyurethane resin AH-1618, 12-18 parts of polyurethane color paste, 0.8-1.2 parts of a leveling agent BYK346, 0.3-0.5 part of an aqueous leveling agent BYK333, 0.3-0.6 part of a polyurethane rheological agent SN612NC, 0.3-0.5 part of a defoaming agent BYK024, 0.08-0.1 part of a defoaming agent Tego901W, 0.8-1.5parts of rutile titanium dioxide, 8-10 parts of wear-resistant ball powder, 0.8-1.5 parts of an aqueous scratch-resistant agent, 1.2-1.6 parts of propylene glycol methyl ether and 12-18 parts of deionized water; the component B is prepared from 95-100 parts of a polyurethane curing agent; the ratio of parts by weight of the component A to parts by weight of the components B is equal to (4-6) to 1. The waterborne polyurethane super wear-resistant finish paint has good wear resistance after being cured.

Owner:SHANGHAI BOGE BUILDING MATERIALS CO LTD

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap