Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

14 results about "Mildew" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mildew is a form of fungus. It is distinguished from its closely related counterpart, mold, largely by its color: moulds appear in shades of black, blue, red, and green, whereas mildew is white. It appears as a thin, superficial growth consisting of minute hyphae (fungal filaments) produced especially on living plants or organic matter such as wood, paper or leather. Both mould and mildew produce distinct offensive odors, and both have been identified as the cause of certain human ailments.

Aqueous texture wallpaper paint and method for making same

The invention relates to a watercraft texture wallpaper paint, characterized in that the invention comprises the following components: 31 percent to 35 percent of styrene-acrylic emulsion, 23.94 percent of superfine weight calcium, 1 percent to 2 percent of nano-titanium dioxide, 10 percent to 18 percent of titanium pigment, 8 percent to 9.8 percent of calcined kaolin, 1.2 percent to 1.8 percent of ethylene glycol, 0.2 percent to 0.5 percent of hydroxyethylcellulose, 0.8 percent to 1.5 percent of film forming additive, 0.15 percent to 0.25 percent of multi-functional additive, 0.3 percent to 0.5 percent of dispersant, 0.1 percent to 0.2 percent of wetting agent, 0.15 percent to 0.21 percent of defoamer, 0.08 percent of anticorrosion and insecticide, 0.8 percent to 2 percent of thickener and 20 percent to 22 percent of water. The invention is the watercraft texture wallpaper paint, is environment-friendly, has strong elastic tension, has good covering and anti-cracking effect on the fine cracking of wall, and has good scrape resistance performance, greatly enhancing the degree of wall surface protection; meanwhile, the invention still has strong waterproof performance, without color-changing and decortication and mildew and can fully solve the common problems existing in wall decoration.

Owner:FOSHAN SHUNDE QINGDA RUNCAI COATING CO LTD

Feed mould inhibitor

InactiveCN101766268AReasonable formulaGood anti-mildew effectAnimal fodder preservationBenzoic acidPropanoic acid

Owner:翁晓强

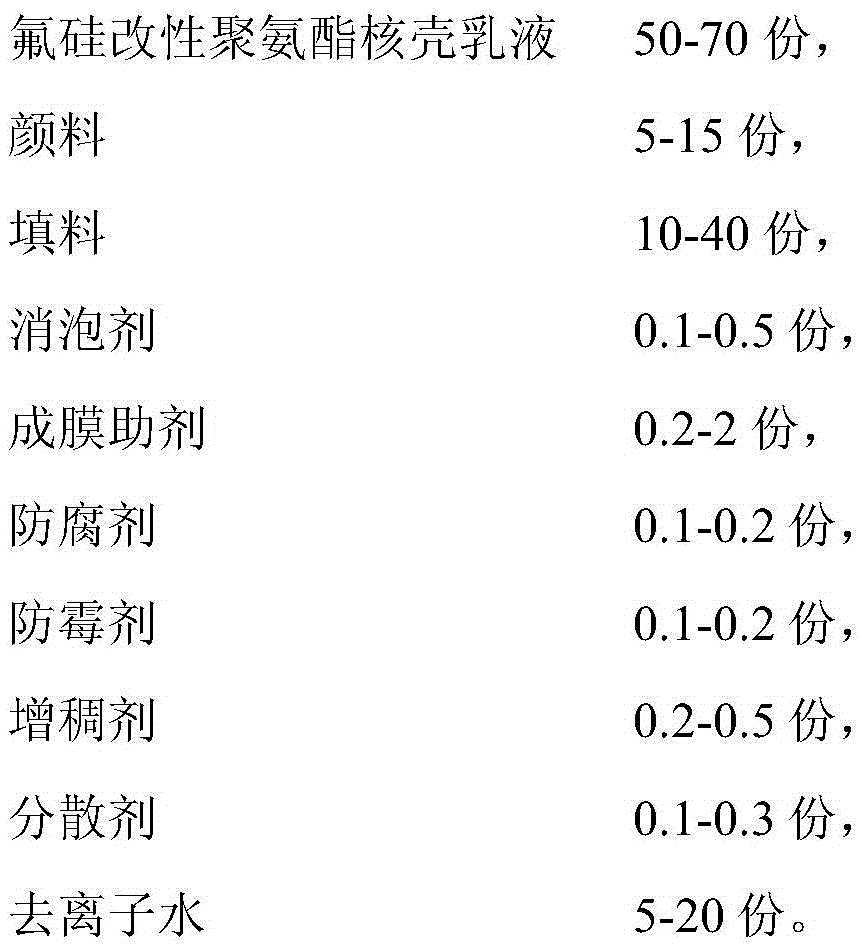

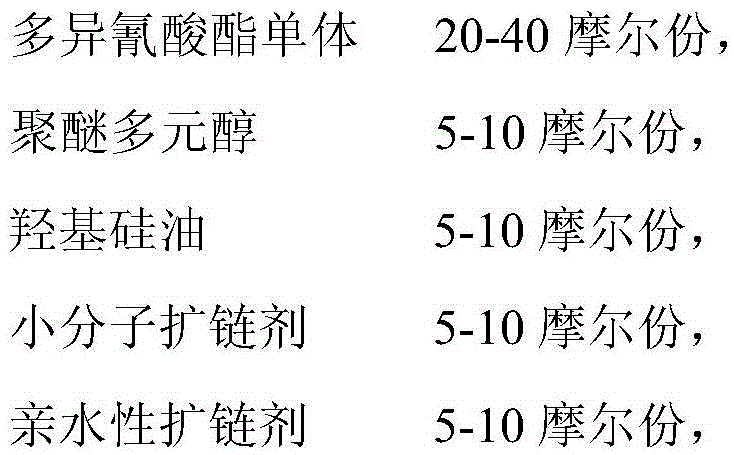

Water-based anti-doodling paint and preparation method thereof

ActiveCN105482604ALow VOC emissionsLow weather resistanceAntifouling/underwater paintsPaints with biocidesWater basedDefoaming Agents

Owner:HANGZHOU JIHUA POLYMER MATERIAL CO LTD

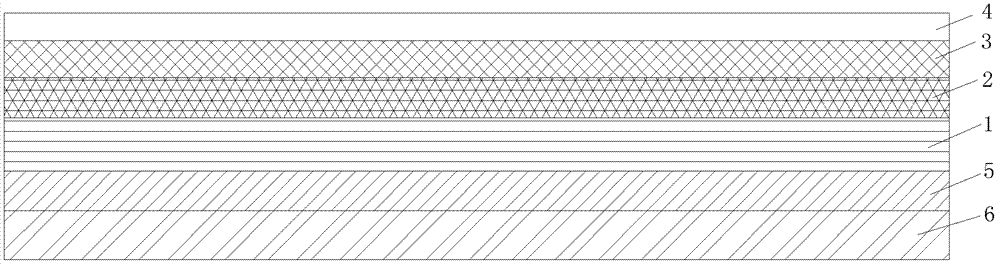

Wallpaper with waterproof and purifying functions

InactiveCN102852046ALong lasting effectImprove waterproof performanceCovering/liningsSpecial paperMildewEngineering

Owner:WUJIANG WALLMATE DECORATION MATERIALS

Method for estimating in-vitro detoxification effect of mycotoxin detoxification agent by using liquid chromatography

InactiveCN105301134AApplicable adsorption rate evaluationThe evaluation results are close toComponent separationMycotoxinSorbent

Owner:江苏奥迈生物科技有限公司

Extraction process of plant mildew-proof preservative

InactiveCN1672536AInfectiousEnhanced inhibitory effectFruit and vegetables preservationSodium bicarbonateWater vapor

Owner:CROPS BREEDING CULTIVATING INST SHANGHAI AGRI SCI ACAD

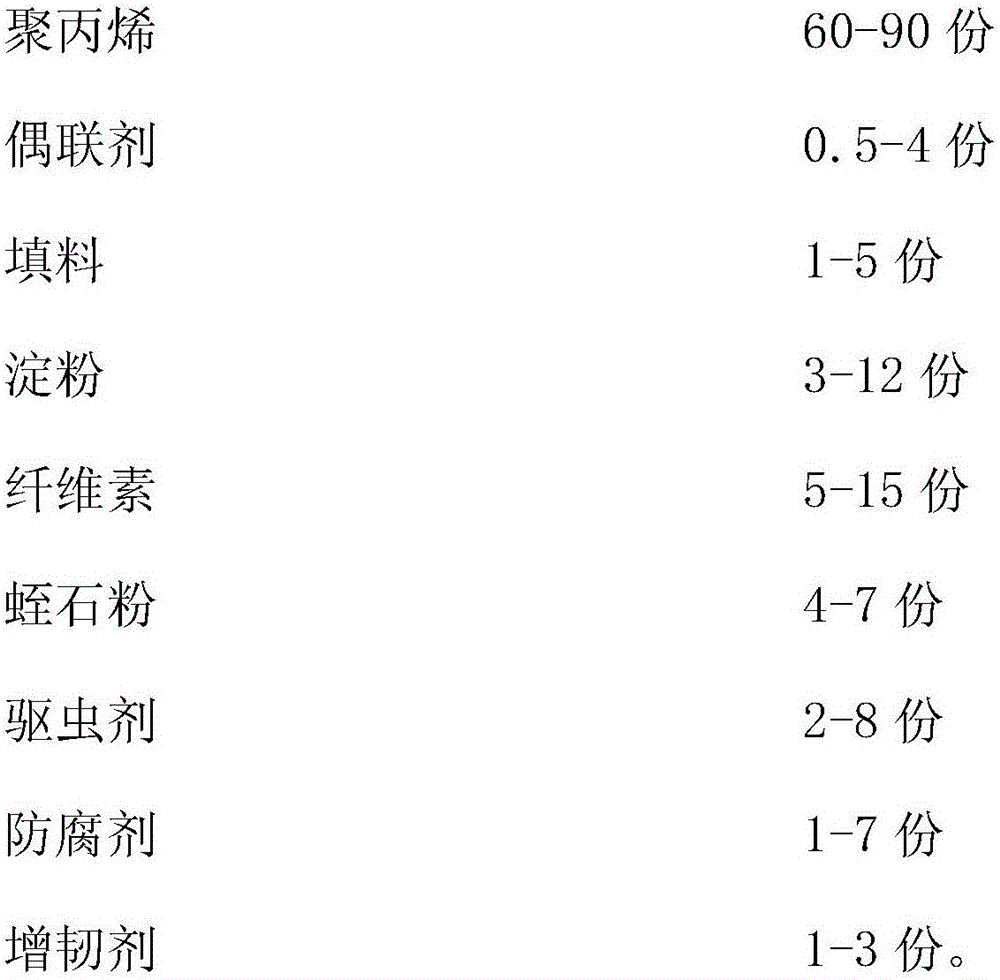

Food packaging bag and preparation method thereof

Owner:安徽明诚塑业有限公司

Wet area wall face wooden product mouldproof technology

The invention relates to a decoration technology, in particular to a wet area wall face wooden product mouldproof technology. Mouldproof treatment is conducted on a wet area wall face back face and acabinet abutting against the back face, and the mouldproof technology comprises the following steps that 1, treatment is conducted on a base layer of a wall face, and an interface agent is brushed; 2,leveling treatment is conducted on the wall face; 3, a waterproof agent is brushed on the wall face, and a damp-proof layer is formed; 4, anti-corrosion treatment is conducted on a back plate, tightly abutting against the wall face, of the cabinet; 5, a damp-proof separation layer is arranged at the position where the back plate is in contact with the wall face when the cabinet is mounted; and 6,the cabinet is mounted. According to the wet area wall face wooden product mouldproof technology, three damp-proof layers are formed by brushing the damp-proof layer on the back face of the wet areawall face, conducting anti-corrosion treatment on the back plate of the cabinet and arranging the damp-proof separation layer at the position where the back plate of the cabinet is in contact with thewall face, dampness transmitted from the wet area wall face can be effectively blocked, dryness and cleanness of the cabinet are ensured, no mildew and bacteria is generated, a clean and sanitary environment in a non-wet area is ensured, physical health is facilitated, and wooden furniture is durable.

Owner:SHANGHAI JUTONG DECORATION GRP

Production process of environment-friendly water-based anti-corrosion coating

InactiveCN104449091AImprove anti-corrosion performanceGood resistance to nitro paintAnti-corrosive paintsWater basedWater resistant

Owner:QINGDAO SHOUSHENG IND

Preparation method of anti-mildew agent for feeds

InactiveCN108371238AIncrease feed intakePromotes decreased feed intake, growthAccessory food factorsFreeze-dryingFiltration

Owner:汪逸凡

Stacked double-circulation low-temperature drying system, using method and application

PendingCN112781330AImprove securityNo mildewDrying gas arrangementsCompression machines with cascade operationRefrigeration compressorVapor–liquid separator

The invention belongs to the field of drying systems, and particularly relates to a stacked double-circulation low-temperature drying system. The drying system is a system with forward Carnot cycle heating and reverse Carnot cycle refrigeration and dehumidification functions. The stacked double-circulation low-temperature drying system comprises a first refrigerating system, a second refrigerating system, a circulating fan and an air distribution and guide plate, a group of first condensers, first evaporators and second evaporators are arranged on each of the two sides of the circulating fan; a first gas-liquid separator and a first refrigeration compressor of the first refrigeration system are sequentially connected with the first condensers; a second gas-liquid separator and a second refrigeration compressor of the second refrigeration system are sequentially connected with second condensers; and the air distribution and guide plate is arranged in a drying chamber. The drying system has the following advantages that the safety of materials to be dried is high, and a mildew phenomenon is avoided; the loss of nutritional ingredients is low; the energy consumption is reduced; and the drying system has the characteristics that he drying speed is high, the drying speed is consistent, and the environment is protected.

Owner:YANTAI RUIJIA ENERGY SAVING TECH CO LTD

Method for improving germination rate of forage grass seeds under salt stress

InactiveCN112931506AImprove germination rateMitigation of salt poisoningBiocidePlant growth regulatorsBiotechnologyPropionate

Owner:HEBEI AGRICULTURAL UNIV.

Quantitative aflatoxin distinguishing method by using quantitative change of chemical constituents

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Integrated bamboo material manufacturing method for sequentially carrying out anti-rot full-permeation impregnation treatment and anti-mildew full-permeation impregnation treatment on fine planing bamboo strip

InactiveCN109664390ASimple processImproved anti-mold and anti-corrosion effectWood treatment detailsReed/straw treatmentMildewPermeation

The invention discloses an integrated bamboo material manufacturing method for sequentially carrying out anti-rot full-permeation impregnation treatment and anti-mildew full-permeation impregnation treatment on a fine planing bamboo strip. According to the present invention, the process is simple, the surface and the interior of the product can be subjected to the consistent full-permeation impregnation anti-rot and anti-mildew treatment, and after the cutting, any surface of the product can achieve the same anti-rot and anti-mildew effect.

Owner:蒋健艳

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap