Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

20 results about "Pore diameter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pore diameter. [′pȯr dī‚am·əd·ər] (design engineering) The average or effective diameter of the openings in a membrane, screen, or other porous material.

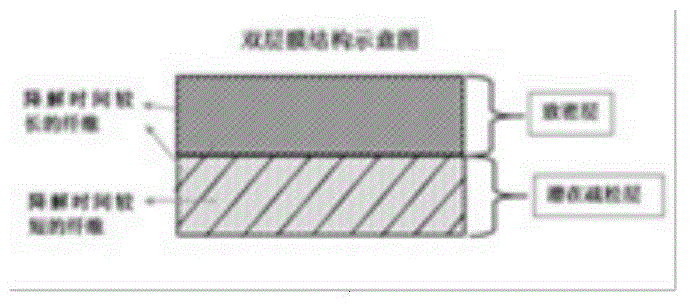

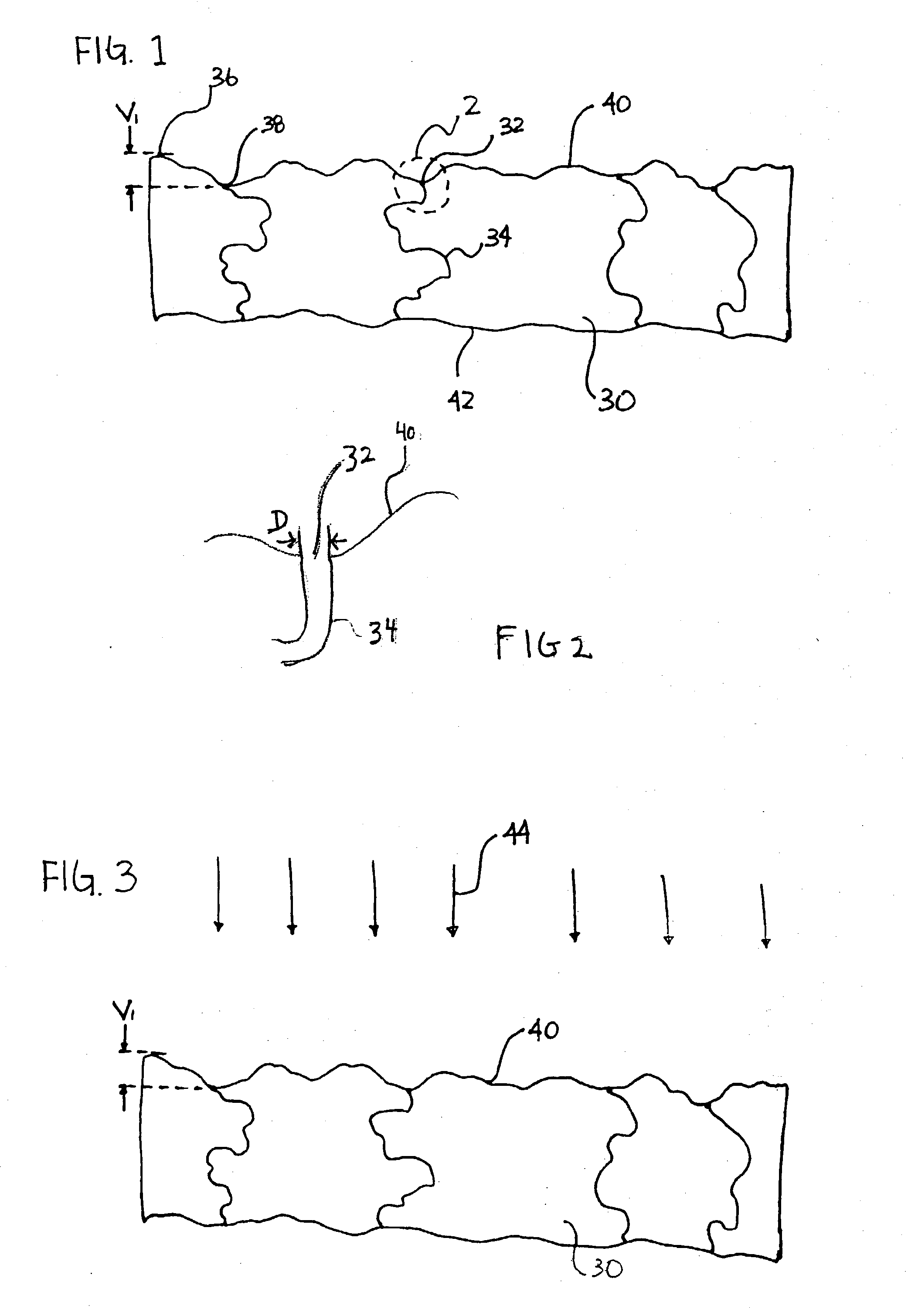

Guided tissue regeneration membrane as well as preparation method and application thereof

ActiveCN104474589APromote degradationLarge apertureCellulosic plastic layered productsProsthesisFiberTissue repair

Owner:烟台蓝创生物技术有限公司

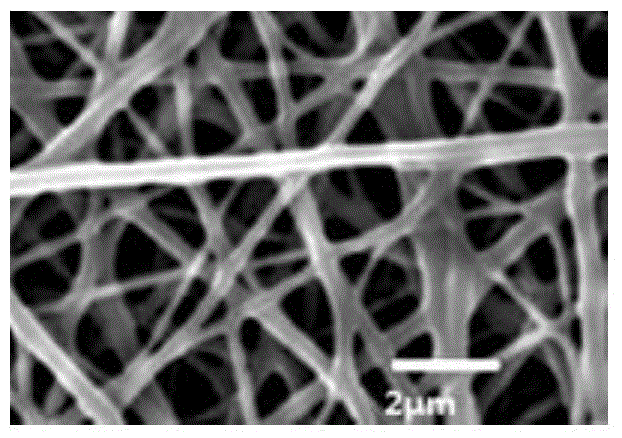

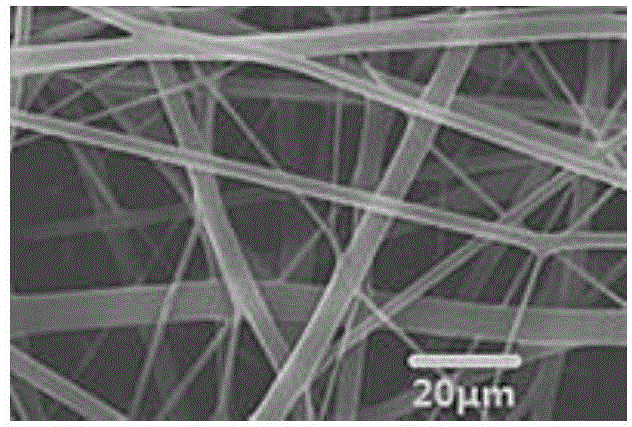

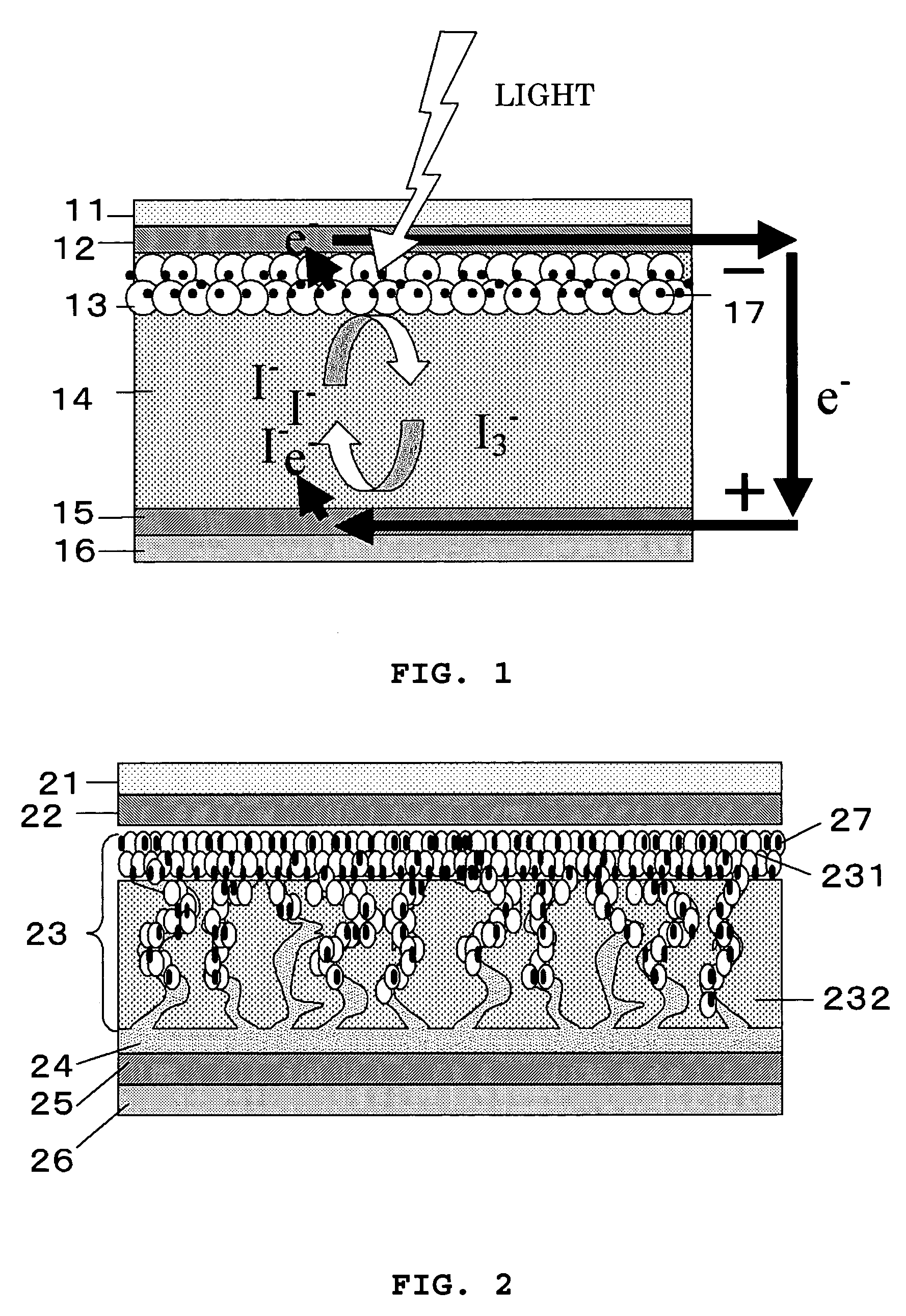

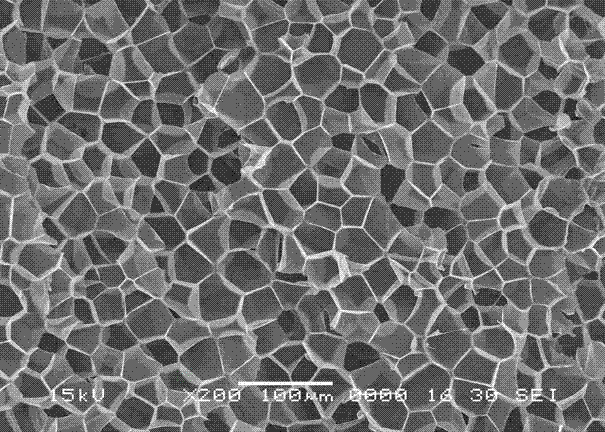

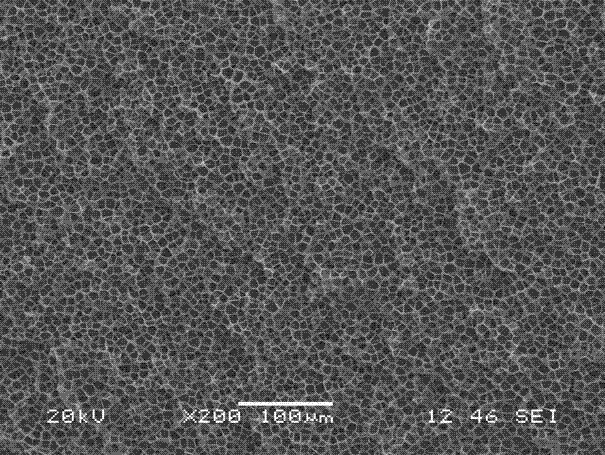

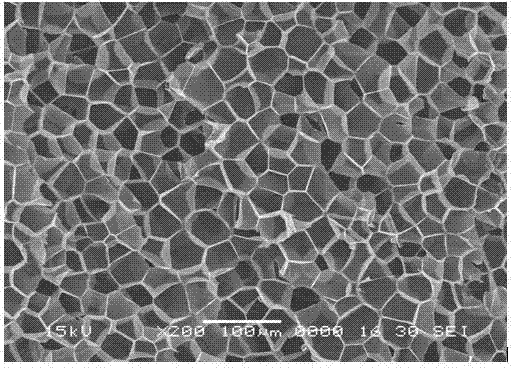

Porous electrodes, devices including the porous electrodes, and methods for their production

InactiveUS20060021649A1Improve efficiencyIncrease flexibilityElectrolytic capacitorsHybrid capacitor electrodesPore diameterConductive materials

Owner:SUMITOMO CHEM CO LTD

Industrially-applicable method for preparing polymer foamed material by using supercritical fluid technology

Owner:CHANGZHOU TIANSHENG NEW MATERIALS RES INST CO LTD

Small pore diameter silicone rubber sponge and preparation method thereof

The invention discloses small pore diameter silicone rubber sponge and a preparation method thereof and relates to the field of processing of high polymer materials. The small pore diameter silicone rubber sponge comprises the following components in parts by weight: a component A: 100 parts of liquid organic silicone rubber; a component B: 3-8 parts of hydrogen-containing silicone oil; a component C: 0.5-10 parts of an emulsifier; a component D: 2-4 parts of a catalyst; a component E: 1-2 parts of an inhibitor; and a component F: 0-35 parts of a silicon resin. An emulsion dispersion mode is adopted, the dispersion phase size is small, and the silicone rubber sponge prepared by the method has the characteristics of bubble dispersion uniformity, small pore diameter and controllable density; and moreover, water serves as a foaming agent, and the sponge has the advantage of environment friendliness. The silicone rubber sponge material prepared by the method can serve as shock absorption, insulating, sound insulation and heat insulation materials.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

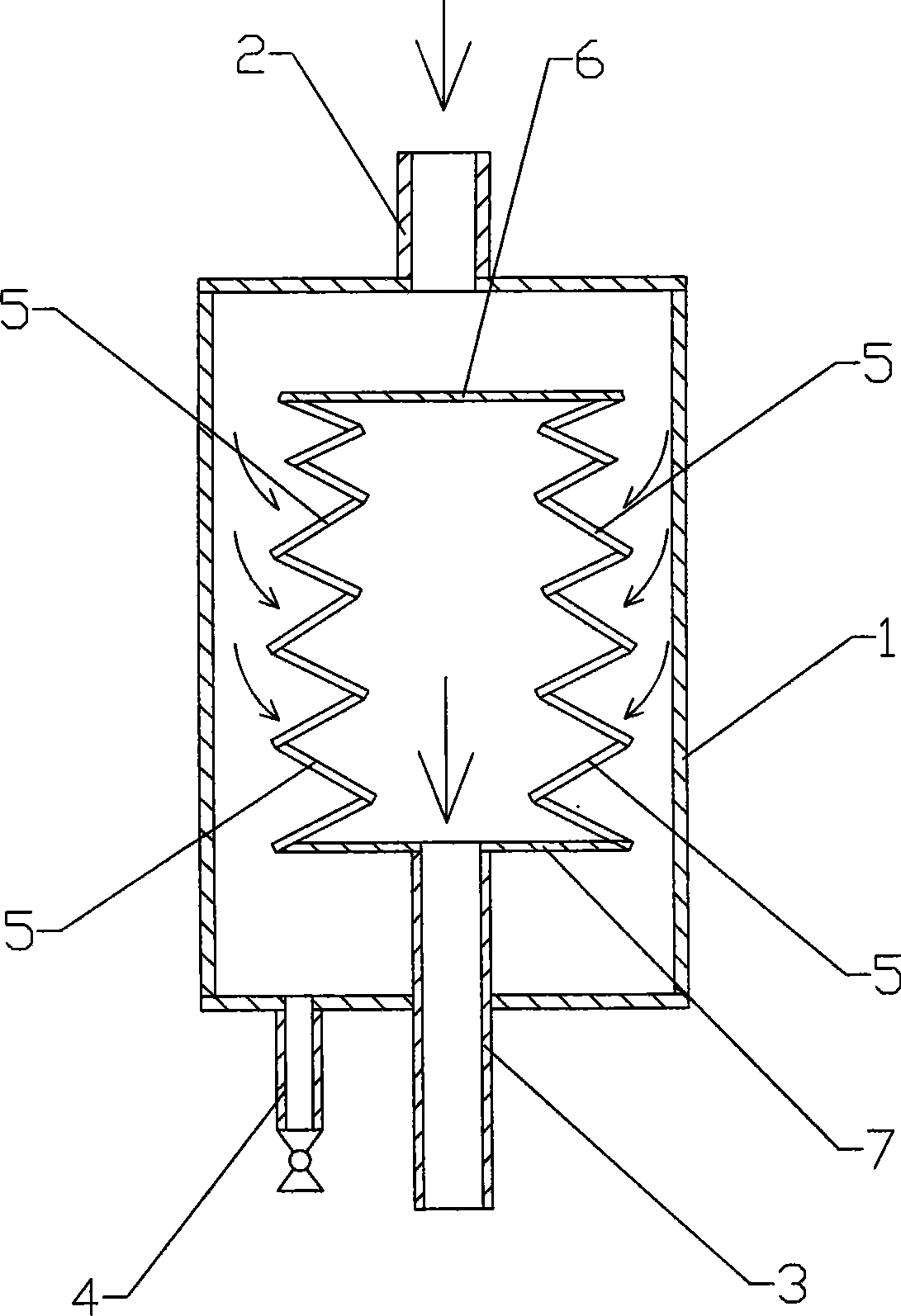

Filter

InactiveCN101462019ASmall apertureHigh densityDispersed particle filtrationBiochemical engineeringFiltration

Owner:薛文伟

Surface modification of porous metal substrates

Owner:INTELLIGENT ENERGY INC

Intelligent label for indicating freshness of aquatic products and preparation method of intelligent label

PendingCN107290335AFreshness real-time monitoringImprove securityMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsBromocresol greenHydrogen

The invention relates to an intelligent freshness label. The intelligent freshness label is characterized in that a bromocresol green pH (Potential of Hydrogen) sensitive dyestuff is utilized and an anodic aluminum oxide film is used as an adsorption carrier of the dyestuff. The anodic aluminum oxide film has a pore diameter less than 200nm, is vertical to the surface and has the pore density of 10<9> pores / cm<2> to 10<10> pores / cm<2>. The intelligent label provided by the invention is a visualized label which can be used for accurately characterizing the freshness of foods and directly feeding food freshness information back to consumers. According to the intelligent freshness label provided by the invention, the quality change of foods in packages can be directly characterized according to changes of environment parameters including temperature, time and the like of the foods.

Owner:GUANGDONG OCEAN UNIVERSITY +1

Composite carbon diaphragm with mesoporous and microporous gradient structure and preparation method for diaphragm

ActiveCN102580567ADecreased gas separation performanceHigh gas separation selectivitySemi-permeable membranesBreaking strengthMicrometer

The invention relates to a composite carbon diaphragm with a mesoporous and microporous gradient structure and a preparation method for the diaphragm. The composite carbon diaphragm with the mesoporous and microporous gradient structure consists of a porous support body, a mesoporous intermediate layer and a surface separation layer, and is characterized in that the pore diameter of the porous support body is 100 to 500 nanometers, the breaking strength is 2 to 15MPa, and the anti-explosion strength is 3 to 10MPa; the pore diameter of the mesoporous intermediate layer is 2 to 10 nanometers, the specific surface area is 400 to 1,000 m<2> / g, the porosity is 30 to 50 percent, and the thickness is 1 to 10 micrometers; and the pore diameter of the surface separation layer is 0.3 to 0.5 nanometer, the specific surface area is 300 to 600 m<2> / g, the porosity is 20 to 40 percent, and the thickness is 0.1 to 5 micrometers. By the composite carbon diaphragm with the mesoporous and microporous gradient structure, the phenomenon that the gas separation performance of the composite carbon diaphragm is greatly reduced due to the defect of the surface of the support body is avoided, and the permeability of the prepared composite carbon diaphragm is improved obviously on the basis of keeping high gas separation selectivity.

Owner:DALIAN UNIV OF TECH

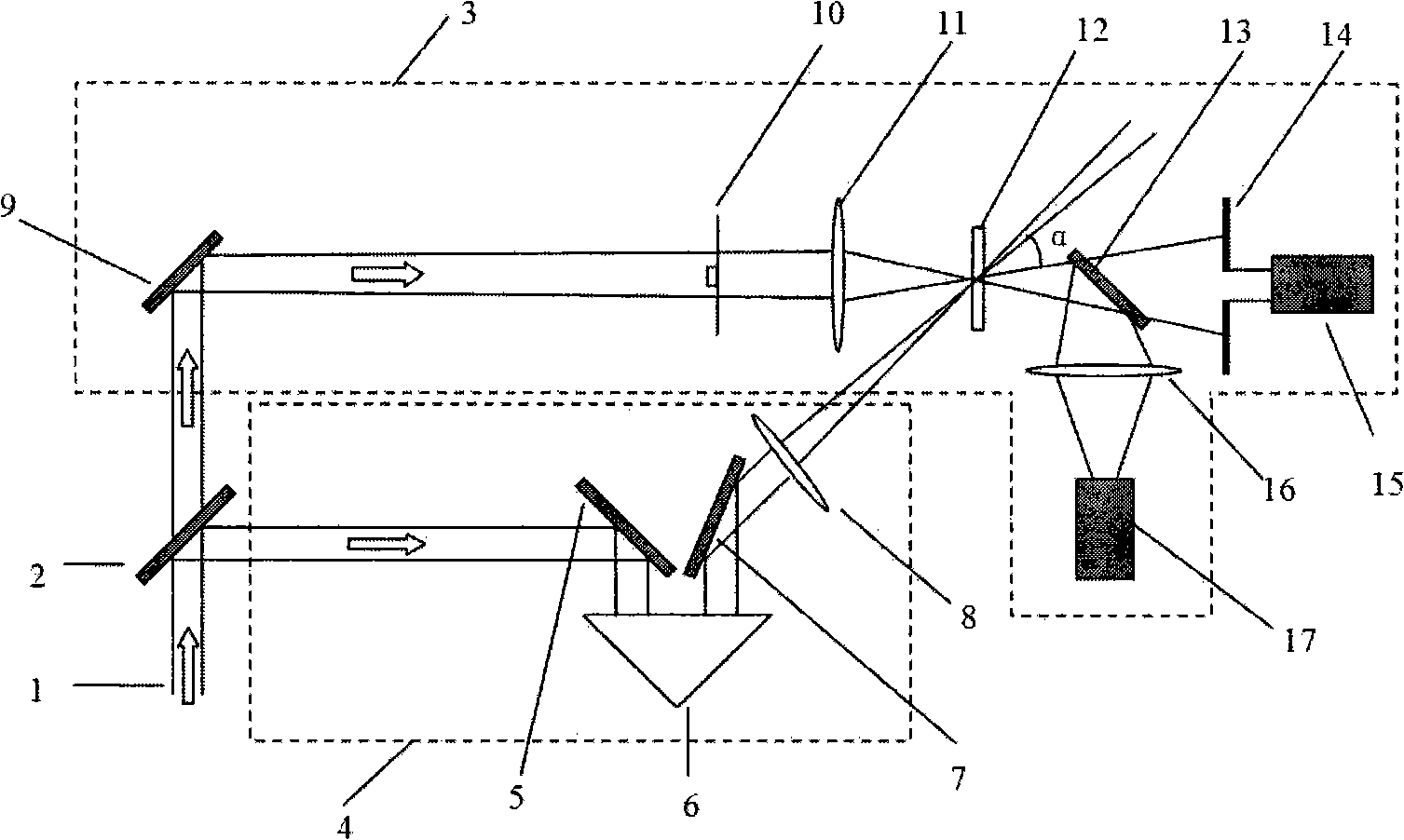

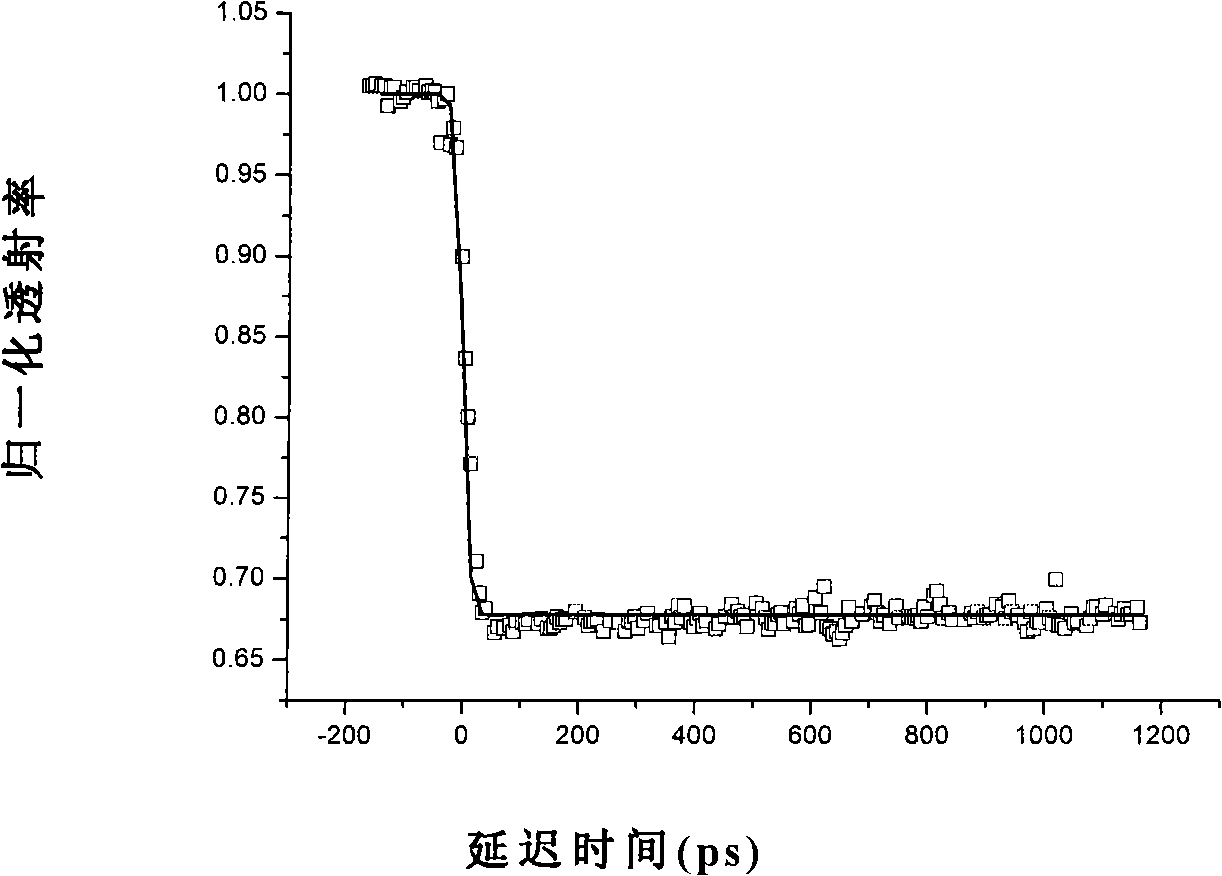

Pumping detection method based on Z scan

InactiveCN101324503ADetermine absorbencyDetermining lifeMaterial analysis by optical meansDelayed timePump probe

Owner:SUZHOU UNIV

Method for preparing foam glass with high foaming rate by utilizing lead-free high-barium abandoned lamp tube

InactiveCN106630649AHigh foaming rateLow melting pointGlass shaping apparatusFoaming agentSodium phosphates

The invention discloses a method for preparing foam glass with a high foaming rate by utilizing a lead-free high-barium abandoned lamp tube and belongs to the field of foam glass. The method comprises the following steps: carrying out ball milling on the lead-free high-barium abandoned lamp tube to form a glass powder raw material; feeding foaming agents, namely manganese dioxide and calcium carbonate, a fluxing agent, namely sodium fluorosilicate, and a stabilizer, namely sodium phosphate into a ball mill to be subjected to ball milling; feeding mixture obtained through ball milling into a high-temperature-resistant mould, preheating for 15-20 minutes at the temperature of 400-430 DEG C, then heating up to 800-820 DEG C, and carrying out heat preservation for 20-30 minutes; then cooling to 500-550 DEG C, annealing, and carrying out heat preservation for 35-40 minutes; and finally carrying out furnace cooling to room temperature. The prepared foam glass is uniform in pore diameter, closed pores are formed mainly, the average pore diameter reaches about 4.2mm, the density is 0.58g / cm<3>, the compressive strength is 3.78MPa, the performance is excellent, and the application standard of the foam glass can be met.

Owner:YANGZHOU UNIV

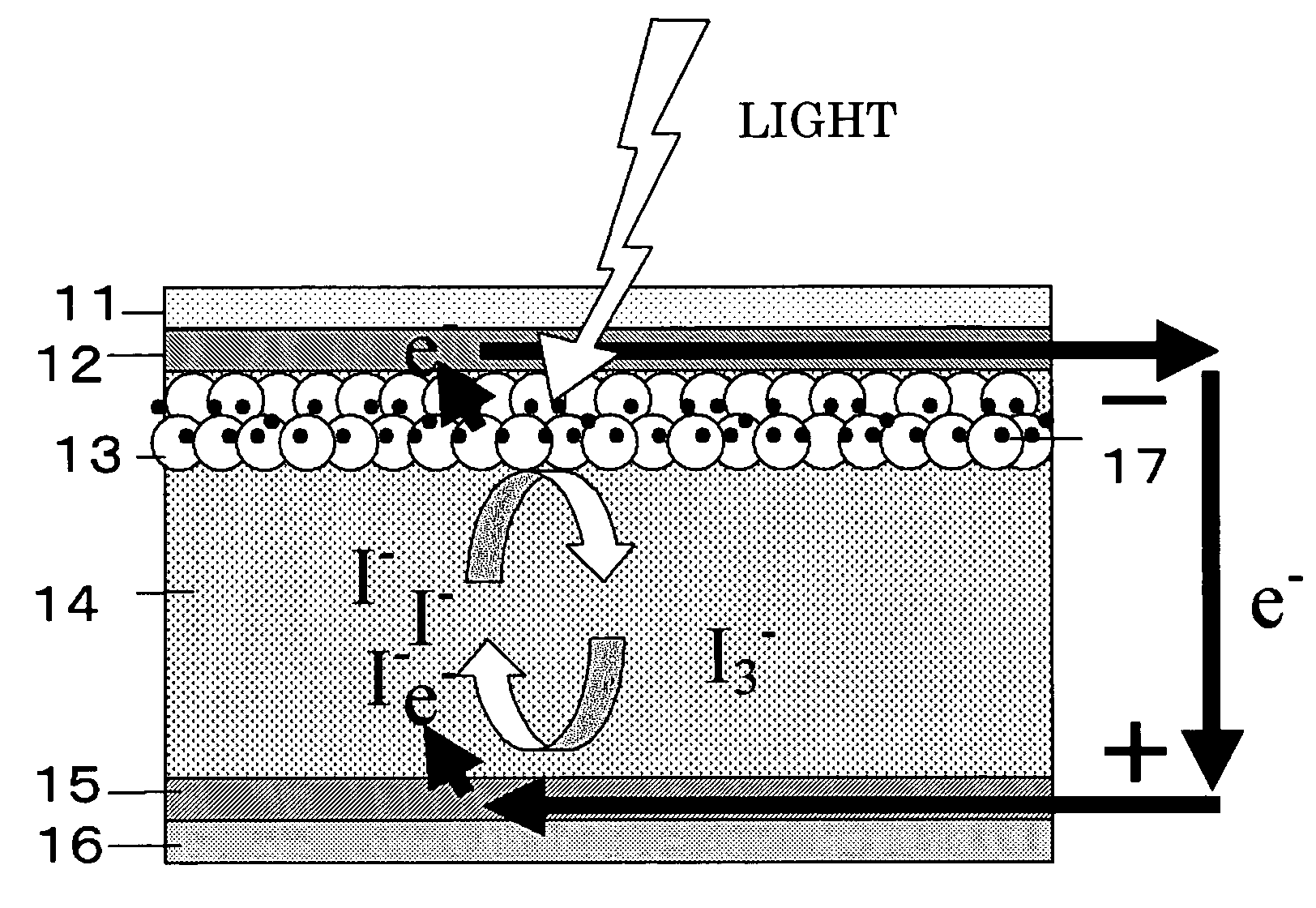

Preparation method for mesoporous titanium dioxide material

InactiveCN102139917AImprove performanceReduce consumptionNanotechnologyTitanium dioxideAlcoholPhysical chemistry

The invention discloses a preparation method for a mesoporous titanium dioxide material. Tween-80, Span-80 and titanate are evenly mixed to be used as precursor; and a sol is prepared after the precursor is dissolved and violently stirred and the pH value of the precursor is adjusted. A xerogel is obtained after the sol is aged, scrubbed by absolute ethyl alcohol and dried in vacuum. Pulse voltage is applied to the xerogel under the constant pressure condition so as to generate plasmas which activate the surface of the xerogel; after being activated, the xerogel is heated by direct current; and after the xerogel is cooled, the mesoporous titanium dioxide material is obtained. The plasma activated sintering method is innovatively adopted for preparing the mesoporous titanium dioxide material. The complex matching of two template agents leads solubilization ability to be greatly improved. The method can effectively inhibit the occurrence of situations such as excessive growing of crystal particles, pore space collapse and difficult pore diameter distribution control and the like, and improves performances of sintering materials in essence. The sintering time is greatly shortened; and the temperature is greatly reduced. Compared with the traditional sintering process, the preparation method not only reduces the power consumption, but also reduces the loss of a device.

Owner:KUNMING METALLURGY COLLEGE

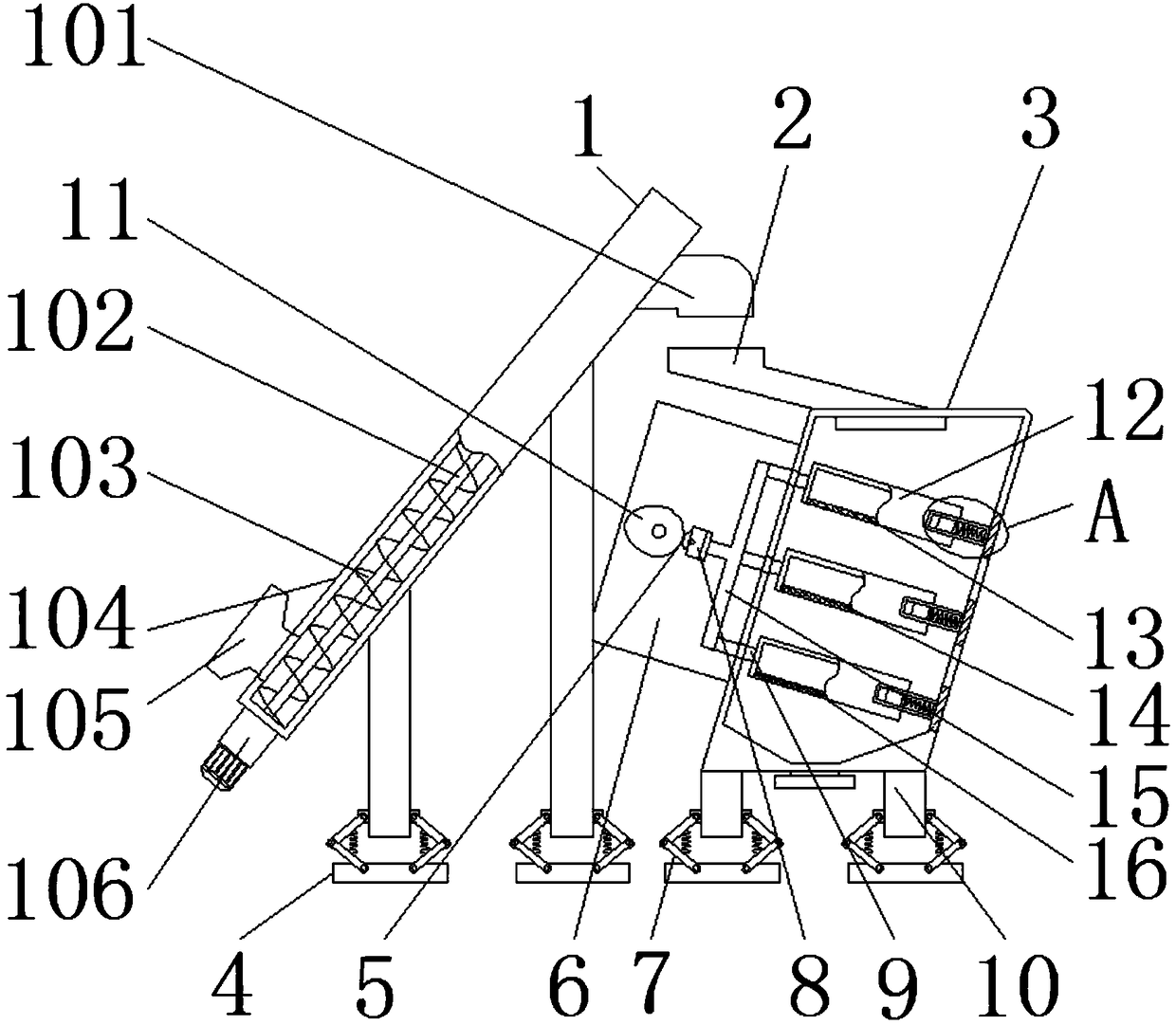

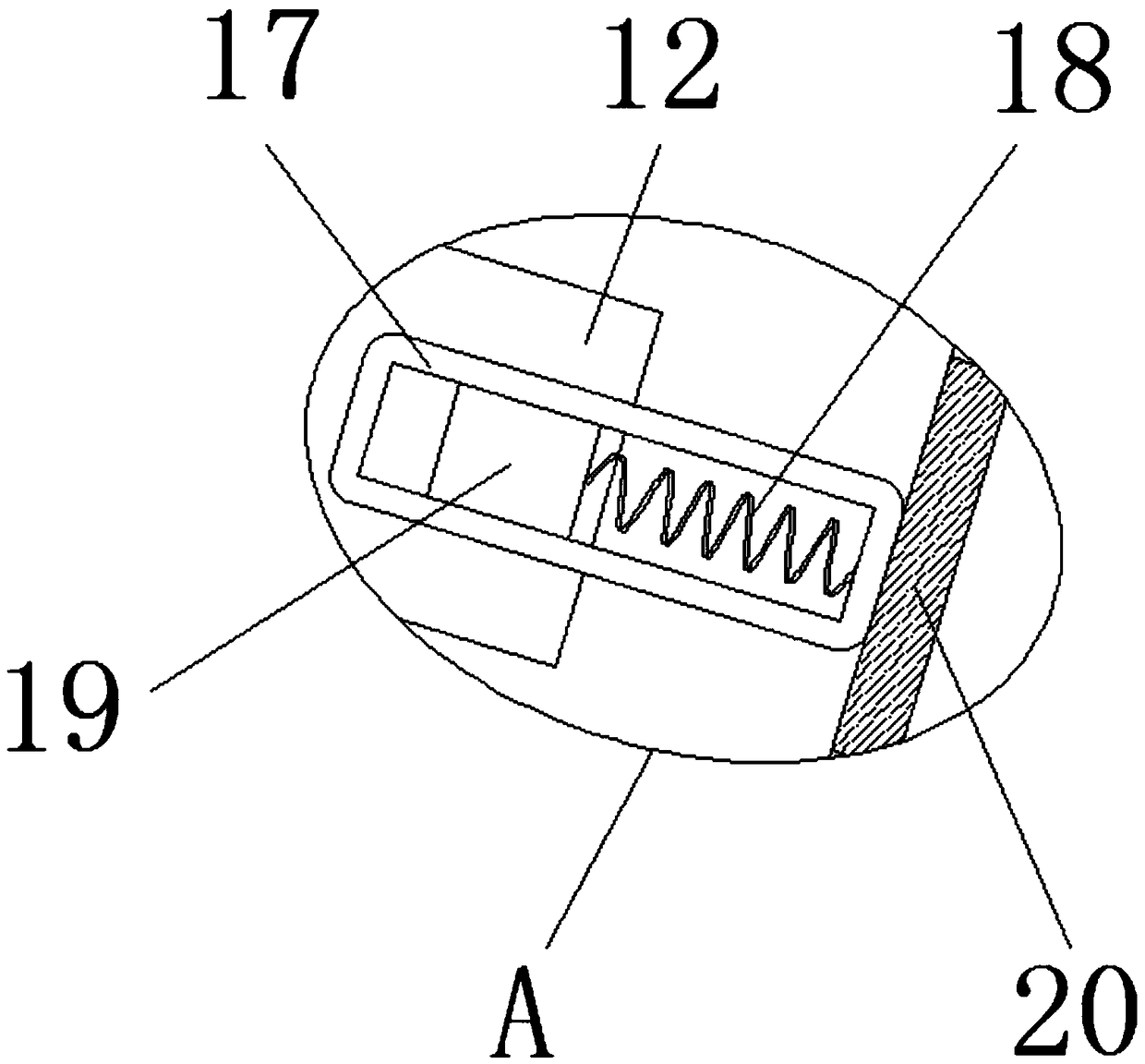

Sandy soil screening device for building construction

ActiveCN108636784AImprove screening efficiencyImprove work efficiencySievingScreeningPore diameterEngineering

Owner:CHINA METALLURGICAL CONSTR HIGH TECH ENG TECH CO LTD

Non-metal honeycomb combustion plate for Chinese food kitchen range

InactiveCN103574608AReduce manufacturing costShorten the processing cycleGaseous fuel burnerEngineeringHearth

Owner:缪传云

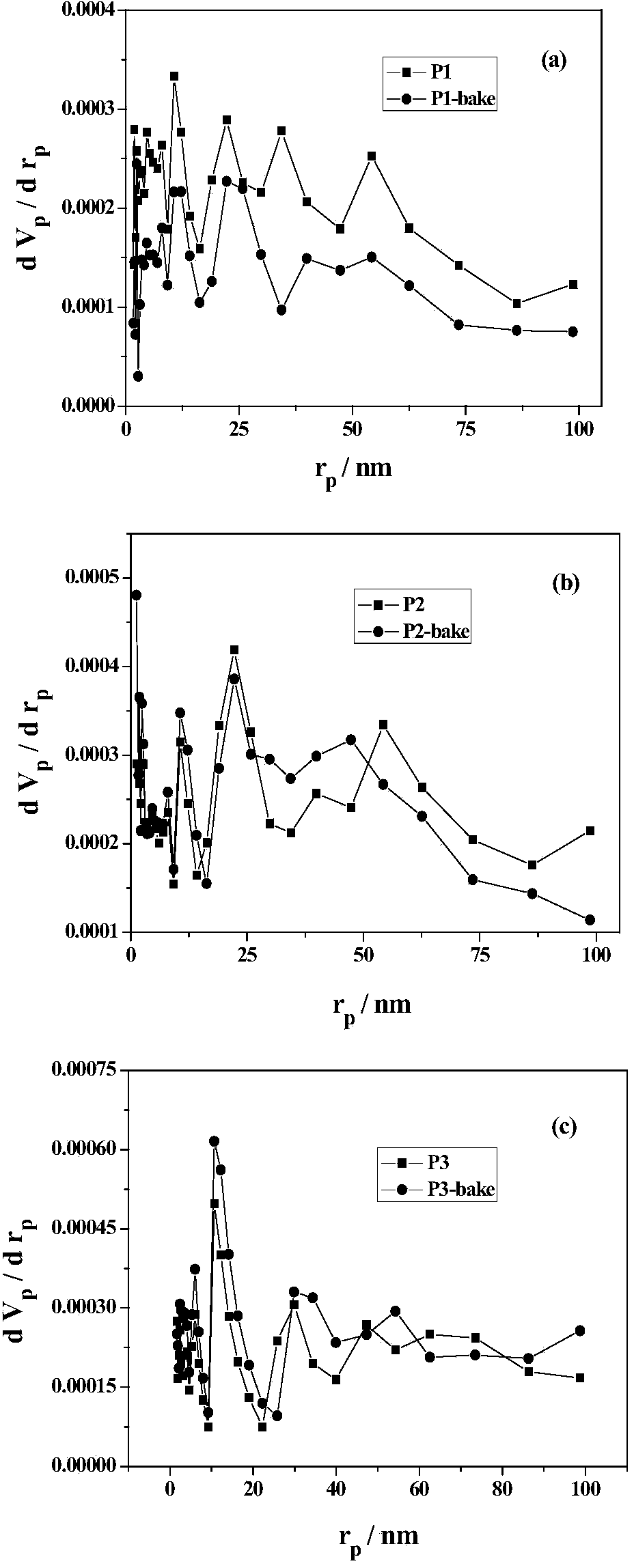

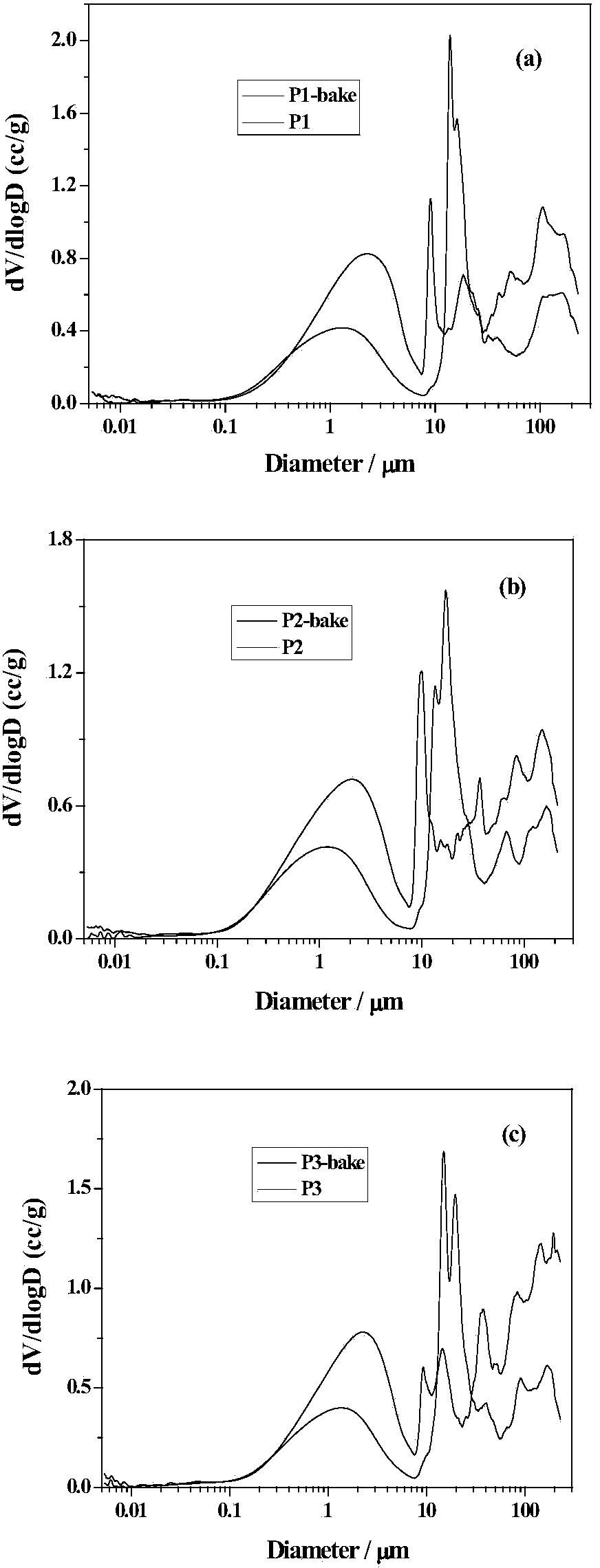

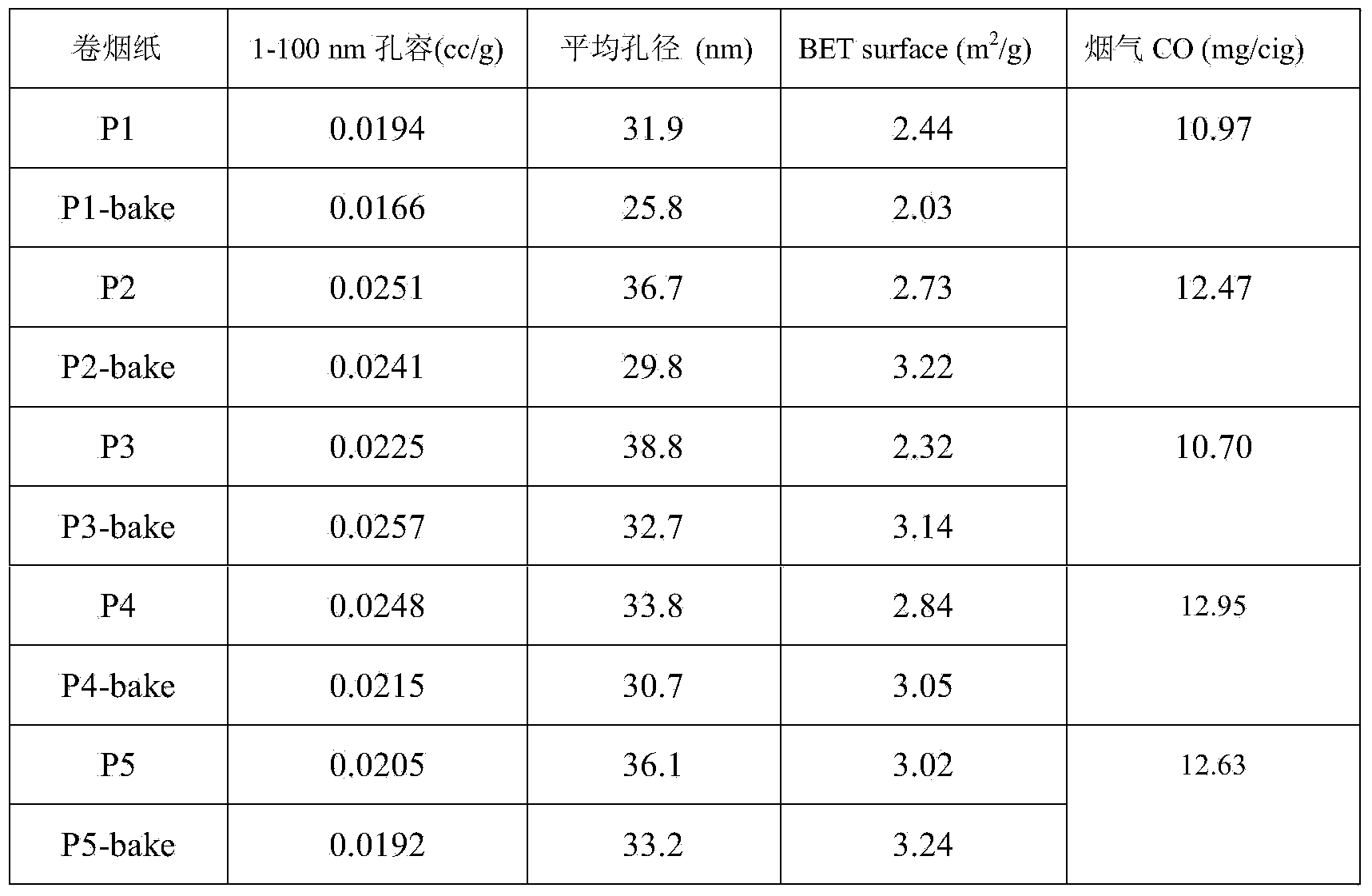

Method for testing relation between cigarette paper pore structure and CO release in main stream smoke in cigarette burning process

ActiveCN103675193ASimple test methodAccurate CO release relationshipChemical analysis using combustionChemistryPore diameter

The invention discloses a method for testing the relation between a cigarette paper pore structure and CO release in main stream smoke in the cigarette burning process. According to the method, the state of cigarette paper nearby a charring line in the cigarette burning process is simulated through baking in combination of a nitrogen absorption and desorption method and a mercury intrusion method, distribution of pore volumes and pore diameters in the range of 1 nm-200 mu m of the cigarette paper before and after baking is represented respectively, the pore structure change of the cigarette paper in the cigarette burning process is more accurately represented, and data of the CO release in main stream smoke of a cigarette are further combined, so that the relation between the cigarette paper pore structure and the CO release in main stream smoke in the cigarette burning process can be accurately obtained, and theoretical direction is provided for research and production of cigarette paper with low CO release.

Owner:CHINA TOBACCO HUNAN INDAL CORP

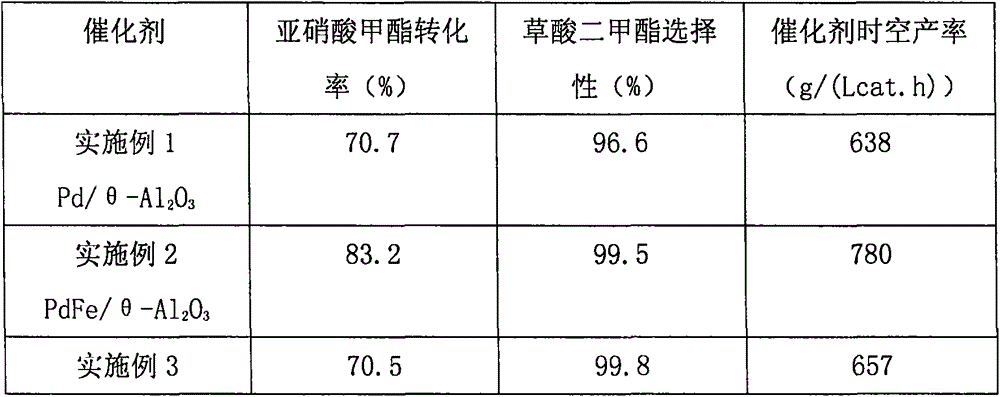

Catalyst used for synthesis of dimethyl oxalate from CO and preparation method and application thereof

InactiveCN105597741AGood dispersionIncreased space-time yieldPreparation by carbon monoxide or formate reactionMetal/metal-oxides/metal-hydroxide catalystsNanoparticleActive component

Owner:NINGBO JINYUANDONG PETROCHEM ENG TECH

Diaphragm for efficient lithium ion secondary battery and preparation method thereof

ActiveCN111341975AImprove flame retardant performanceReduce the risk of explosionSecondary cellsCell component detailsActivated carbonSurface oxidation

The invention discloses a diaphragm for an efficient lithium ion secondary battery. The diaphragm comprises polyethylene microporous layers and a composite material coating. The thickness of each polyethylene microporous layer is 5-10 [mu]m, the pore diameter is 0.03-0.12 [mu]m, and the porosity is 40-50%. The thickness of each composite material coating is 5-10 [mu]m. The material coating comprises the following raw materials in parts by weight: 90-95 parts of organic silicon resin, 5-10 parts of modified activated carbon and 20-30 parts of a curing agent, wherein the water content of the organic silicon resin is 0.5-1%, the modified activated carbon is modified activated carbon obtained by surface oxidation, and the modified activated carbon is nano modified activated carbon. The diaphragm comprises the polyethylene microporous layers and the composite material coating, and is specifically of a polyethylene-composite material-polyethylene layered structure, and organic silicon resinin the composite material layer has good flame retardance, so that the explosion risk of the battery is reduced.

Owner:SICHUAN YOUYUAN NEW ENERGY CO LTD

Slag-corrosion-resistant lightweight alumina clinker and preparation method thereof

Owner:WUHAN UNIV OF SCI & TECH

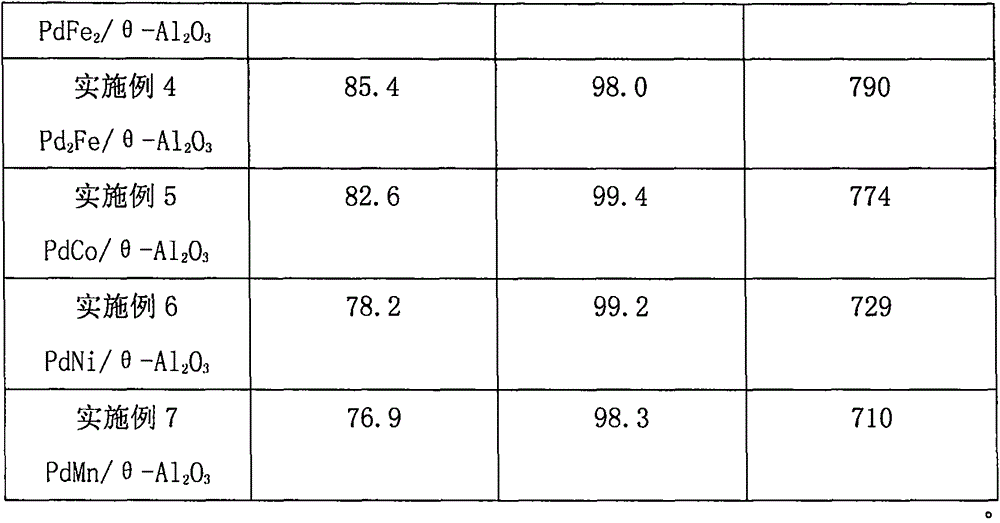

Preparation method of porous high-load electrode for lithium-sulfur battery

PendingCN113948678ARich porous structureIncrease the number ofElectrode rolling/calenderingElectrode thermal treatmentElectrolytic agentCarbon film

Owner:CHANGSHA RES INST OF MINING & METALLURGY +1

High-strength foam aluminum material and preparation method thereof

The invention discloses a high-strength foam aluminum material and a preparation method thereof and belongs to the technical field of aluminum materials. The foam aluminum material is prepared with aluminum powder and aluminum alloy powder as a base material and includes, by weight, 30-50 parts of aluminum powder, 15-30 parts of aluminum alloy powder, 5-15 parts of a foamer, 10-20 parts of asbestos fiber, 2-8 parts of potassium hexafluorozirconate, and 5-10 parts of silicon nitride. The aluminum alloy powder is Al / Mg alloy powder. The foamer is CaCO3 modified by a fluoride. The preparation method includes adding a dispersant to the components for dispersion and uniform mixing, and ball-milling, drying and sintering the mixture to obtain the material. By adding the silicon nitride and compounding the CaCO3 modified by a fluoride, the potassium hexafluorozirconate and the like with the base material, the foam aluminum material is high in strength, is high in porosity and small in pore diameter, and is low in density.

Owner:INNER MONGOLIA AGRICULTURAL UNIVERSITY

Foam concrete foaming agent

InactiveCN106007459AEvenly distributedDoes not significantly reduce strengthFoam concreteFatty alcohol

The invention discloses a foam concrete foaming agent, which comprises the following components in proportion by weight: 50-60 parts of hydrogen peroxide, 3-5 parts of hydrochloric acid, 2-3 parts of borax, 0.1-0.2 parts of rosin emulsion, fat Alcohol polyoxyethylene ether sodium sulfate 0.2-0.4 parts, magnesium sulfate 2-3 parts, water 28.4-42.7 parts, a total of 100 parts of each component. The invention has the advantages of strong foaming ability, uniform distribution of pores, small and consistent pore size, and does not significantly reduce the strength of the concrete under the premise of satisfying various properties of the foamed concrete.

Owner:JIANGSU MINGHE GRP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap