Method for testing relation between cigarette paper pore structure and CO release in main stream smoke in cigarette burning process

A mainstream flue gas and combustion process technology, applied in the direction of chemical analysis using combustion, can solve problems such as not meeting the development of the industry, and achieve the effect of simple and effective test methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

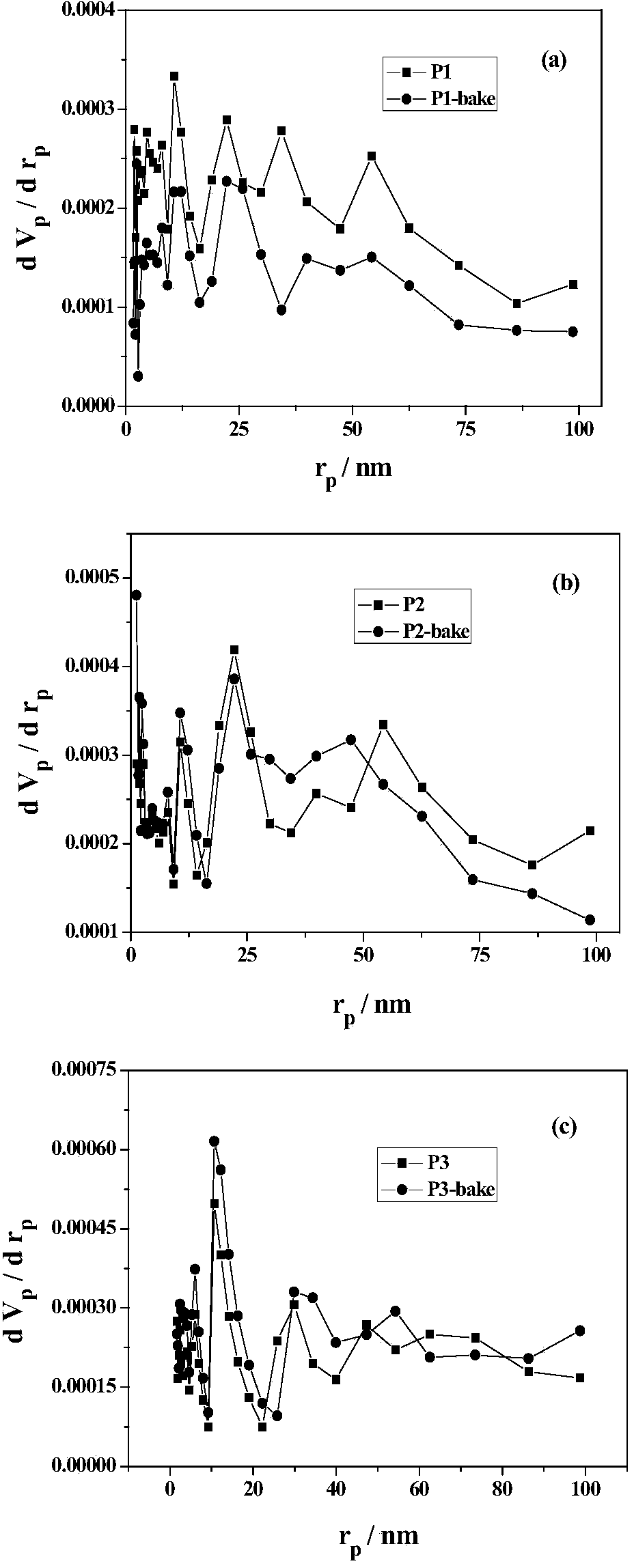

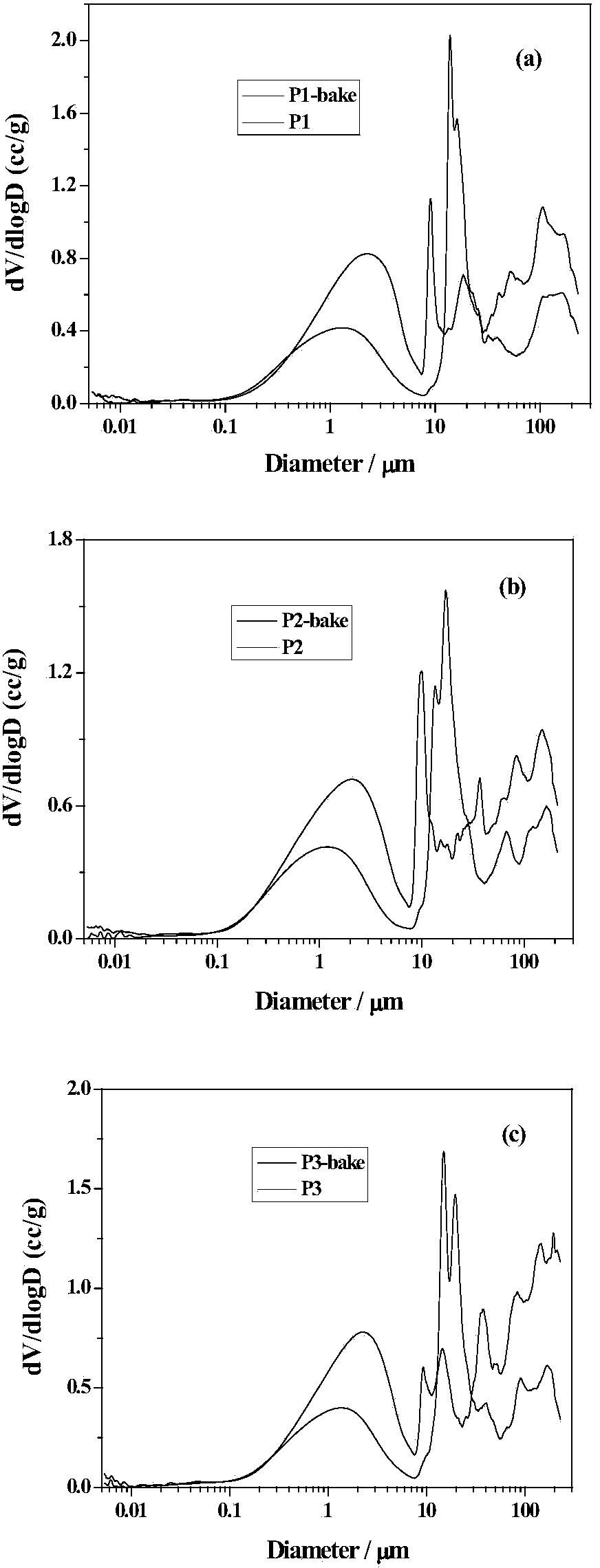

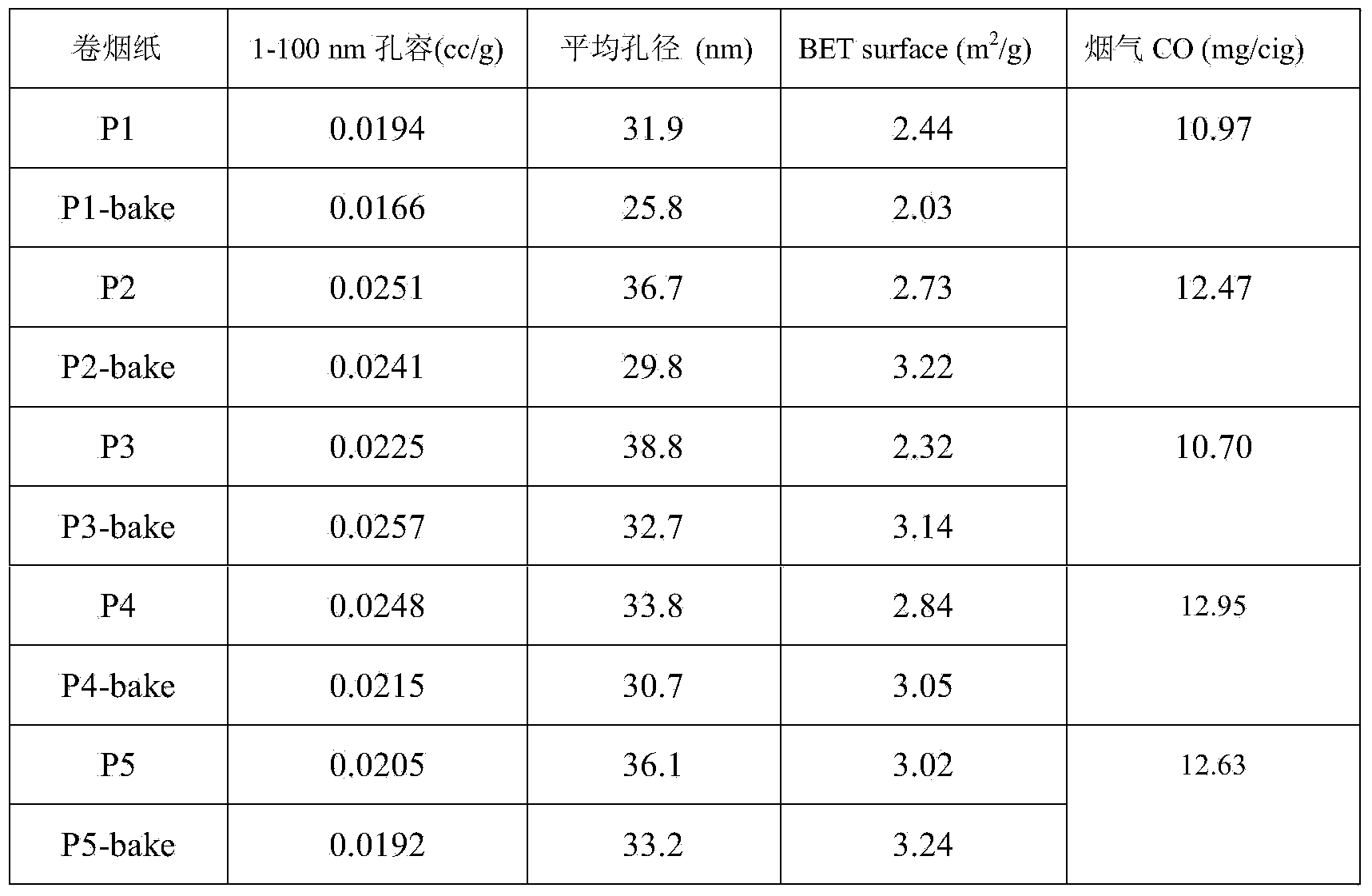

Embodiment 1

[0030] 1) Take A, B, and C three groups of 1# cigarette paper samples of the same type, and A cigarette paper includes A of the same type 1 and A 2 Cigarette paper, B cigarette paper including B 1 and B 2 cigarette paper;

[0031] Accurately weigh the mass of each cigarette paper sample: put the cigarette paper to be tested into a pre-weighed nitrogen adsorption-desorption sample tube, and pre-dry at 80°C for about 5 hours under nitrogen purge until all the water vapor is absorbed. Take it away, the quality of the cigarette paper will not change, put the dried sample tube in the cooling tank to cool to room temperature, weigh the quality of the sample tube again, and obtain the cigarette paper A 1 with B 1 The masses are 0.2228g and 0.2045g respectively, and put into the blank sample tube as a reference at the same time;

[0032] 2) will be fitted with a 1 Put the sample tube of cigarette paper into the nitrogen adsorption and desorption instrument, and put the A measure...

Embodiment 2

[0042] 1) Take A, B, and C three groups of 2# cigarette paper samples of the same type, A cigarette paper includes A of the same type 1 and A 2 Cigarette paper, B cigarette paper including B 1 and B 2 cigarette paper;

[0043] Accurately weigh the mass of each cigarette paper sample: put the cigarette paper to be tested into a pre-weighed nitrogen adsorption-desorption sample tube, and pre-dry at 80°C for about 5 hours under nitrogen purge until all the water vapor is absorbed. Take it away, the quality of the cigarette paper will not change, put the dried sample tube in the cooling tank to cool to room temperature, weigh the quality of the sample tube again, and obtain the cigarette paper A 1 with B 1 The masses are 0.1758g and 0.1857g respectively, and put into the blank sample tube as a reference at the same time;

[0044] 2) will be fitted with a 1 Put the sample tube of cigarette paper into the nitrogen adsorption and desorption instrument, and put the A measured in...

Embodiment 3

[0054] 1) Take A, B, and C three groups of 3# cigarette paper samples of the same type, A cigarette paper includes the same model A 1 and A 2Cigarette paper, B cigarette paper including B 1 and B 2 cigarette paper;

[0055] Accurately weigh the mass of each cigarette paper sample: put the cigarette paper to be tested into a pre-weighed nitrogen adsorption-desorption sample tube, and pre-dry at 80°C for about 5 hours under nitrogen purge until all the water vapor is absorbed. Take it away, the quality of the cigarette paper will not change, put the dried sample tube in the cooling tank to cool to room temperature, weigh the quality of the sample tube again, and obtain the cigarette paper A 1 with B 1 The masses are 0.2149g and 0.1985g, respectively, and put into the blank sample tube as a reference;

[0056] 2) will be fitted with a 1 Put the sample tube of cigarette paper into the nitrogen adsorption and desorption instrument, and put the A measured in step 1) 1 The mas...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap