Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

15 results about "Desorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Desorption is a phenomenon whereby a substance is released from or through a surface. The process is the opposite of sorption (that is, either adsorption or absorption). This occurs in a system being in the state of sorption equilibrium between bulk phase (fluid, i.e. gas or liquid solution) and an adsorbing surface (solid or boundary separating two fluids). When the concentration (or pressure) of substance in the bulk phase is lowered, some of the sorbed substance changes to the bulk state.

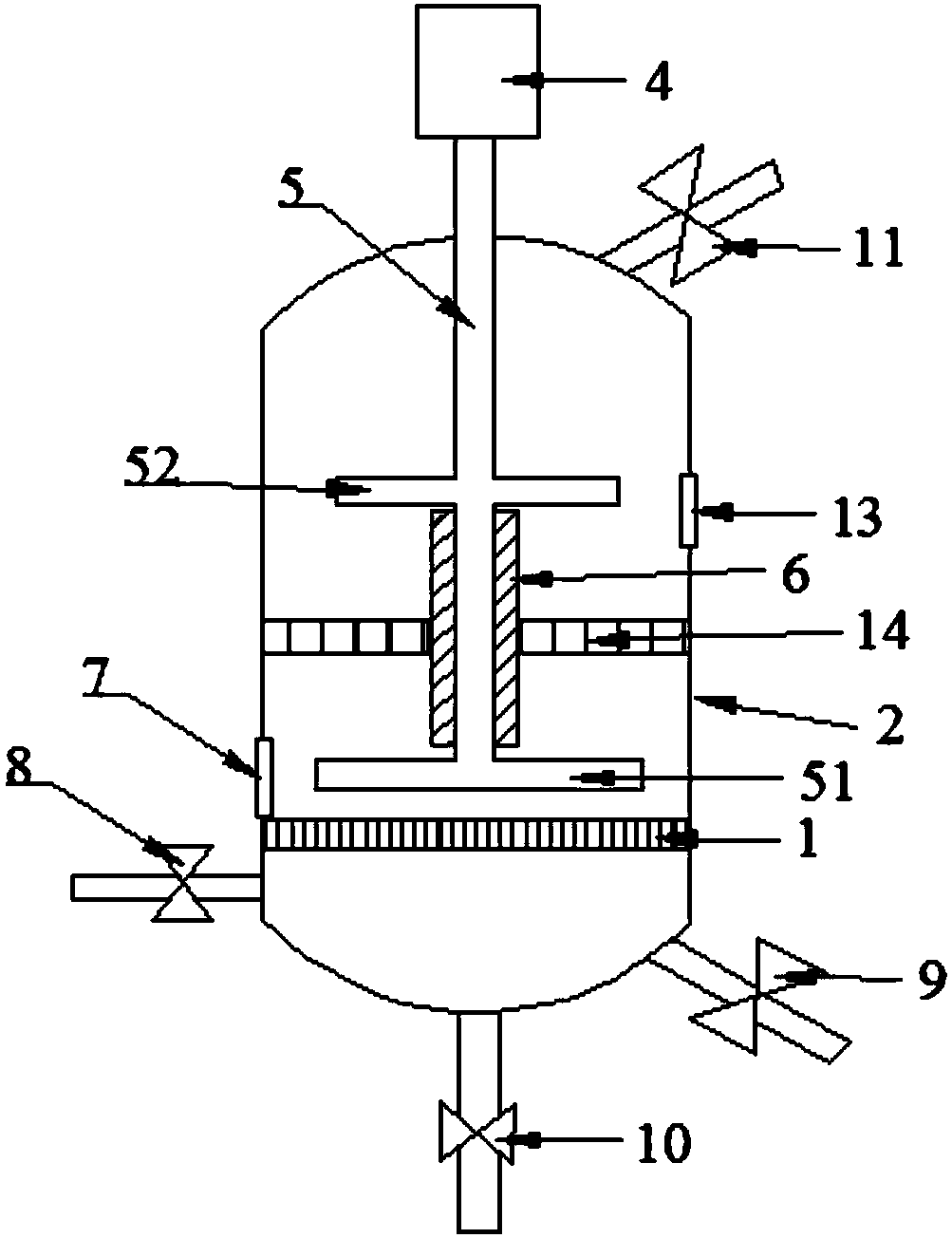

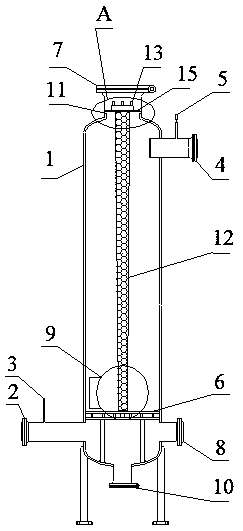

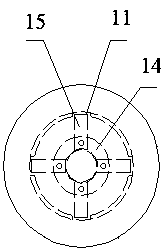

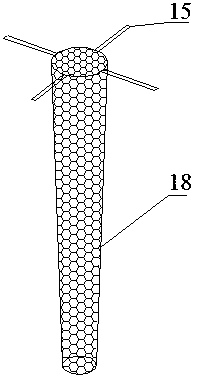

Microwave excitation coal-bed gas desorption and seepage experimental device

Owner:LIAONING TECHNICAL UNIVERSITY

Method for extracting lithium from brine to prepare battery-grade lithium carbonate by ion exchange method

ActiveCN106629789AHigh recovery rateLarge particle sizeHydrotalciteLithium carbonates/bicarbonatesDesorptionManganese

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Resin adsorption treatment process of high-salt wastewater containing amine system

PendingCN109912098AEfficient removalBiotoxicMultistage water/sewage treatmentWater/sewage treatment by sorptionAdditive ingredientDesorption

The invention discloses a resin adsorption treatment process of a high-salt wastewater containing an amine system. The resin adsorption treatment process mainly comprises the following specific steps:adjusting the pH value of raw water, feeding the adjusted raw mater into a raw water pool, pumping the raw water into a precise filter and filtering out mechanical impurities; enabling outlet water to enter a resin adsorption tower; enabling outlet water after resin adsorption to enter a resin outlet water tank, performing triple effect evaporation for evaporative crystallization and enabling mother liquid to return to a raw water buffer tank; performing desorption after adsorption, washing with water and enabling washing water to enter the raw water pool; performing desorption with methanol,evaporating desorption liquid and enabling evaporated methanol to enter a rectifying tower for refining; washing with water, feeding washing water into the rectifying tower for refining, recycling methanol at the top of the tower and feeding kettle residues into a dehydrogenation tower; enabling an ingredient at the top of the dehydrogenation tower to return to the rectifying tower and feeding kettle residues into the raw water pool. Compared with the prior art, the resin adsorption treatment process has the advantages of being low in operating cost, low in investment cost of equipment and high in removal rate, causing no secondary pollution, being cleaner, being high in selectivity and good in regeneration of the equipment and having reusability.

Owner:NANJING JIANDI ENVIRONMENTAL ENG CO LTD

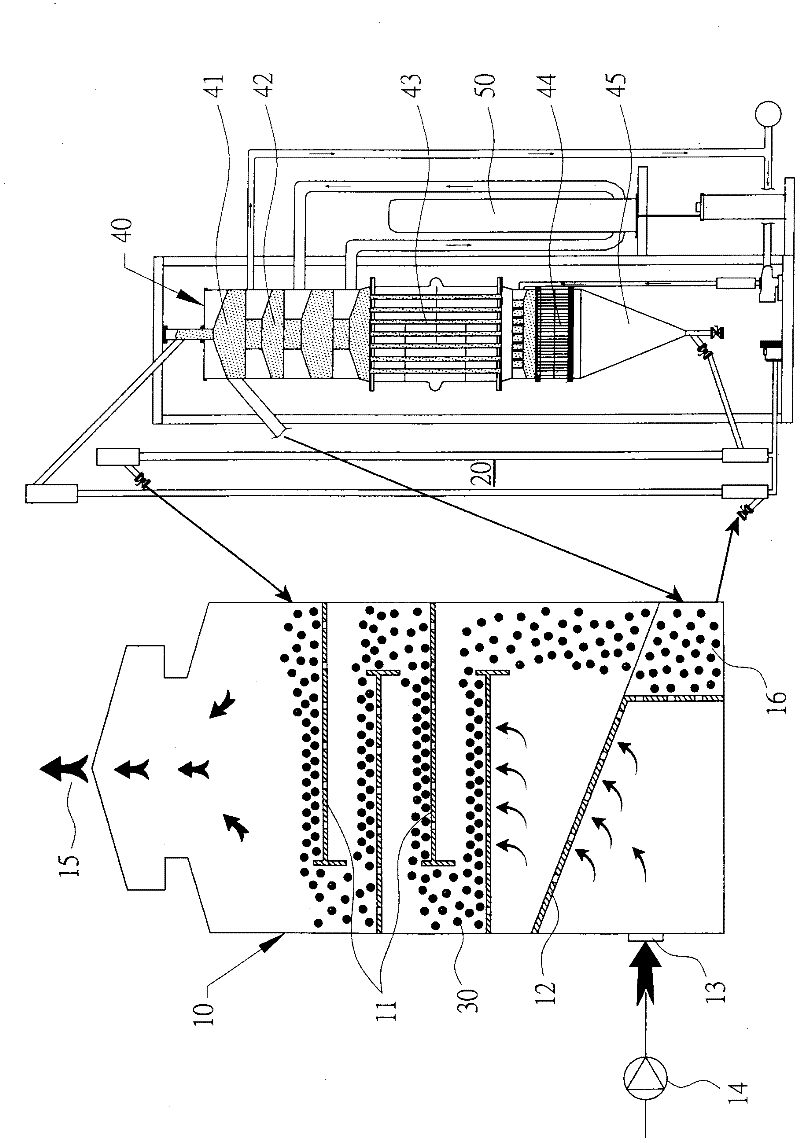

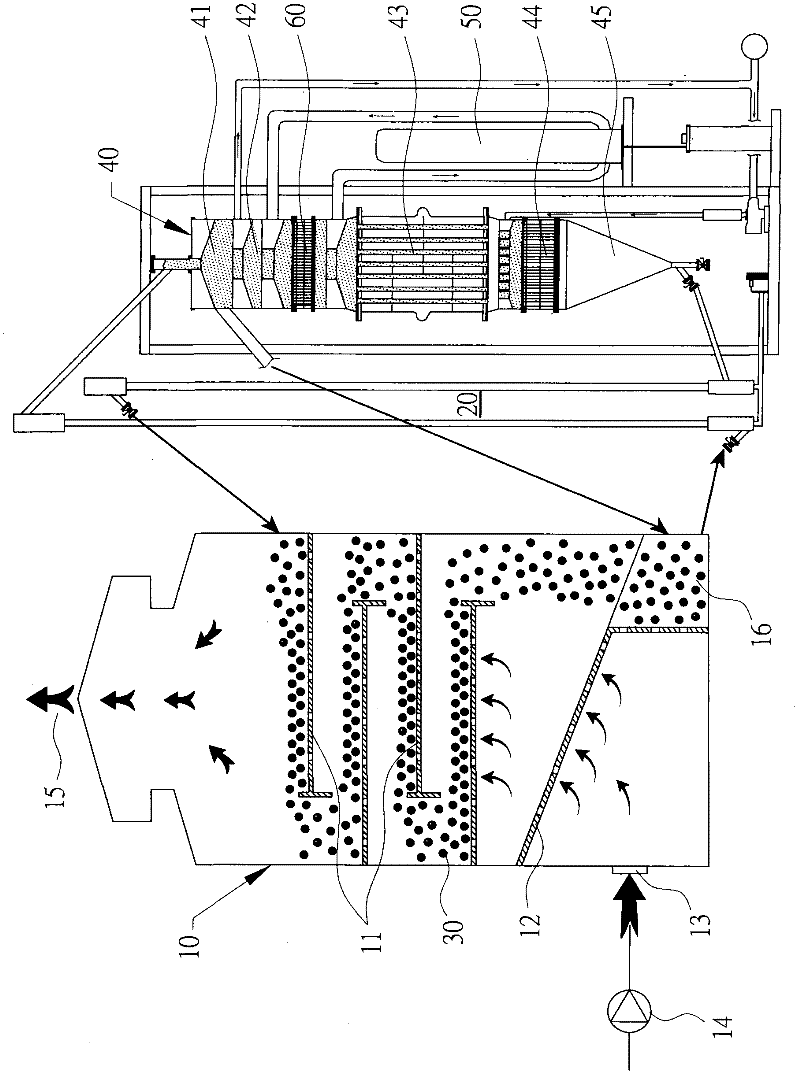

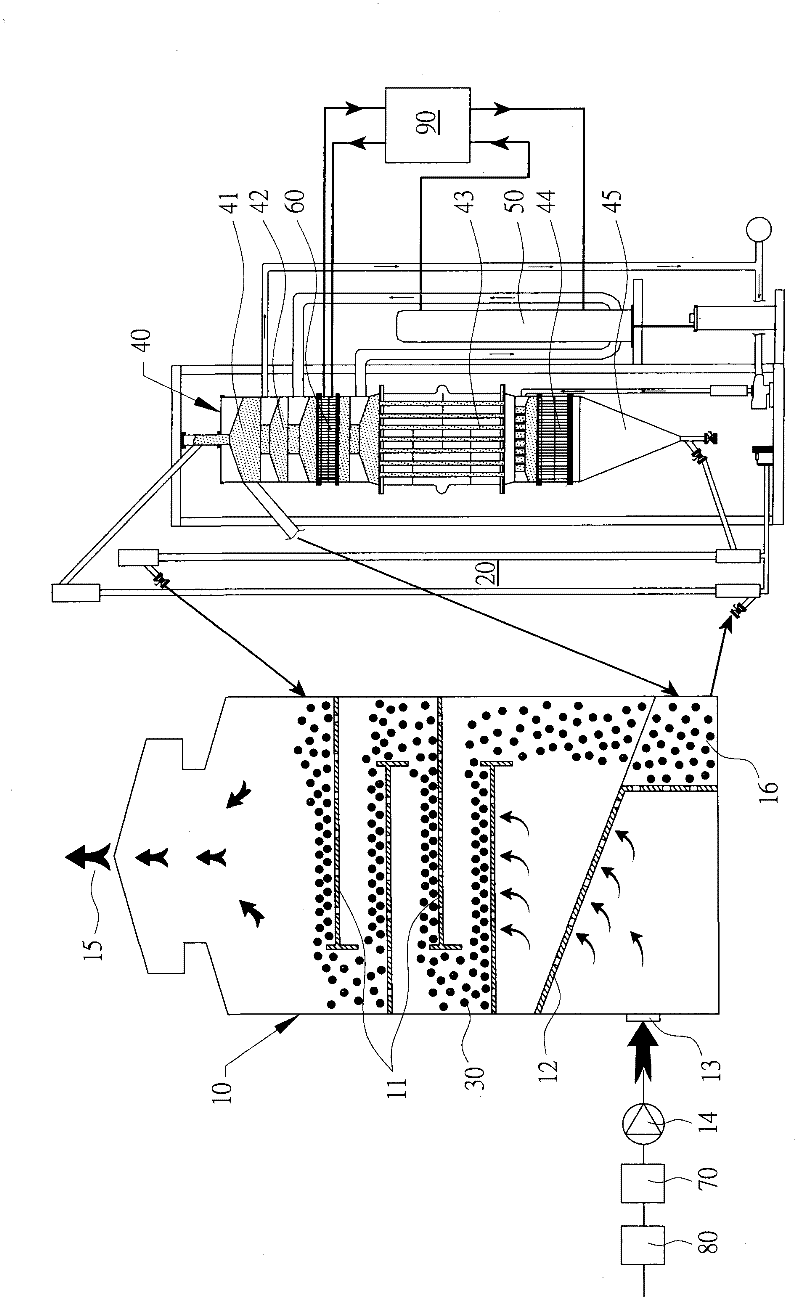

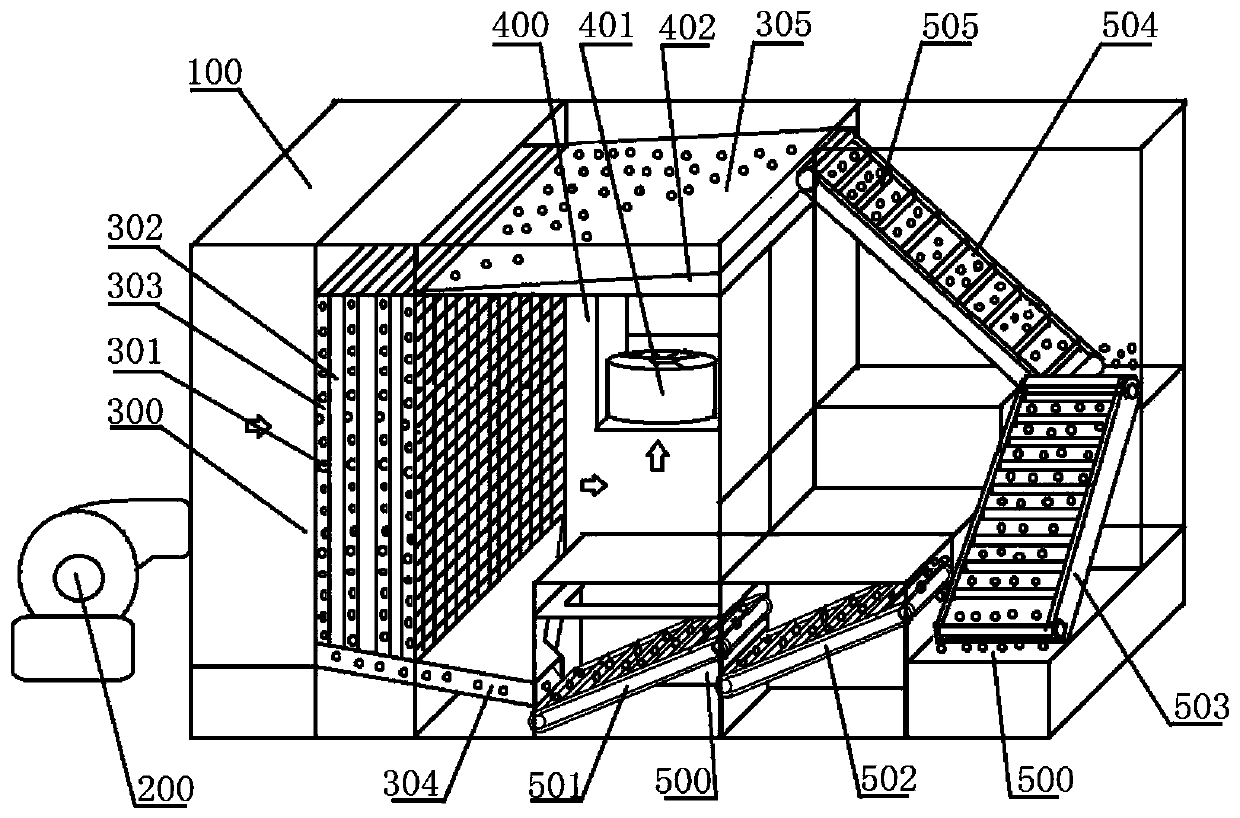

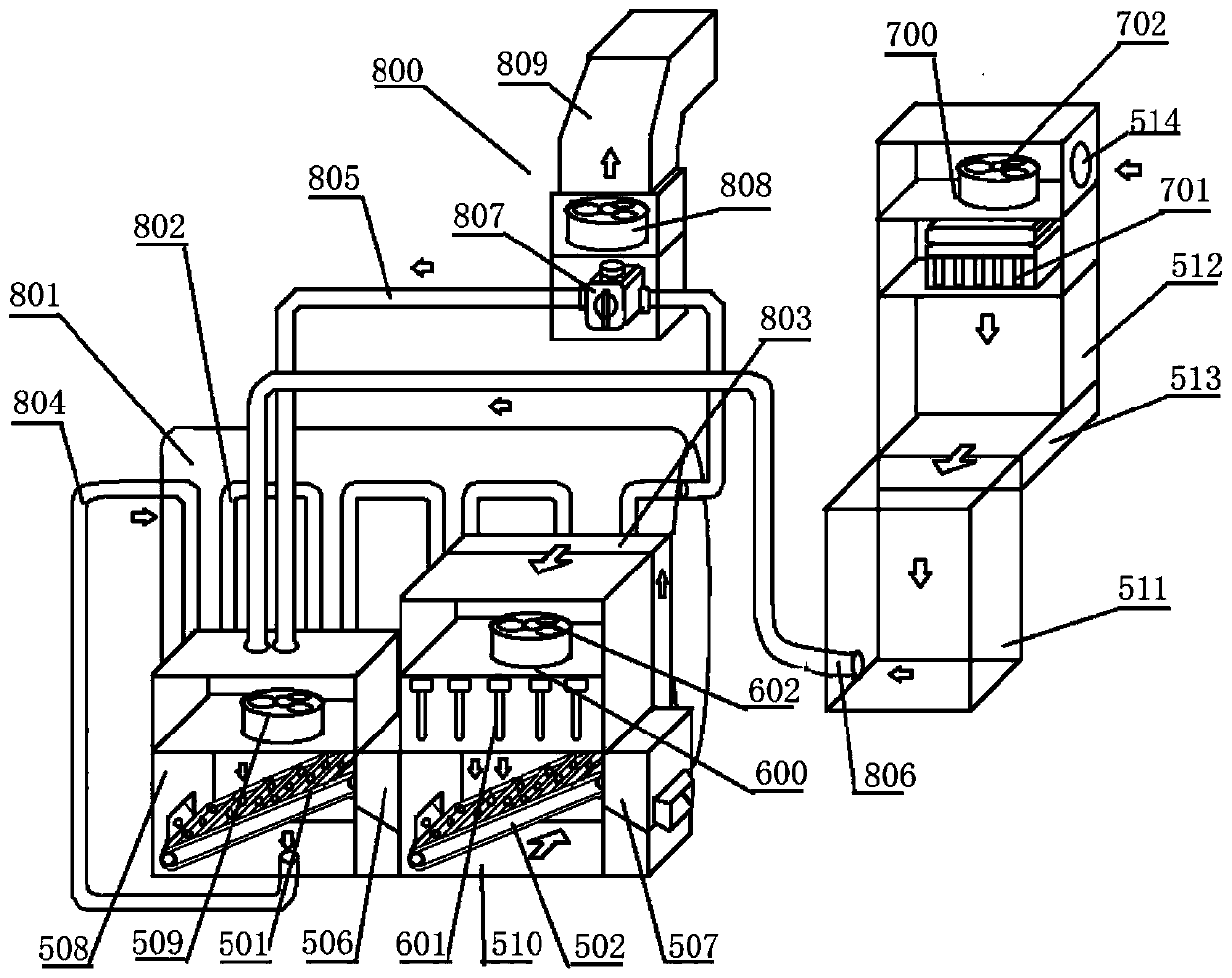

Organic waste gas purifying system and method for preventing surface of absorbing material from condensing and caking

InactiveCN102205197AAvoid condensationAvoid cakingDispersed particle separationCombustible gas purificationDesorptionEngineering

Owner:JG ENVIRONMENTAL TECH +1

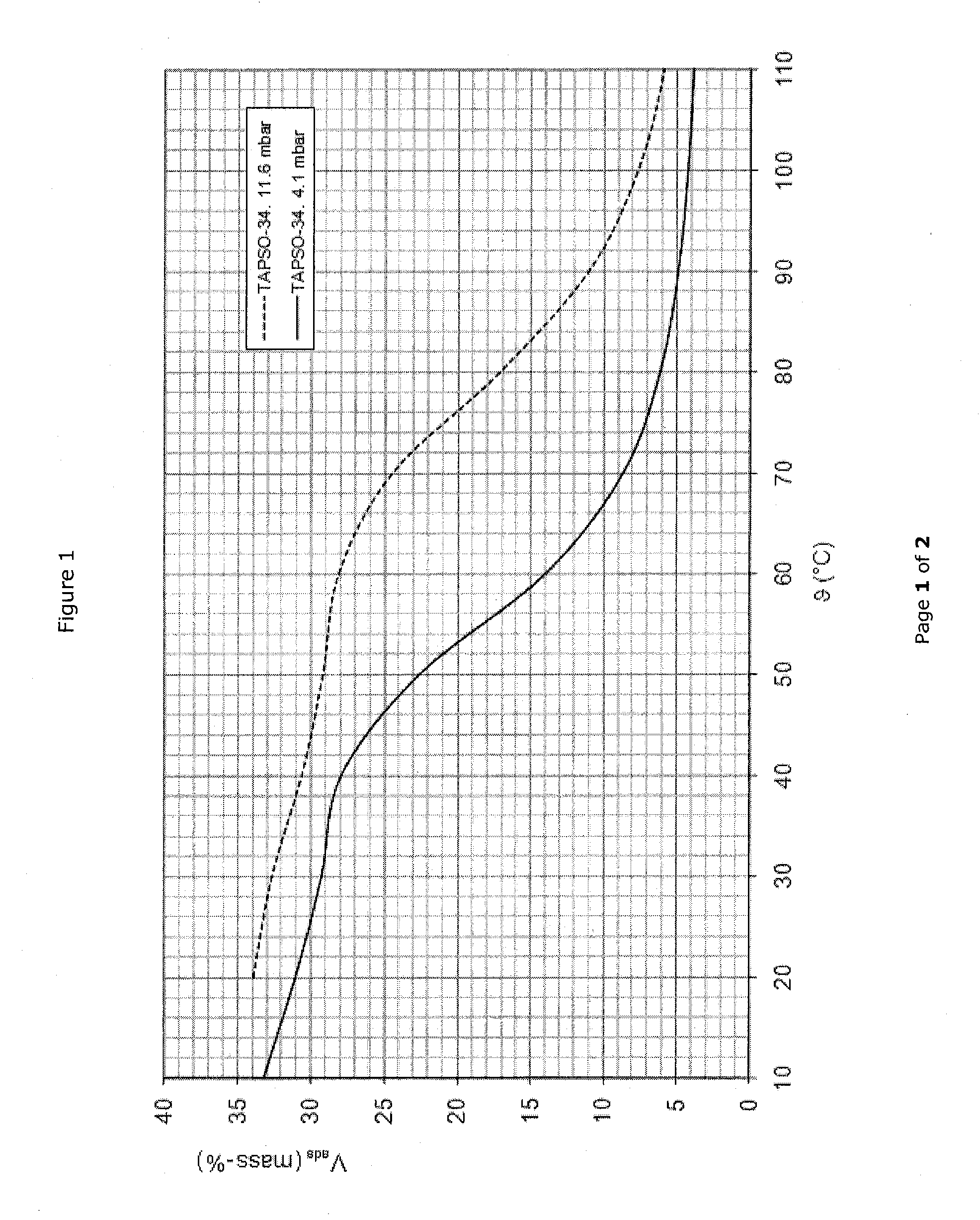

Drying device containing a titanium aluminum phosphate

InactiveUS20120159804A1Low costWeaken energyAluminium compoundsSilicon halogen compoundsSodium aluminium phosphatePhosphate

Owner:CLARIANT INT LTD

Method for recovering gold from printed circuit board of waste mobile phone

ActiveCN108642289AImprove adsorption efficiencyAchieve reuseOther chemical processesProcess efficiency improvementElectrolysisResource utilization

Owner:NANKAI UNIV

VOC runner performance testing device

InactiveCN107727795AWill not cause secondary pollutionMeet the needs of wheel testingGas treatmentDispersed particle separationCombined testDesorption

The invention discloses a VOC runner performance testing device. According to the device, a large circulating pipe, a VOC solvent box and an air compressor are sequentially connected by virtue of airpipes; the large circulating pipe is sequentially connected with a fresh air mixing box, a VOC adsorption runner, a fan and an air exhausting device; a middle circulating pipe is sequentially connected with the VOC adsorption runner, a purifier, a heat exchanger, a heat exchange unit and a fan; a small circulating pipe is sequentially connected with the heat exchange unit and a catalytic combustion device; the heat exchanger is connected with the large circulating pipe by virtue of an air pipe penetrating through the VOC adsorption runner, and is connected with the air exhausting device by virtue of an air pipe. Compared with the prior art, the VOC runner performance testing device disclosed by the invention has the advantages that the VOC runner can be subjected to comprehensive evaluation, secondary pollution is avoided, and requirements on various runner tests are met. Moreover, the device disclosed by the invention is creative, is provided with the novel large circulating pipe, middle circulating pipe and small circulating pipe, is capable of comprehensively testing the treatment capacity and desorption ability of the VOC runner and is high in efficiency and excellent in effect.

Owner:PURESCI ENVIRONMENTAL TECH CO LTD

Catalyst used in oxidative desorption of carbon monoxide in hydrogen and preparation method for catalyst

ActiveCN102921431AReduce usageReduce dosageHydrogen separationMetal/metal-oxides/metal-hydroxide catalystsHigh concentrationCarrying capacity

Owner:DALIAN CATALYTIC ENG TECH

Air purification device and method

PendingCN110180324AEfficient removalTo achieve the purification effectGas treatmentDispersed particle separationMolecular sieveDesorption

Owner:GUANGDONG CHENGYU IND CO LTD

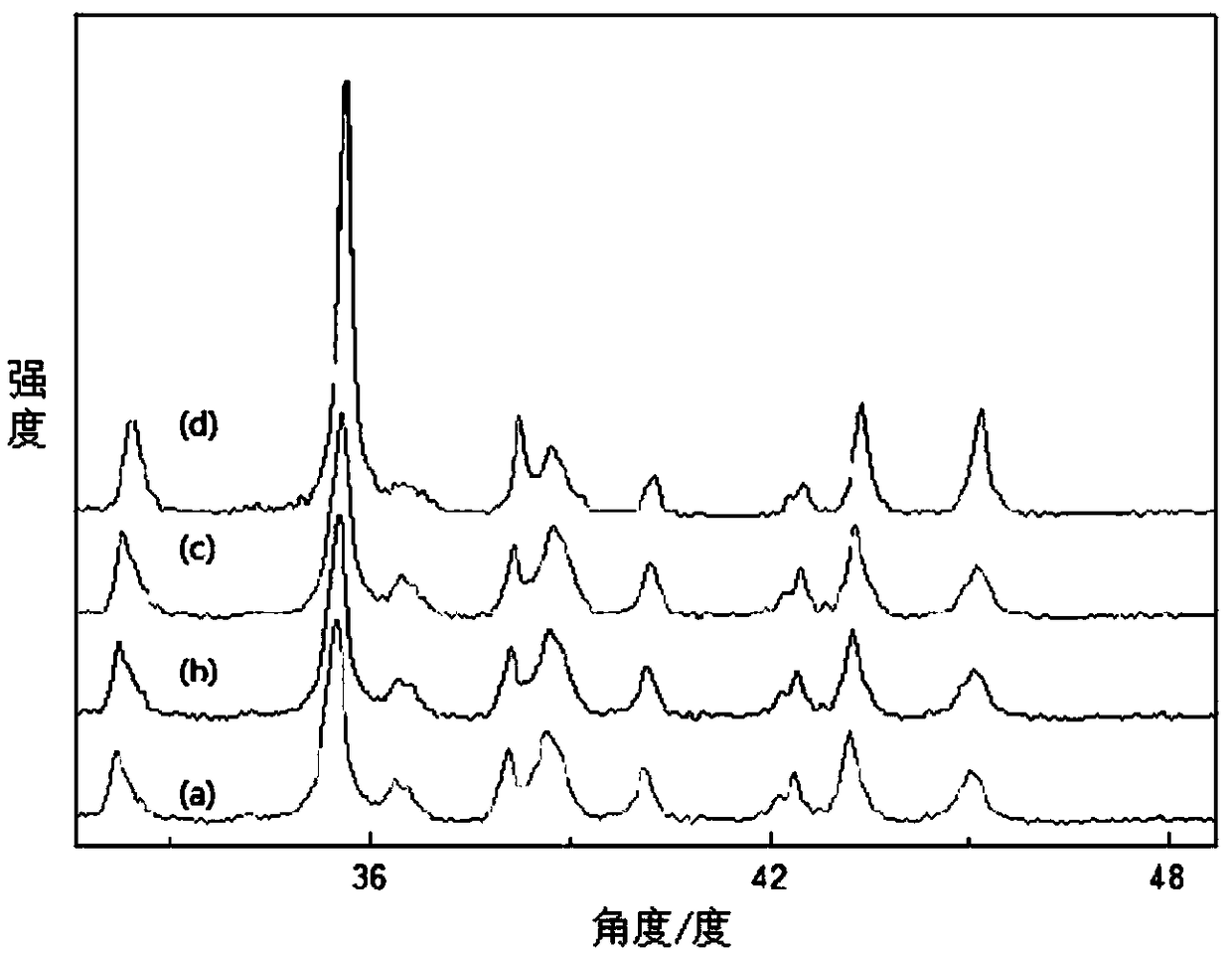

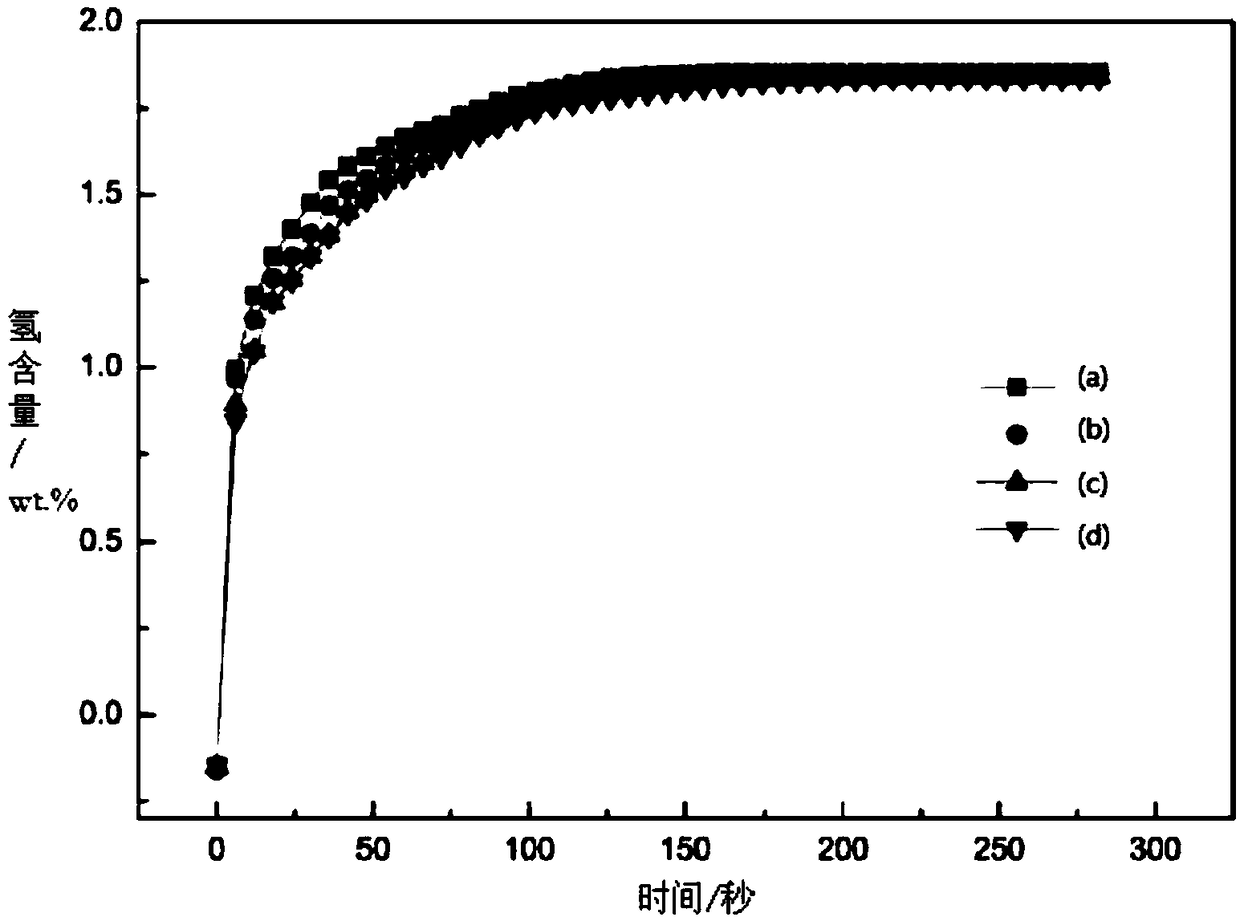

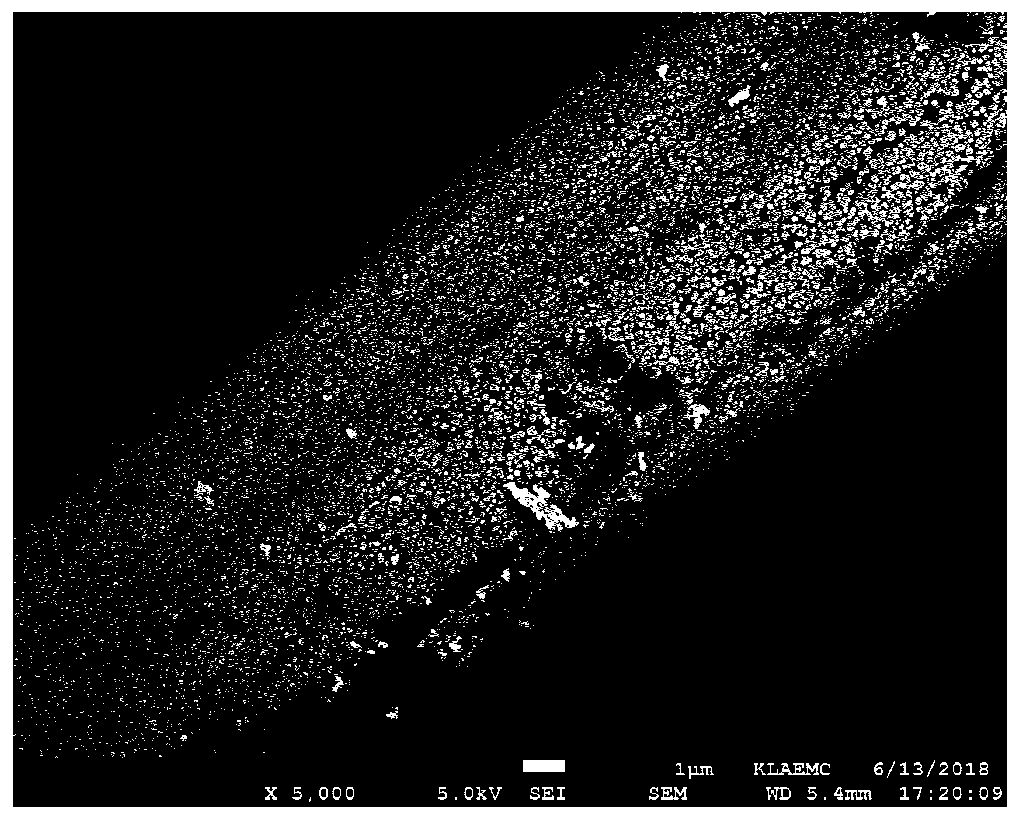

Zr-Fe alloy for tritium storage and preparation method thereof

InactiveCN108149070ALow costFast rate of hydrogen absorption and desorption (tritium)Electric arc furnaceDesorption

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Method for directly scenting scented tea by using fragrance adsorbent

The invention relates to a method for directly scenting scented tea by using a fragrance adsorbent. The fragrance adsorbent after saturation adsorption is mixed with a desorption solvent so as to be directly added to a scenting device, and basic tea in the scenting device is prepared into scented tea. The method comprises the following manufacturing steps of: firstly, refiring the basic tea to be dried, adjusting the optimum moisture content of the basic tea to be scented, and then putting into a saucer of the scenting device; mixing 5% to 50% fragrance adsorbent by weight percent of the basic tea and 0.5 to 3 times the desorption solvent by weight percent of the fragrance adsorbent so as to be sealed, placing the mixture into a cooler so as to be cooled to -5 DEG C to -30 DEG C, then putting the mixture into the scenting device, and sealing the scenting device; or firstly, cooling 5% to 50% fragrance adsorbent by weight percent of the basic tea at the temperature of -5 DEG C to -30 DEG C, quickly putting the fragrance adsorbent into a sealing tank at the temperature of 50 DEG C to 100 DEG C so as to be desorbed for 5 to 30 minutes, circularly sending the fragrance adsorbent into the sealed scenting device by an exhaust fan through a pipeline, and providing proper scenting conditions such as temperature and humidity so as to scent the basic tea into the scented tea.

Owner:NANNING CHEM IND RES & DESIGN INST

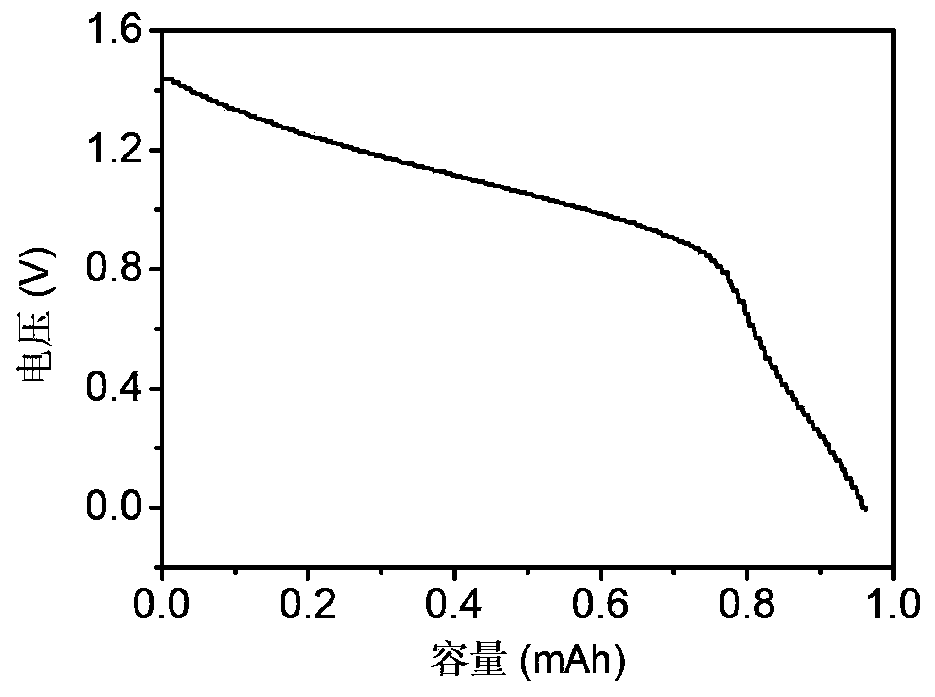

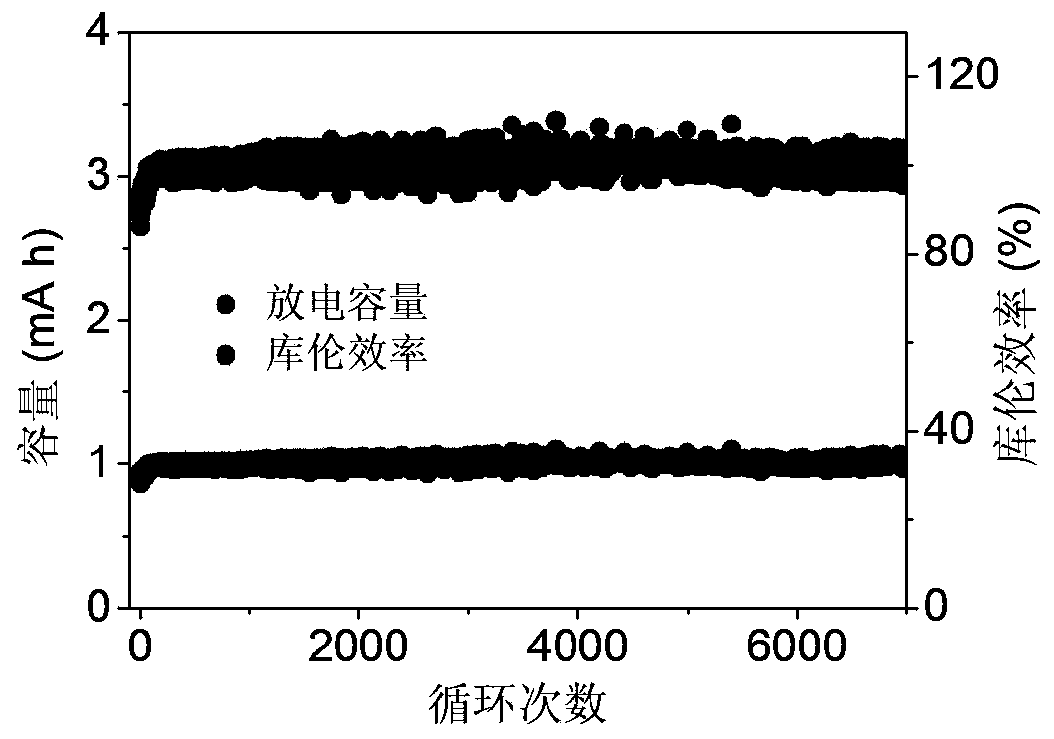

Long-cycle high-rate aqueous sodium-manganese battery

InactiveCN110061310ACathodic reaction kinetics are fastImprove cycle stabilityFinal product manufactureSecondary cellsHigh rateElectrical battery

Owner:NANKAI UNIV

Active carbon recovery apparatus

InactiveCN108014763AImprove desorption efficiencyFast regenerationSpecific water treatment objectivesCombustible gas purificationActivated carbonFiltration

Owner:天津道森科技发展有限公司

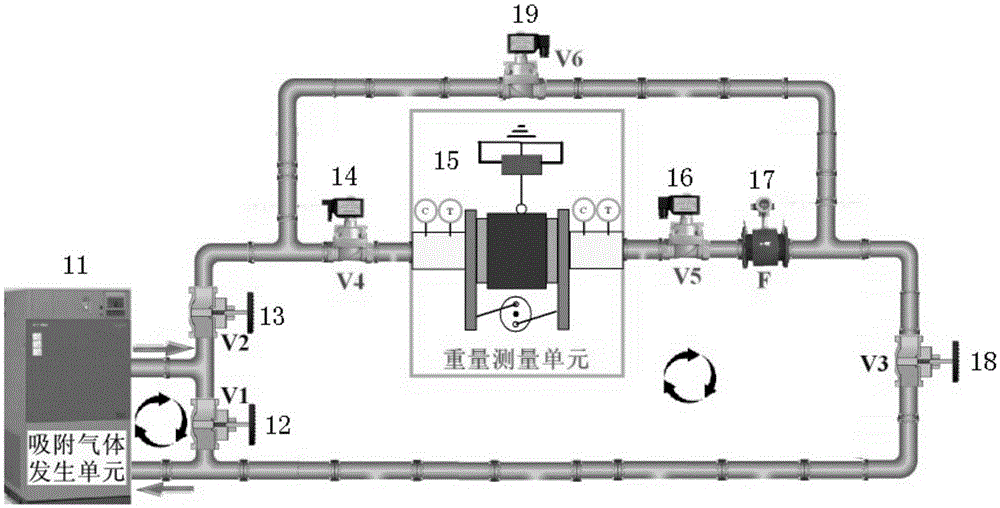

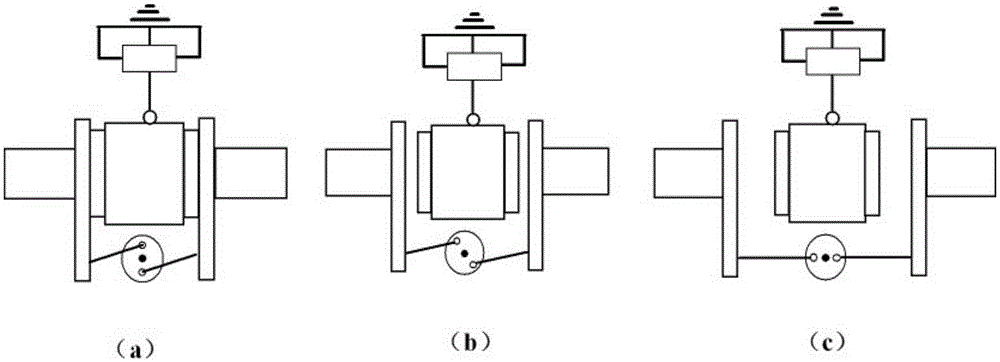

Method and device for measuring performances of gas adsorbent material with gravimetric method

ActiveCN105300828AAccurate and direct measurementGet rid of uncertaintyWeighing by absorbing componentSorbentDesorption

Owner:XI AN JIAOTONG UNIV

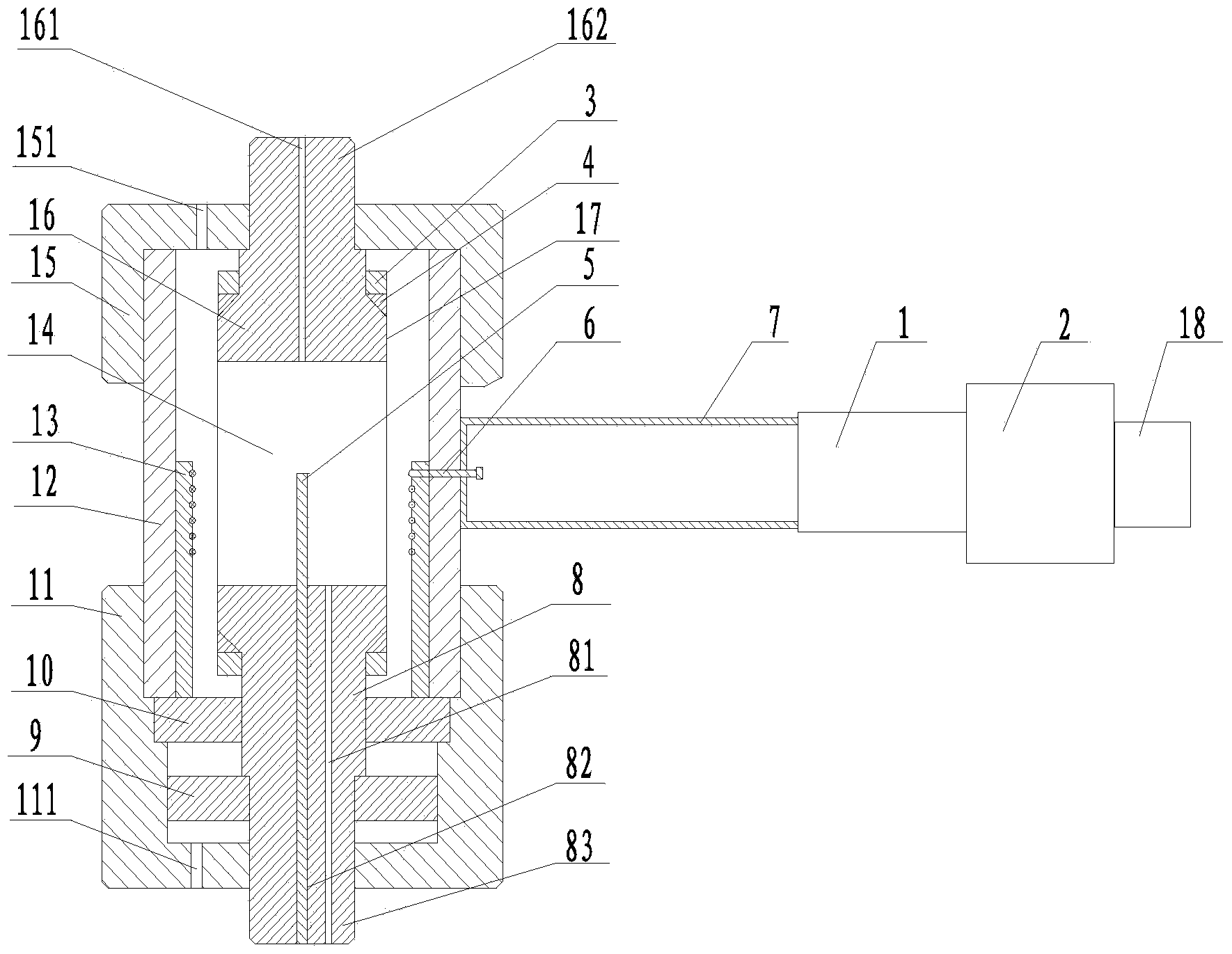

Oil and gas adsorption tower packing sampling device and sampling method

ActiveCN109406332ASimple structureReduce manufacturing costWeighing by removing componentWeighing by absorbing componentDesorptionEnvironmental engineering

Owner:CHANGZHOU UNIV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap