Oil and gas adsorption tower packing sampling device and sampling method

A sampling device and adsorption tower technology, which is applied to the field of packing sampling devices for oil and gas adsorption towers, can solve problems such as difficult sampling of adsorbents, and achieve the effects of avoiding poor results, simple structure and low preparation cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0031] It should be noted that the embodiments provided by the present invention are only for effectively explaining the technical features of the present invention, and the positioning words such as left, right, upper end, and lower end are only for better understanding of the embodiments of the present invention. The description should not be regarded as a limitation on the technical solution of the present invention.

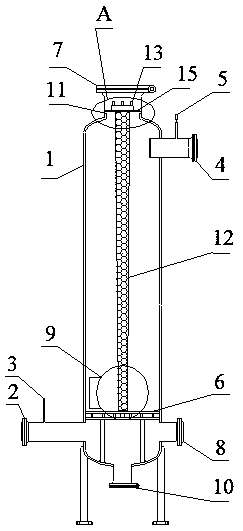

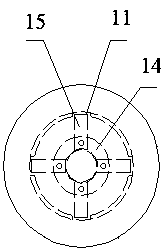

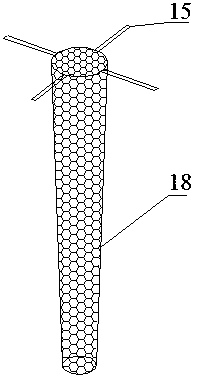

[0032] In order to solve the problem of difficult sampling of the adsorbent in the oil and gas adsorption equipment in the prior art, the present invention discloses a packing sampling device for the oil and gas adsorption tower. Trachea 2, right top is exhaust pipe 4, and right bottom is desorption p

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Mesh diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap