Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

66 results about "Exhaust pipe" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

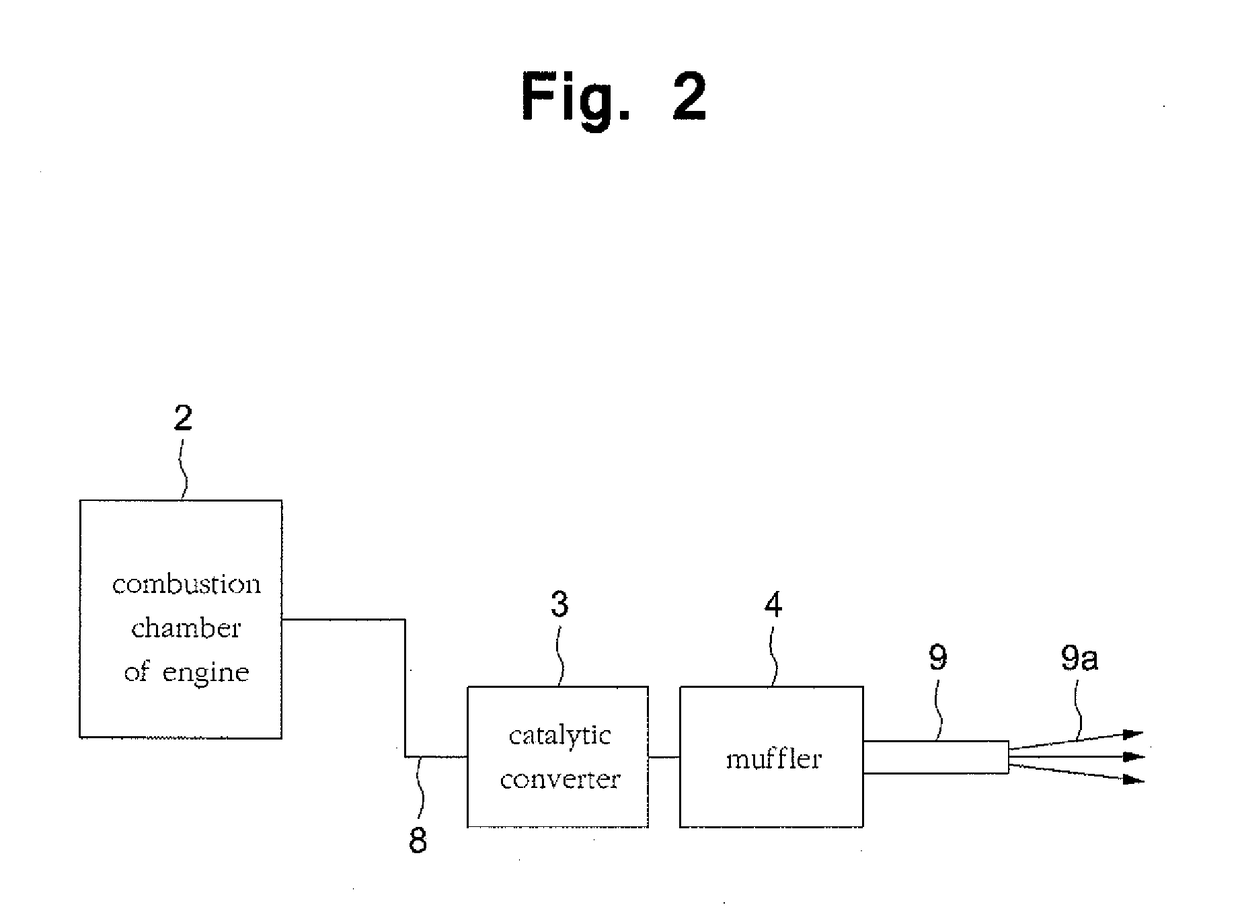

Aftertreatment system and control strategy for internal combustion engine

ActiveUS20120260633A1Shorten speedBreakage of the DPFElectrical controlNon-fuel substance addition to fuelExternal combustion engineLow load

In an exhaust gas treatment device in which a diesel oxidation catalyst and a DPF are provided in an exhaust pipe of an internal combustion engine, abnormal combustion in the DPF, occurring when the internal combustion engine varies from a high load condition to a low load condition, poses a problem. To solve this problem, in the present invention, a DPF abnormal combustion causing operation is determined to have occurred when the internal combustion engine shifts from a high rotation or high load operation region α to a low rotation, low load operation region β within a set time T1. When it is determined that a DPF abnormal combustion causing operation has occurred, abnormal combustion of PM collected in the DPF is suppressed by fully opening an intake throttle valve 44 in order to increase an exhaust gas flow so that heat is removed by sensible heat of the exhaust gas, thereby cooling a DPF device 52, and continuing a late post-injection in order to reduce an oxygen concentration of the DPF. As a result, an abnormal temperature increase in the DPF device 52 can be suppressed early.

Owner:MITSUBISHI HEAVY IND ENGINE & TURBOCHARGER LTD

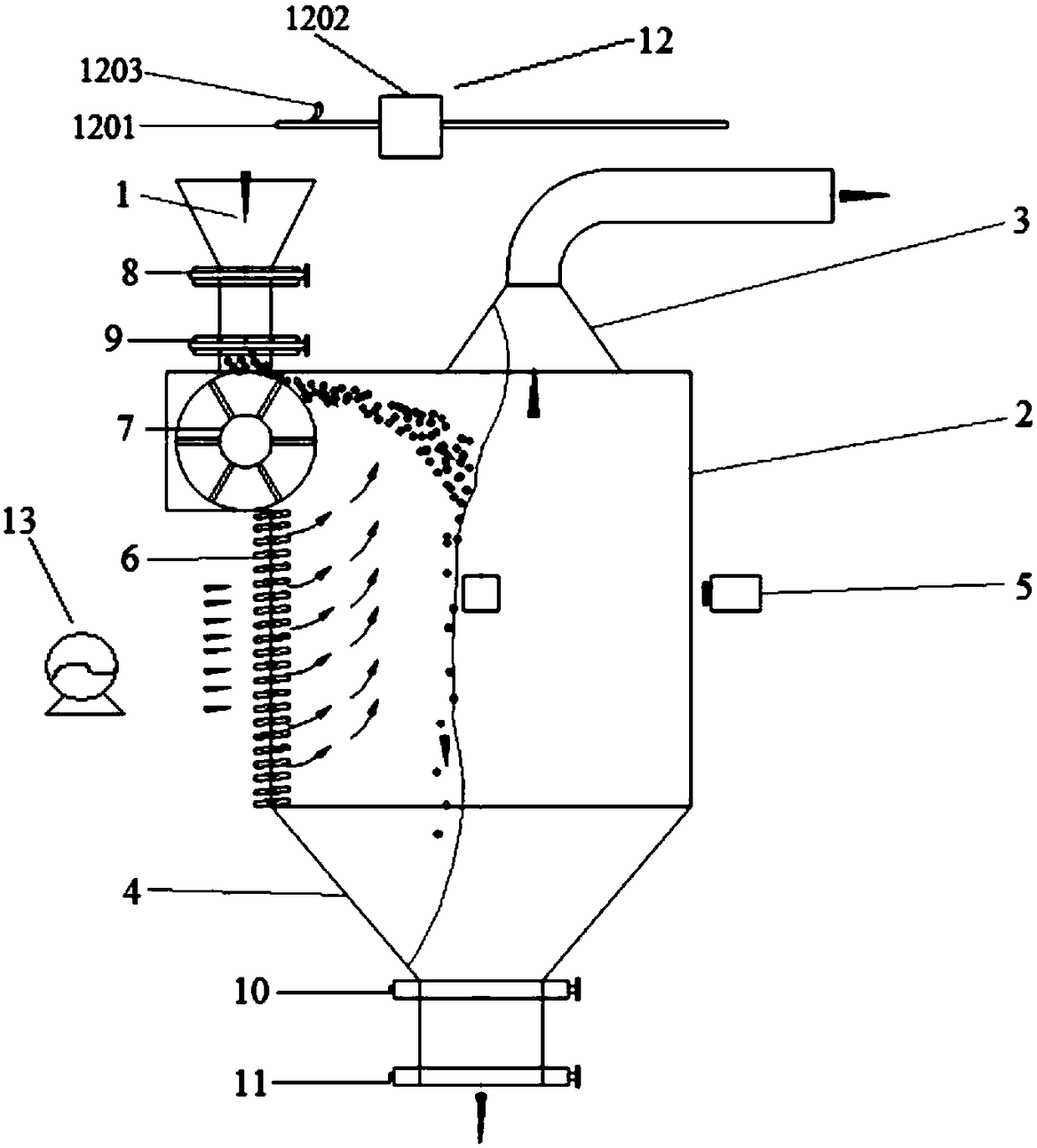

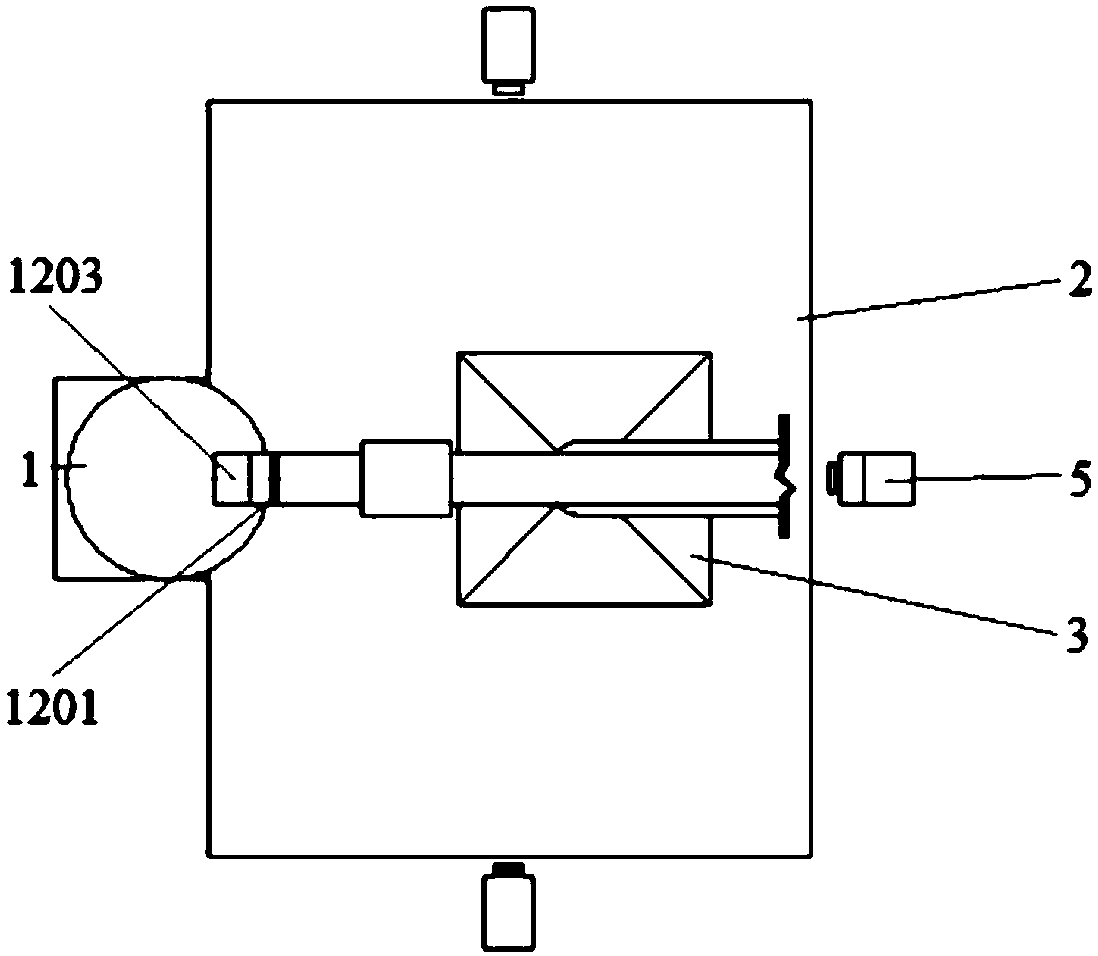

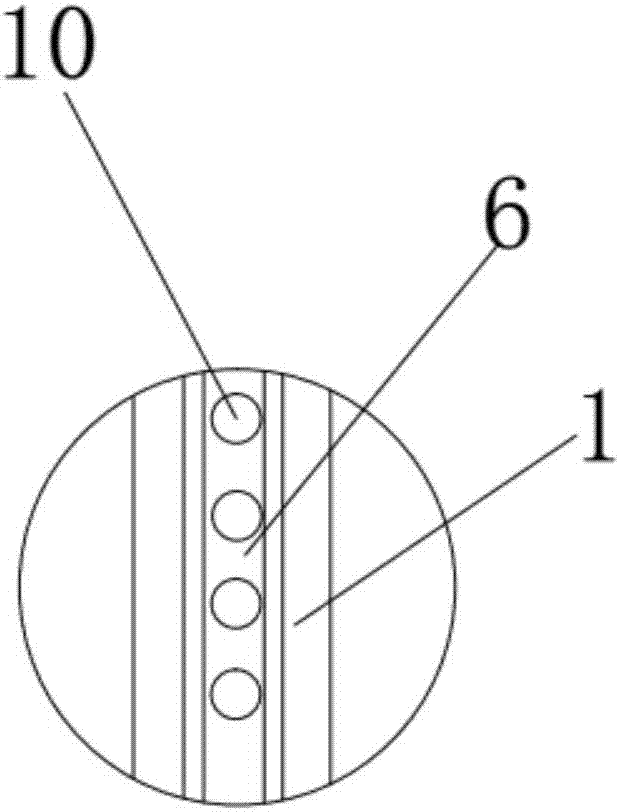

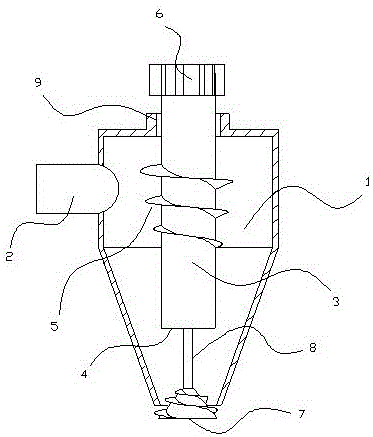

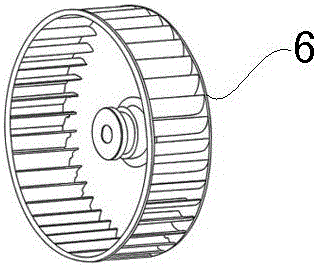

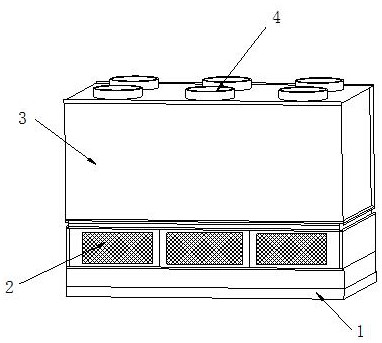

Multiple spiral dust collector

InactiveCN1548245AReduce interactionReduce resistanceSuction filtersVortex flow apparatusEngineeringAtmospheric pressure

The present invention is multiple vortex dust collector in duster. The multiple vortex dust collector includes cylindrical vortex body with partitioning wall to separate it two parts including the lower or first part and the upper or the second part. The first vortex part is provided with sucking pipe, pollutant exhaust hole, the first dust collecting chamber with exhaust port in the center of the partitioning wall, and leading pipe to the second vortex part. The second vortex part has central exhaust pipe with filtering part and sucking force generator, pollutant exhaust hole, and the second dust collecting chamber. The present invention has basically the same pollutant and air sucking direction and vortex and exhaust direction, reduced conflict between the ascending airflow and vortex, reduced friction resistance, less pressure loss, less noise and less pollutant jamming in filtering part.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

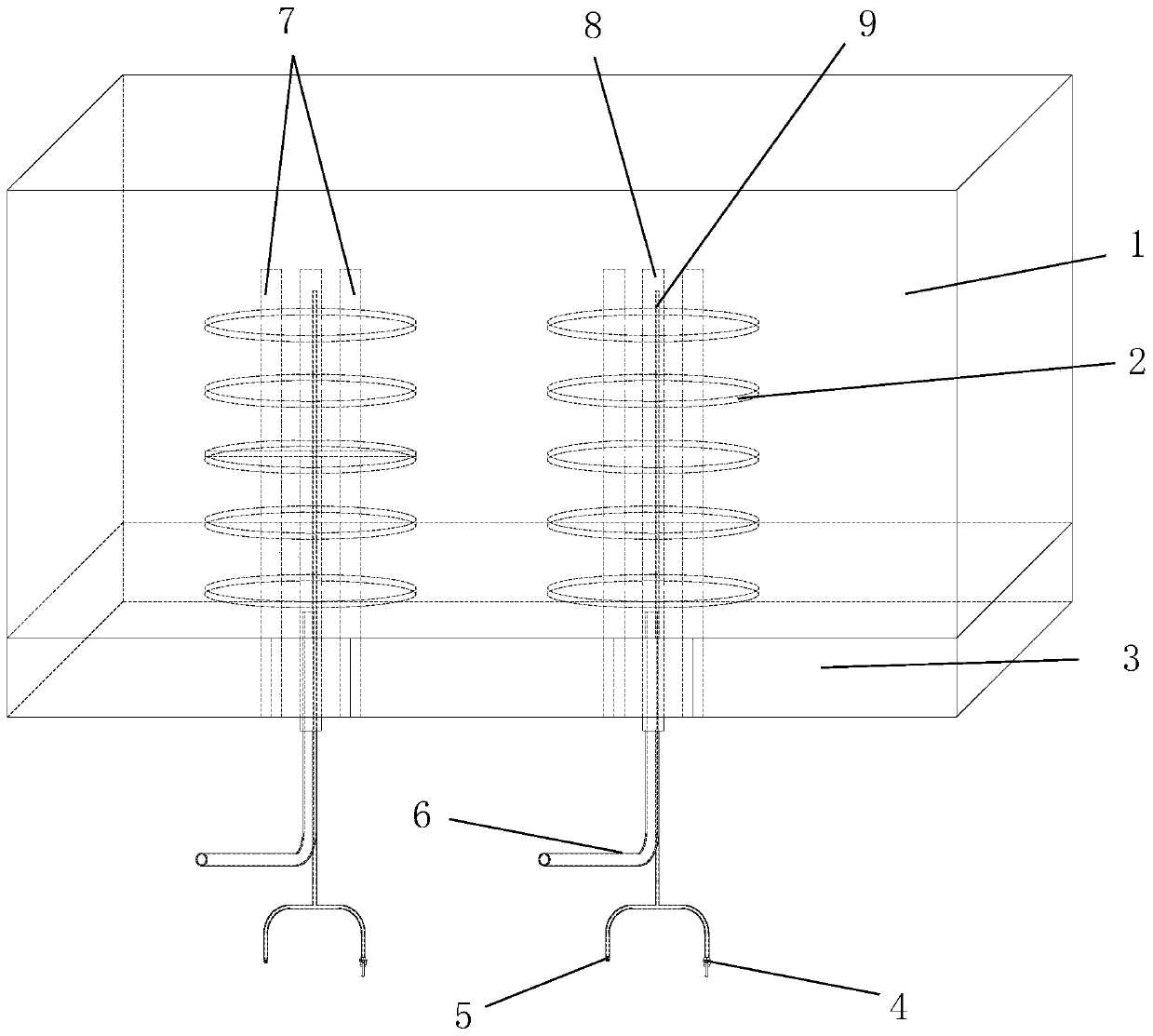

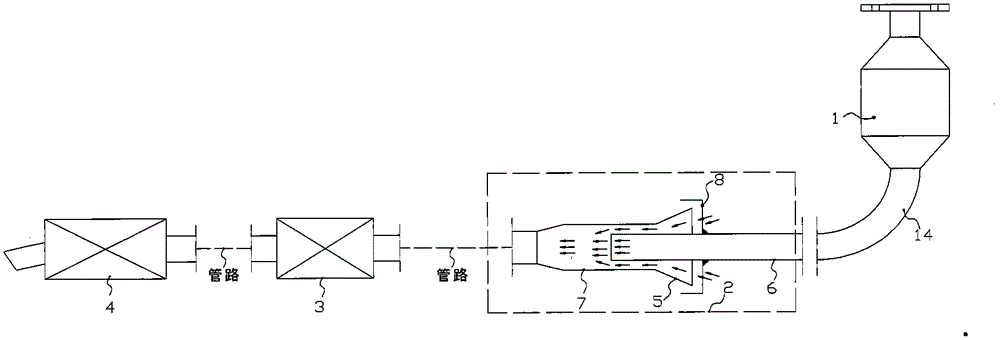

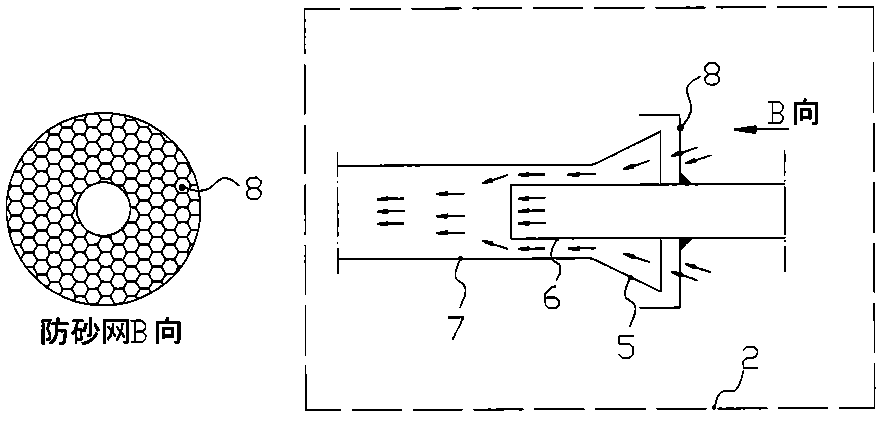

Coal seam anti-reflection method for circular damage by using cold shock of liquid nitrogen and phase change gas

ActiveCN111119829AGood cracking and anti-reflection effectFast injectionDrilling rodsFluid removalEngineeringNitrogen gas

Owner:CHINA UNIV OF MINING & TECH

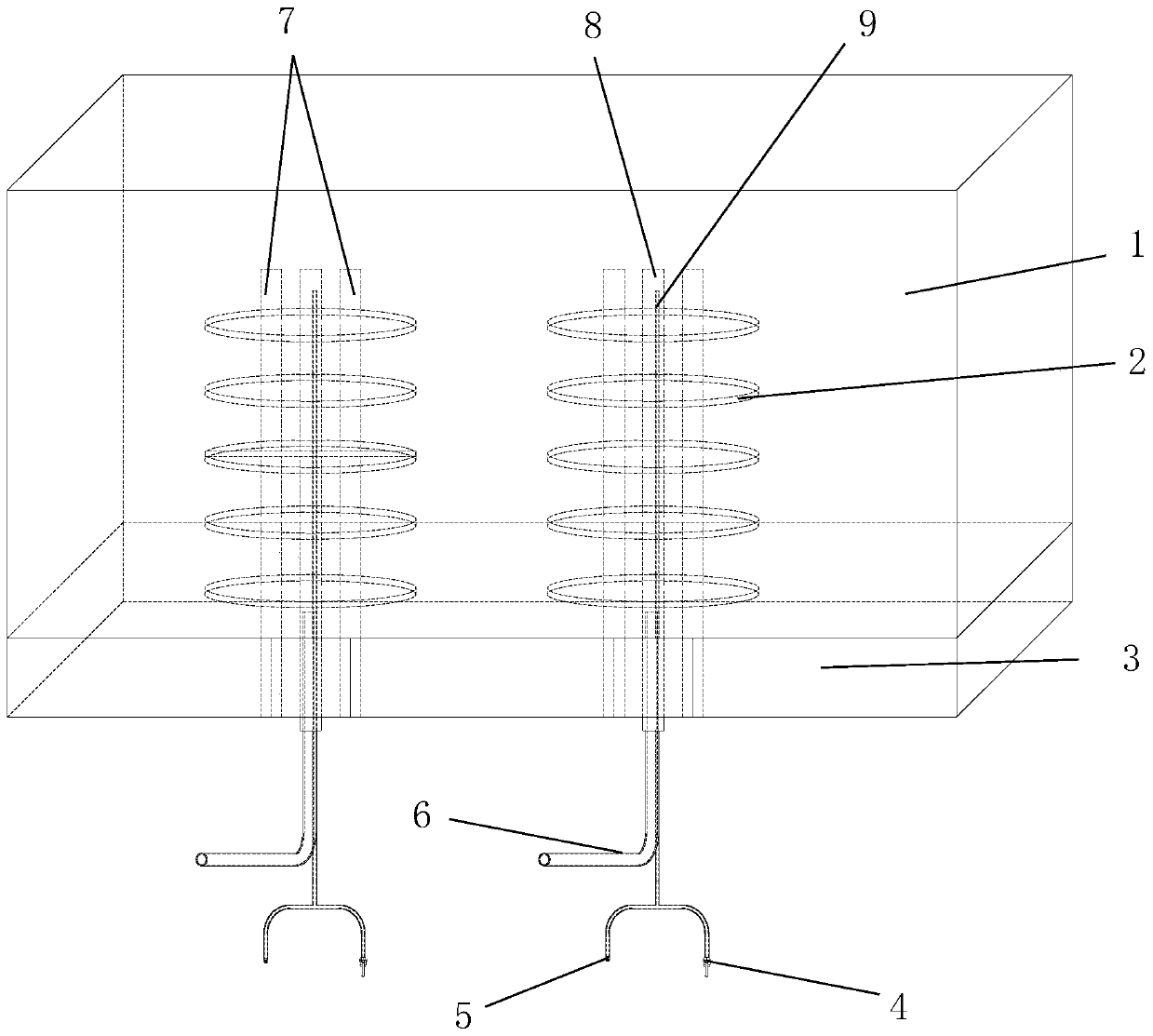

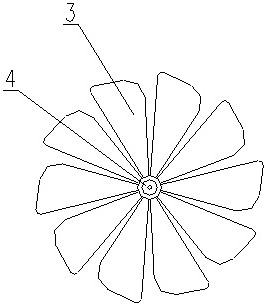

Semi-automatic precision seeding machine

InactiveCN102577715AImprove work efficiencyEasy up and down operationSeed depositing seeder partsRegular seed deposition machinesSeederRestoration device

The invention relates to a semi-automatic precision seeding machine, which is characterized in that the semi-automatic precision seeding machine comprises a base, a worktable is arranged on the base, a supporting arm is installed on the base and is connected with a seed suction disc, the base comprises a cabinet and a suction fan which is installed in the cabinet, the suction fan is provided withan air suction port and an exhaust port, the air suction port is connected with an air suction pipe, the air suction pipe is connected with a seeder, the exhaust port is connected with an exhaust pipe and the exhaust pipe stretches out of the cabinet; and the worktable is a foldable worktable, the supporting arm comprises a bent restoration device, the seed suction disc comprises an air suction disc and a seed disc, a bidirectional rotating mechanism comprises rotating shafts which are connected on the two sides of the air suction disc of the seeder, the rotating shafts are connected with a frame, a left frame handle and a right frame handle are arranged on the frame, and the rotating shafts are respectively installed on the inner walls of the two frame handles and are matched with the seed suction disc of the seeding machine.

Owner:HANGZHOU SAIDELIN INTELLIGENT EQUIP CO LTD

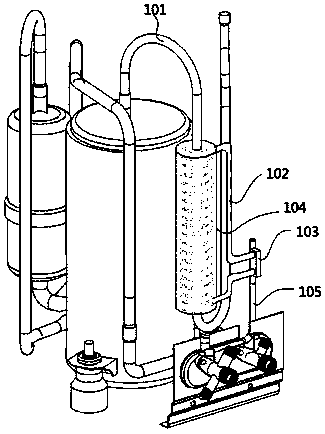

Internal combustion engine exhaust cooling and removal apparatus

An internal combustion engine exhaust cooling and removal apparatus includes a heat exchange assembly connected to an exhaust pipe of an internal combustion engine. A flexible hose is connected to the heat exchange assembly, and an exhaust fan assembly is connected to the flexible hose. Use of the internal combustion engine exhaust cooling and removal apparatus of the invention provides a clean air environment in an indoor confined space by removing the engine exhaust gases which are hazardous to one's health. The apparatus of the invention is especially useful with non-electric powered tools and machines, such as for indoor excavations with diesel-powered excavators or other construction equipment. The apparatus of the invention can also be used with diesel-powered saws.

Owner:PATRY IVAN J

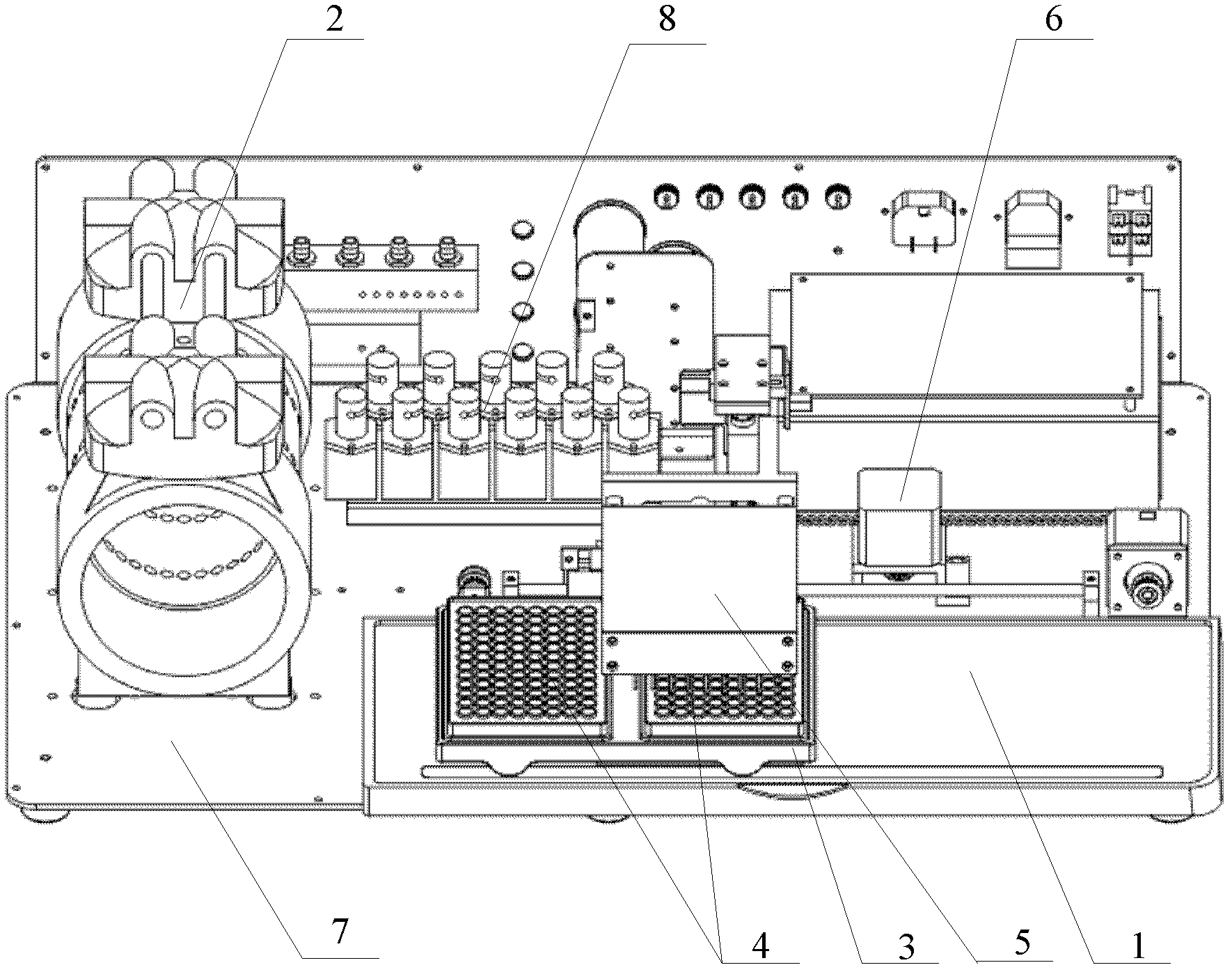

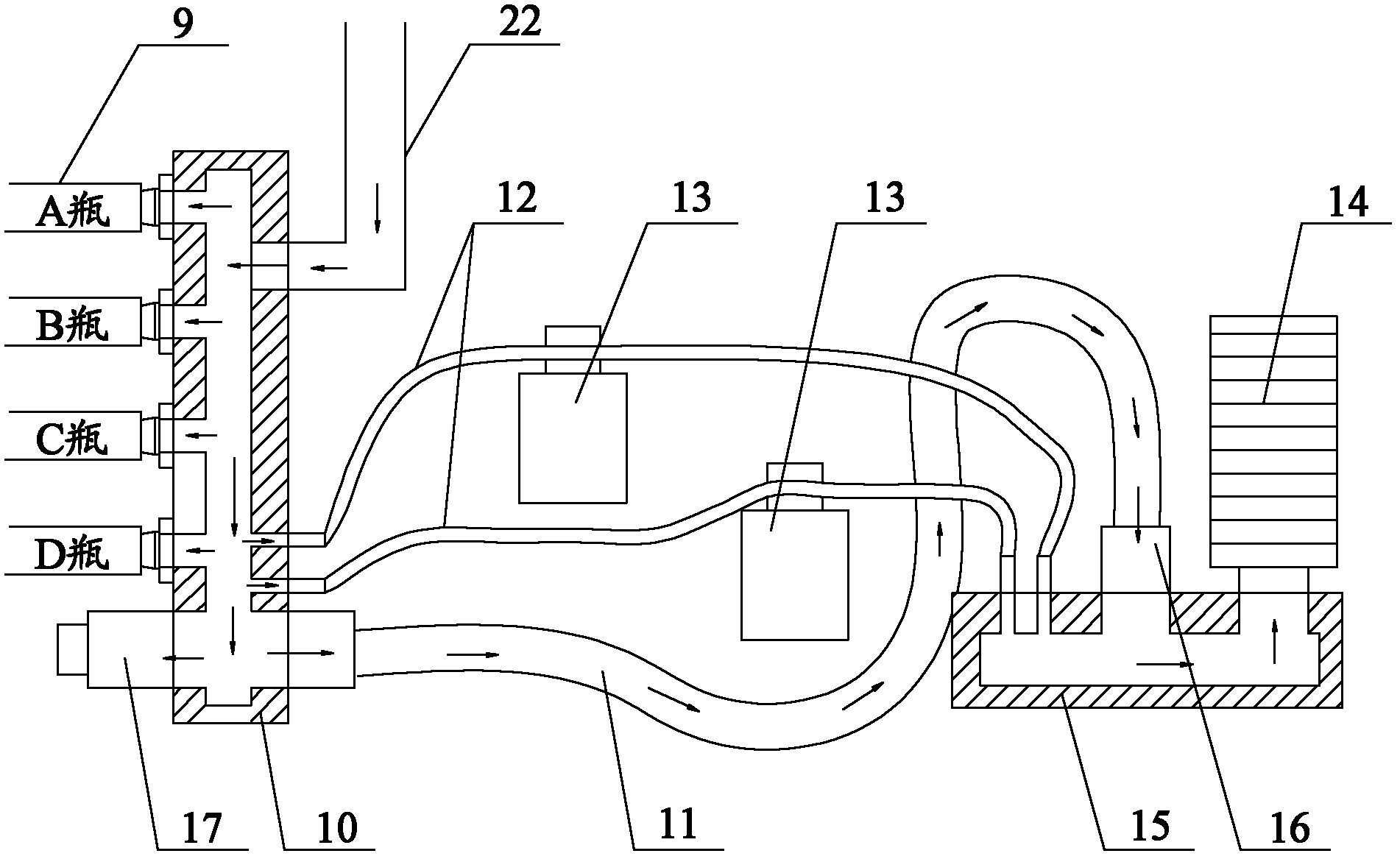

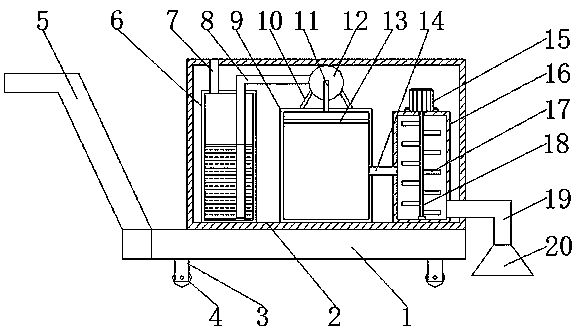

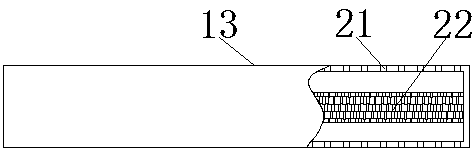

Pressure balance system of automatic ELISA (Enzyme-Linked Immunosorbent Assay) plate washer and automatic ELISA plate washer

Owner:SHENZHEN PERWIN BIO TECH

Fallen leaf clearing device for gardens

InactiveCN107604867ASolve the problem of not having the dust removal functionImprove practicalityRoad cleaningEngineeringExhaust pipe

Owner:徐俊浩

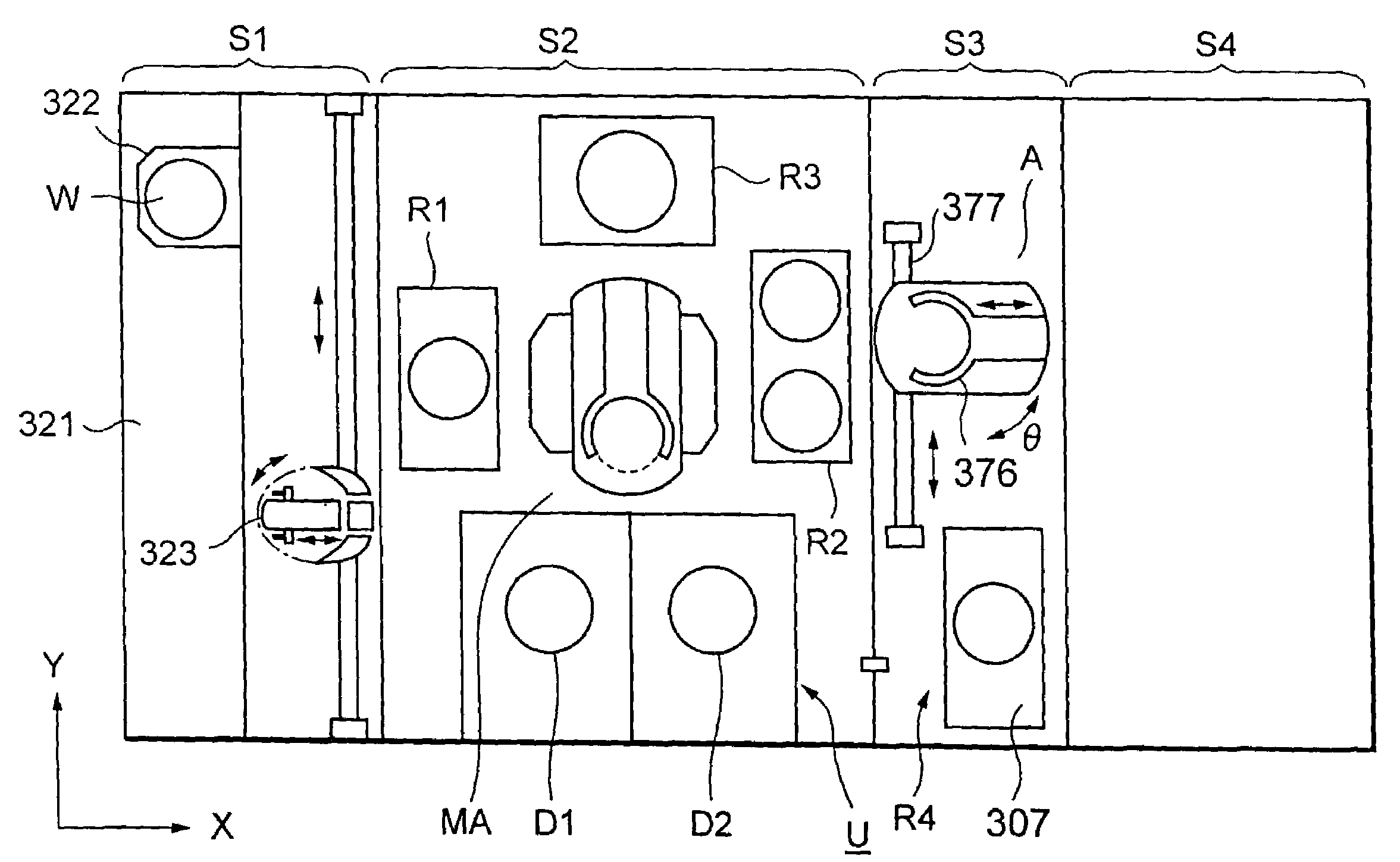

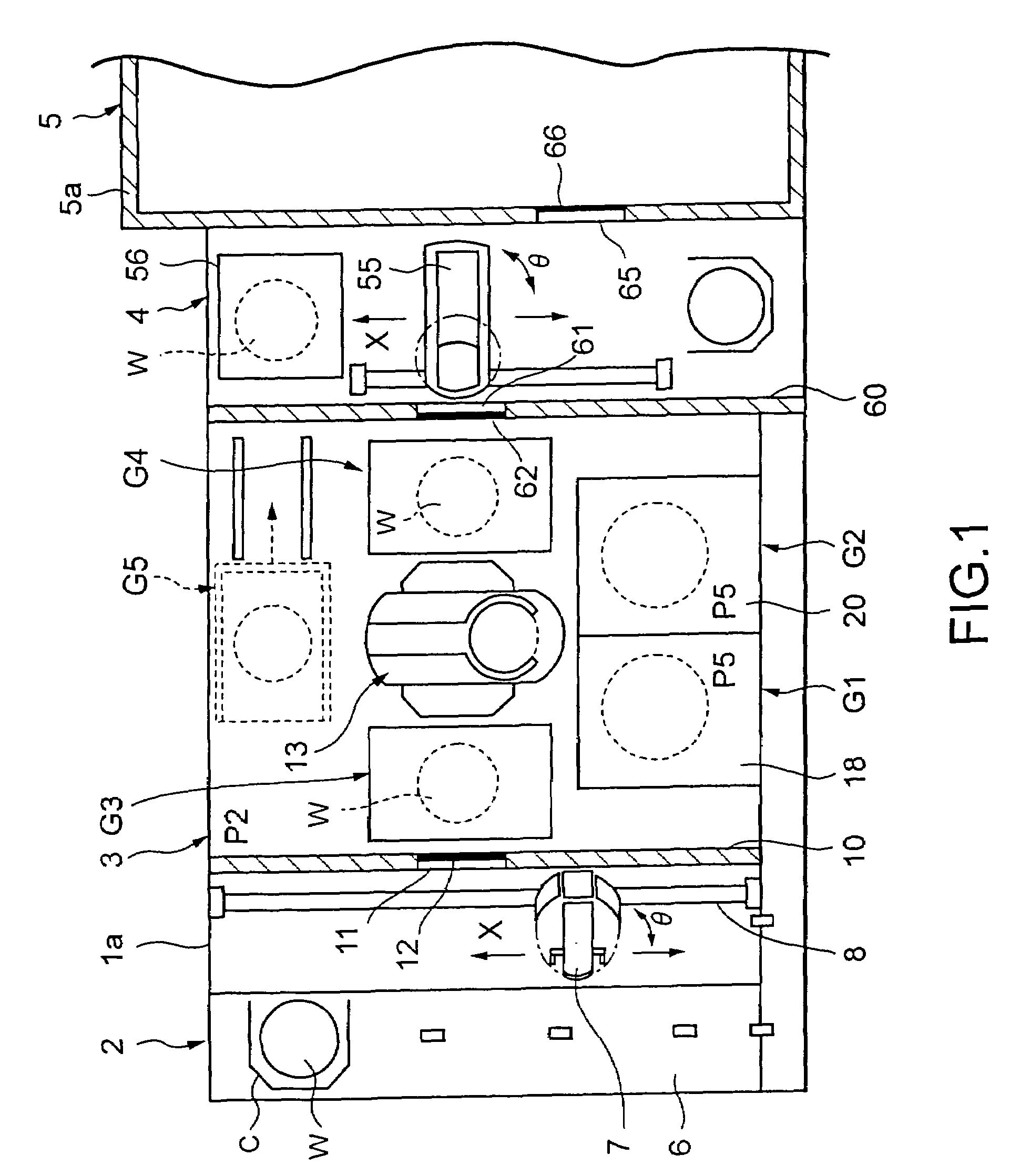

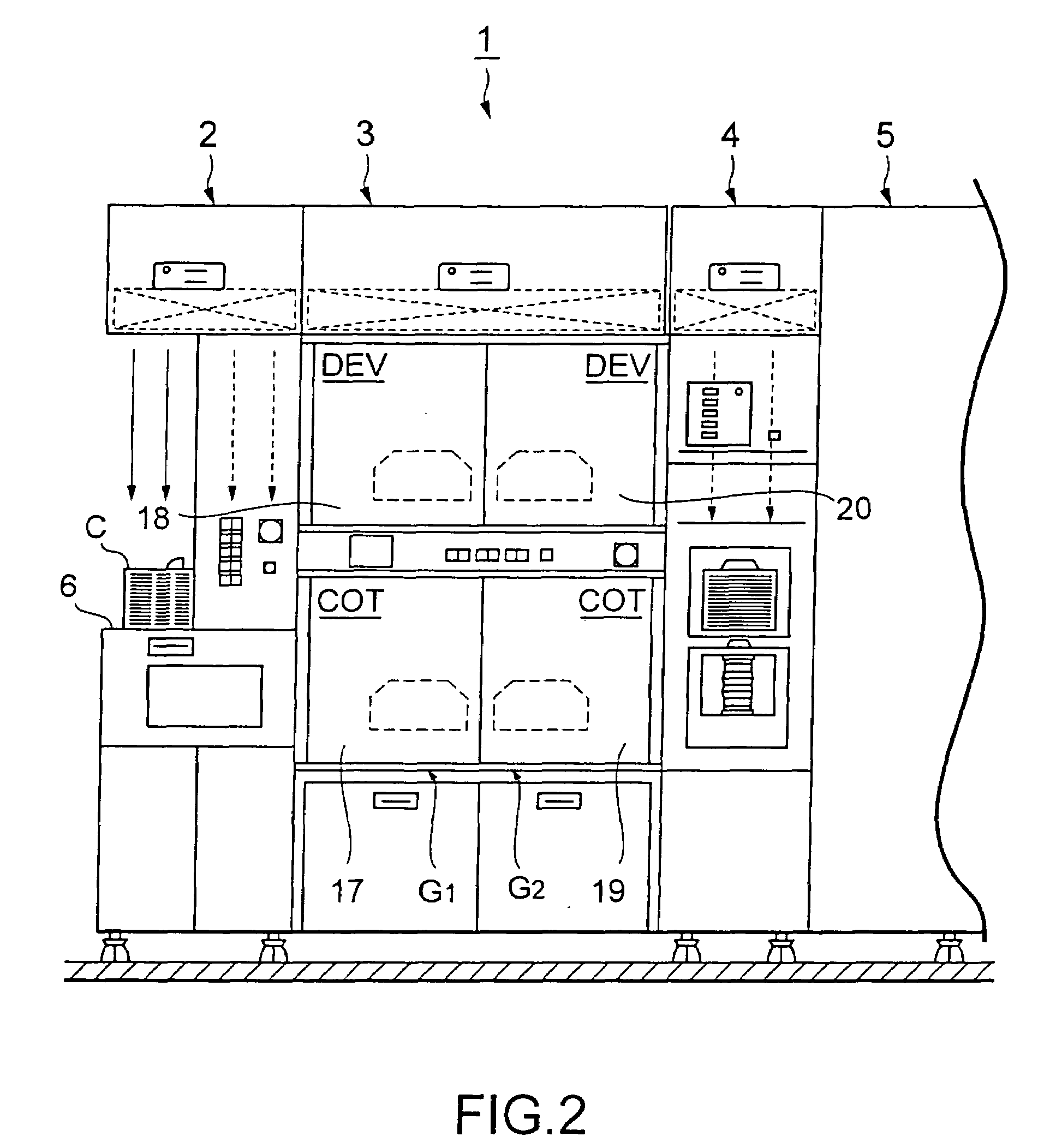

Substrate processing apparatus and substrate processing method

InactiveUS7208066B2Avoid levelingLiquid surface applicatorsPhotomechanical apparatusAtmospheric airEngineering

Owner:TOKYO ELECTRON LTD

Exhaust system

ActiveUS20130161124A1Reduce heat loadInternal combustion piston enginesExhaust apparatusExhaust fumesEngineering

An exhaust system (1) for an internal combustion engine, in particular of a motor vehicle, has at least one exhaust tract (2), which has at least one exhaust pipe (3) which conducts exhaust gas, and has at least one active silencer (5). The active silencer (5) has a silencer housing (6) and at least one electro-acoustic converter (7) which is arranged in the silencer housing (6) and at least one connection pipe (8), which connects the silencer housing (6) fluidically to the exhaust pipe (3). The thermal loading of the converter (7) is reduced with a sound propagation path (9) formed for the propagation of airborne noise in the connection pipe (8) being impermeable to thermal radiation (16) emanating from the exhaust gas in the exhaust pipe (3).

Owner:PUREM GMBH

Automobile exhaust pipe with tail gas filtering function

InactiveCN108561217AEvenly through theIncrease contact areaInternal combustion piston enginesExhaust apparatusCircular discSpiral blade

The invention discloses an automobile exhaust pipe with a tail gas filtering function. The automobile exhaust pipe comprises an exhaust pipe body and an air inlet pipe, wherein one side of the exhaustpipe body is communicated with the air inlet pipe; the other side of the exhaust pipe body is communicated with a filtering pipe through a flow guide pipe; the inner surface wall of the flow guide pipe is welded with a fixed circular disc positioned on the horizontal axial line of the flow guide pipe through flow guide plates in equal angle distribution; a rotating shaft is movably connected witha position at one side of the fixed circular disc and positioned inside the filtering pipe; a spiral blade is welded on the outer surface wall of the rotating shaft in the horizontal direction; a plurality of sound absorption convex blocks are uniformly distributed on the inner surface wall of the filtering pipe; a vacuum cavity is formed inside the casing of the filtering pipe. The automobile exhaust pipe has the advantages that the spiral blades can rotate under the tail gas circulation effect; the rotating shaft is driven to rotate; through the rotating effect of the spiral blade, the contact area between the active carbon adsorption plate and the tail gas can be effectively increased, so that the adsorption efficiency is improved; harmful gas in the tail gas can be efficiently adsorbed; the goals of filtering and environment protection are achieved.

Owner:CHENGDU YIRUIXIN TECH CO LTD

Material particle size online detector and detection method thereof

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Fireproof door with smoke-proof function

Owner:TIANJIN LONGJIA SPECIAL DOOR & WINDOW

Smoke cleaner device for tractor

InactiveCN103195544AAvoid pollutionSimple structureExhaust apparatusSilencing apparatusExhaust pipeAtmosphere

The invention discloses a smoke cleaner device for a tractor. The smoke cleaner device is connected on a smoke exhaust pipe of the tractor and comprises a cleaner shell, a smoke inlet pipe is communicated at the bottom of the cleaner shell, a smoke exhaust pipe is communicated at the top of the cleaner shell, a first-level cleaning baffle plate and a second-level cleaning baffle are sequentially fixed in the cleaner shell from top to bottom, a first-level cleaning filter core is arranged between the top face of the cleaner shell and the first-level cleaning baffle plate, a second cleaning filter core is arranged between the first-level cleaning baffle plate and the second-level cleaning baffle plate, a third cleaning filter core is arranged between the second-level cleaning baffle plate and the bottom face of the cleaner shell, and smoke exhaust holes are respectively reserved on the first-level cleaning baffle plate and the second-level cleaning baffle plate. By mounting the smoke cleaner device at a smoke exhaust hole of the tractor, smoke exhausted from the tractor can be filtered for several times, so that dust, grains and the like in the smoke are filtered and prevented from being exhausted to the air to pollute the atmosphere, and the smoke cleaner device is simple in structure and convenient to use.

Owner:CHANGYI XINGYUAN FOUNDING CO LTD

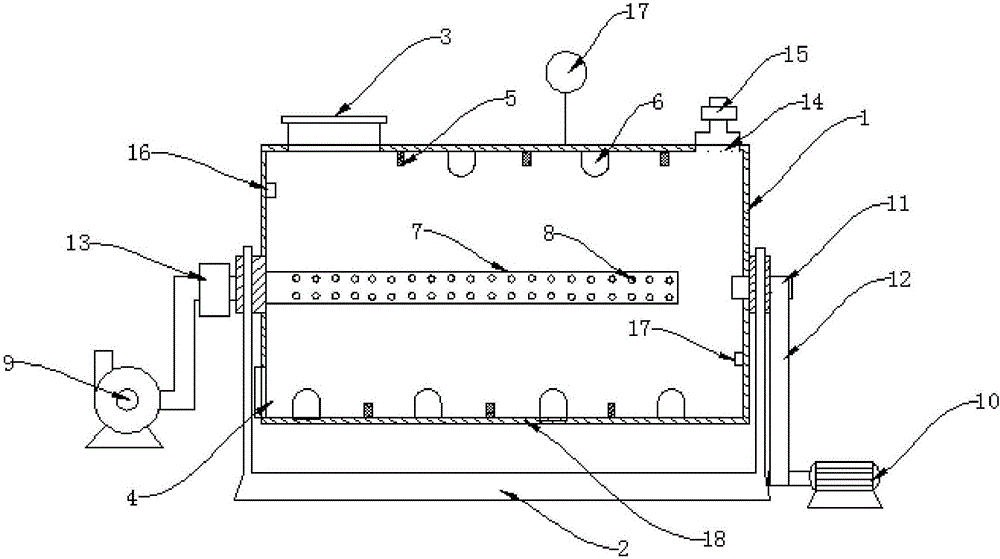

Textile cleaning and drying integrated machine

InactiveCN108035102AReduce cost inputEasy to integrateMechanical cleaningPressure cleaningAgricultural engineeringProcessing cost

The invention discloses a textile cleaning and drying integrated machine and relates to the technical field of textile processing equipment. The textile cleaning and drying integrated machine includesa box body, a filtering mechanism, a lifting mechanism, a material guiding mechanism, a water inlet pipe, a water outlet pipe, a partition plate, a long hole, strip-shaped holes, mounting plates, bearings, rotating shafts, mounting holes, connecting rods, motors, bobbins, a hot air fan, a three-way pipe, air outlet pipes, air exhaust pipes, a box door and a water tank. The middle of the front face of the box body is movably connected to the box door through hinges, and the water tank is fixedly installed in the inner bottom wall of the box body. According to the textile cleaning and drying integrated machine, the box body can be divided into two spaces for cleaning and drying through the partition plate fixedly connected in the box body, the cleaning and drying operation in the same machine can be conducted, the integration degree is high, the processing cost of the machine can be effectively saved, and accordingly the cost input of manufacturers is reduced.

Owner:SHAOXING KEQIAO CHENGXIN PRECISION CASTING CO LTD

Cyclone separator

Owner:SHENTONG TECH GRP CO LTD

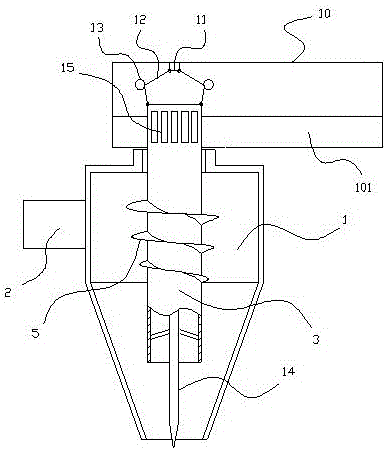

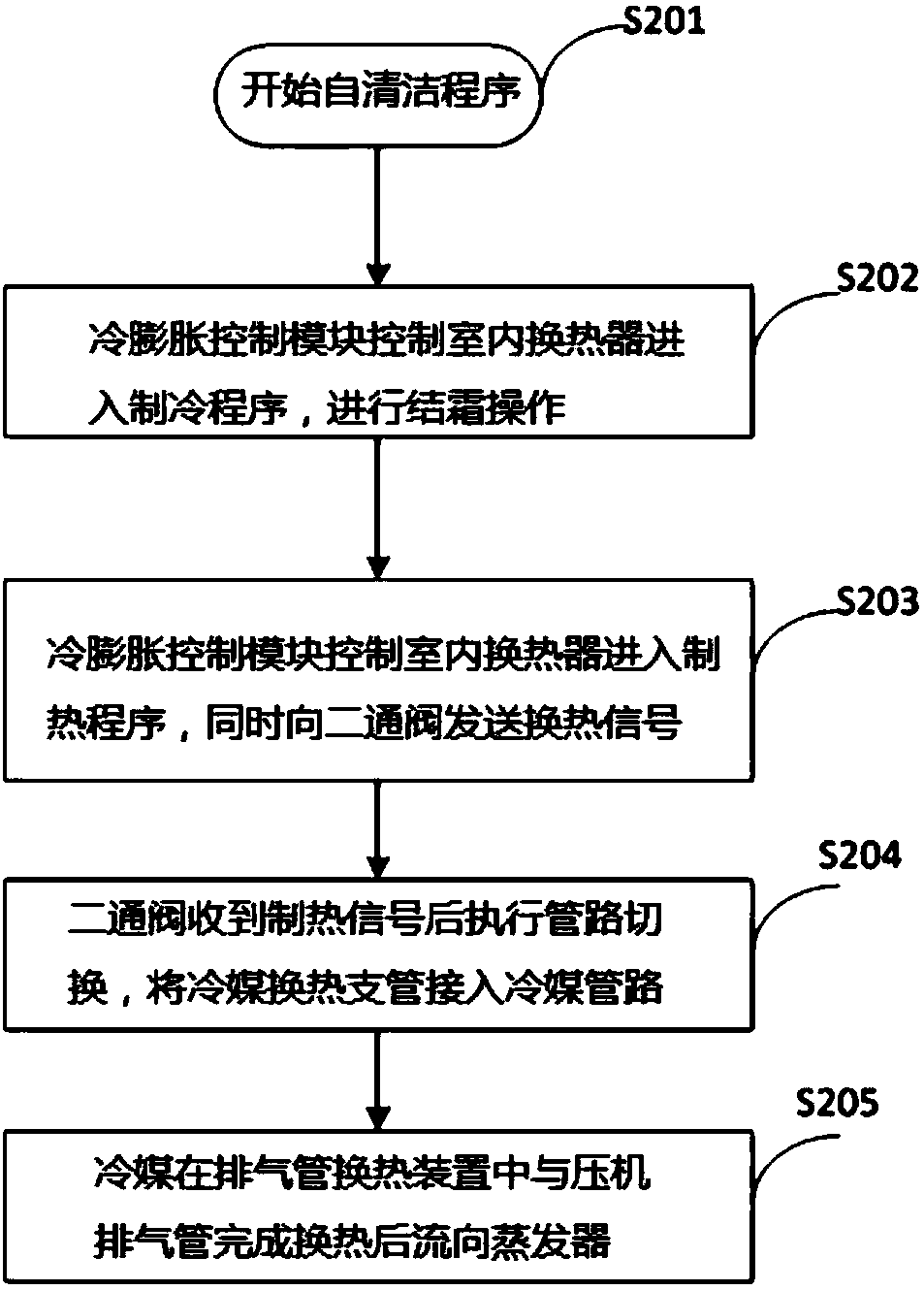

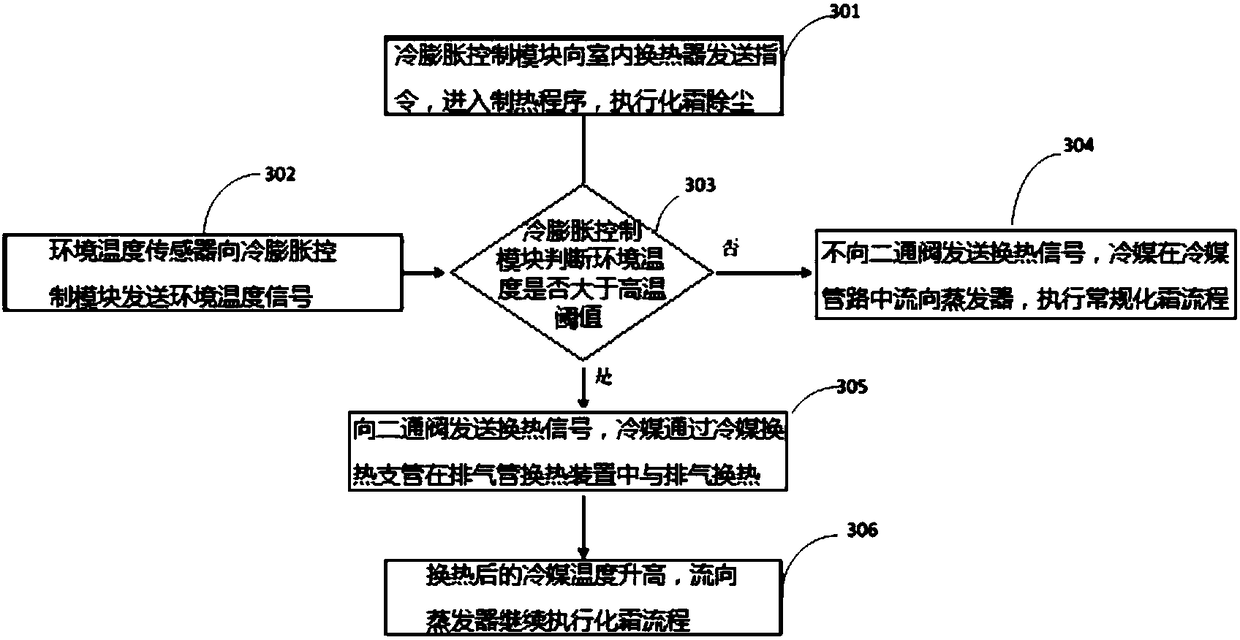

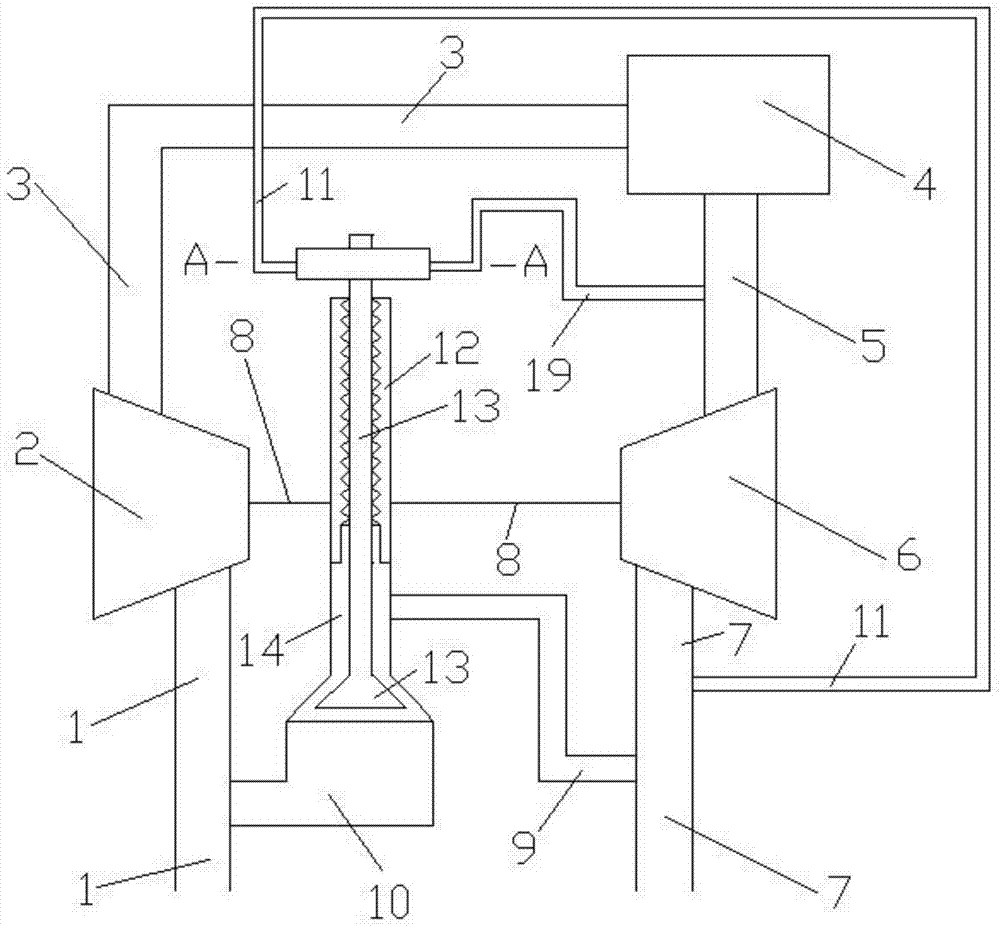

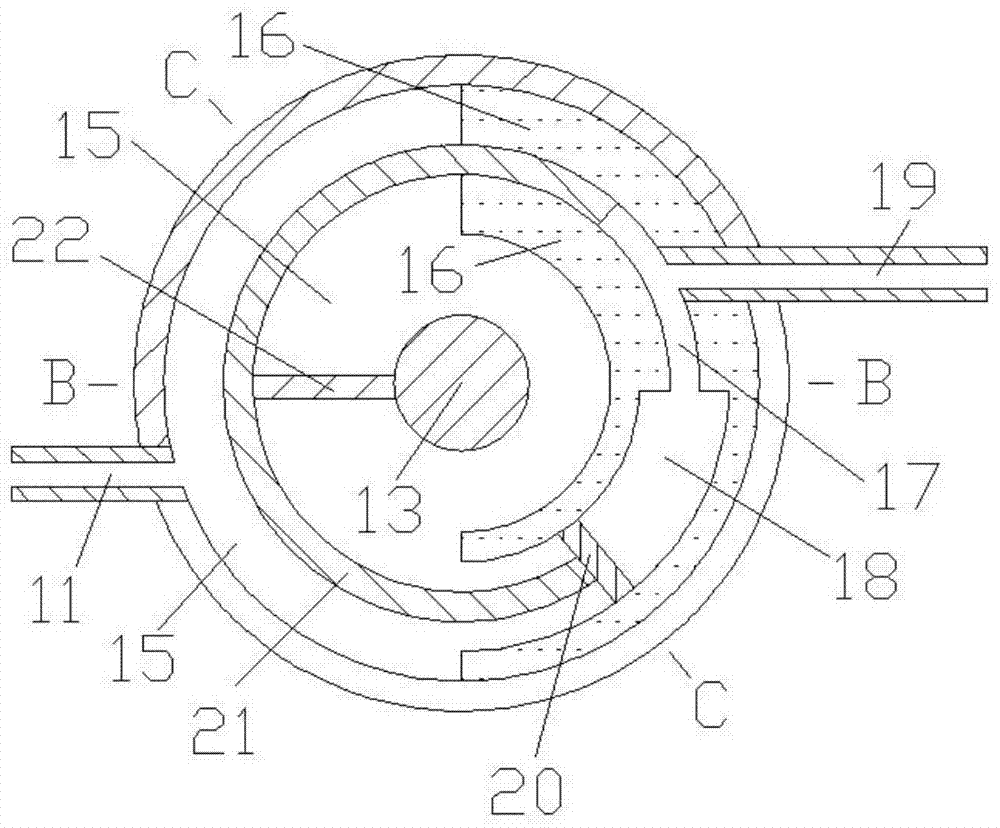

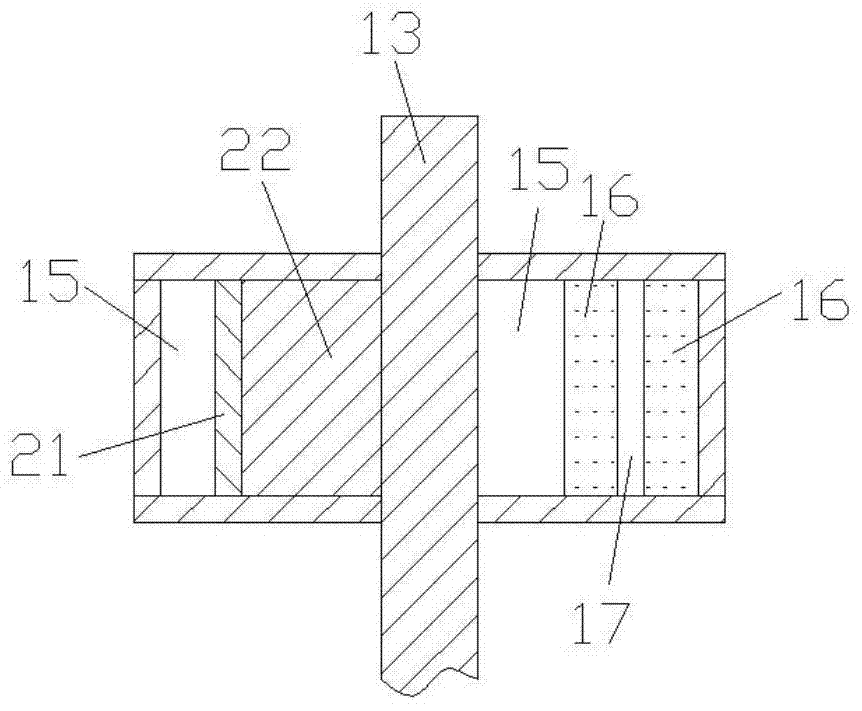

Self-cleaning system of indoor unit of air conditioner and control method thereof

ActiveCN108413560AIncrease temperatureProtection stabilityMechanical apparatusSpace heating and ventilation safety systemsElectricityEngineering

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

Turbine front-and-back pressure difference control type low-pressure circulating system

InactiveCN103573396ATaking into account low and medium speed conditionsReasonable designInternal combustion piston enginesDetonationGas compressor

Owner:刘洪涛

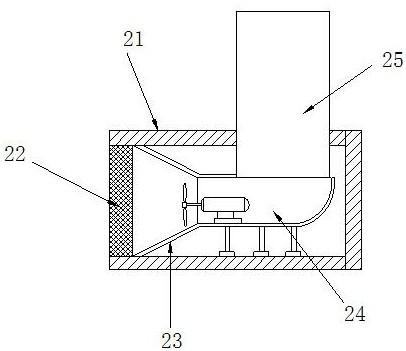

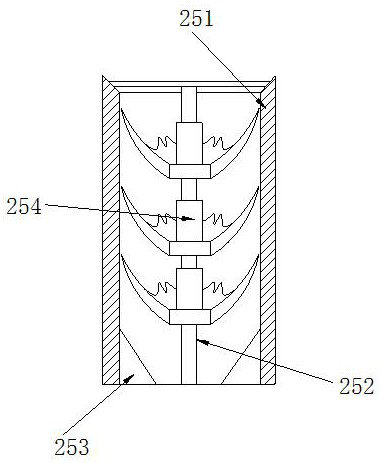

Composite piezoelectric-thermoelectric automobile exhaust gas micro energy collector

ActiveCN108448939AImprove collection efficiencySolve the defects of single energy supply modePiezoelectric/electrostriction/magnetostriction machinesInternal combustion piston enginesElectricityCantilevered beam

The invention provides a composite piezoelectric-thermoelectric automobile exhaust gas micro energy collector. One end of a cantilever beam is fixedly connected to a support base, and the other end extends along a horizontal direction to form a free end. A mass block is fixed at the free end of the cantilever beam. A piezoelectric sheet is fixed on an upper surface of the cantilever beam. Film electrodes are respectively located on the upper and lower surfaces of the piezoelectric sheet. A heat radiation piece is fixed to the upper surface of an upper film electrode. An energy collector is placed on an outer tube wall of an automobile exhaust pipe. The cantilever beam is subjected to the vibration of an automobile to generate vibration, and the piezoelectric sheet senses the vibration of the cantilever beam to generate an electric charge which is taken out by the film electrodes. The lower surface of the piezoelectric piece receives the heat of exhaust gas conducted from an exhaust tube wall, the heat radiation piece is placed on the upper surface of the upper film electrode, thus a temperature change is caused on the piezoelectric sheet, the charge is generated by a pyroelectric effect and then is led out through film electrode leads, and power is supplied to a gas monitoring sensor.

Owner:XIAMEN UNIV

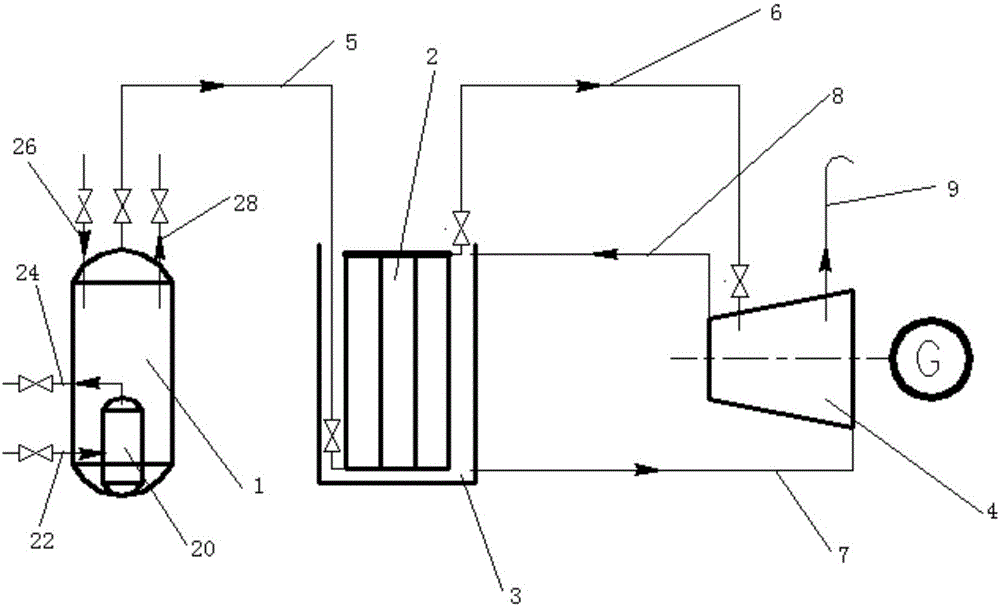

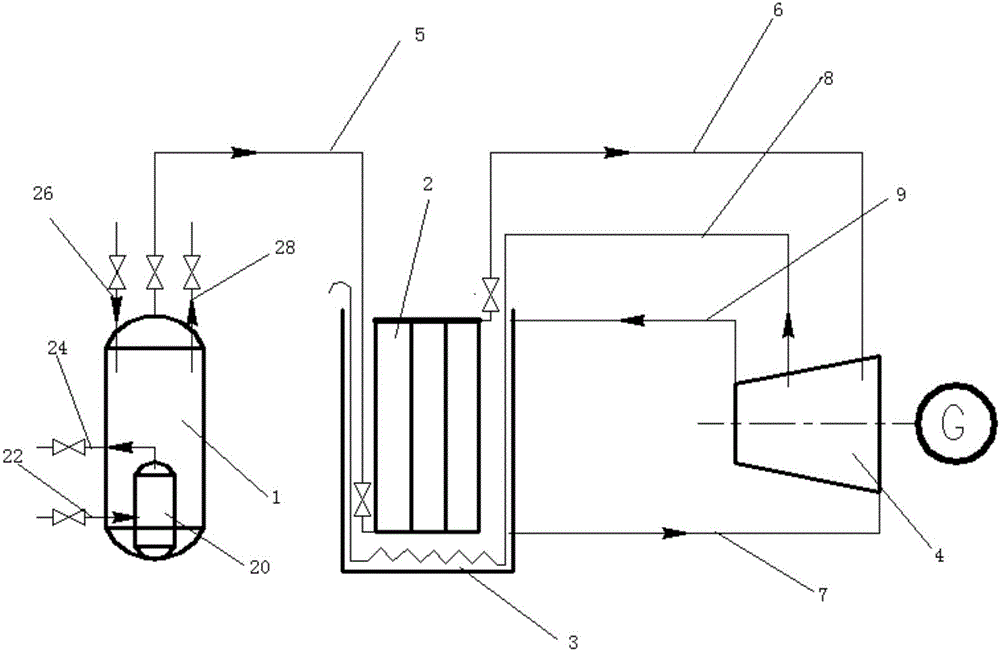

Mobile energy station and energy utilization method

ActiveCN105715952AGuaranteed stabilityImprove securityPressure vesselsSteam engine plantsNitrogenProduct gas

Owner:ENN SCI & TECH DEV

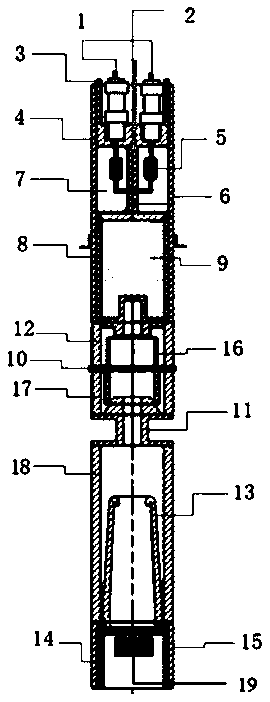

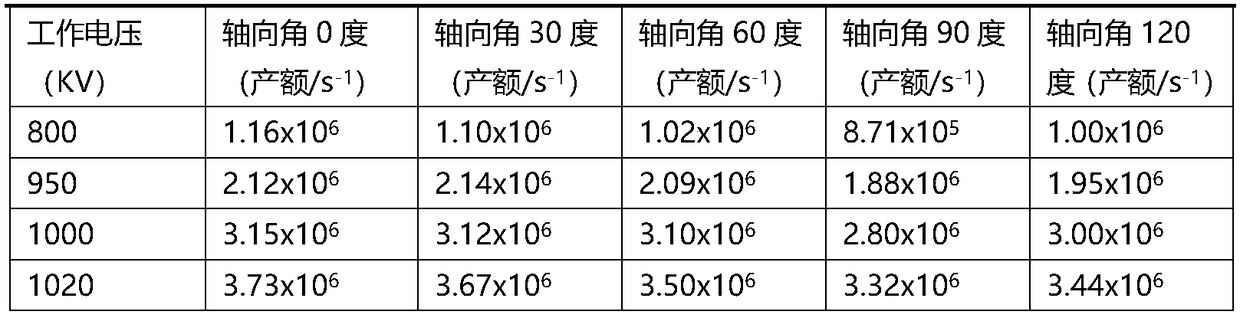

A subminiature neutron tube

ActiveCN109041397ASmall diameterReduce Design ComplexityDirect voltage acceleratorsHigh pressureExhaust pipe

Owner:珠海市纽创科技有限公司

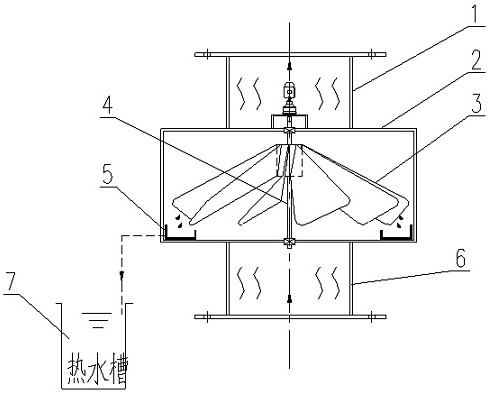

Waste heat utilization system of electric heating steam generator

PendingCN112626819AAchieve recyclingShorten heating timeHand ironTextiles and paperExhaust valveThermodynamics

The invention relates to the field of steam equipment in the garment processing industry, and in particular relates to a waste heat recovery system of an electric heating steam generator. The waste heat recovery system comprises an electric heating steam generator body, a water supply pipe, a first water pump, a steam outlet pipe, a steam exhaust pipe, an exhaust valve and a heat preservation water storage tank, wherein the electric heating steam generator body comprises a box body, an inner container and a heater; the inner container is arranged in the box body; the heater is arranged in the inner container; and the water supply pipe is sequentially connected with the heat preservation water storage tank, the first water pump and the inner container; one end of the steam outlet pipe is connected with the inner container, and the other end of the steam outlet pipe is connected with an ironing device; one end of the steam exhaust pipe is connected with a steam iron, and the other end is in communication with the heat preservation water storage tank; and the exhaust valve is arranged on the top wall of the heat preservation water storage tank. The system has the effect of reducing resource waste.

Owner:SHAANXI MEIGE GARMENT CO LTD

Online wet and hot water vapor recovery device for electroplating treatment

InactiveCN113398714AReduce heating energy consumptionCapture implementationCellsGas treatmentWater vaporEnvironmental engineering

Owner:中航长沙设计研究院有限公司

Roller type high-efficiency dryer for processing food

Owner:TIANJIN BAOHESHENG FOODS

Air valve starting device of piston of air cylinder

InactiveCN103711679ANot easy to damageExtended service lifePositive displacement pump componentsPositive-displacement liquid enginesStops deviceExhaust pipe

The invention relates to an air valve starting and stopping device, in particular to an air valve starting device of a piston of an air cylinder. The air valve starting device comprises a base and an air valve and is additionally provided with a tappet rod, an air valve ejector rod, a tappet rod spring and a spring seat. A first air inlet pipe, a second air inlet pipe and an exhaust pipe are arranged on the air valve, the air valve, the spring seat is connected onto the tappet rod, one end of the tappet rod is slidably connected with the air valve ejector rod and can push the air valve ejector rod, a plane capable of bearing force is arranged at the other end of the tappet rod, the tappet rod spring is arranged on the tappet rod, one end of the tappet rod spring is carried under the air valve ejector rod, and the other end of the tappet rod spring is supported on the spring seat. The air valve starting device has the advantage that the service life of the air valve can be prolonged.

Owner:CHONGQING FENGGUO QIYANG TECH DEV

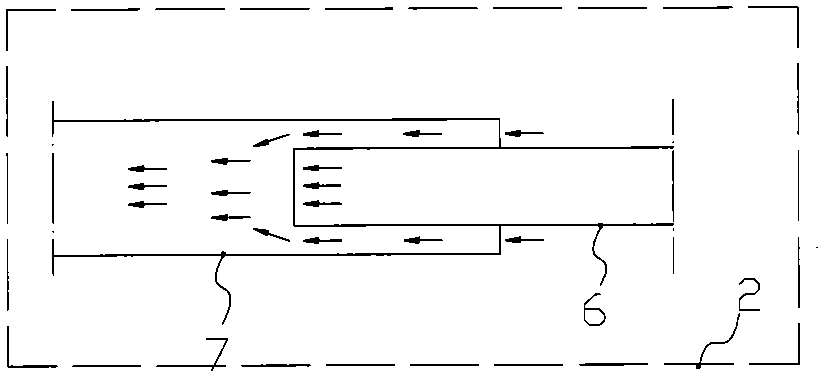

Auto exhaust pipe with function of internal cooling based on airflow effect

InactiveCN105888804AOmit flexible sectionReduce manufacturing costExhaust apparatusSilencing apparatusCold airExhaust pipe

Owner:杨洋 +1

Novel building supermarket ventilation fireproof floor tile

InactiveCN113027068AReduce labor intensityImprove air qualityBatteries circuit arrangementsLighting and heating apparatusElectrical batteryTurbine blade

The invention discloses a novel building supermarket ventilation fireproof floor tile. The novel building supermarket ventilation fireproof floor tile comprises a box body, a metal plate is fixedly connected to one side of the box body, a sliding block is welded and fixed to the lower part of the metal plate, the sliding block penetrates through the box body, a permanent magnet is welded and fixed to the end, located in the box body, of the sliding block, and an electromagnetic coil is arranged outside the permanent magnet. The electromagnetic coil is connected with a battery through a wire, the battery is fixedly connected into the box body, a connecting box is fixedly connected into the box body, an air inlet is formed in the top of the box body, the air inlet communicates with the connecting box, and a heat conduction plate is arranged at the top of the box body. The novel building supermarket ventilation fireproof floor tile has the advantages that a pedestrian walks on the floor tile to drive a felt to move left and right, so that a rack moves up and down and is meshed to drive a straight gear to rotate and drive a turbine blade to rotate, air in a supermarket is sucked in through the air inlet and exhausted through an exhaust pipeline, air exchange is carried out, and the air quality in the supermarket is improved.

Owner:蒋岱青

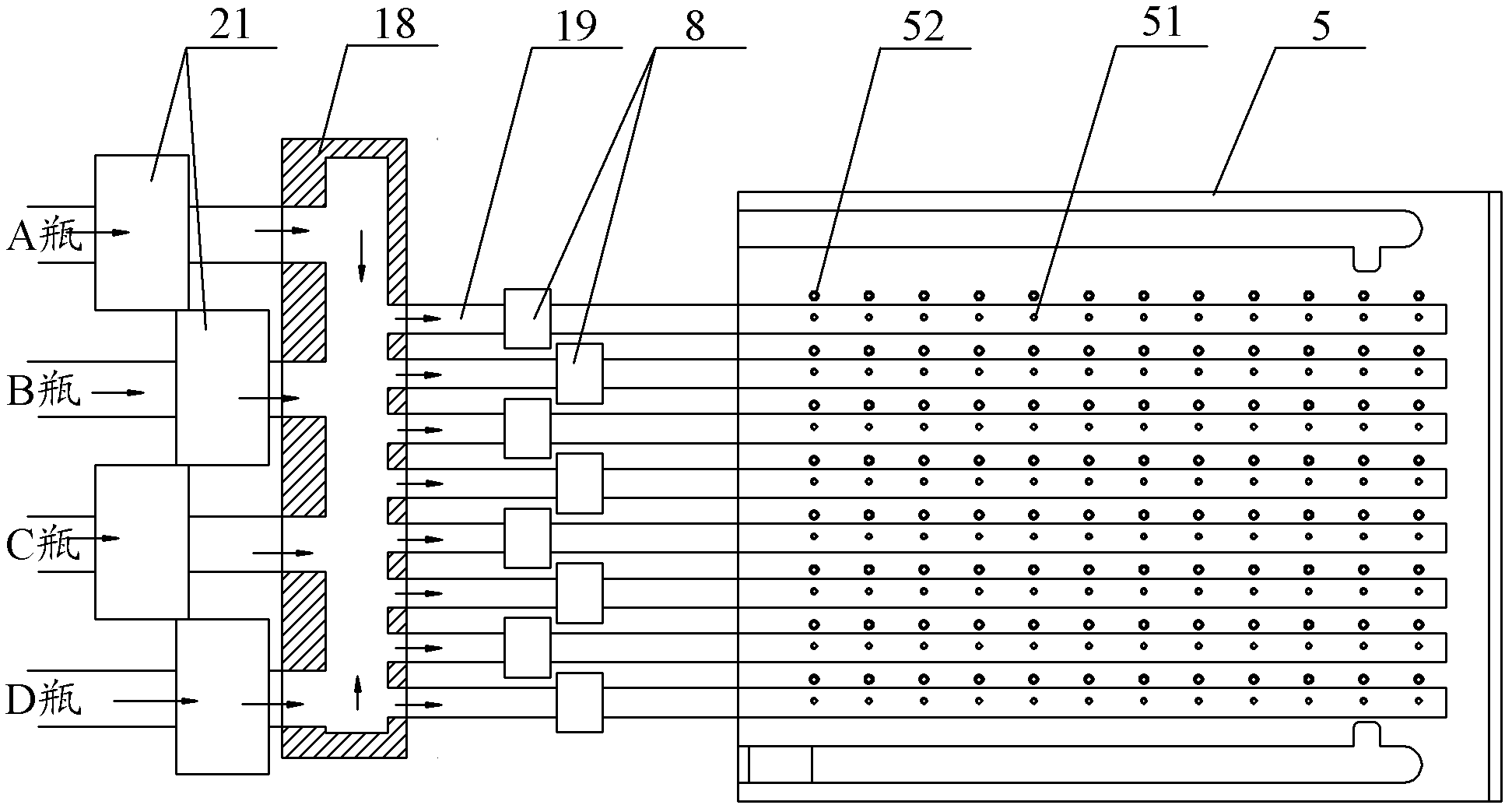

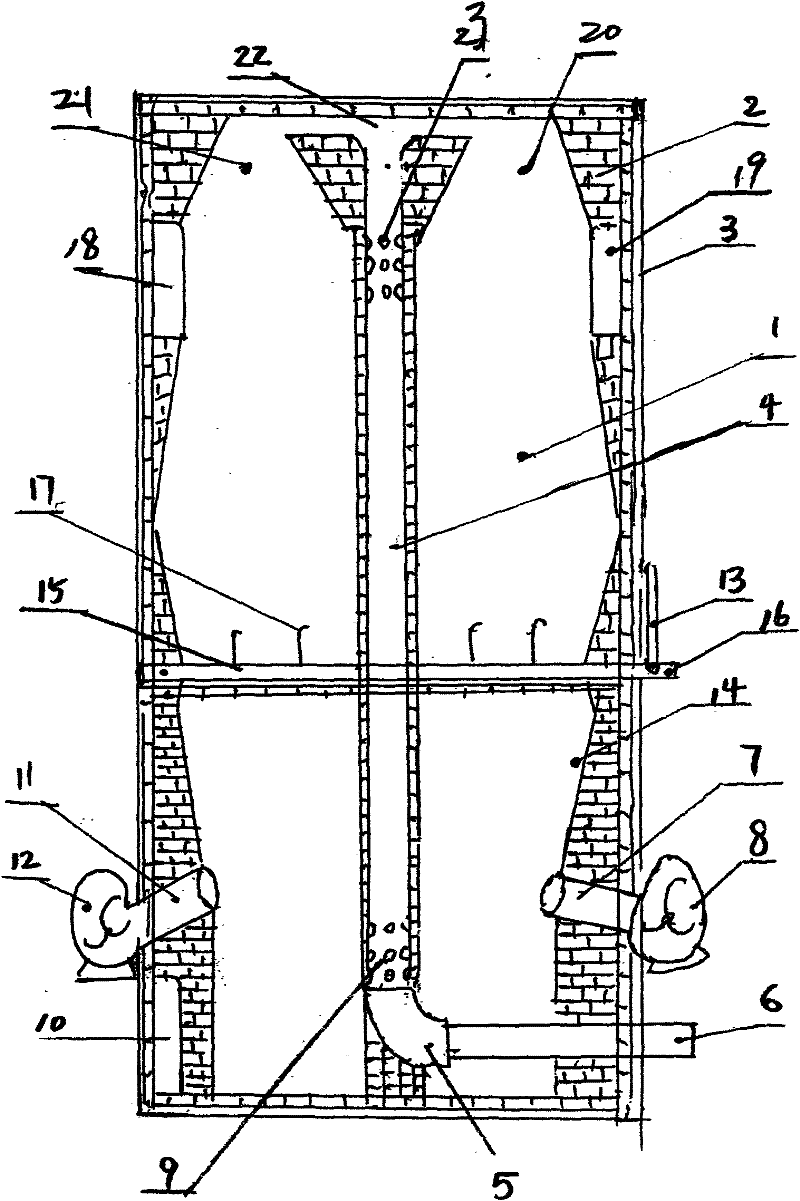

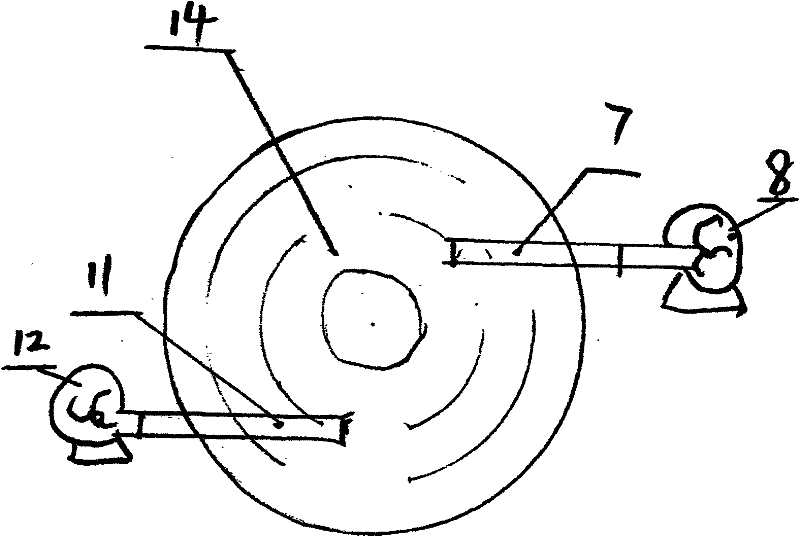

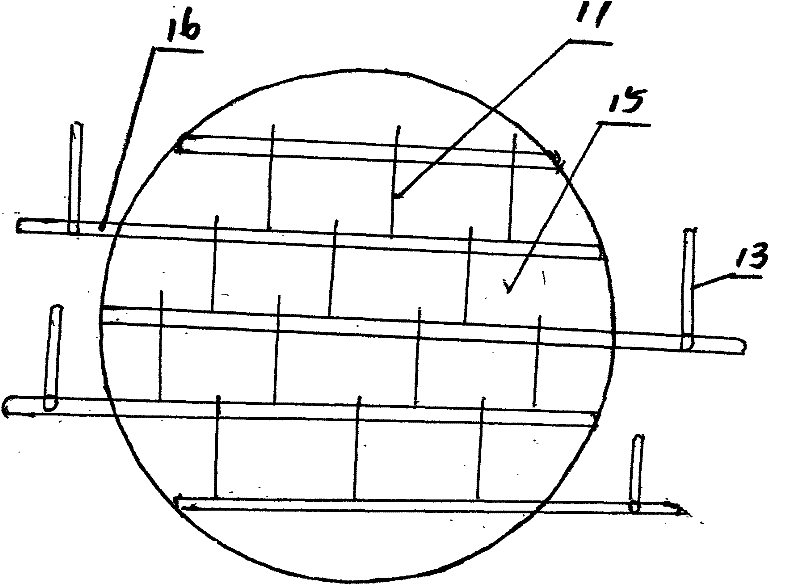

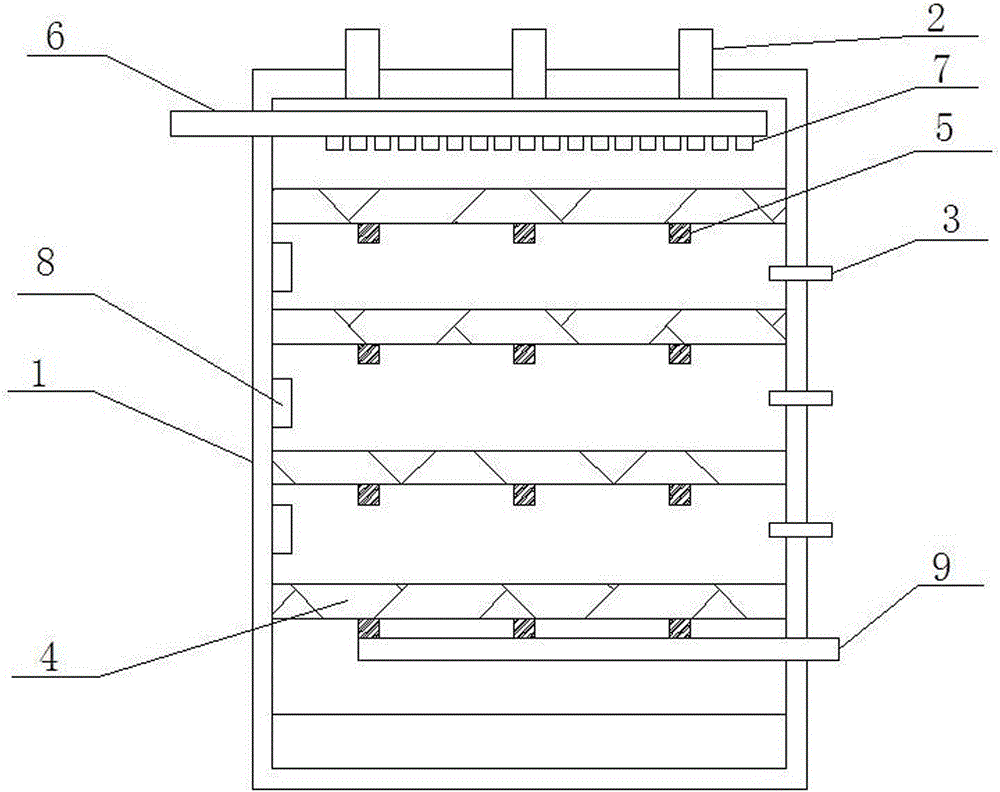

Multilevel fungus culture cabinet

InactiveCN105838597ALow costTo achieve the purpose of energy saving and environmental protectionBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringControl circuit

Owner:HEILONGJIANG ZHENMEI BROADCAST COMM EQUIP

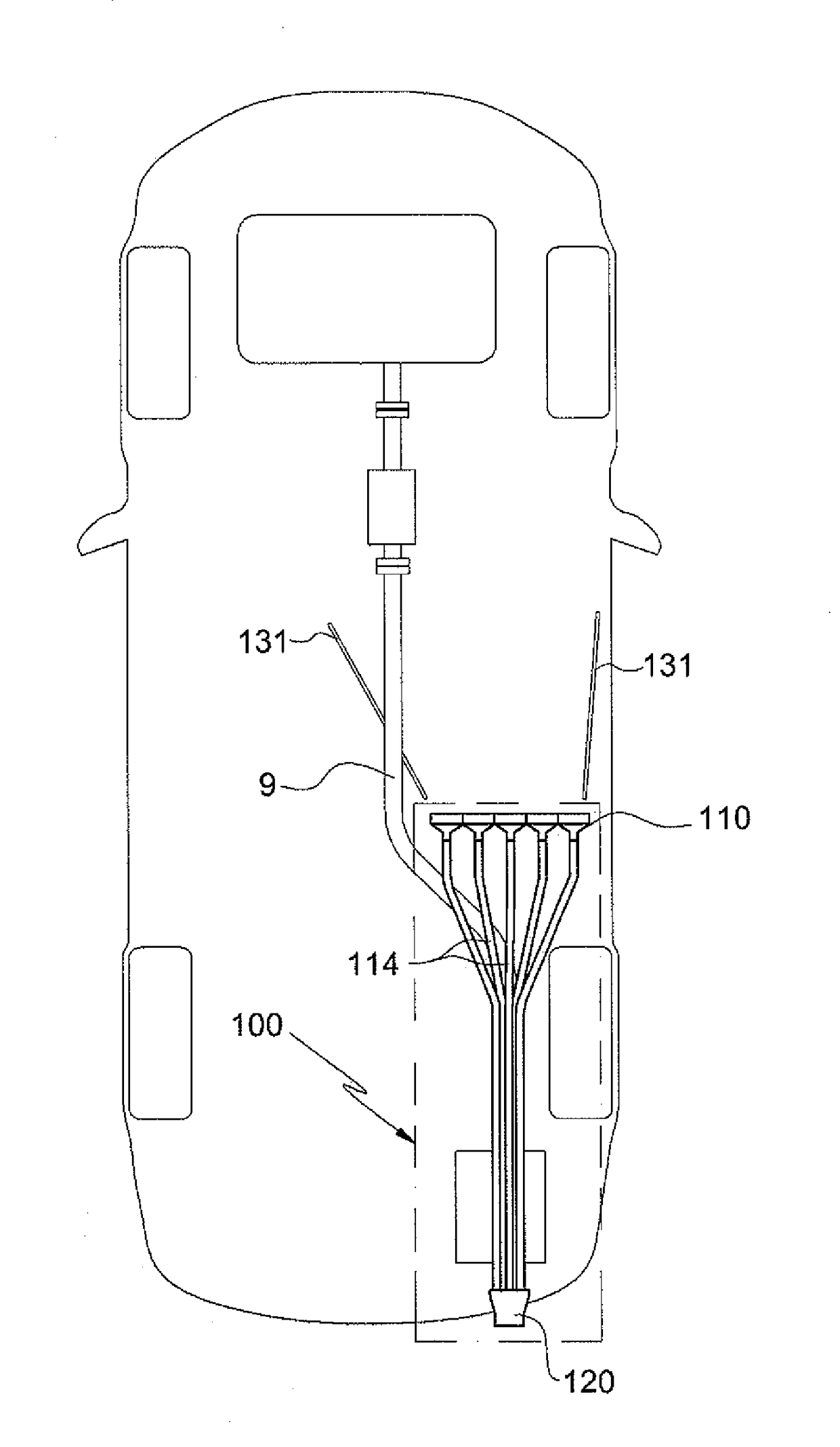

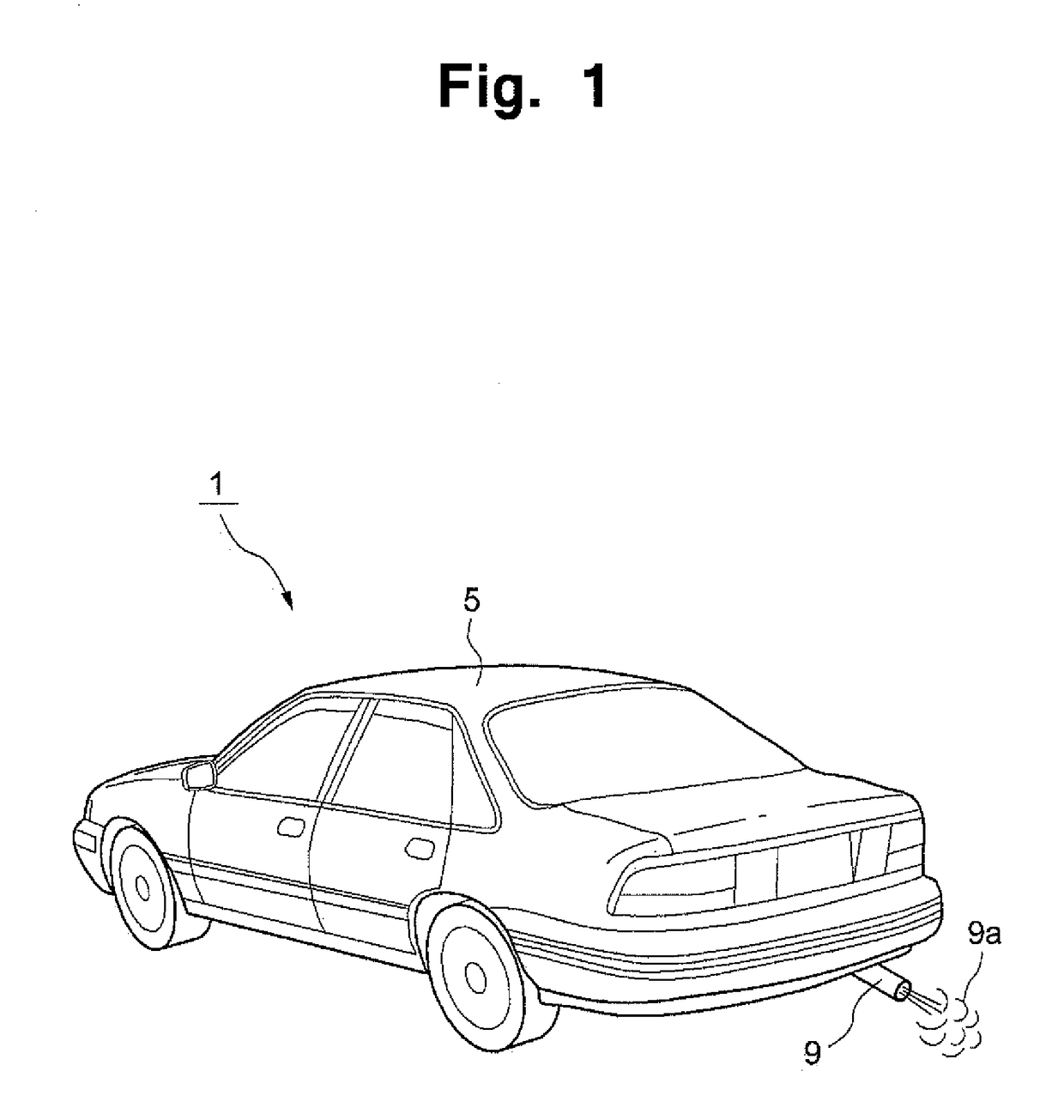

Exhaust gas discharge inducing apparatus for vehicle

ActiveUS20170198623A1Maximize discharge efficiencyImprove fuel efficiencyExhaust apparatusSilencing apparatusExhaust pipeExhaust gas

Owner:LEE BUM HYUNG

Rapid cooling equipment for ceramic tiles

ActiveCN112696876AReduce qualityAutomatic shake offLighting and heating apparatusCooling fluid circulationSand filterMechanical engineering

Owner:广州宏成科技信息有限公司

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap