Rapid cooling equipment for ceramic tiles

A ceramic tile, fast technology, applied in the field of ceramics, can solve problems such as easy cracks, ceramic appearance damage, ceramic strength reduction, etc., and achieve the effect of convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

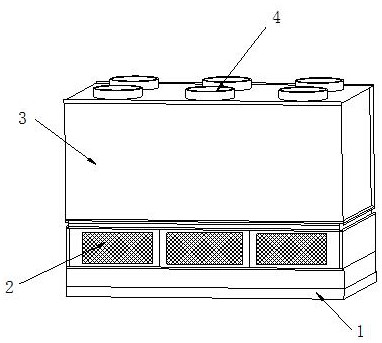

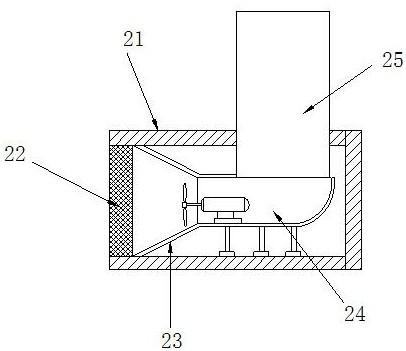

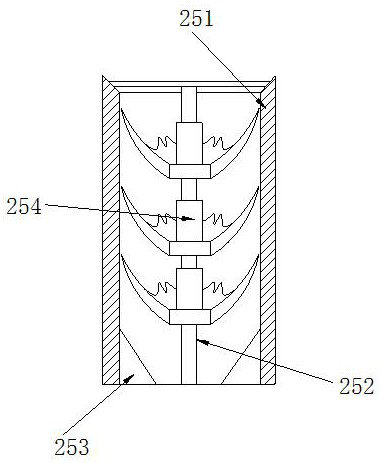

[0026]SeeFigure 1 - Figure 5 In particular, the present invention is specifically implemented, for example, a ceramic brick fast cooling device including a base 1, a winder 2, a cooling row 3, an exhaust pipe 4, the base 1 top surface and a winder 2 bottom welding, The top surface of the exhaust cartridge is embedded inside the cooling line 3, the venting tube 4 is turned on and the cooling line 3 is connected to each other and is connected by a welded; the exhaust fan 2 includes a housing 21, a filter cover 22, a centralized tube 23 The venting tube 24, the filter 25, the filter cover 22 is embedded on the left side of the outer casing 21, and the central tube 23 is welded to the outer casing 21, and the exhaust pipe 24 is left and centralized. 23 On the right side, the right side is connected to each other and the upper pipe 25 is embedded in the top surface of the outer casing 21, the upper surface of the upper pipe 25 and the exhaust pipe 24 to each other and by a welded connection

Embodiment 2

[0032]SeeFigure 6 - Figure 8The present invention is specifically implemented, for example, the contact handle A42 includes a mounting sleeve B1, a handle B2, a navigated head B3, a backgaged groove B4, a bonded head B5, and the mounting sleeve B1 outer layer is embedded in the bottom surface of the handle B2 The empty groove B3 is integrated with the inside of the handle B2, and the backgaged groove B4 is integrated with the right side of the handle B2, and the bonded head B5 is embedded in the inner layer of the reflow groove B4. The return groove B4 is provided with the bonded head B5, and the four return grooves B4 are uniformly distributed on the right side of the handle B2, which facilitates increasing the number of reflows and filters.

[0033]Wherein, the bonded head B5 includes a fixed block B51, a strond b 52, a rotary head B53, a contact plate B54, and the fixed block B51 bottom surface passes through the trust B52 and the rotary head B53 internal activity, the rotary head B53

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap