Device and method for online measurement and calibration of heat content of high-temperature pyrolysis coal gas

A high-temperature pyrolysis and heat-containing technology, which is applied to measuring devices, measuring heat, calorimeters, etc., to achieve the effects of reducing production costs, increasing production costs, and reducing product volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

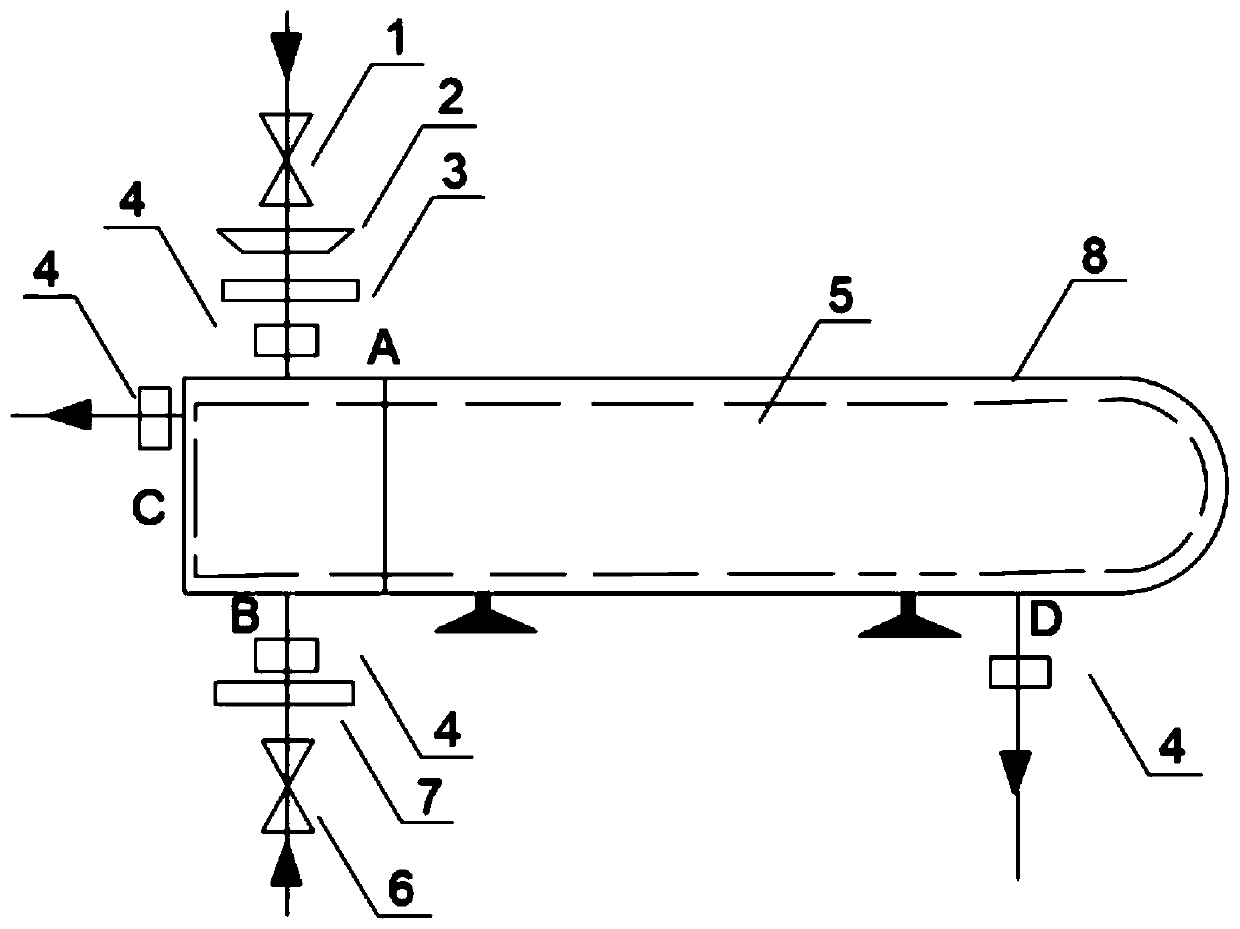

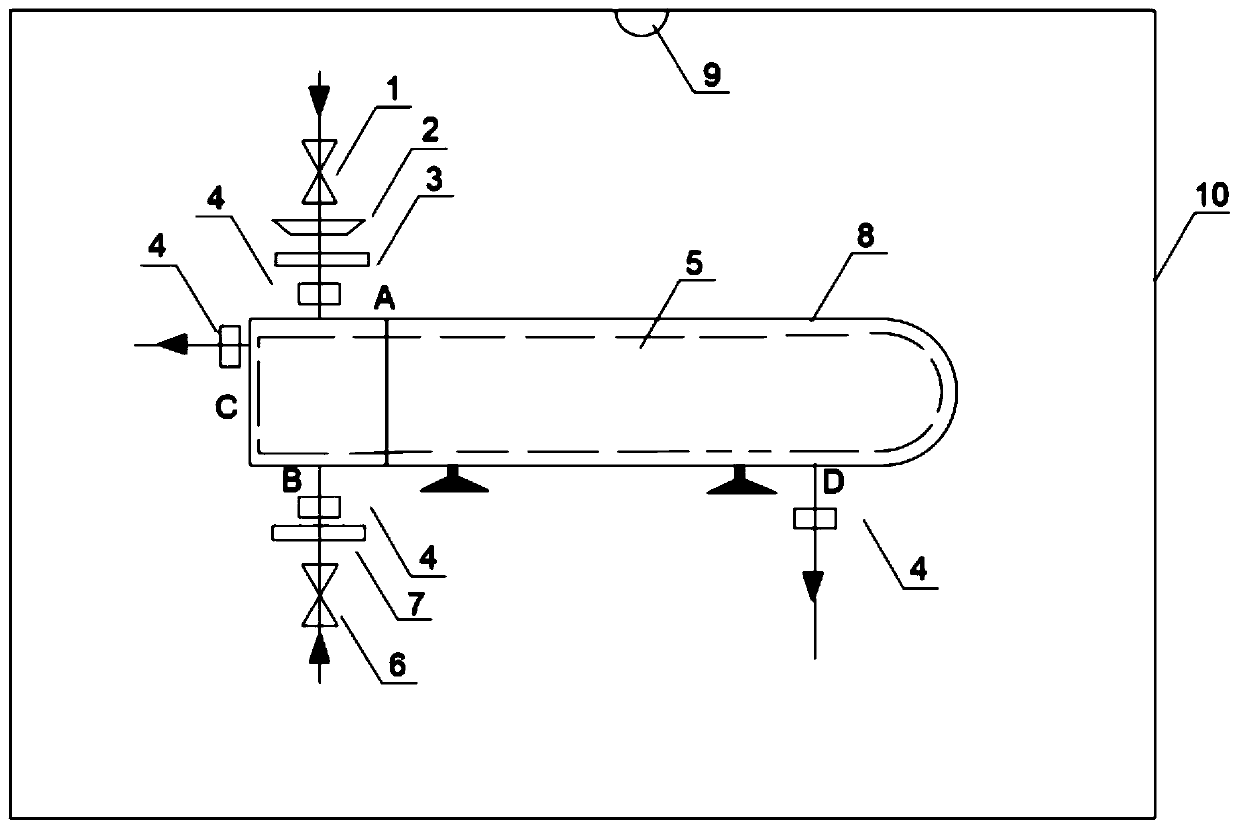

[0023] like figure 1 As shown, a device for online measuring and calibrating the heat content of high-temperature pyrolysis gas described in this embodiment includes a first regulating valve 1, a quartz sand filter 2, a gas flow meter 3, a ceramic heat exchanger 5, Second regulating valve 6, flowmeter 7, heat preservation device 8; Wherein, the inlet of described quartz sand filter 2 is connected with high temperature gas pipeline, the outlet of quartz sand filter 2 is connected with the inlet of gas flowmeter 3; The outlet of the gas flowmeter 3 is connected to the gas inlet A of the ceramic heat exchanger 5 through a delivery pipeline; the first regulating valve 1 is installed before the inlet of the gas flowmeter 3; the second regulating valve 6 is installed in the ceramic heat exchanger 5 After the gas outlet D; install a temperature sensor 4 at the gas inlet A, gas outlet D, water inlet B and water outlet C of the ceramic heat exchanger 5, and install a thermal insulation...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap