Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6 results about "Sand filter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sand filters are used as a step in the water treatment process of water purification. There are three main types; rapid (gravity) sand filters, upward flow sand filters and slow sand filters. All three methods are used extensively in the water industry throughout the world. The first two require the use of flocculant chemicals to work effectively while slow sand filters can produce very high quality water with pathogens removal from 90% to >99% (depending on the strains), taste and odour without the need for chemical aids. Sand filters can, apart from being used in water treatment plants, be used for water purification in singular households as they use materials which are available for most people.

Anti-pressure anti-torsion high-strength V-groove self-cleaning sand-proof screen pipe

The invention discloses a pressure and torsion resistance high-strength V groove self-cleaning anti-sand sieve tube which belongs to a petroleum exploitation mechanical anti-sand device. A coupling is connected with a base tube; the base tube is provided with a round through hole along the axial direction; a filter component is fixed in the round through hole on the base tube; the outer diameter of the base tube is provided with a protective tube. The filter component of the invention is welded on the base tube, and then a protective cover is welded on the filter component; next, the filter component is connected with the coupling and access to the lower end of a petroleum pipe to produce the petroleum. In the anti-sand sieve tube of the invention, the filter component with a V groove filter element consisting of a plurality of circular rings with V-shaped gaps is fixed on the tube wall of the base tube, so as to overcome the defects of low strength, high processing difficulty, high cost, etc. Fine sand can be discharged as the petroleum through elastic and vermicular filtering crack and spacing, so that the sand filtering procedure keeps self-cleaning; in this way, the gap size can mostly meet the petroleum production requirements.

Owner:詹其国

Method for treating coking wastewater

ActiveCN104291474AImprove water quality stabilityImprove water qualityWater contaminantsTreatment involving filtrationOperational costsWater quality

Owner:LIUZHOU IRON & STEEL

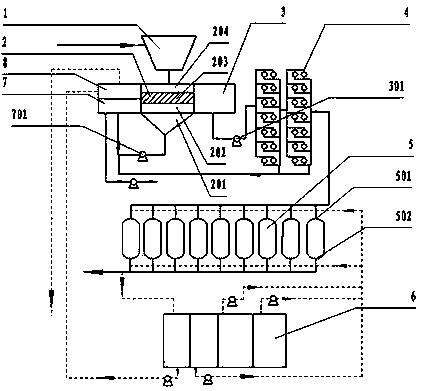

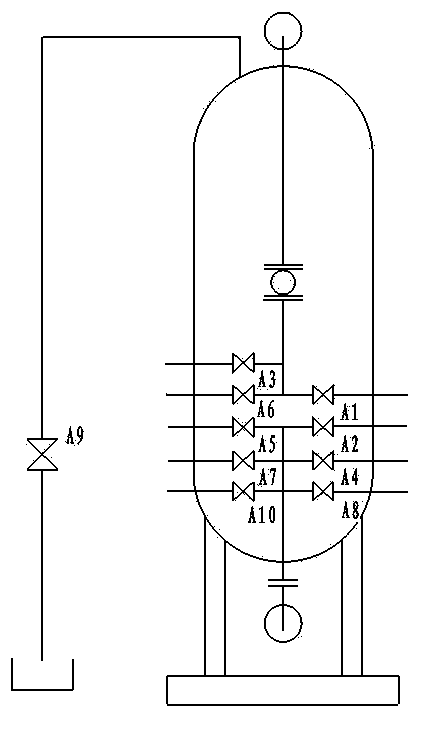

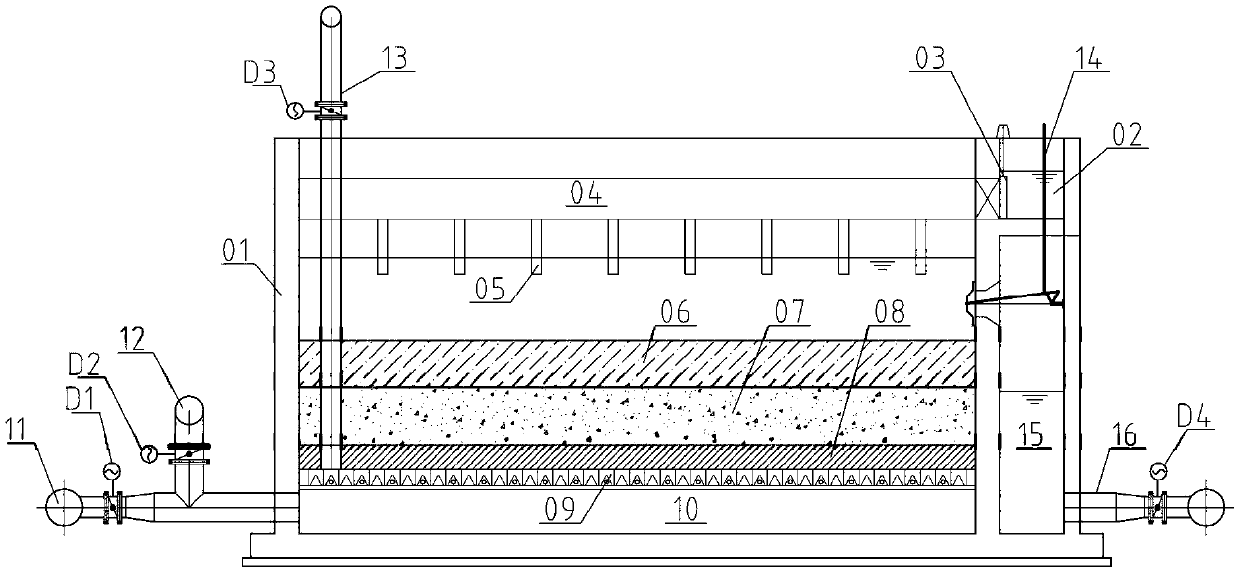

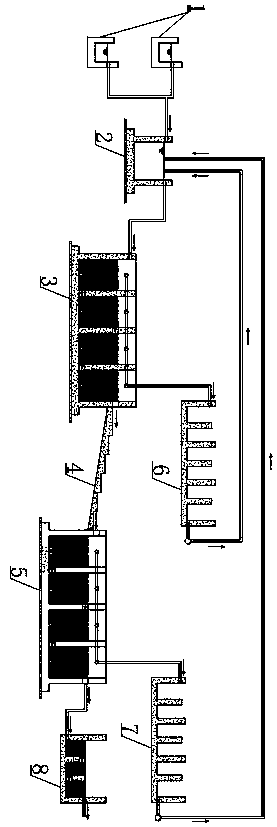

Organic polymer carrier-based novel denitrification filter tank process and device

InactiveCN109942081ACause dosingEven distribution of waterTreatment with anaerobic digestion processesInlet channelFilter media

Owner:ZHEJIANG BOHUA ENVIRONMENTAL TECH & ENG

Mine acidic iron-containing wastewater treatment method and system

PendingCN110950464AReduce dosageLess investmentWaste water treatment from quariesSpecific water treatment objectivesSludgeCatalytic oxidation

Owner:SICHUAN INST OF GEOLOGICAL ENG INVESTIGATION

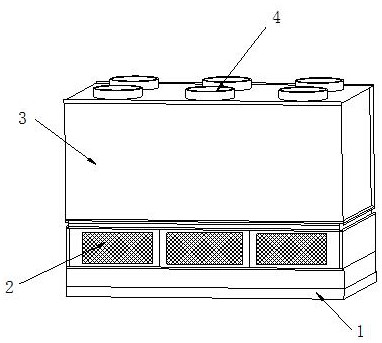

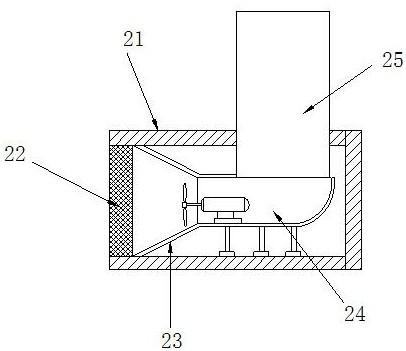

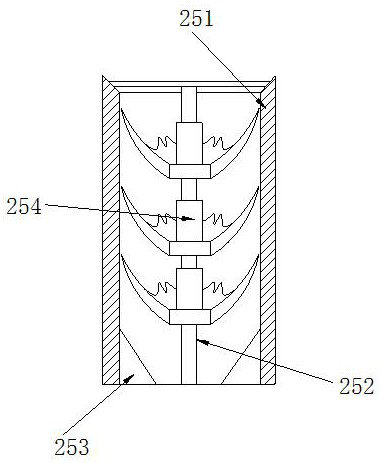

Rapid cooling equipment for ceramic tiles

ActiveCN112696876AReduce qualityAutomatic shake offLighting and heating apparatusCooling fluid circulationSand filterMechanical engineering

Owner:广州宏成科技信息有限公司

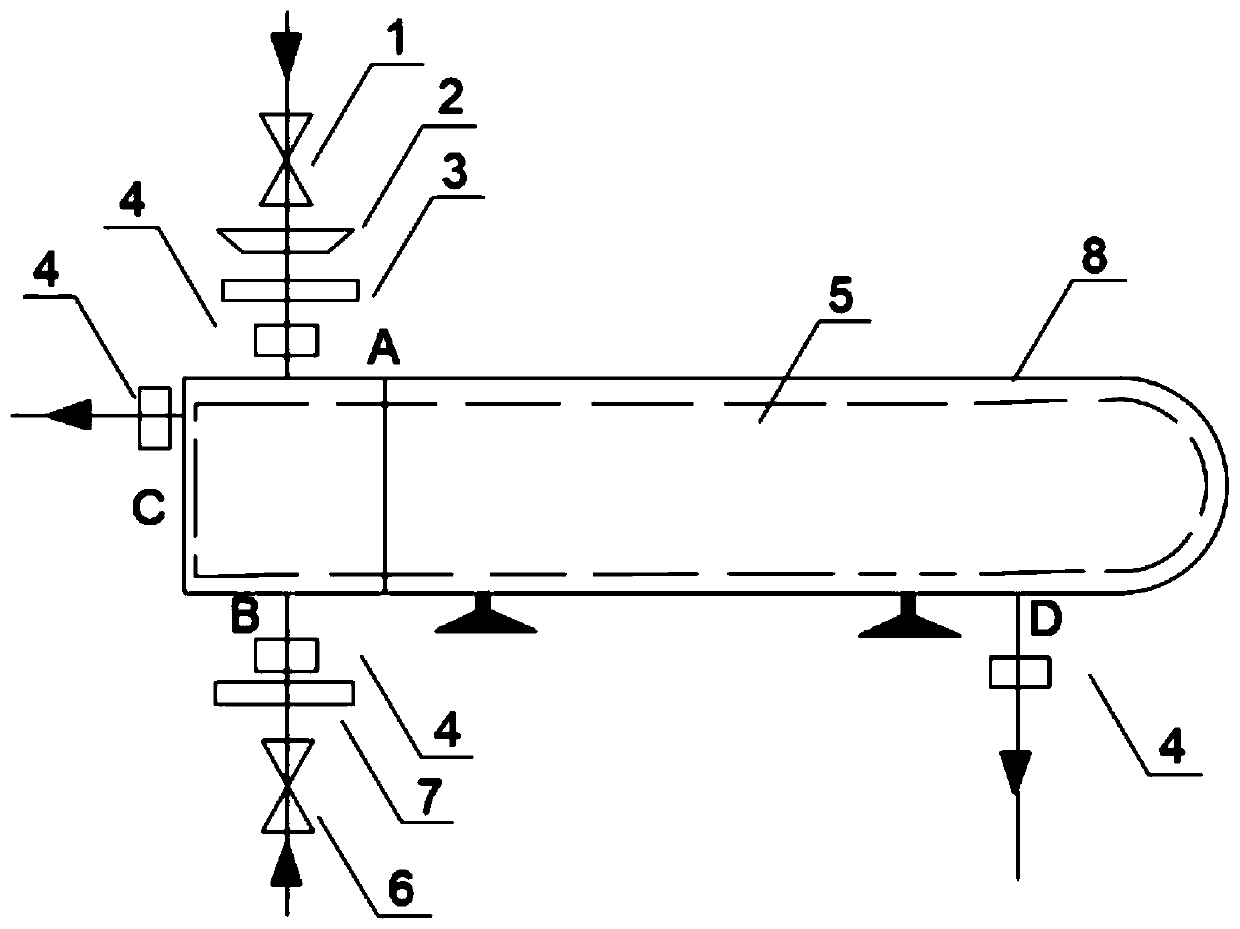

Device and method for online measurement and calibration of heat content of high-temperature pyrolysis coal gas

PendingCN111351816AIncrease production costReduce product volumeMaterial heat developmentCalorimeterSand filterHeat conservation

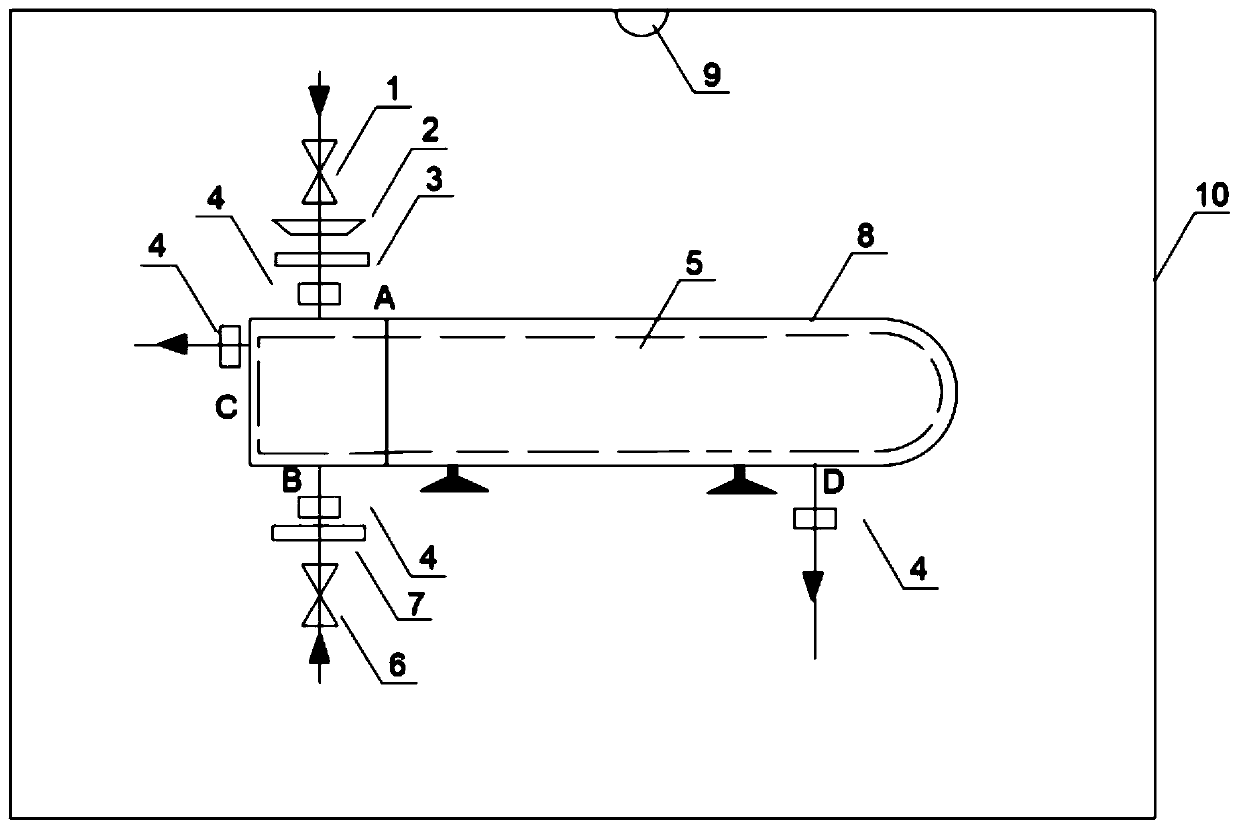

The invention belongs to the field of measurement and calibration of heat content of high-temperature pyrolysis coal gases, and particularly relates to a device and a method for online measurement andcalibration of the heat content of a high-temperature pyrolysis coal gas. Part of the high-temperature coal gas passes through a quartz sand filter, a flue gas flow meter and heat exchange equipmentwhich is manufactured by arranging a temperature measuring element, a water system, a heat preservation system, a water side heat exchange element in parallel and the like, the heat exchange amount ofthe coal gas and the water is obtained according to a formula Q = Cm delta t, and the heat contained in all the coal gas is obtained according to the coal gas flow and heat data. According to the method, the heat of the high-temperature coal gas is accurately measured, clean and efficient gradient utilization of the heat is achieved, the heat utilization rate is maximized, and heat utilization equipment cannot be damaged due to the fact that the heat utilization equipment bears the limit temperature.

Owner:ZHEJIANG UNIV +1

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap