Method for treating coking wastewater

A coking wastewater and treatment method technology, applied in the direction of gaseous effluent wastewater treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of unstable operation of the device, high yield of concentrated liquid, difficult final treatment, etc., to achieve Low operating cost, short process, effective improvement of tail water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

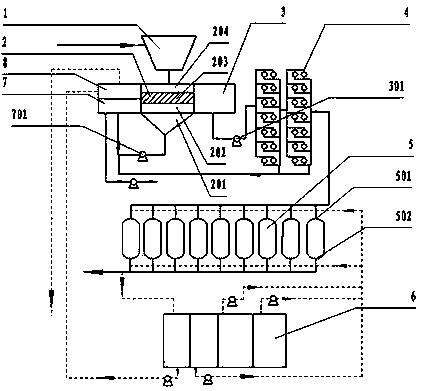

[0017] Such as figure 1 The coking wastewater treatment system shown includes a water separator 1, the bottom of which is connected to an inclined tube sedimentation tank 2 through a pipeline, and one side of the inclined tube sedimentation tank is connected to a desorption liquid pool 8 and a sludge pool 7, and the other There is an upper column liquid pool 3 on one side, and the inclined tube sedimentation tank 2 is respectively a sludge collection bucket 201, a buffer zone 202, an inclined tube filling area 203, and a water collection area 204 from bottom to top. The bottom of the sludge collection bucket 201 passes through the sludge pump 701 communicates with the sludge tank 7, and the side of the water collection area 204 on the top of the inclined tube sedimentation tank is provided with an opening to communicate with the upper column liquid pool 3; the upper column liquid pool 3 communicates with the shallow sand filter group 4 through the upper column liquid pump 301 , t

Embodiment 2

[0019] In this example, the waste water flow rate is 290 m 3 / h, the resin adsorption time is 100h, the concentration of hydrochloric acid desorbing agent is 2%, the concentration of sodium hydroxide desorbing agent is 6%; all the other are the same as embodiment 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap