Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

111results about "Chemical/physical processes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

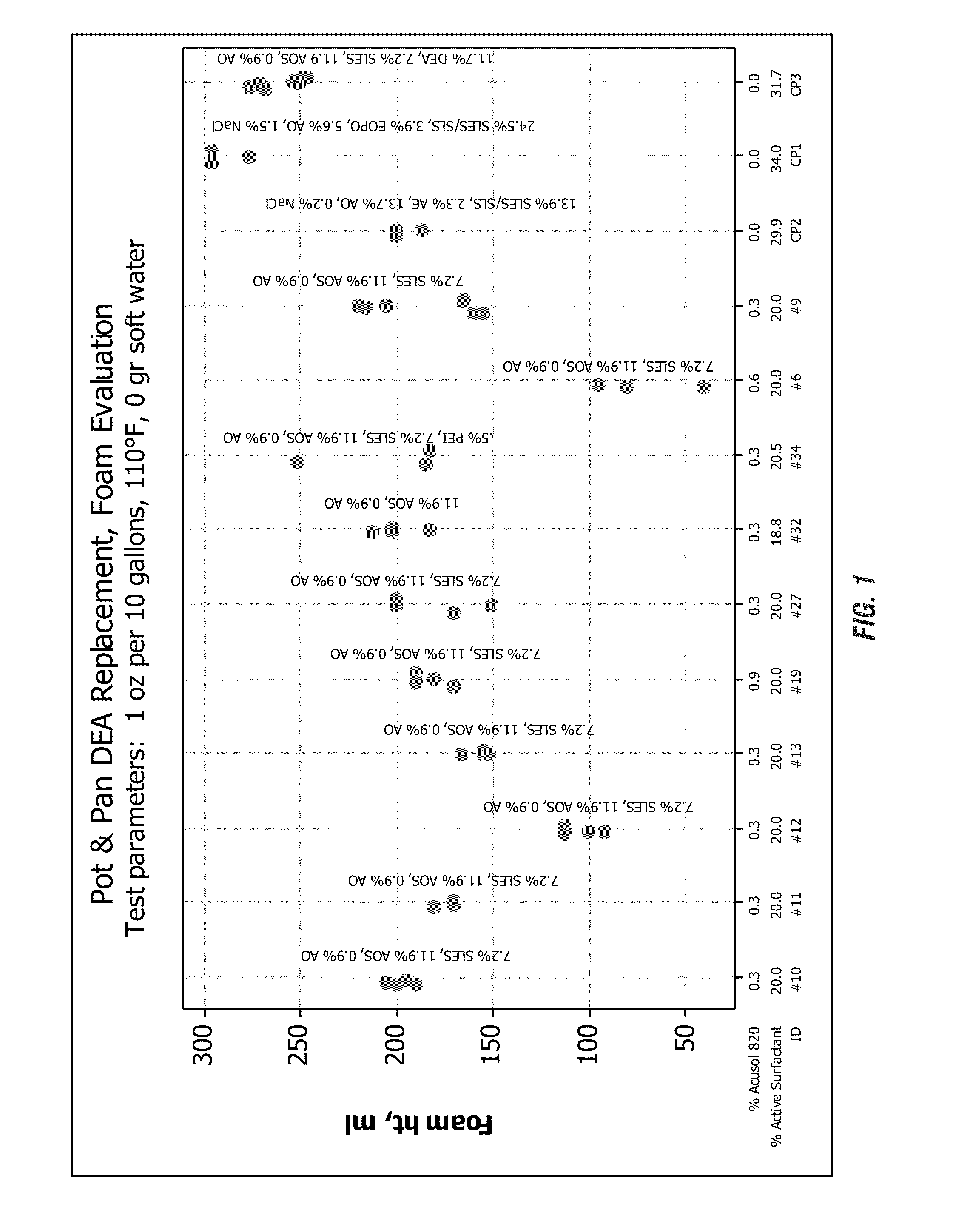

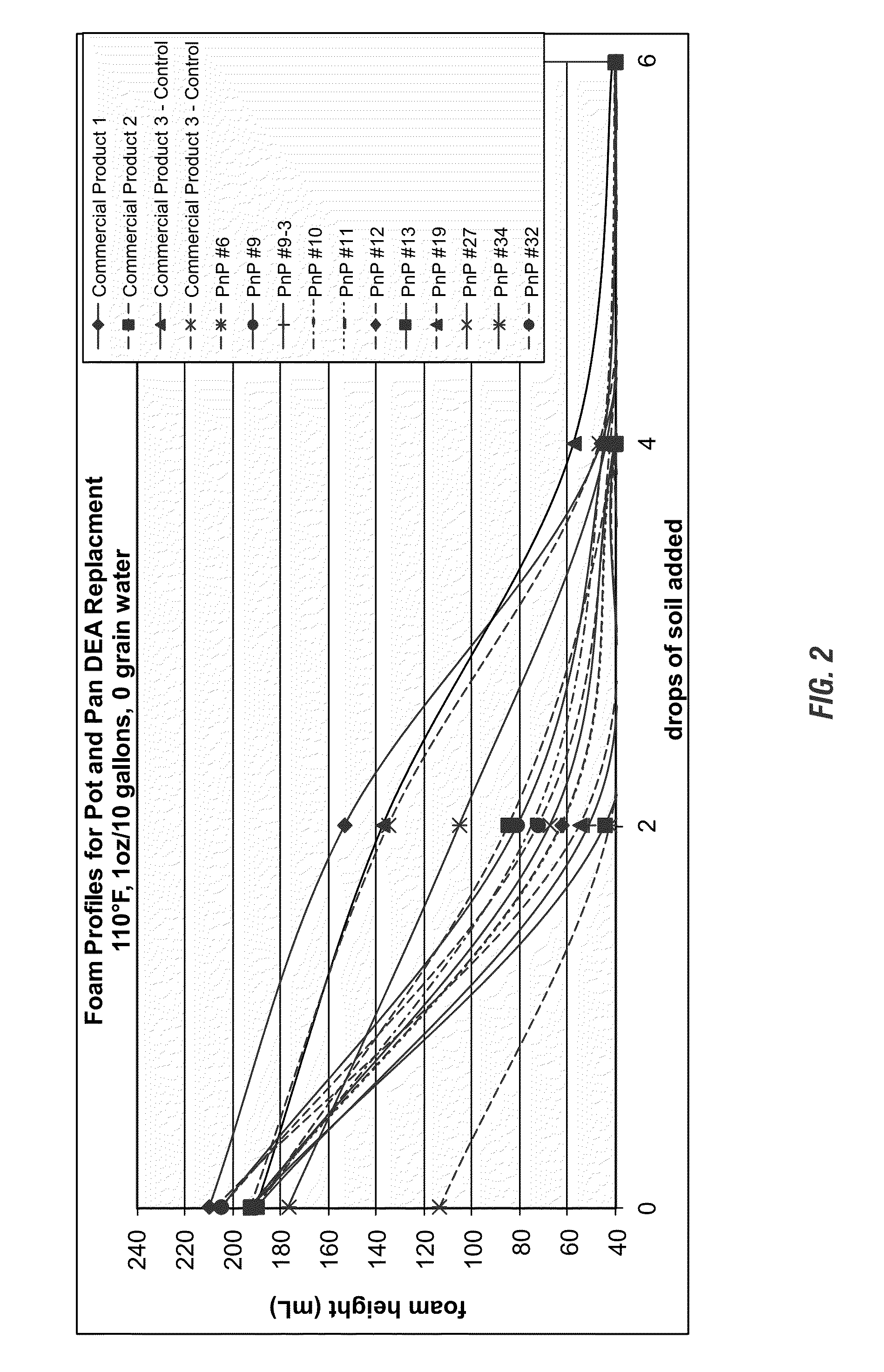

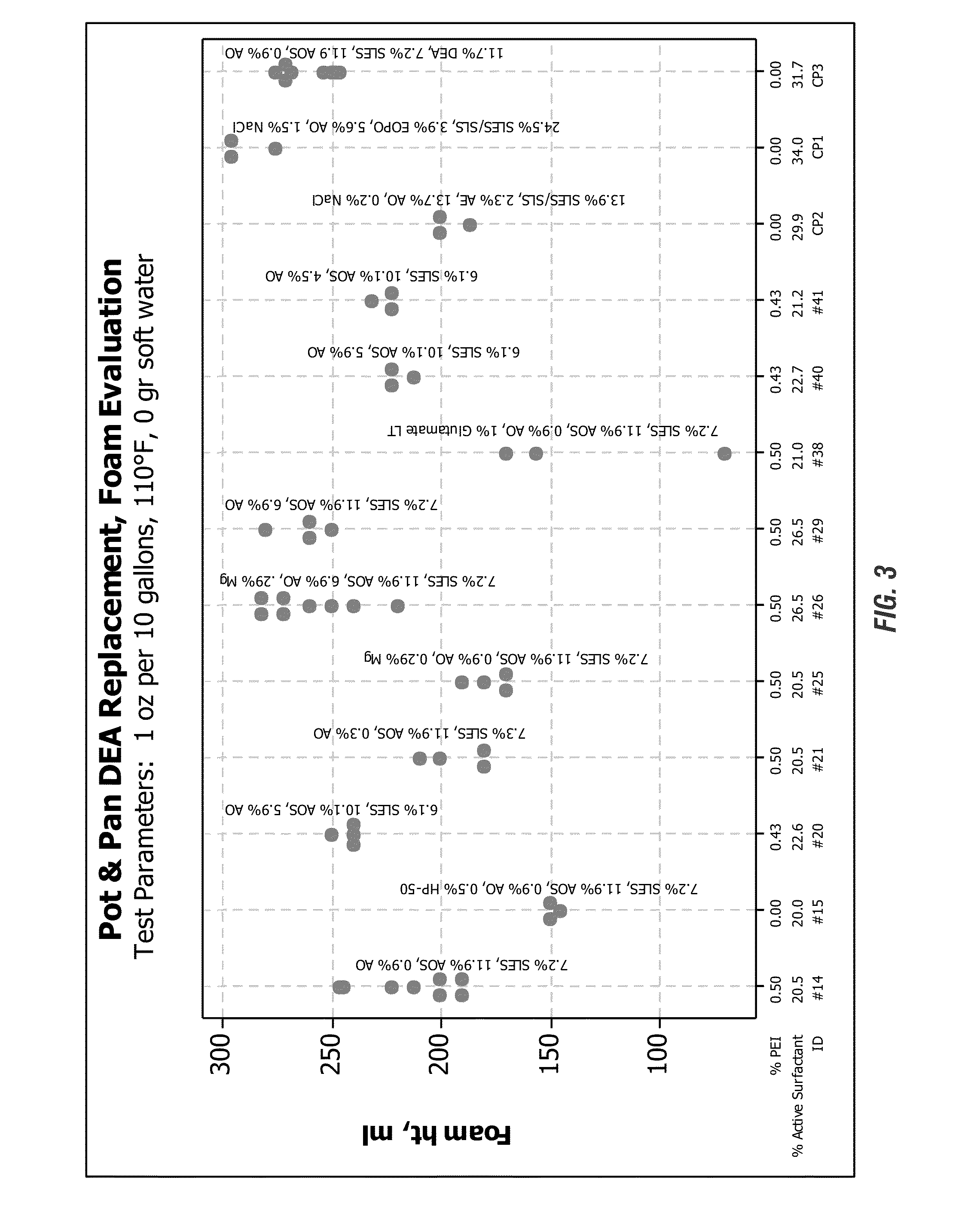

Foam stabilization with polyethyleneimine ethoxylates

ActiveUS20140148374A1Provide stabilityCosmetic preparationsOrganic detergent compounding agentsElectrostatic interactionCocamide DEA

Owner:ECOLAB USA INC

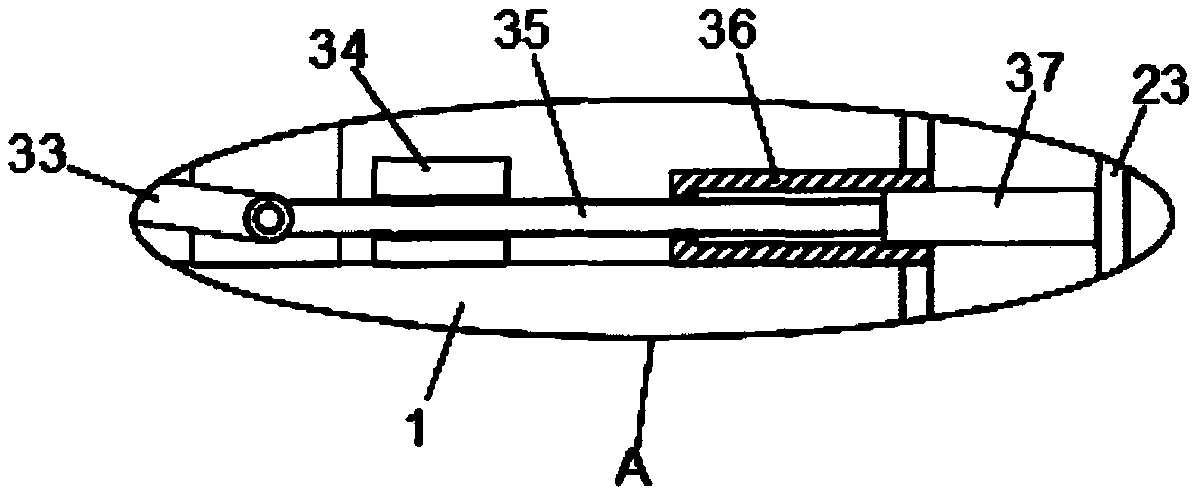

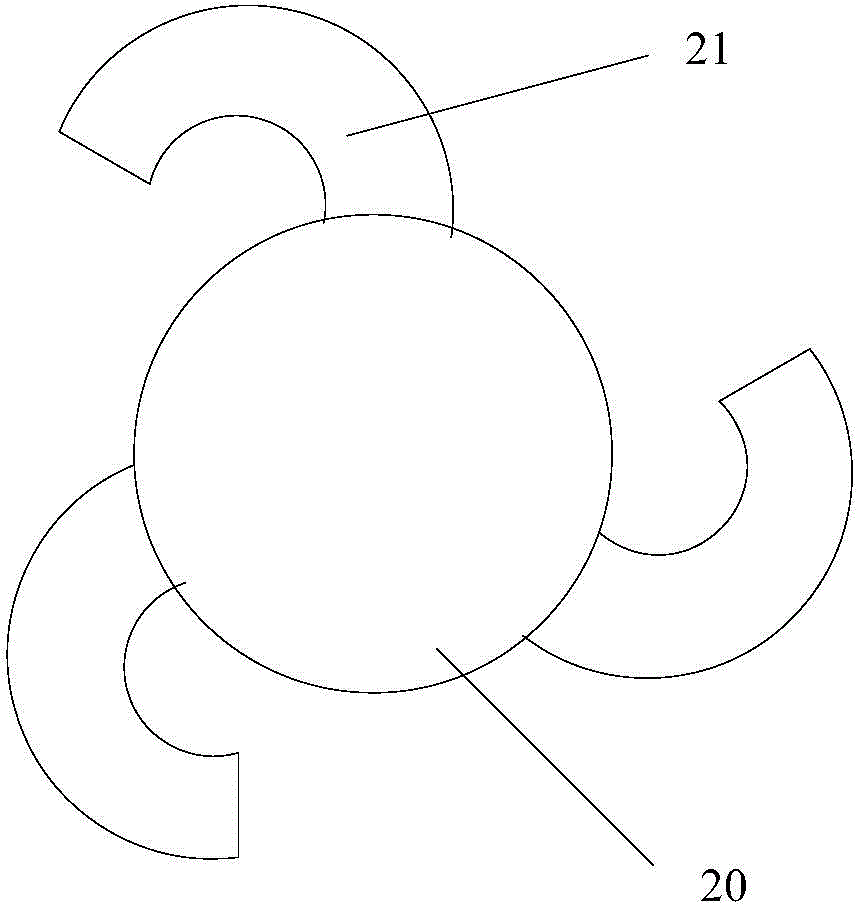

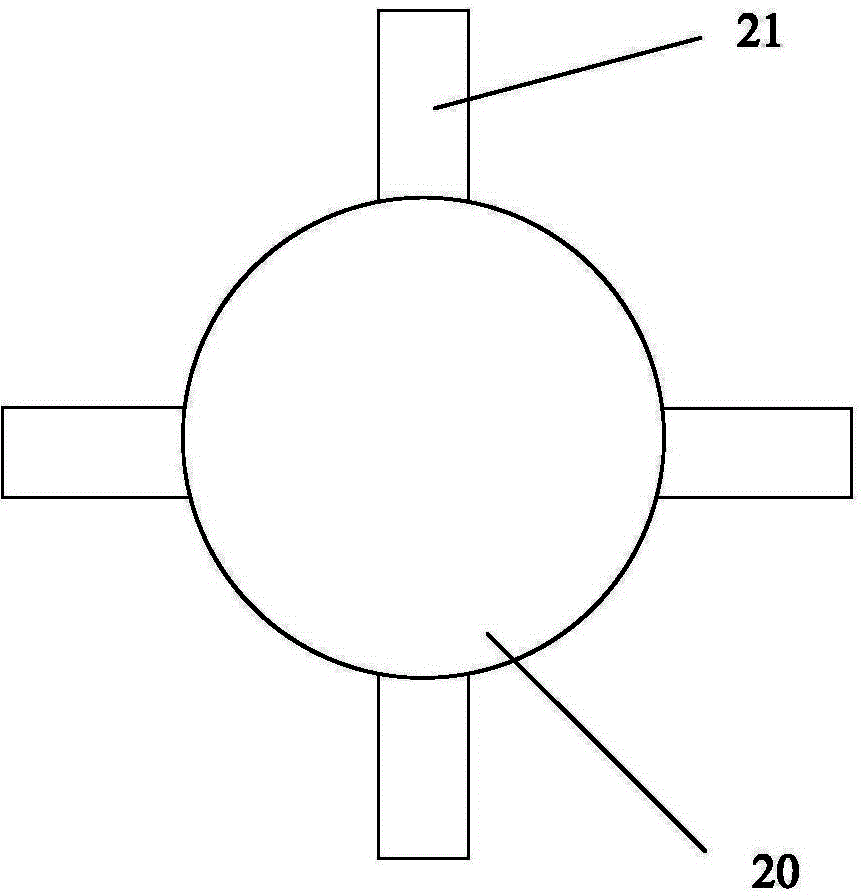

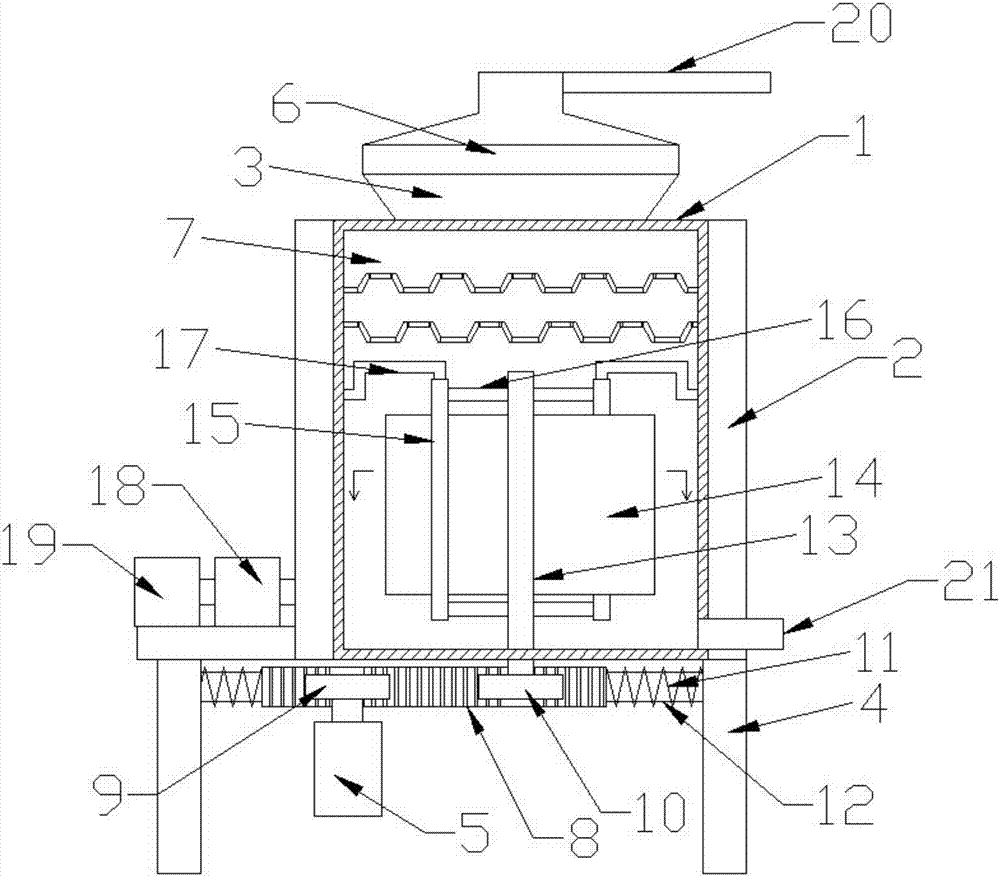

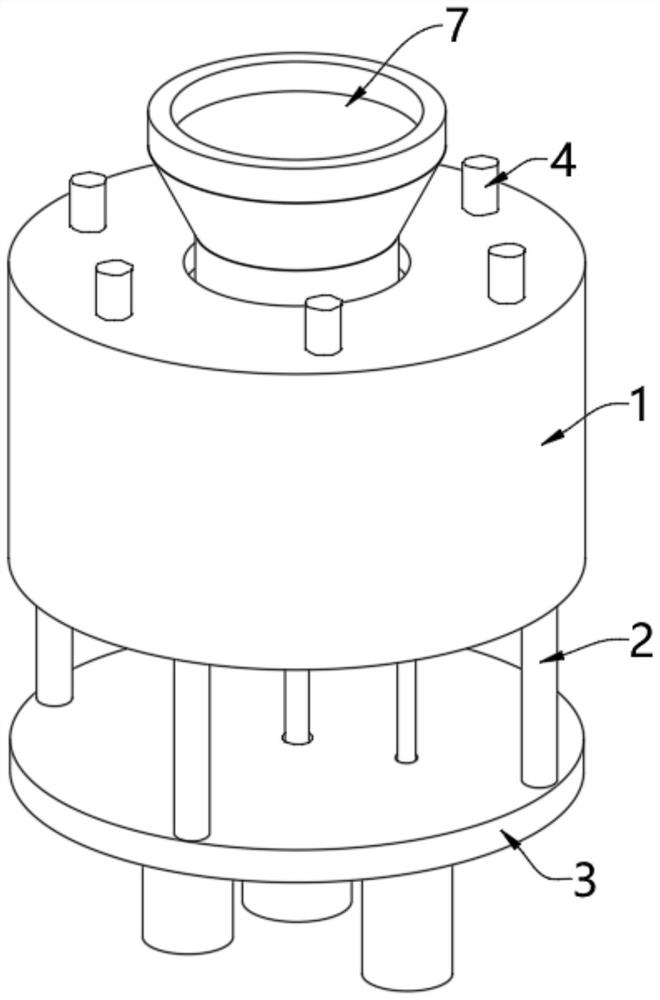

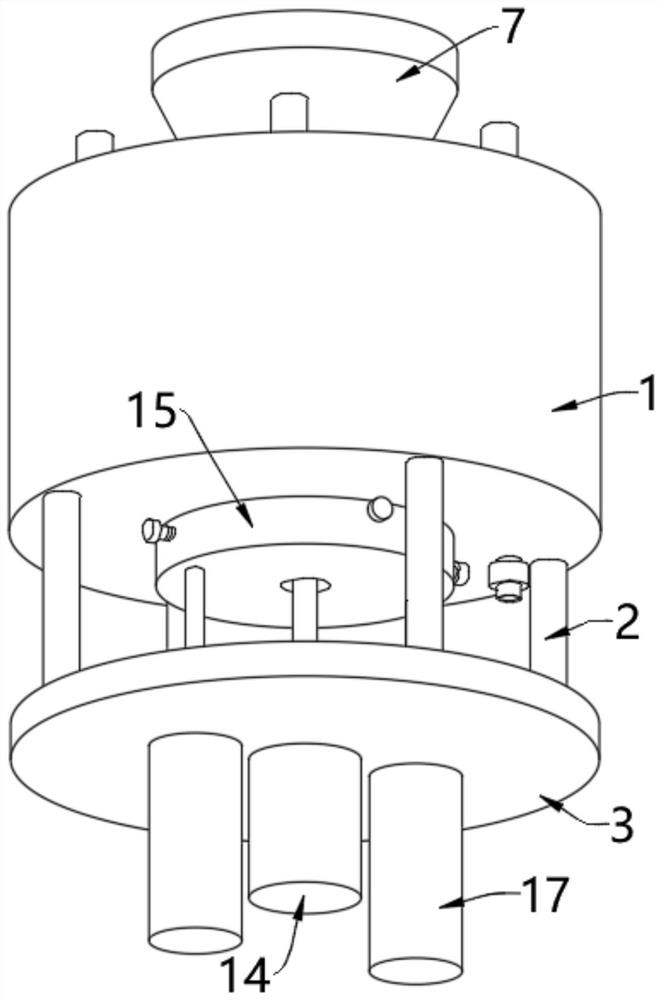

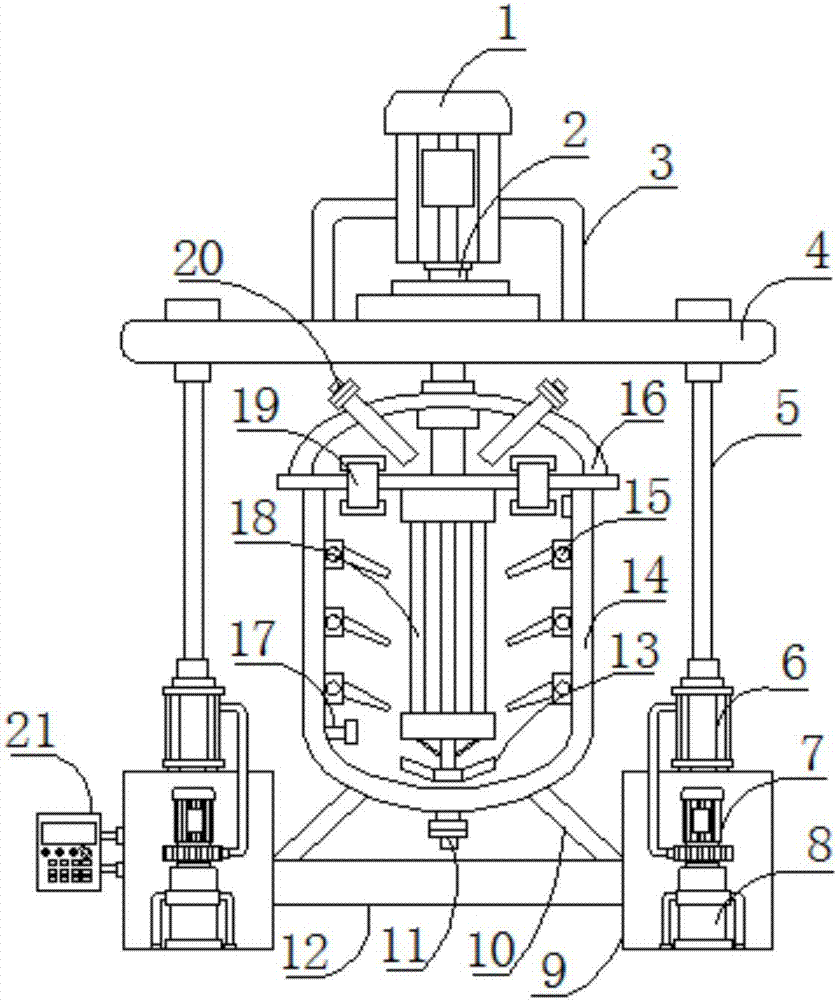

Slurry bed ft synthetic reactor and technique

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Device and Method for Admixing Liquids into Flowable Bulk Material

ActiveUS20080144425A1High energyEfficient mixingMixing/kneading structural elementsFlow mixersSpray nozzleImpact area

A device for admixing a liquid into flowable dry materials has a housing with a mixing chamber having an inner wall with an impact area and an exit opening at a bottom end of the mixing chamber. Dry material is supplied from above into the mixing chamber and falls downwardly toward the impact area in front of the inner wall of the mixing chamber and exits through the exit opening. A nozzle generates a pressurized high-speed jet of a liquid impacting on the inner wall of the mixing chamber in the impact area and wetting the dry material with the liquid as the jet passes through the dry material and impacts against the inner wall. An opening inside the housing is provided for supplying liquid and pasty additives, wherein the opening is directed toward an area of the mixing chamber between the nozzle and the impact area.

Owner:DIERKS & SOHNE GMBH & CO KG

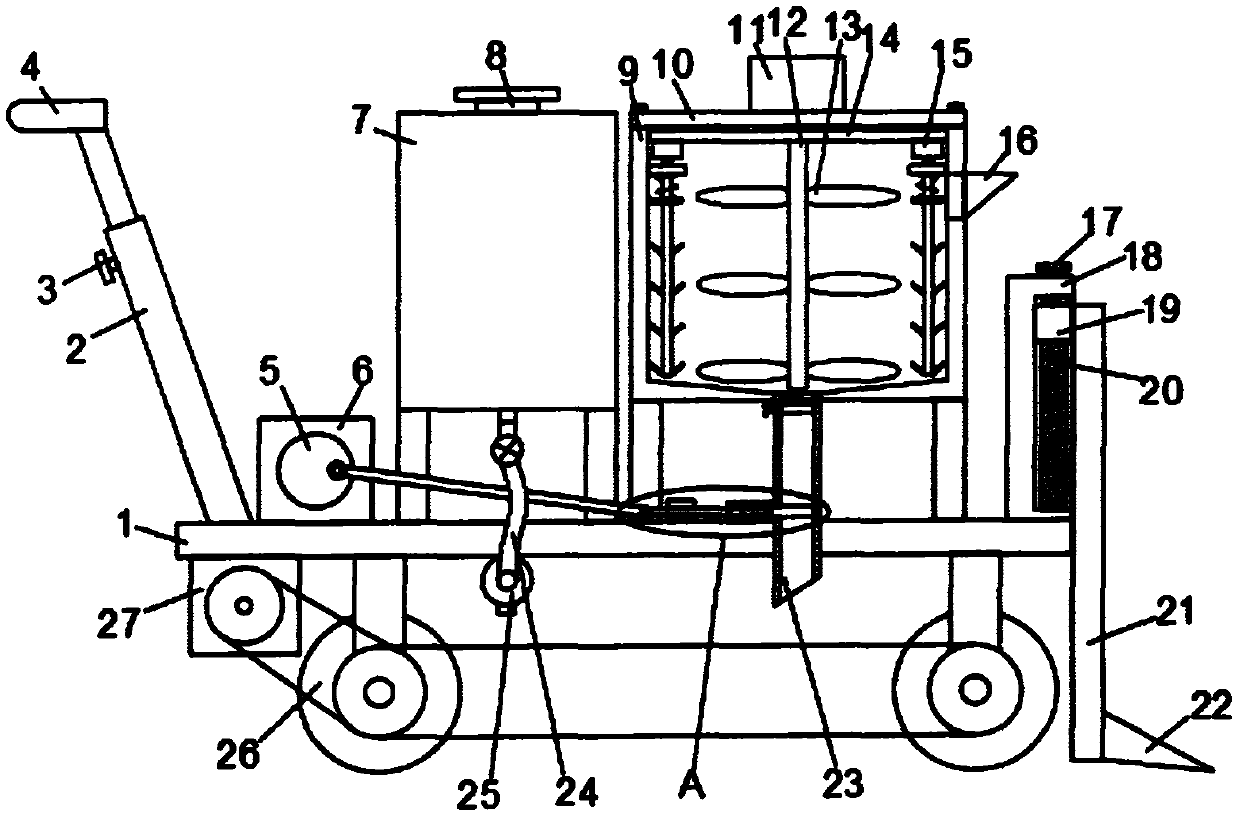

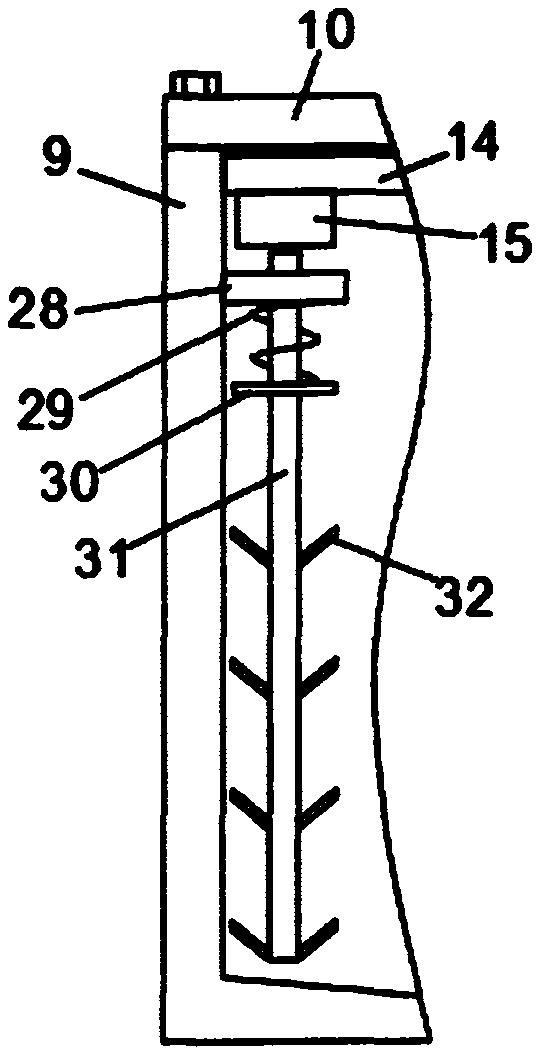

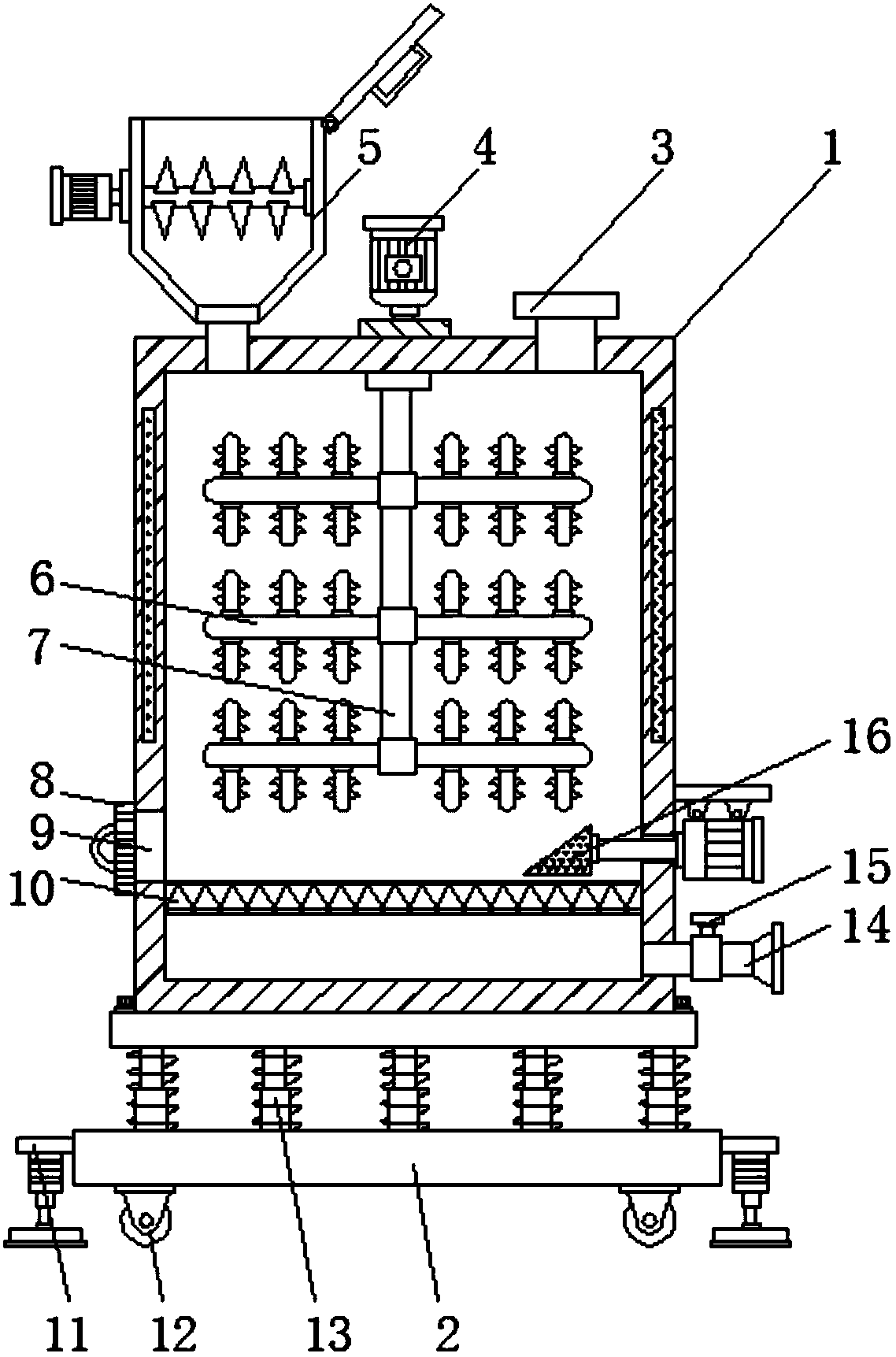

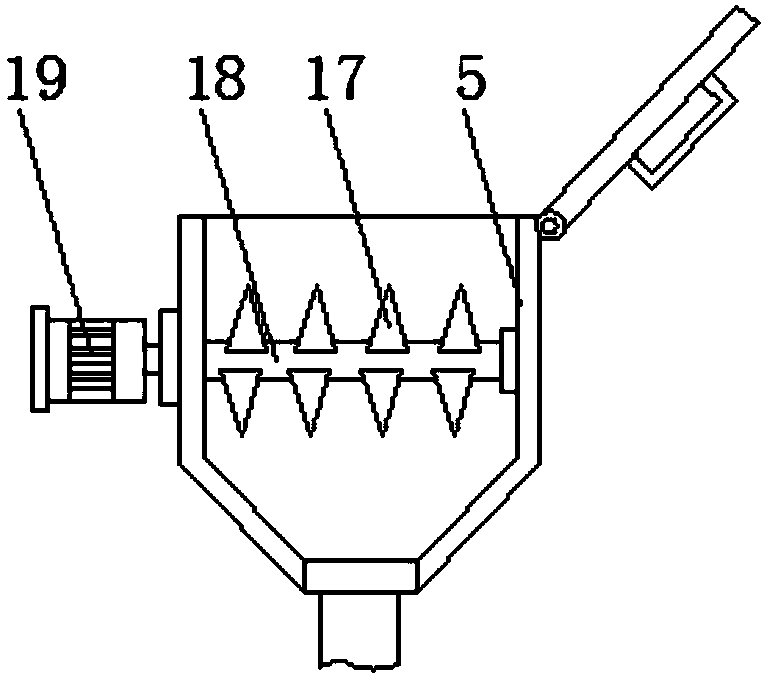

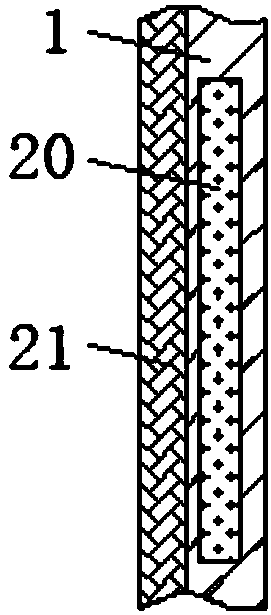

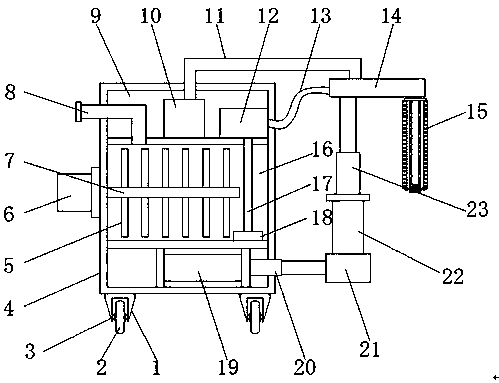

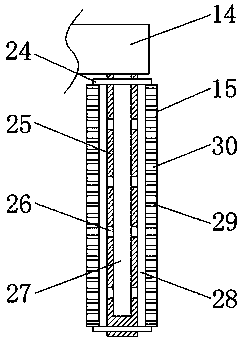

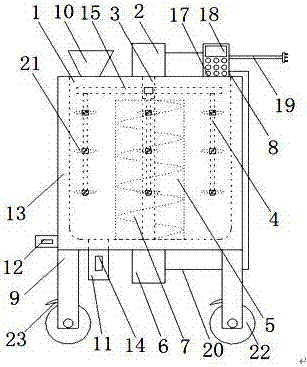

Automatic fertilization device for agriculture science and technology

InactiveCN110178509AImprove mixing uniformityImprove stirring efficiencyRotary stirring mixersTransportation and packagingEngineeringMixing effect

Owner:XUZHOU CITY JIAWANG DISTRICT LUOZI AGRI TECH CO LTD

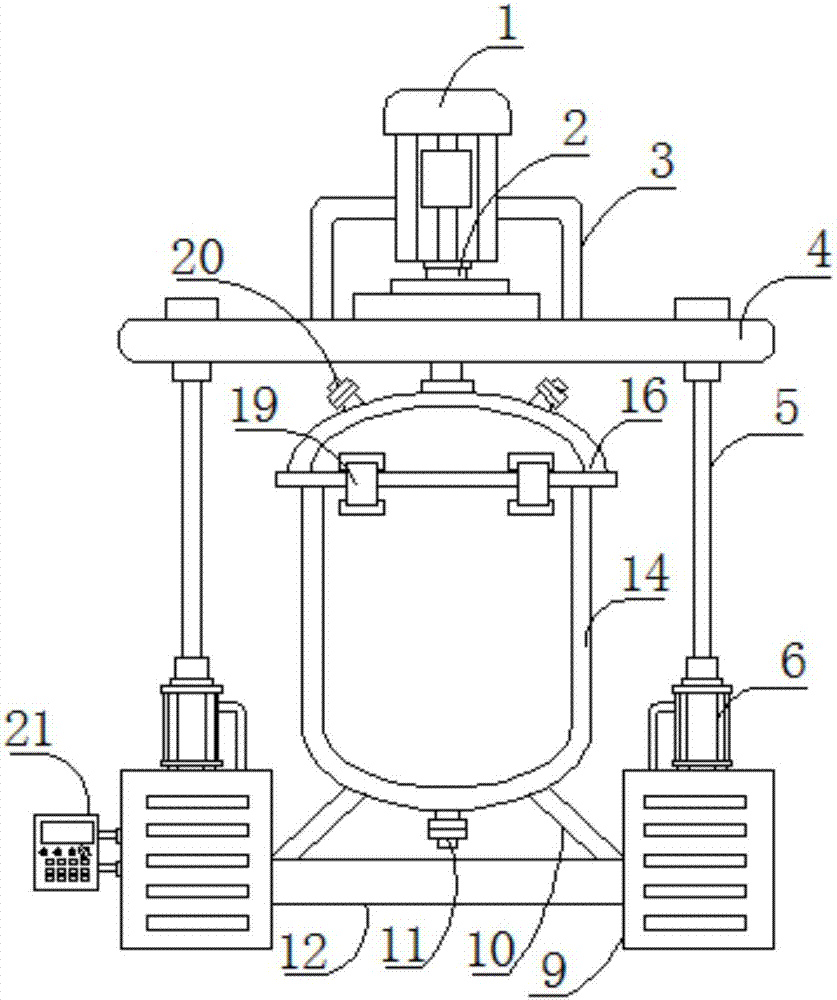

Slurry stirring device for coated fabric production

PendingCN108607463AStir wellEffective crushing and refiningRotary stirring mixersTransportation and packagingPulp and paper industryReducer

Owner:浙江唐艺织物整理有限公司

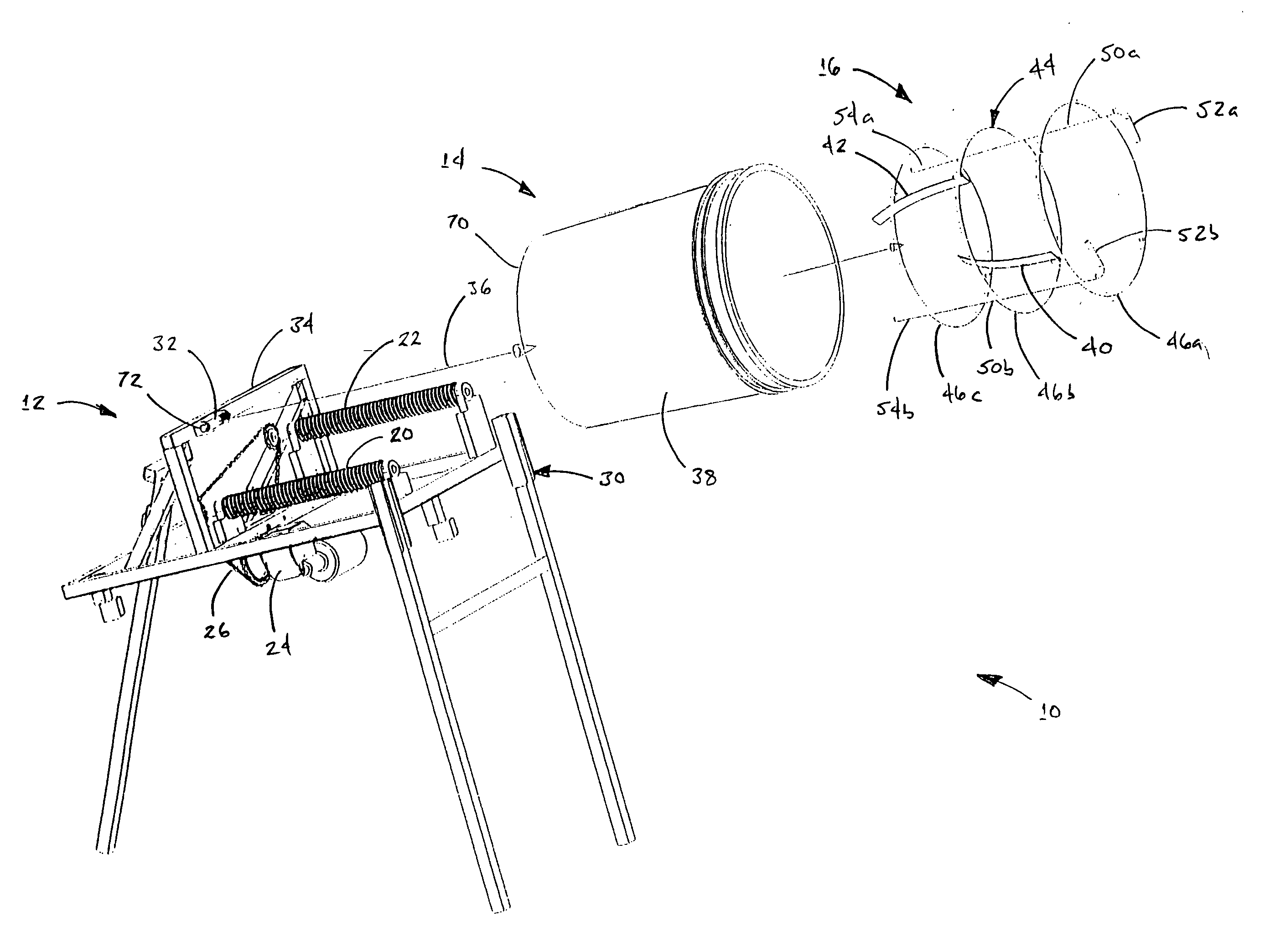

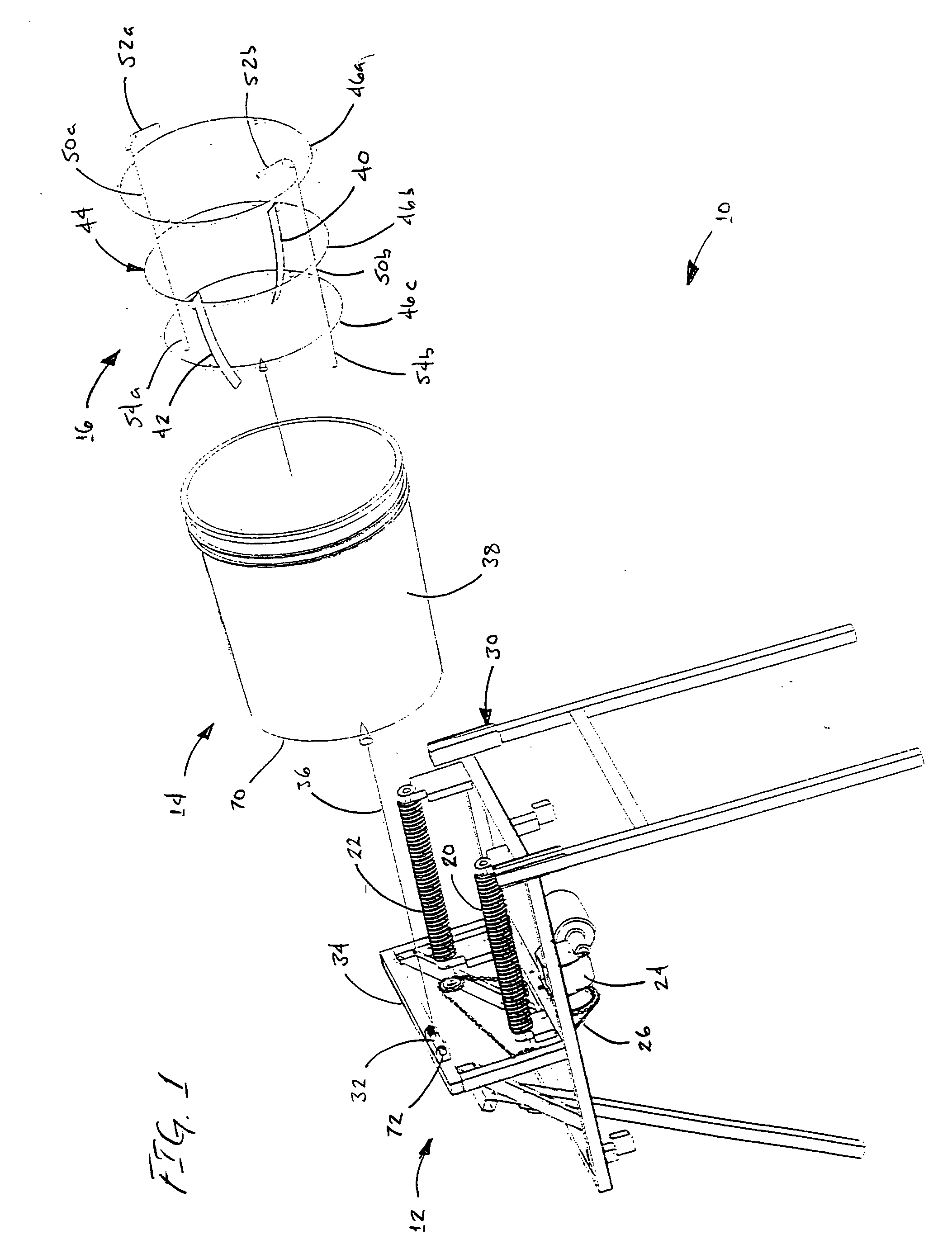

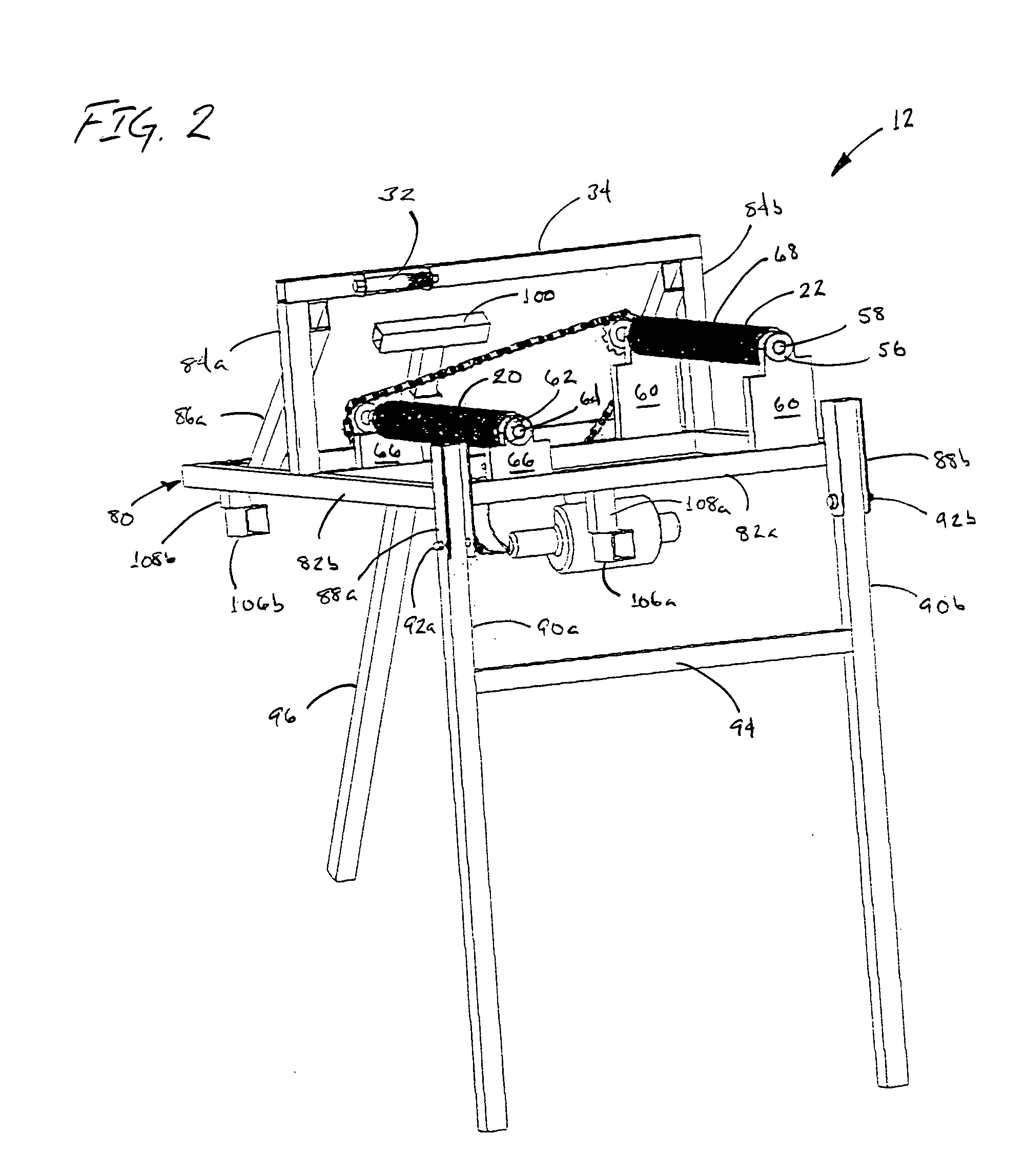

Portable mixing apparatus

InactiveUS20060028913A1Easy to transportRotating receptacle mixersTransportation and packagingMotor driveSlope angle

Owner:HASKELL GEORGE L

Loop reaction device in slurry bed, application and method for producing hydrogen peroxide

ActiveCN104549066AExtended operating cycleIncrease profitPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesChemical/physical processesHigh concentrationFiltration

Owner:CHINA PETROLEUM & CHEM CORP +1

Simple and convenient synthesis method and application of waste grease based polyhydric alcohol

InactiveCN104262561ALow costSolve pollutionFatty acid esterificationPolyureas/polyurethane adhesivesTransesterification reactionAlcohol products

Owner:ZHEJIANG HENGFENG NEW MATERIAL

Feed processing dryer capable of stirring in positive and negative rotation mode

InactiveCN107280051AEasy to storeSmooth and safe deliveryFeeding-stuffRotary stirring mixersDrive shaftEngineering

Owner:王淑兰

Movable type wall coating spraying device

InactiveCN107842183AAvoid layeringPrevent precipitationRotary stirring mixersTransportation and packagingAgricultural engineeringMovable type

Owner:蒋丹丹

Magnetic Suspension Type Water Adding Device and Air Humidifier

ActiveUS20180195747A1Reasonable structureEasy to useOperating means/releasing devices for valvesLighting and heating apparatusPower flowElectric generator

Owner:AIRPPLE ELECTRONICS TECH XIAMEN

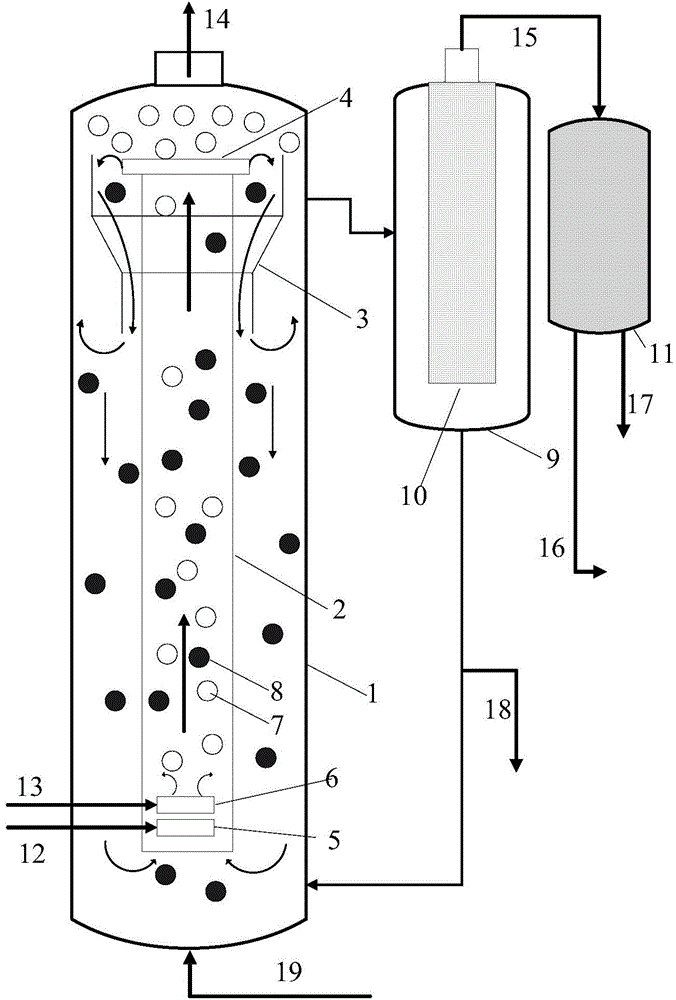

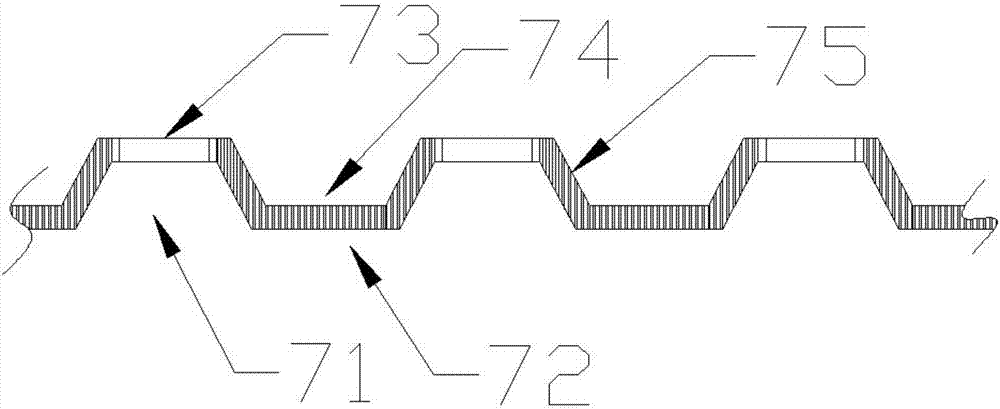

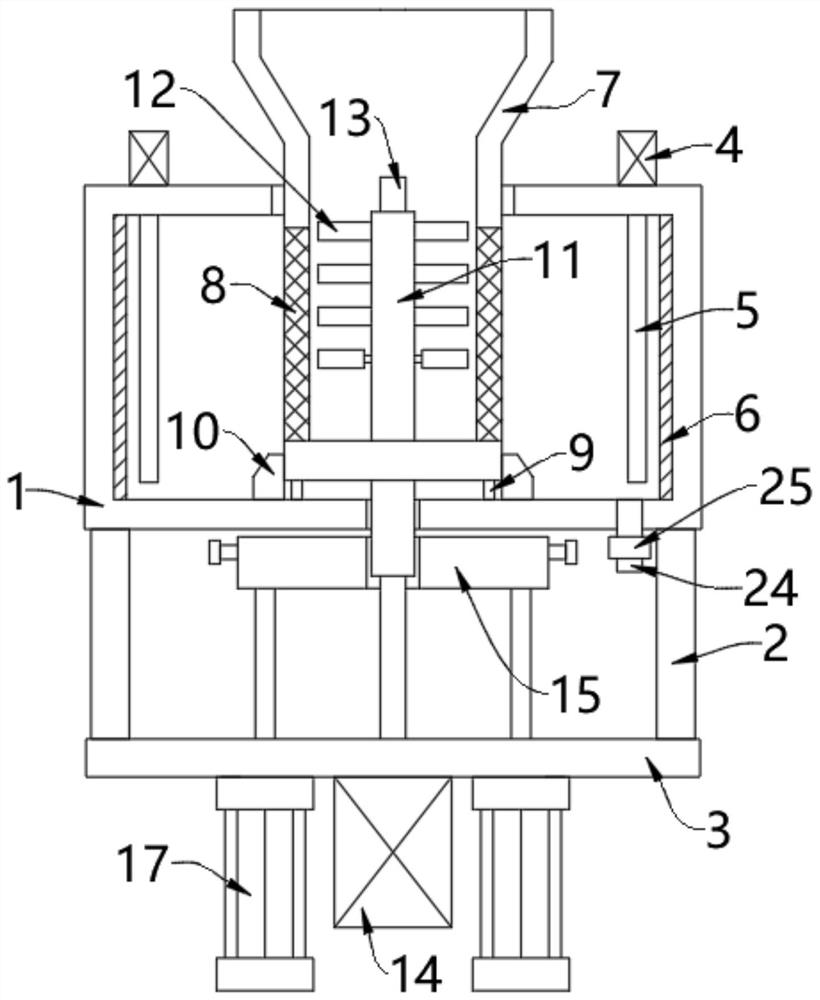

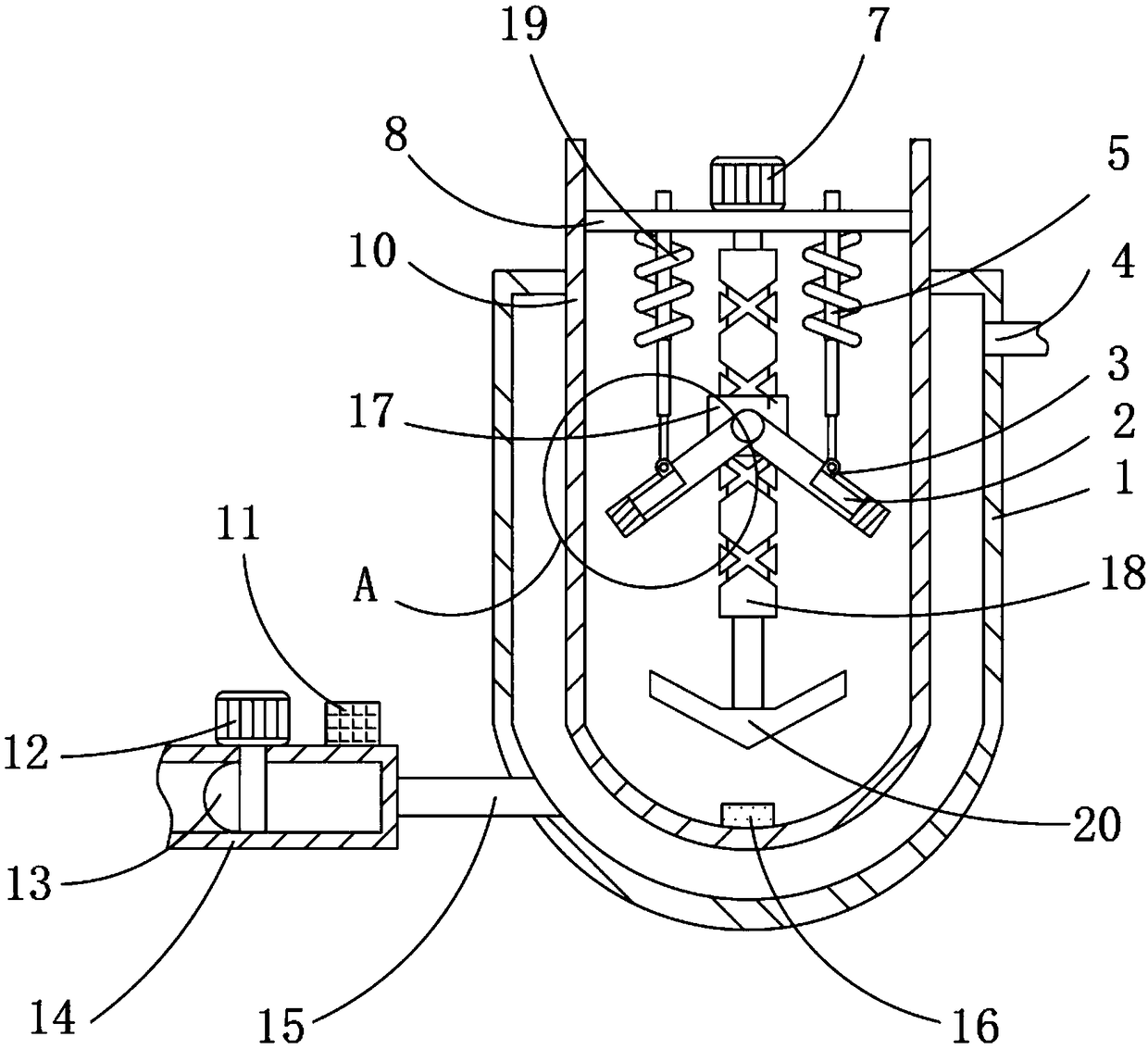

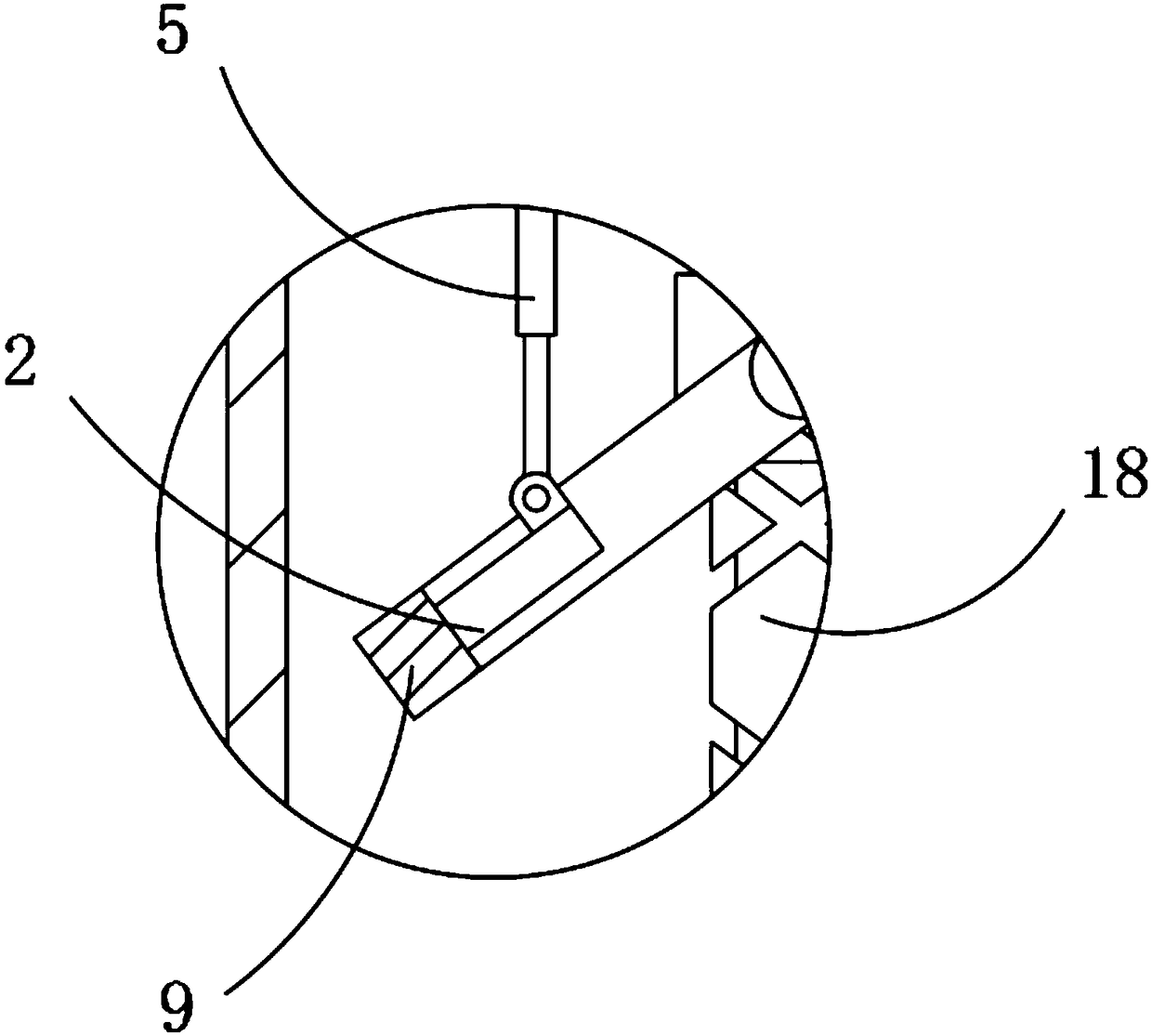

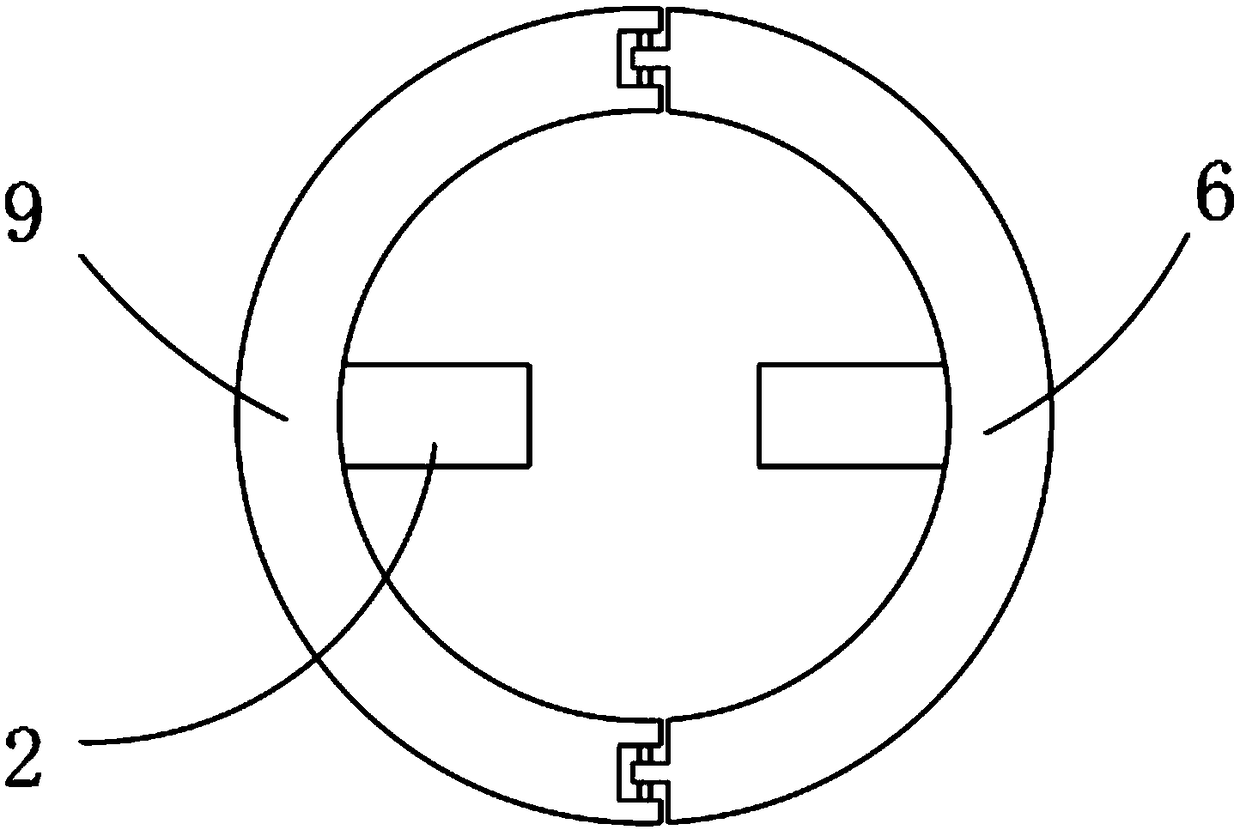

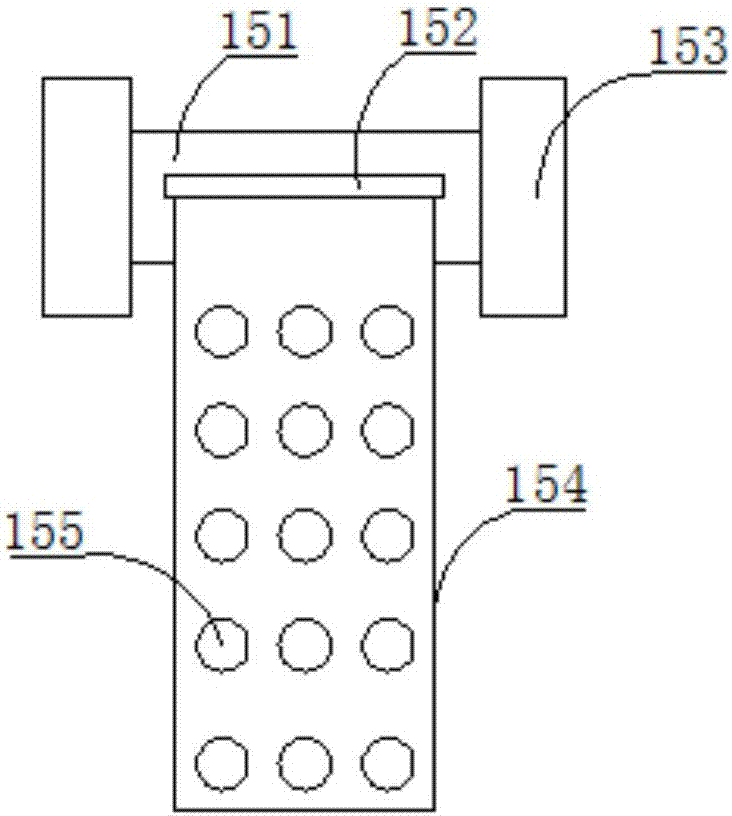

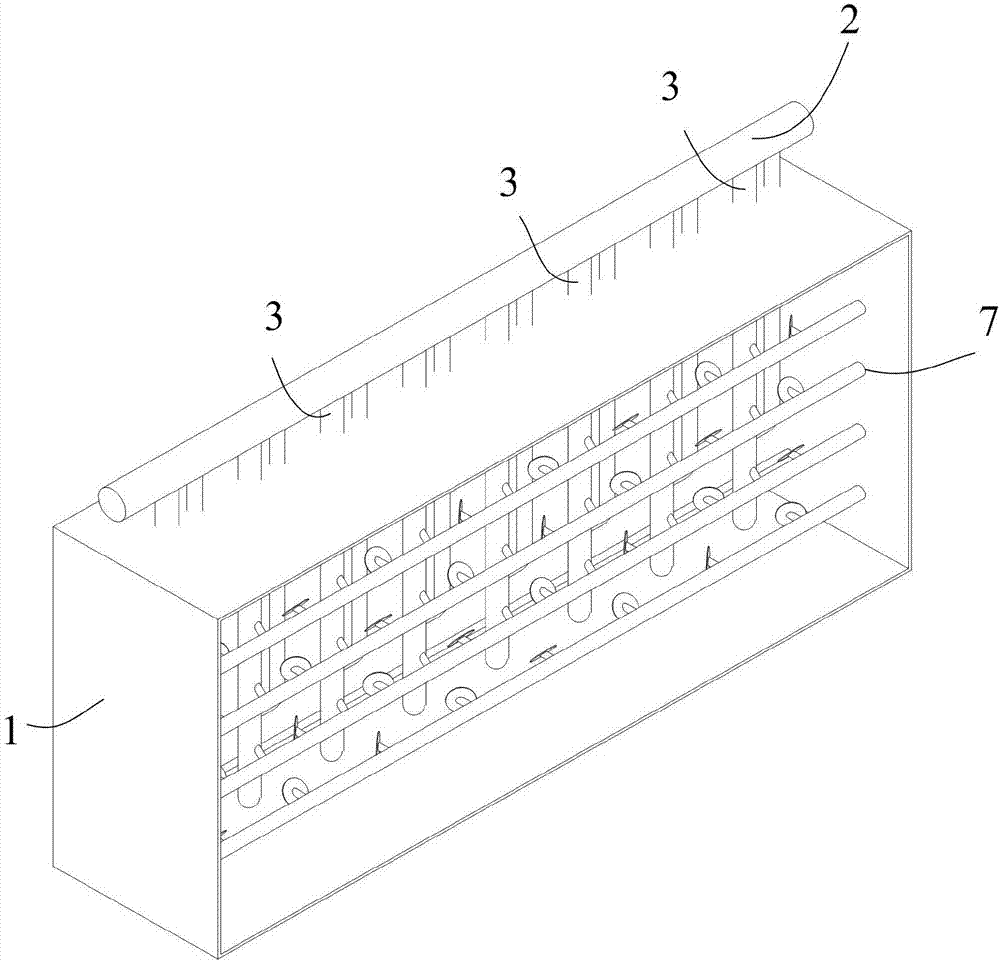

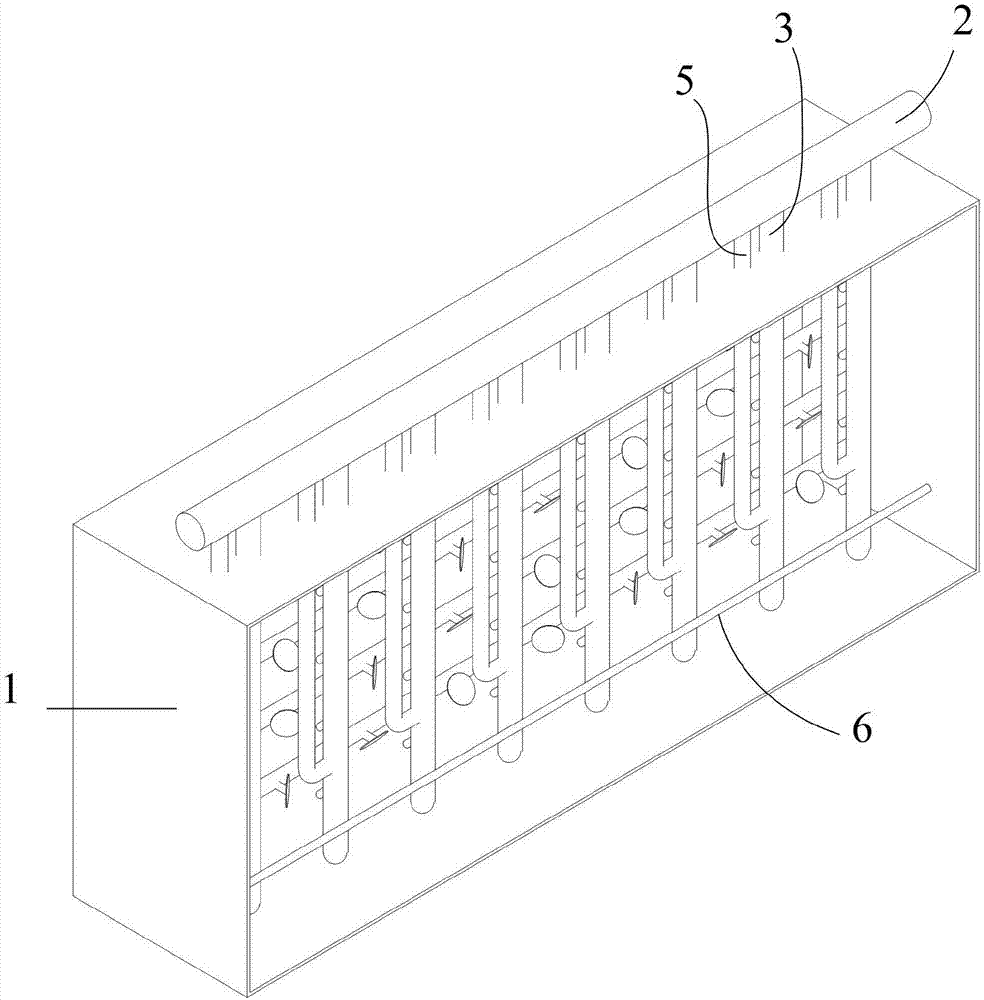

Fluidized-bed reaction device and fluidization reaction method for hydrogenation of nitrobenzene

ActiveCN111298727AImprove fluidization qualityReduce the presence of air bubblesOrganic compound preparationAmino compound preparationPtru catalystGas phase

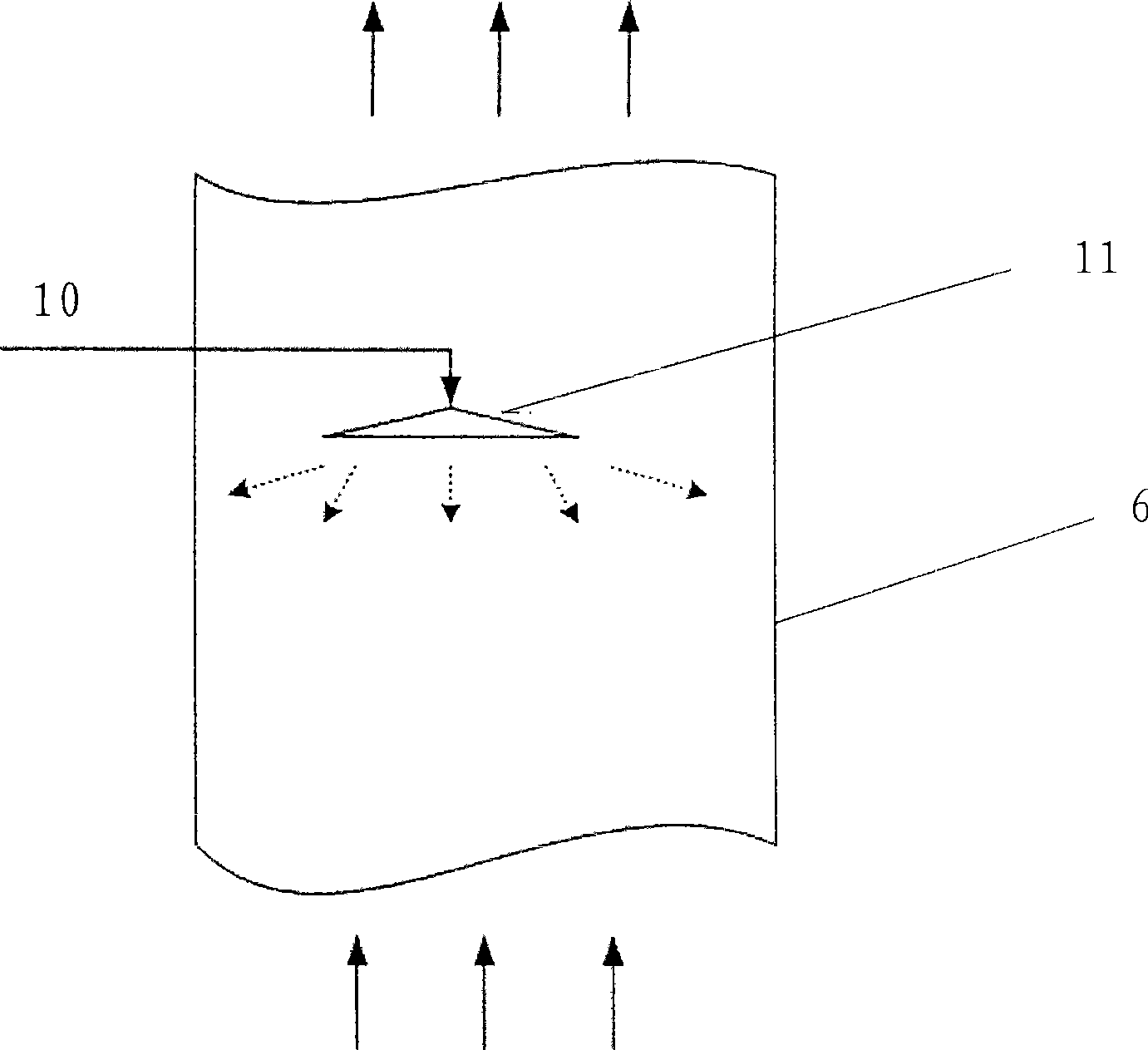

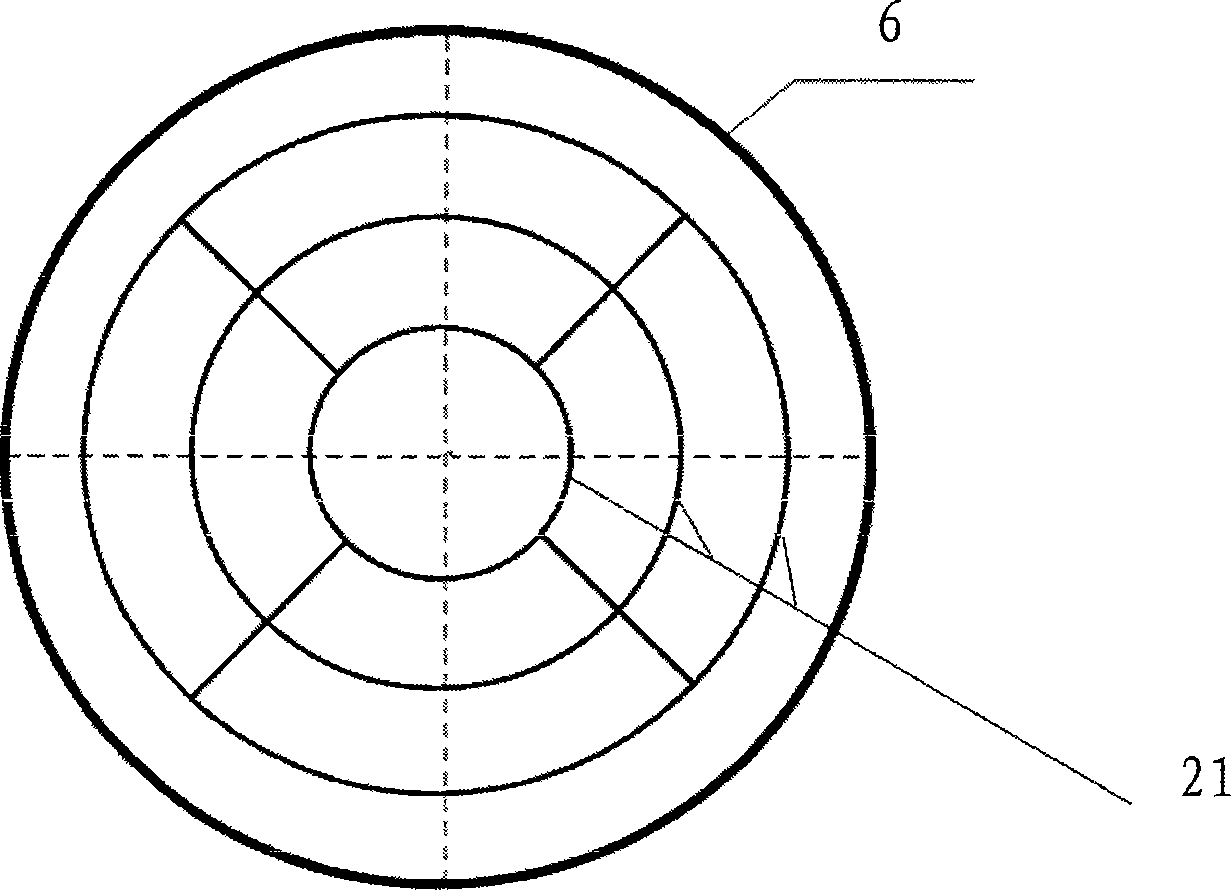

The invention relates to a fluidized-bed reaction device and a fluidization reaction method for hydrogenation of nitrobenzene. The invention mainly aims to solve the problems of low gas-solid contactefficiency, large bubble size, low fluidization quality and the like in a fluidized bed. According to a technical scheme in the invention, at least one group of composite components are arranged in afluidized-bed reactor, so when gas and catalyst particles pass through the components, bubbles and particle clusters are broken, fluidization quality is effectively improved, and the above technical problems are well solved; and the device and the method can be applied to industrial production of gas-phase catalytic hydrogenation of nitrobenzene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Mixing equipment for coating preparation and use method of mixing equipment

InactiveCN107413233AImprove processing speedImprove mix qualityRotary stirring mixersTransportation and packagingDrive shaftProcess engineering

Owner:WUHU SANSHAN LONGCHENG NEW MATERIALS

Traditional Chinese medicine extraction stirring device facilitating residue-liquid separation

ActiveCN113144672AEasy to separateEasy extractionRotary stirring mixersTransportation and packagingMedicinal herbsEngineering

Owner:XUCHANG UNIV

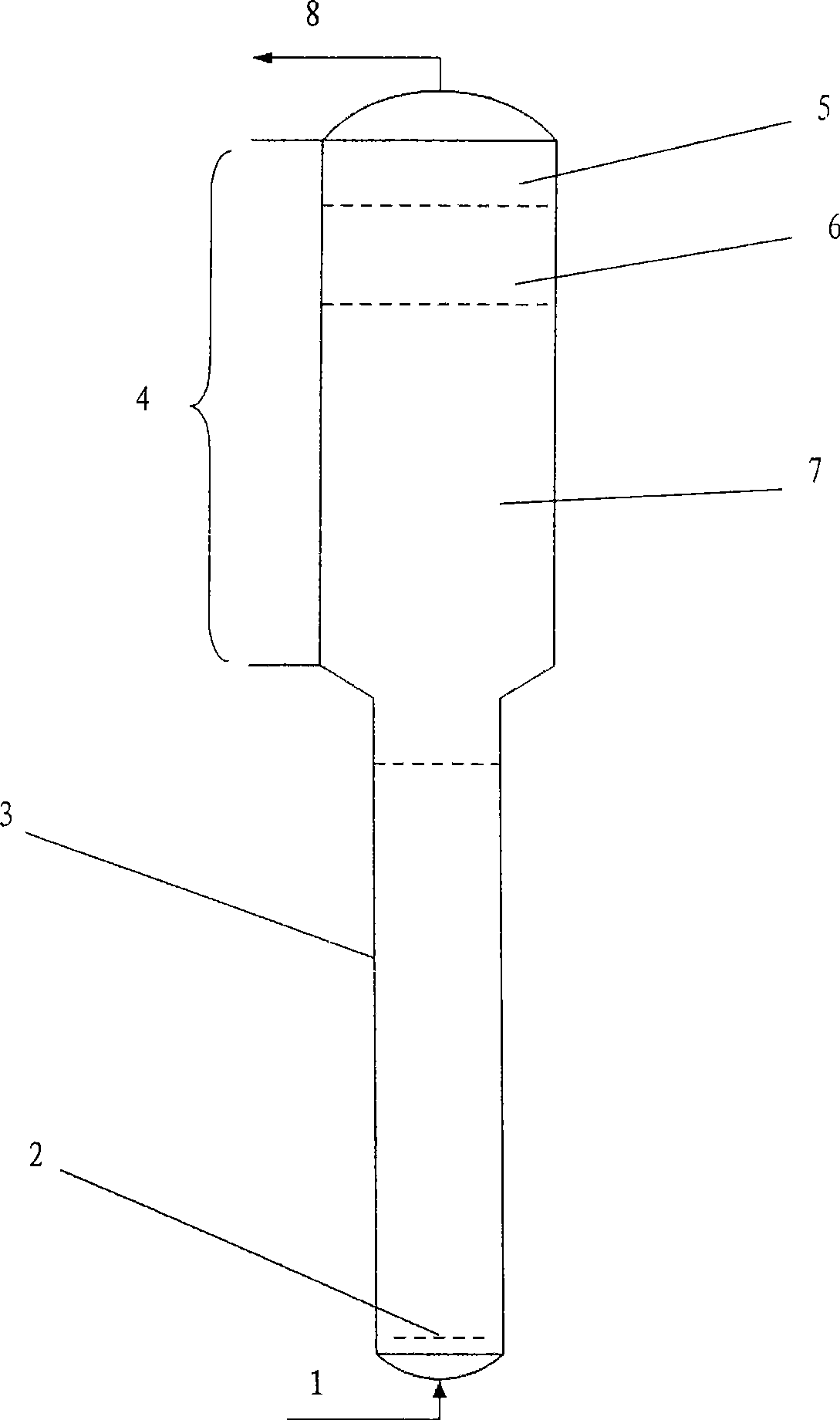

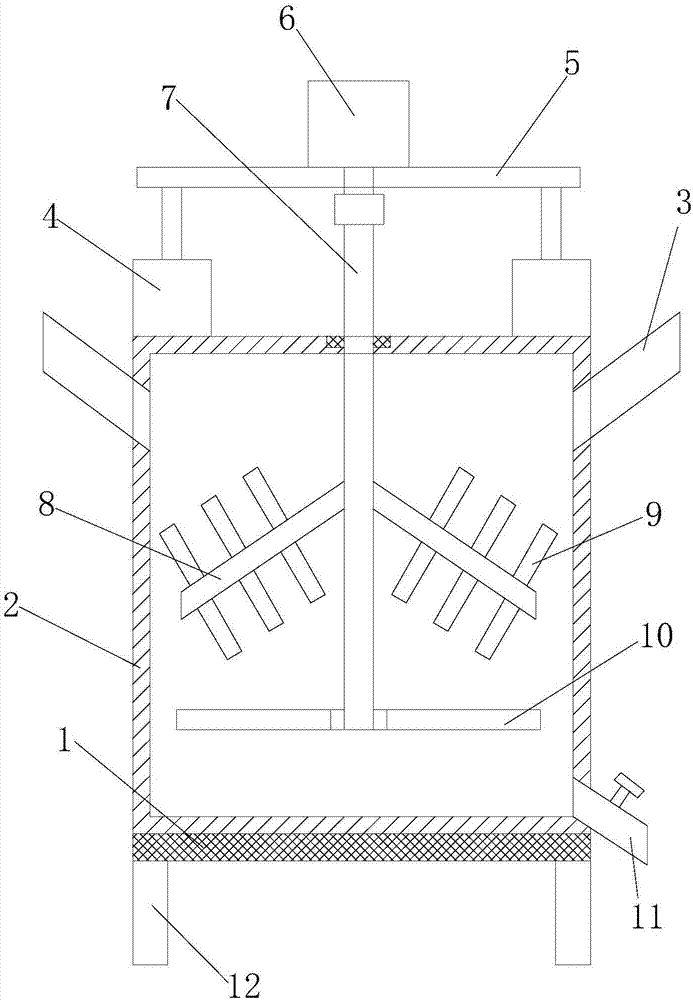

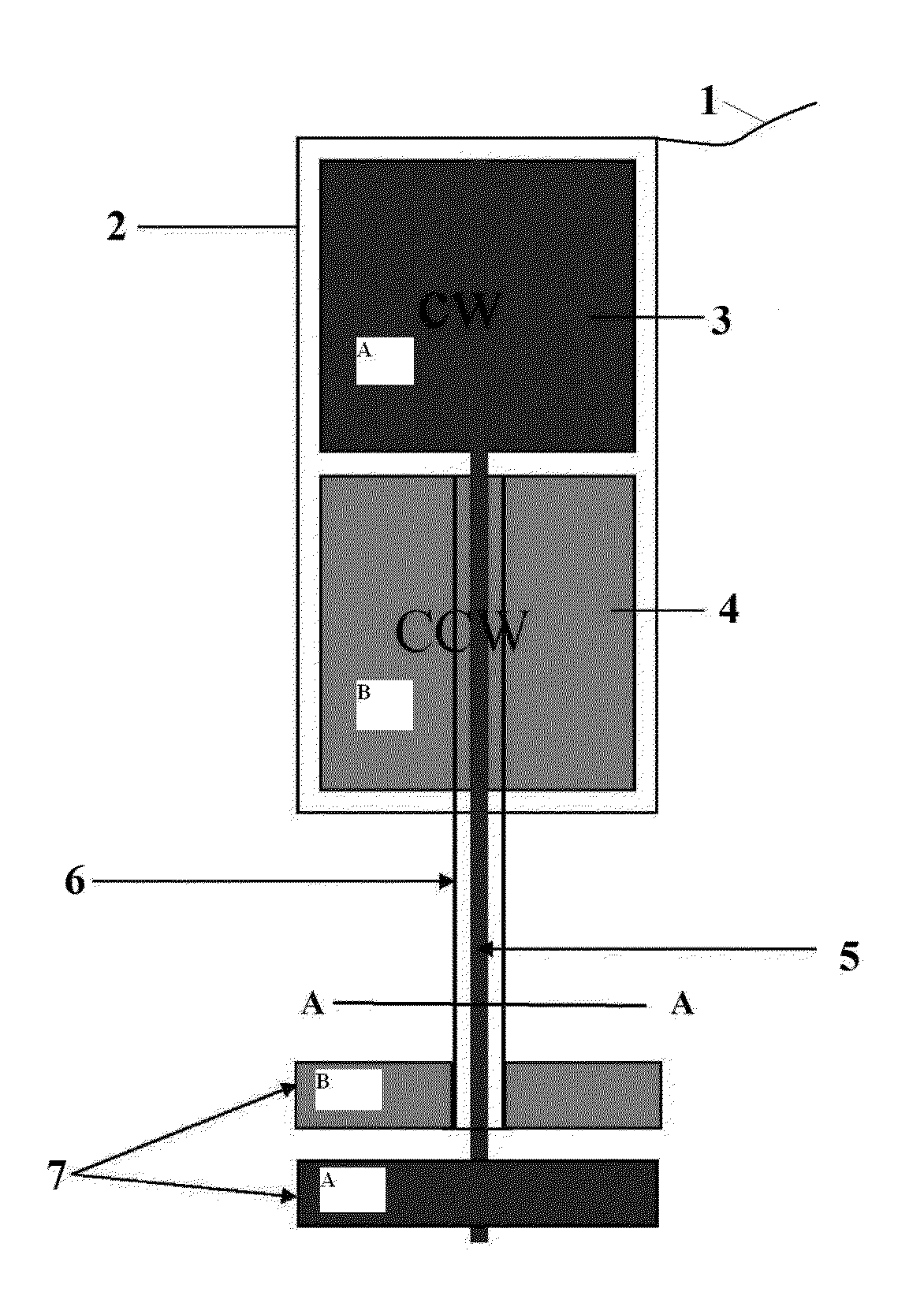

Large fluidized bed reactor for wide sieving fluidized particles

InactiveCN1425494AAdjust the fluidized cross-sectional areaImprove fluidization qualityChemical/physical processesFluidized bedProcess engineering

The present invention relates to chemical equipment technology. The large fluidized bed reactor consists of main bed, conic bed, internal finger-shaped tube heat-exchange member and gad distributor, and features the inner cone structure in the conic bed and sectional introduction of heat-exchange medium to the heat exchange pipe. Using the fluidized bed reactor of the present invention can regulate effectively the fluidizing cross-section area, improve fluidizing quality and realize industrial application easily.

Owner:TSINGHUA UNIV

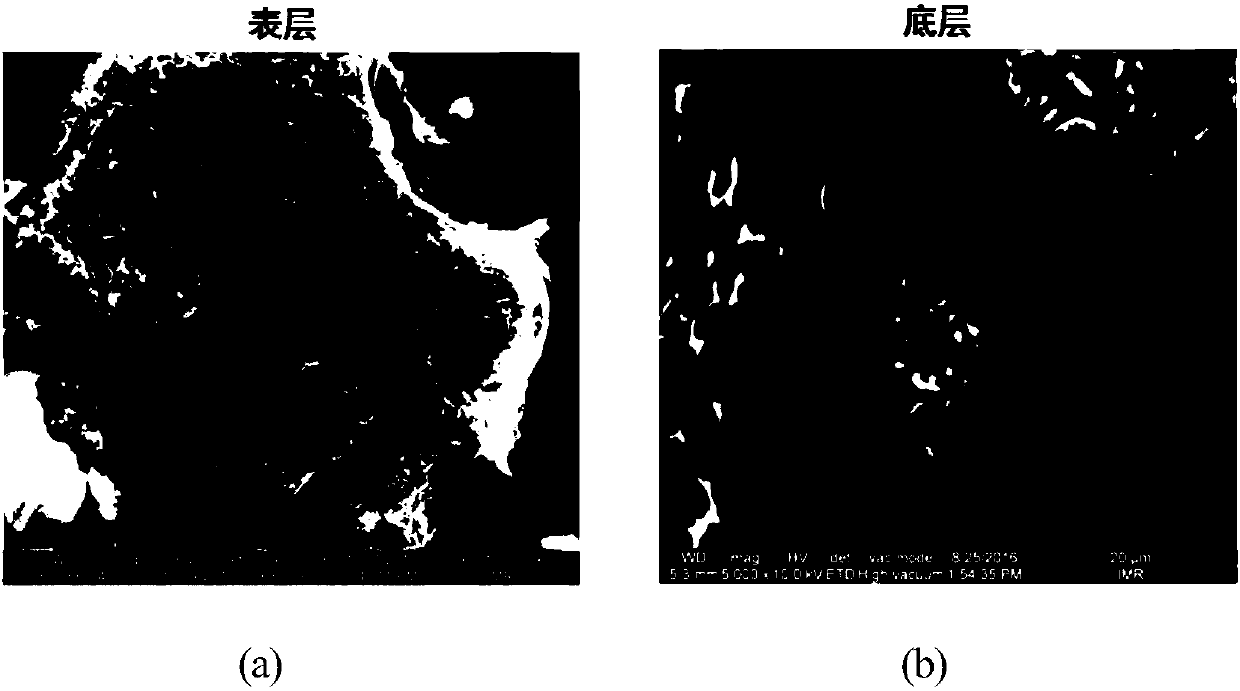

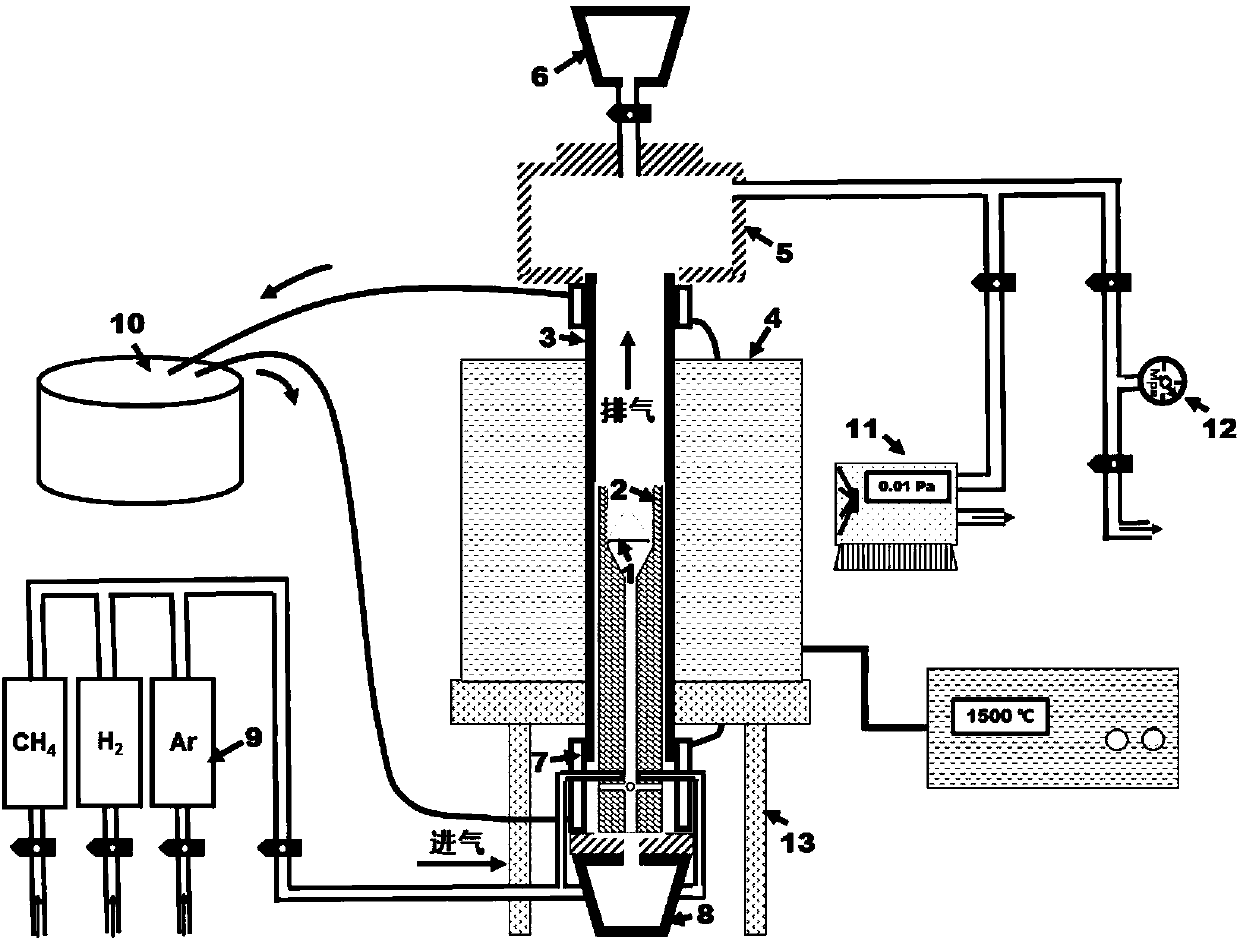

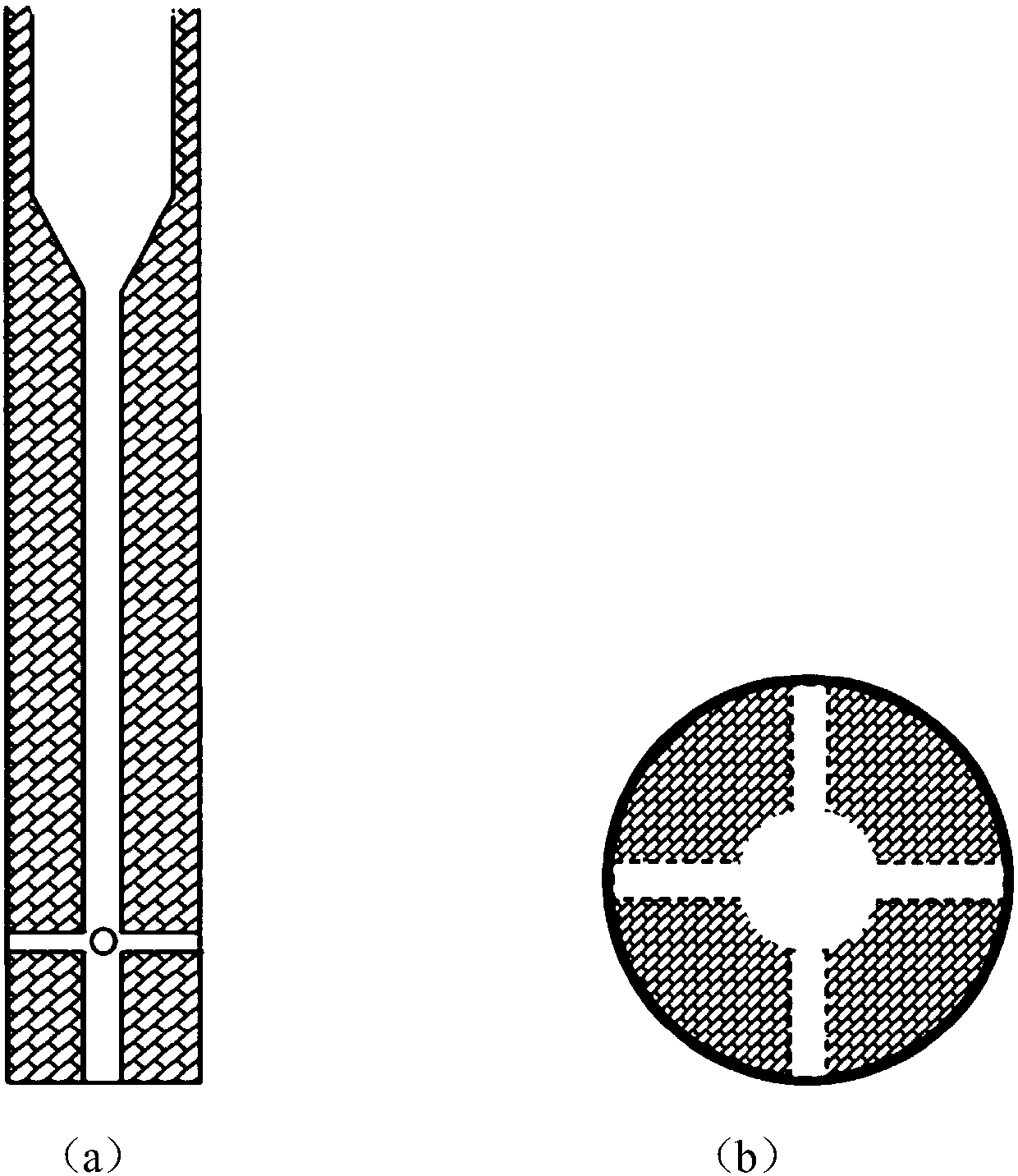

High-temperature fluidized bed reaction device

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Left/right swinging type feed mixing equipment

InactiveCN107970819AImprove the mixing effectExpand the mixing rangeFeeding-stuffRotary stirring mixersEngineeringCentrifugal force

The invention discloses left / right swinging type feed mixing equipment which comprises a shell, wherein mounting bases are symmetrically and fixedly connected with the outer side wall of the shell; support columns are fixedly connected with the mounting bases; support plates are fixedly connected with top ends of the support columns; support bases are fixedly connected with the middle parts of thelower sides of the support plates; swinging columns are moveably hinged with the support bases; first motors are fixedly connected with the bottom ends of the swinging columns; first rotating shaftsare fixedly connected with output shafts of the first motors; two stirring devices are fixedly and symmetrically connected with bottom ends of the first rotating shafts; the stirring devices comprisehorizontal rods. The equipment has the beneficial effects that moving blocks on the stirring devices are moved away from the first rotating shafts because of a centrifugal force, at the same time thefirst springs are compressed, and then stirring bulges are driven by the moving blocks to change the stirring range; with the combination of pull devices and second springs, the stirring devices are swung leftwards and rightwards, so that the stirring range is effectively increased, and the feed mixing effect is improved.

Owner:ZHENGZHOU MOORE ELECTRONICS INFORMATION TECH CO LTD

Mixing machine for powder materials

InactiveCN107096427AWell mixedImprove stabilityRotary stirring mixersTransportation and packagingEngineeringMixing effect

Owner:LIANGXI XUZHONG GENERAL MACHINERY DESIGN STUDIO

Fluorine-carbon surfactant and method of producing the same

InactiveCN101279217AReduce surface tensionReduce manufacturing costTransportation and packagingMixingAdditive ingredientHigh surface

Owner:上海亚孚化工科技有限公司

Multifunctional stirring device for biological pharmacy

ActiveCN112237881AWell mixedEasy to stir and mixTransportation and packagingMixer accessoriesPharmacyReciprocating motion

The multifunctional stirring device for biological pharmacy comprises a box body; a partition plate is fixedly connected to the upper end of an inner cavity of the box body, two feeding hoppers are fixedly connected to the left side of a top plate of the box body in a front-back symmetrical mode, and lower end openings of the feeding hoppers penetrate through the top plate of the box body and extend into the box body to communicate with upper end holes of feeding pipes; the lower opening of the feeding pipe penetrates through the partition plate and extends to the lower part of the partition plate; the top end of the left side wall of the inner cavity of the box body is fixedly connected with a motor; according to the invention, the motor drives a first rotating shaft to rotate, the firstrotating shaft rotates to drive a first connecting rod to rotate, then a first sliding block drives a second connecting rod to do left-right reciprocating motion, and further, the second sliding blockdrives the third connecting rod to swing with the second fixing rod as the axis, the check block synchronously swings along with the third connecting rod and is matched with the feeding hopper, and therefore raw materials are controlled to intermittently fall into the feeding pipe downwards.

Owner:XIAN TIANYI QINKUN PHARMA

Printing and dyeing raw material mixing device

InactiveCN108686574AWell mixedRotary stirring mixersTransportation and packagingEconomic benefitsEngineering

Owner:ZHEJIANG XINGFEIER TECH CO LTD

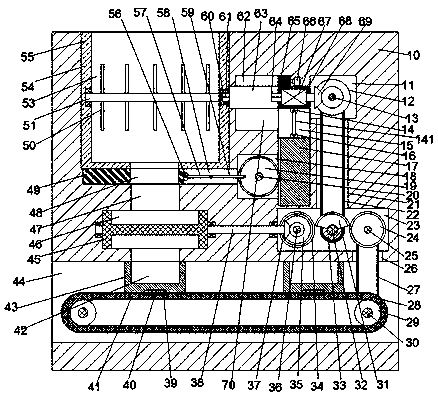

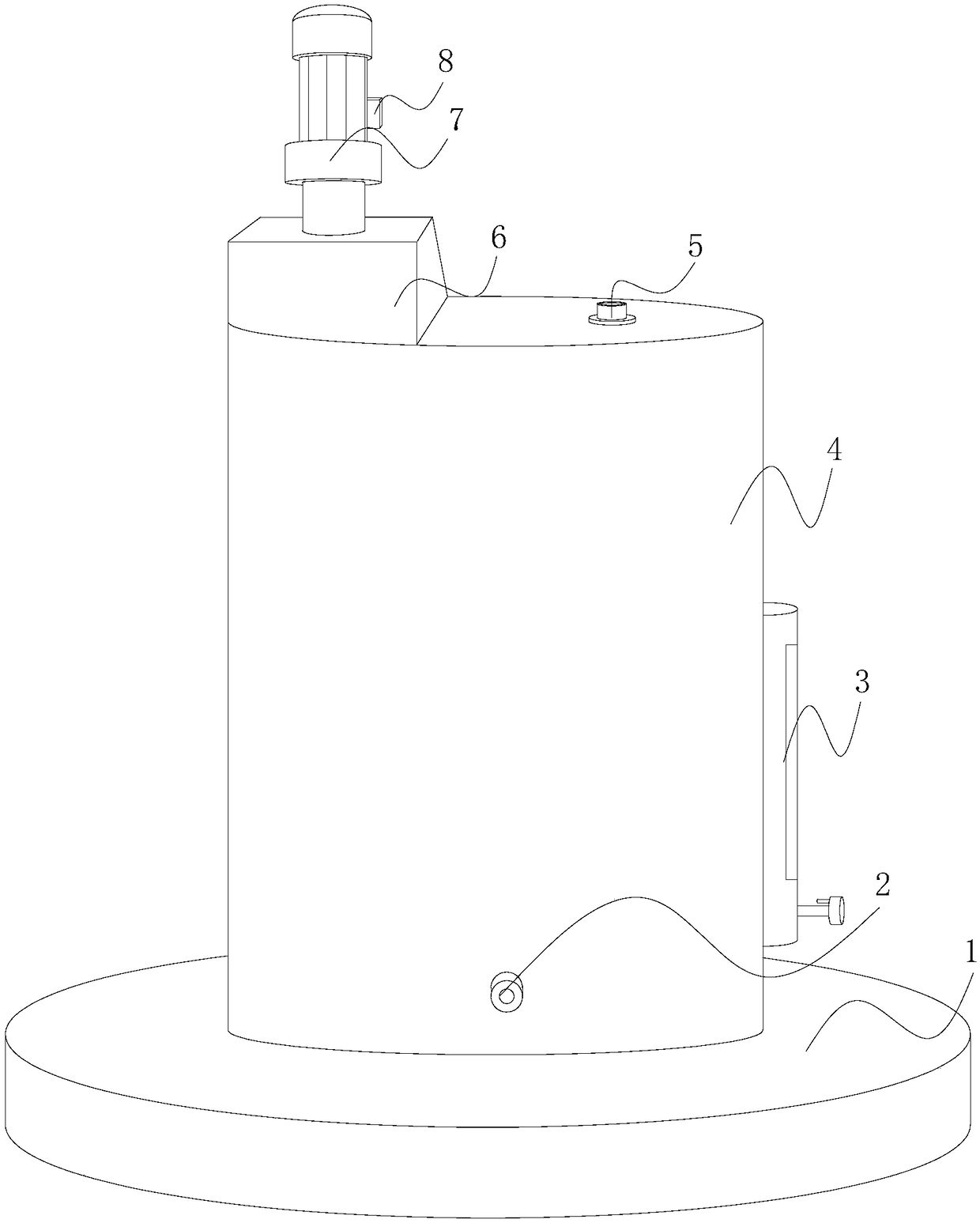

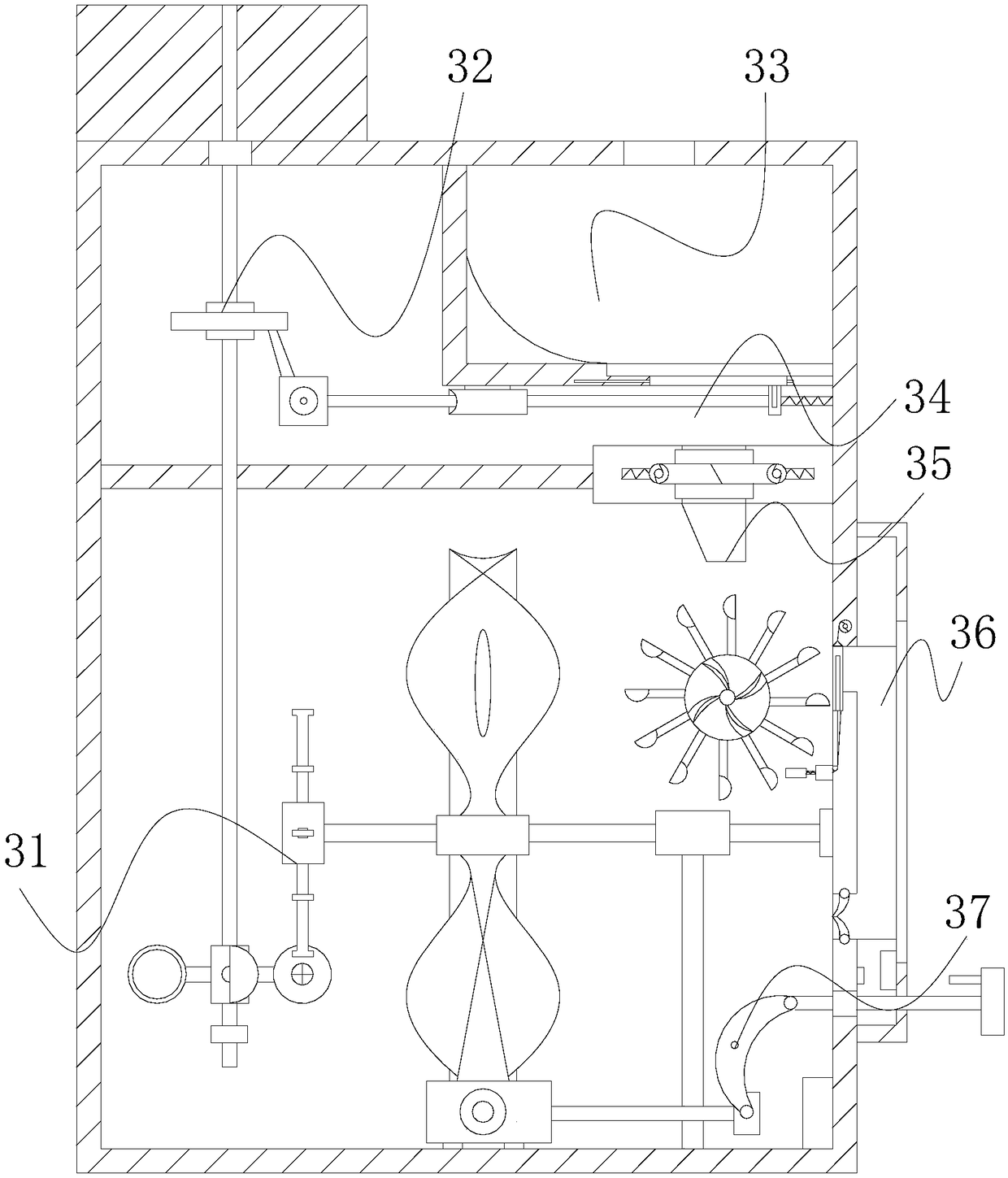

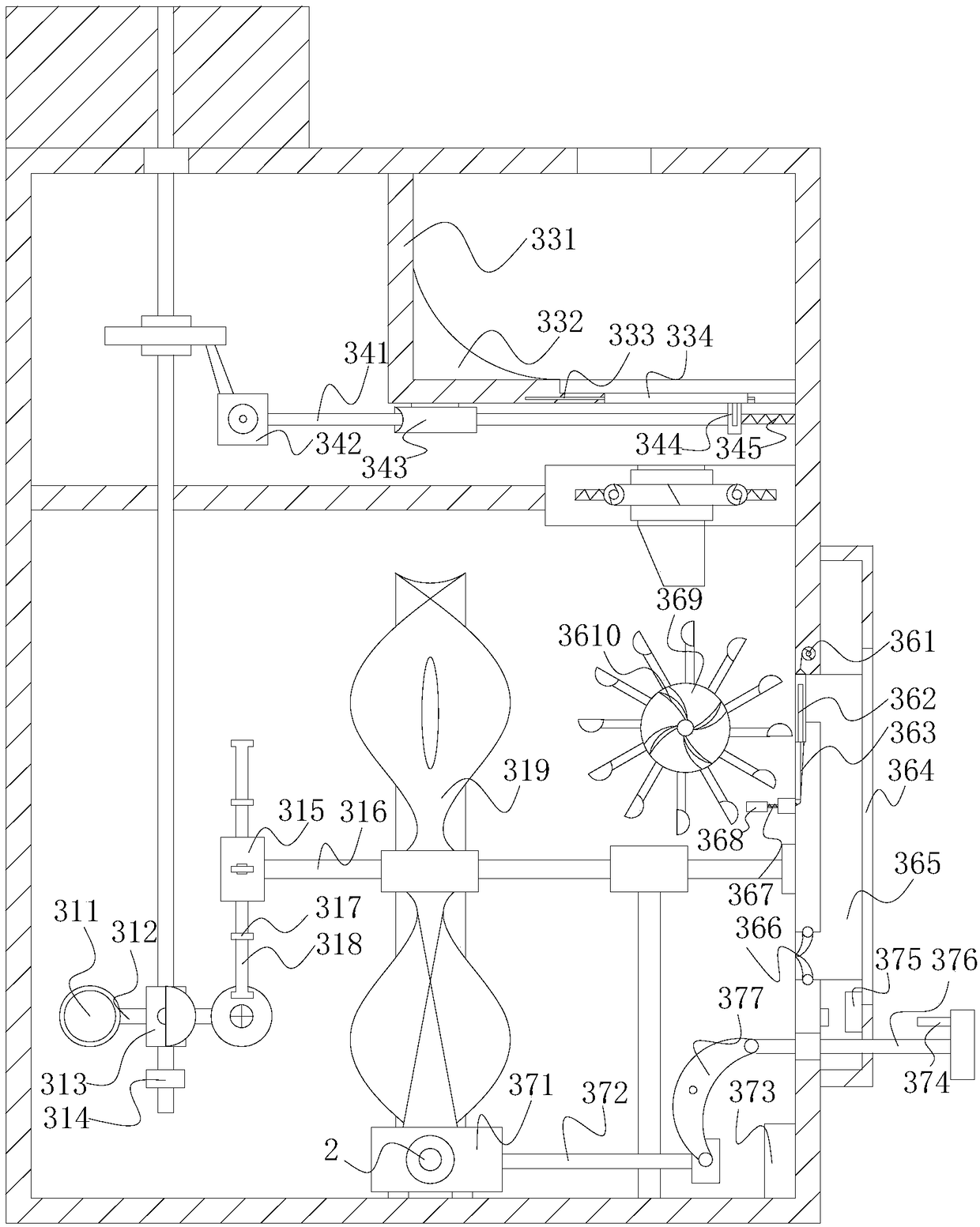

Continuous production equipment and process for hexafluoropropylene oxide oligomer

PendingCN111530383AContinuous operationReduce consumptionChemical recyclingCarboxylic acid halides preparationOligomerPtru catalyst

The invention provides continuous production equipment and a continuous production process for a hexafluoropropylene oxide oligomer. The continuous production equipment comprises a stirring kettle anda liquid phase separation kettle, wherein a stirrer is arranged in the stirring kettle; a discharge pipe is arranged at the bottom of the stirring kettle; a discharge pipe is arranged at the bottom of the liquid phase separation kettle; the discharging pipe is communicated with the discharge pipe through a feeding pipe; the feeding pipe is provided with a conveying pump; the top of the stirring kettle is communicated with the top of the liquid-phase separation kettle through a liquid-phase circulating pipe and a gas-phase circulating pipe respectively; the liquid-phase circulating pipe is provided with a circulating pump; the gas-phase circulating pipe is provided with a condenser; one end of the liquid-phase circulating pipe, which is positioned at the liquid-phase separation kettle, extends into the lower part of the liquid-phase separation kettle; and one end of the liquid-phase circulating pipe, which is positioned at the stirring kettle, is connected with a nozzle. The equipmentand the process have the advantages of continuous production, simplicity in operation, high production efficiency, stable product quality and the like, meanwhile, the catalyst, the solvent and byproducts can be recycled, and the process is low in cost and environmentally friendly.

Owner:JIUDING FLUORIN CHEM CO LTDZHANGPING FUJIAN

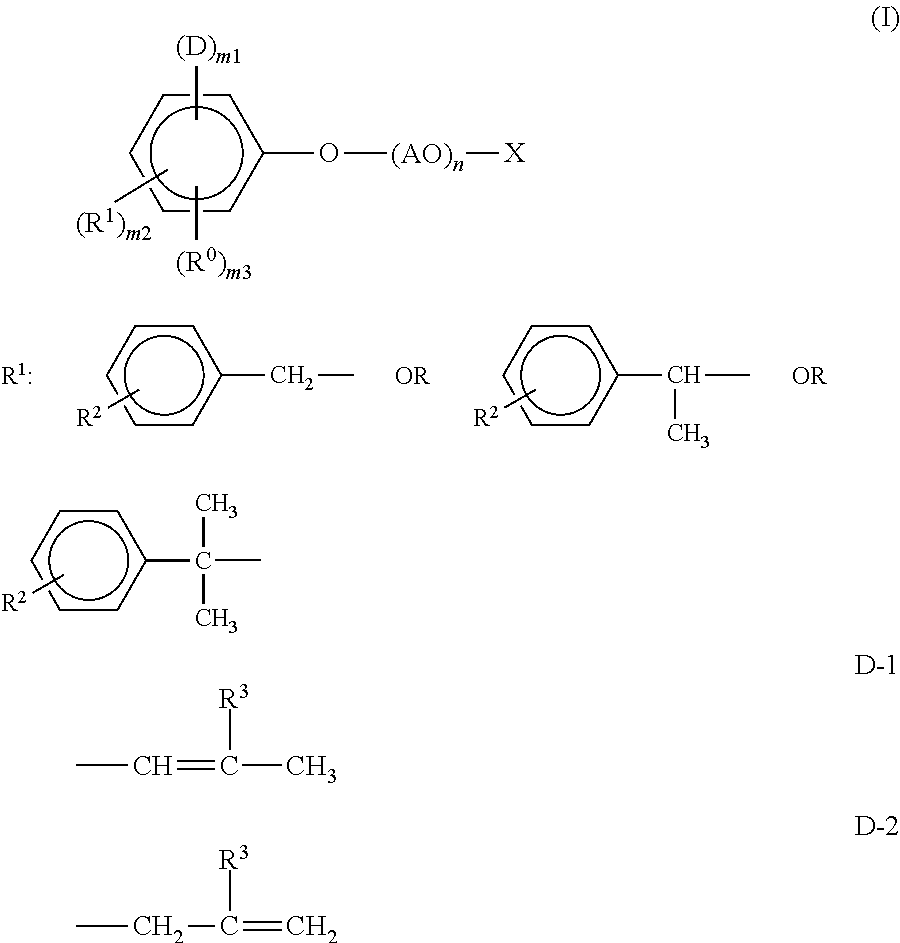

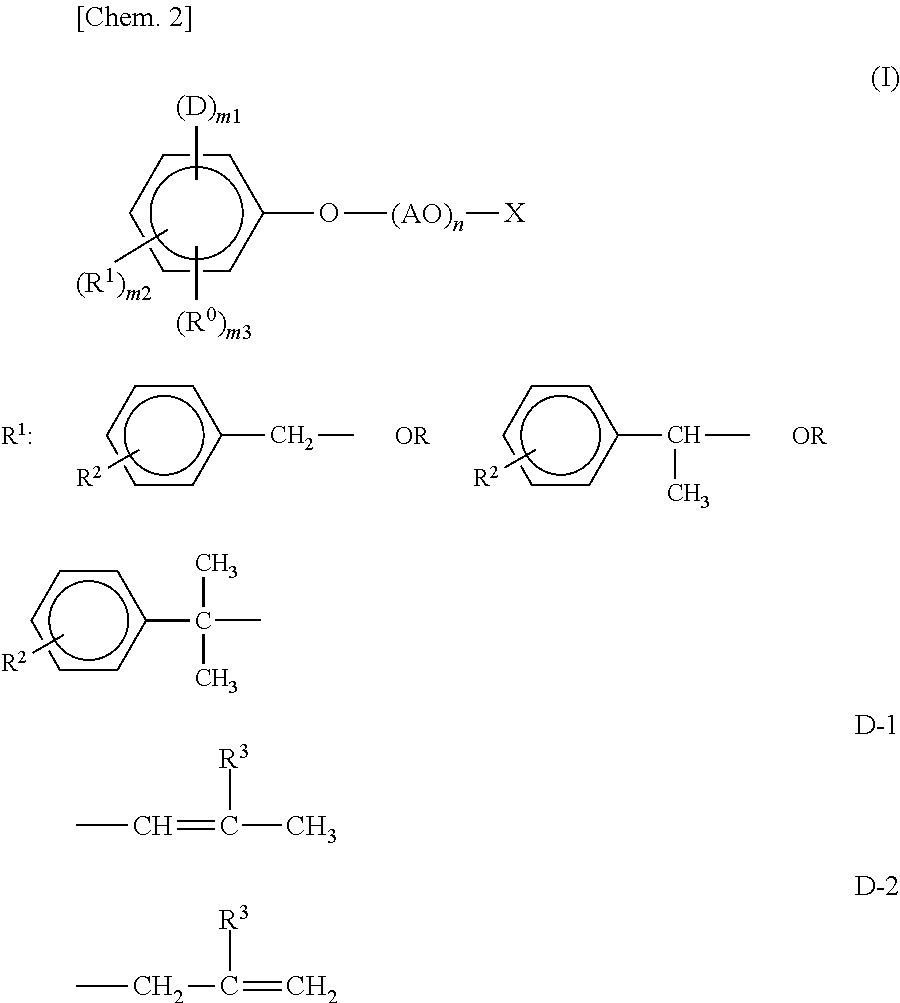

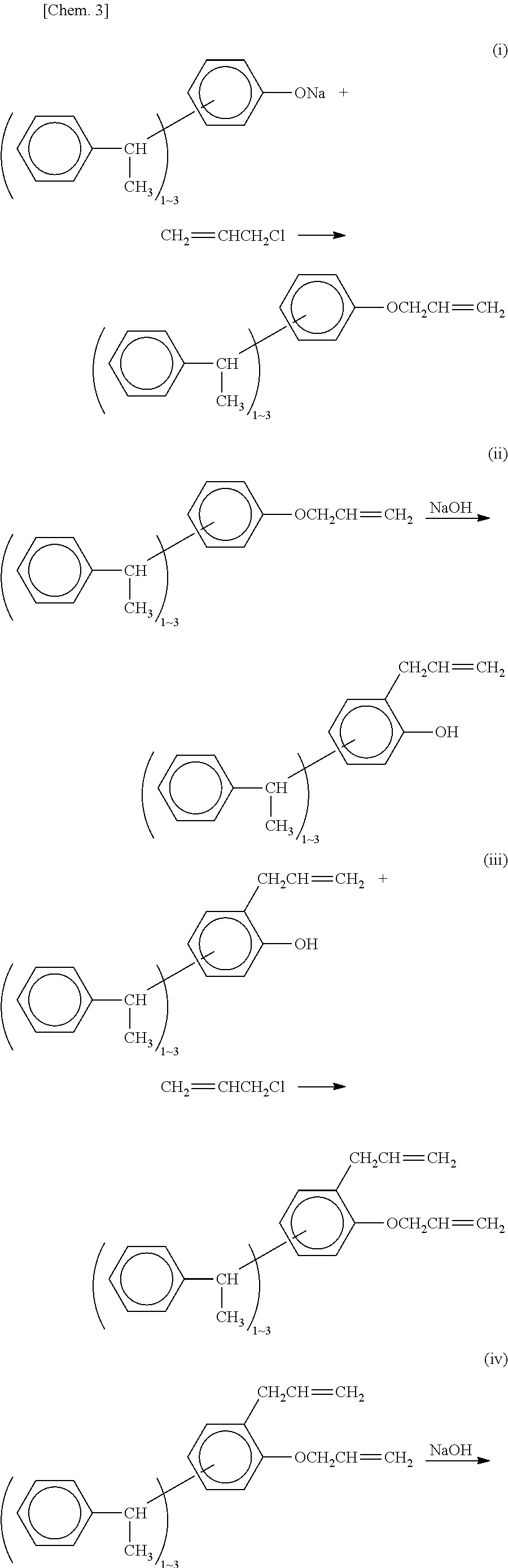

Water-based resin dispersion and coating material

ActiveUS20170327602A1InhibitionLow water resistanceTransportation and packagingMixingWater basedEmulsion polymerization

Owner:DAI ICHI KOGYO SEIYAKU CO LTD

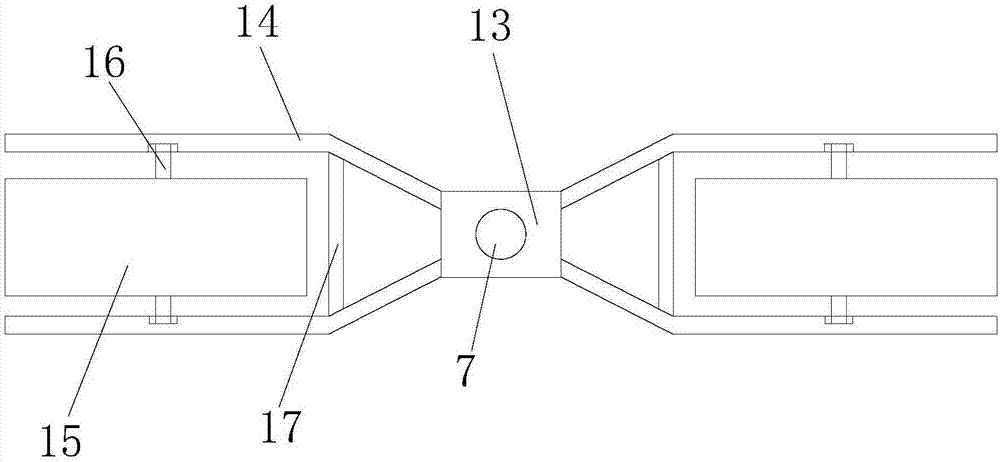

Caustic soda recycling device for chemical machinery

InactiveCN109173941AGuaranteed FusionJoin smoothlyAlkali metal hydroxidesChemical/physical processesChemical reactionRaw material

The invention discloses a caustic soda recycling device for chemical machinery. The caustic soda recycling device comprises a first tank body and a second tank body, wherein a feed pipe is arranged inside the first tank body; another feed pipe is fixed above the feed pipe; an auxiliary material pipe penetrates through the inner wall of the left side of the first tank body; a heating ring is arranged at the bottom of the interior of the first tank body, and a through pipe penetrates through the lower side of the right wall of the first tank body; a valve is arranged on the outer side of the through pipe; a partition plate is fixed on the inner wall of the second tank body; and the second tank body is positioned on the right side of the through pipe. According to the caustic soda recycling device for chemical machinery, due to the arrangement of the feed pipe, raw materials containing caustic soda can be smoothly added into the first tank body, and the materials are uniformly dispersed due to an inclined plate and a semicircular mesh arranged in the feed pipe, so that the materials are scattered; chemical reaction additives are introduced into the auxiliary material pipe and are usedfor reducing and purifying the caustic soda; and due to the arrangement of a first ring pipe, a second ring pipe and a third ring pipe, the addition range area of the additives is enlarged.

Owner:戴聪聪

Stirring and emulsifying equipment for preparing energy-saving color paste

InactiveCN107469656AImprove centrifugal extrusionIncreased force between impactsRotary stirring mixersMixing methodsHydraulic cylinderLiquid layer

Owner:长兴利其科技有限公司

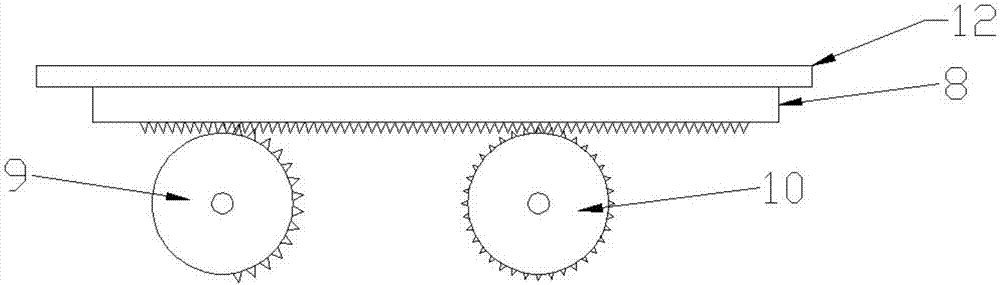

Dying device

InactiveCN109279053ASimple structureHigh degree of automationRotary stirring mixersMixer accessoriesPower modeGear wheel

Owner:岑浩明

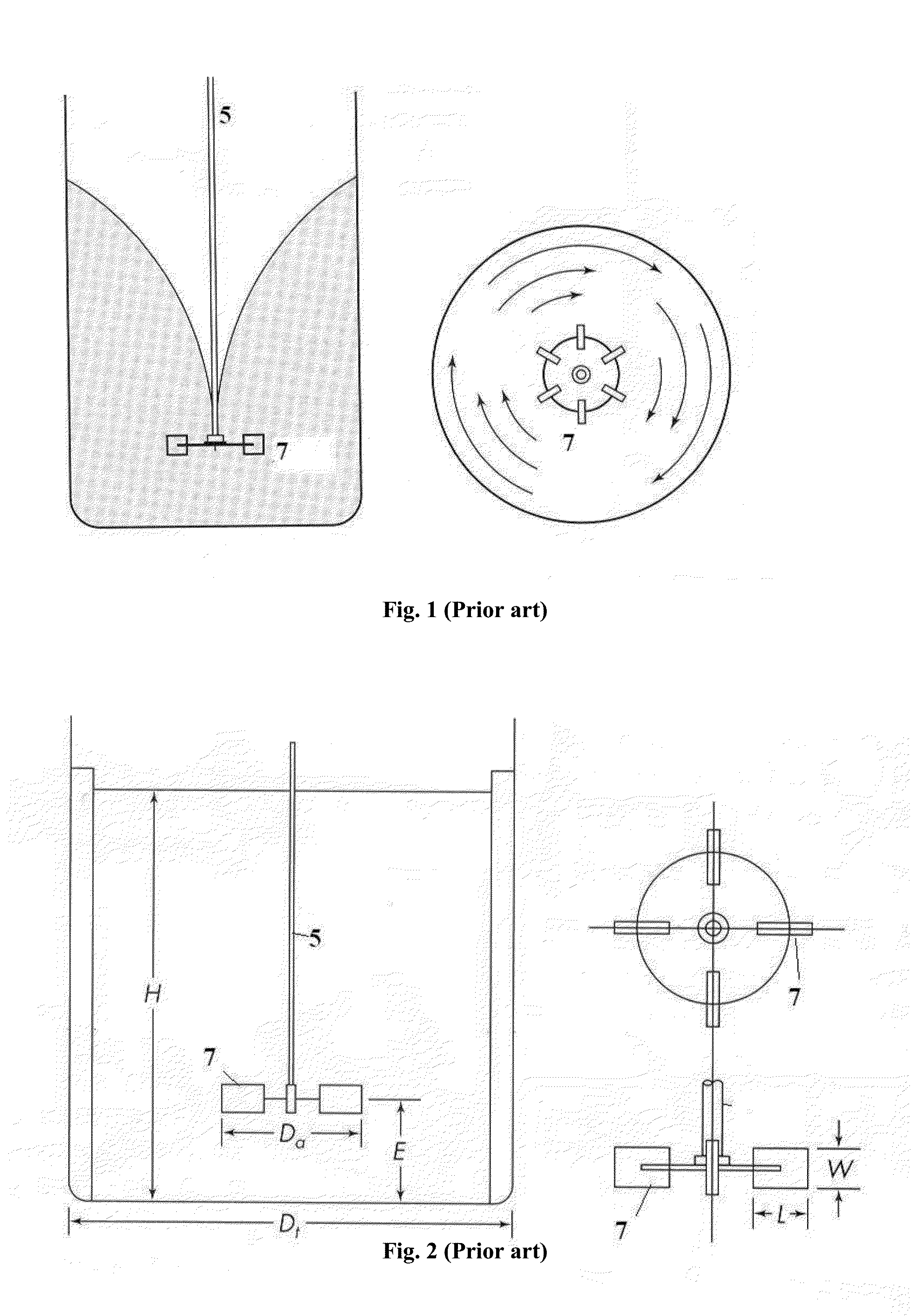

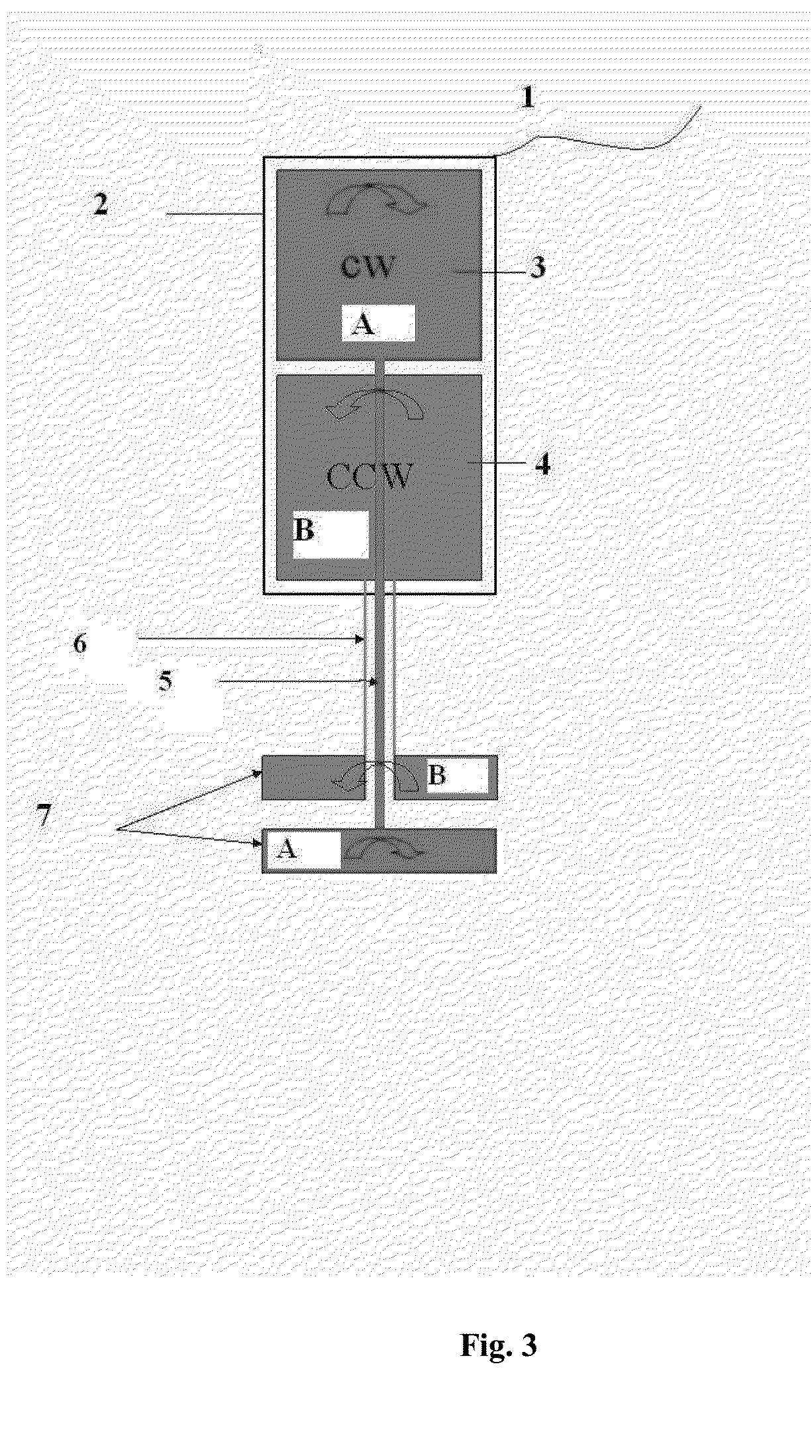

Enhancement of agitation by an innovative blender

InactiveUS20160038892A1Less energyQuick combinationRotary stirring mixersTransportation and packagingImpellerChemical compound

Owner:KORAI GASHTASEB MARDANI +2

Ozone static mixing device

Owner:中瑞工程设计院有限公司

Efficient stirring device for paint production

Owner:湖州御筵科技有限公司

Extruder screw for a multi-screw extruder for plastics extrusion

ActiveUS20200282369A1Shorten the timeIncrease contact areaRotary stirring mixersTransportation and packagingPolymer scienceEngineering

An extruder screw for a multi-screw extruder for plastics extrusion includes: a feeding and metering zone for melting and homogenizing the plastic and an evacuating zone for carrying away gaseous constituents and a compressing and / or discharging zone; a multi-screw section, which has a plurality of planetary screws, which lie open on the outer circumference of the extruder screw, at least over part of their length; and a driving zone, in which the planetary screws engage by way of a toothing in an external toothing on a central shaft or in an internal toothing in a stator ring or in the inner wall of an extruder bore of the multi-screw extruder. The feeding and metering zone extends into the multi-screw section, wherein the respective part of the planetary screws that is lying in the metering zone is at least partially enclosed.

Owner:GNEUSS GMBH

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap