High-temperature fluidized bed reaction device

A high-temperature fluidized bed and reaction device technology, applied in chemical/physical processes, chemical instruments and methods, etc., can solve problems such as the difficulty of implementing a fluidized bed device, and achieve the effect of symmetrical and uniform air flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

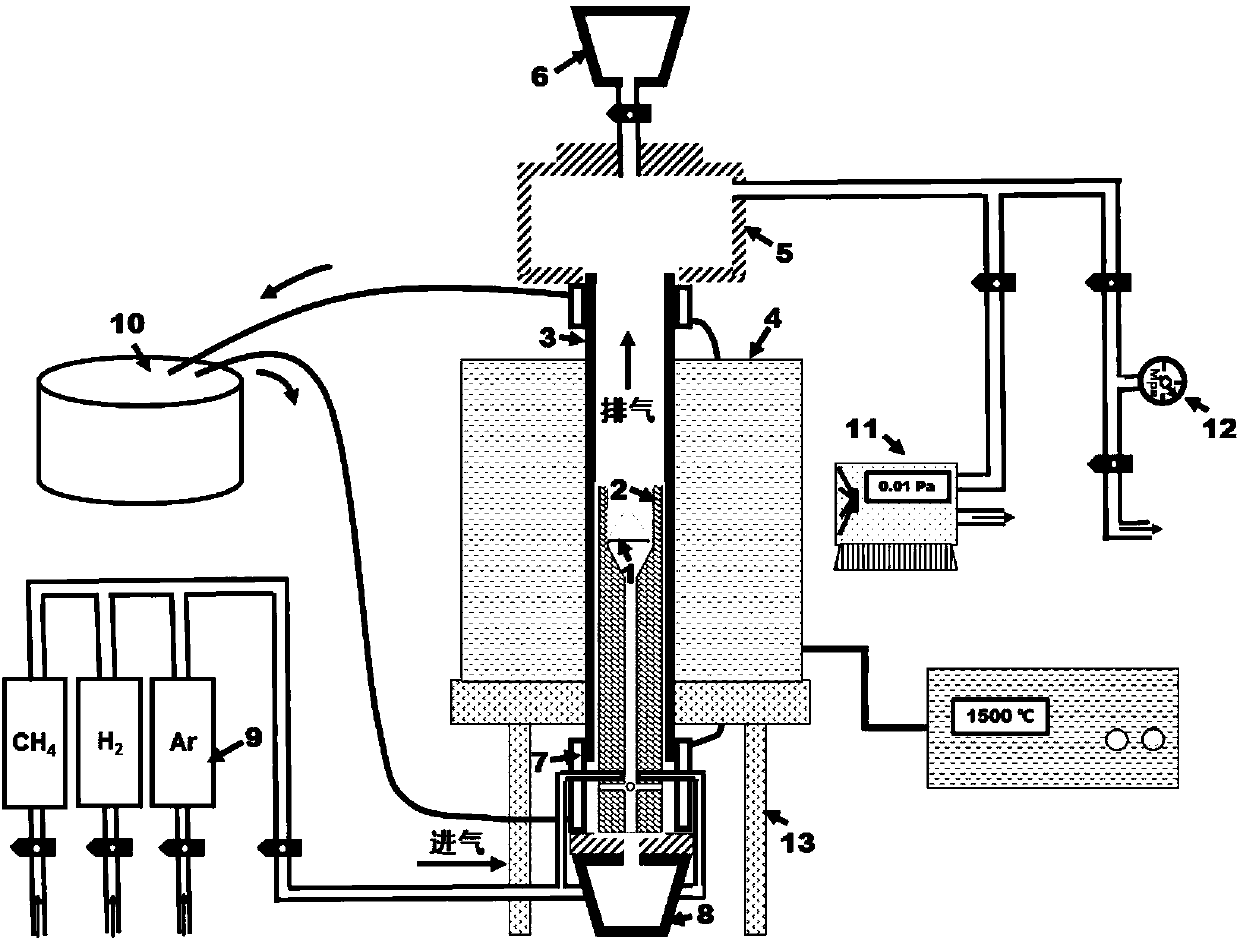

[0041] In this embodiment, the size of each component of the heating device is designed and processed according to the actual situation according to the drawing matching, and the real object is as follows Figure 7 shown.

[0042] In the embodiment, the high-temperature heating furnace body can be heated to 2000° C., and the heating furnace is placed on the furnace body support 13 . In the embodiment, the high-temperature-resistant furnace tube 3 is a high-temperature-resistant corundum furnace tube with an outer diameter of 50 mm, an inner diameter of 40 mm, and a tube length of 120 cm. The two ends of the furnace tube are hermetically connected by a set of fast-loading and dismounting flanges (upper sealing flange and lower sealing flange).

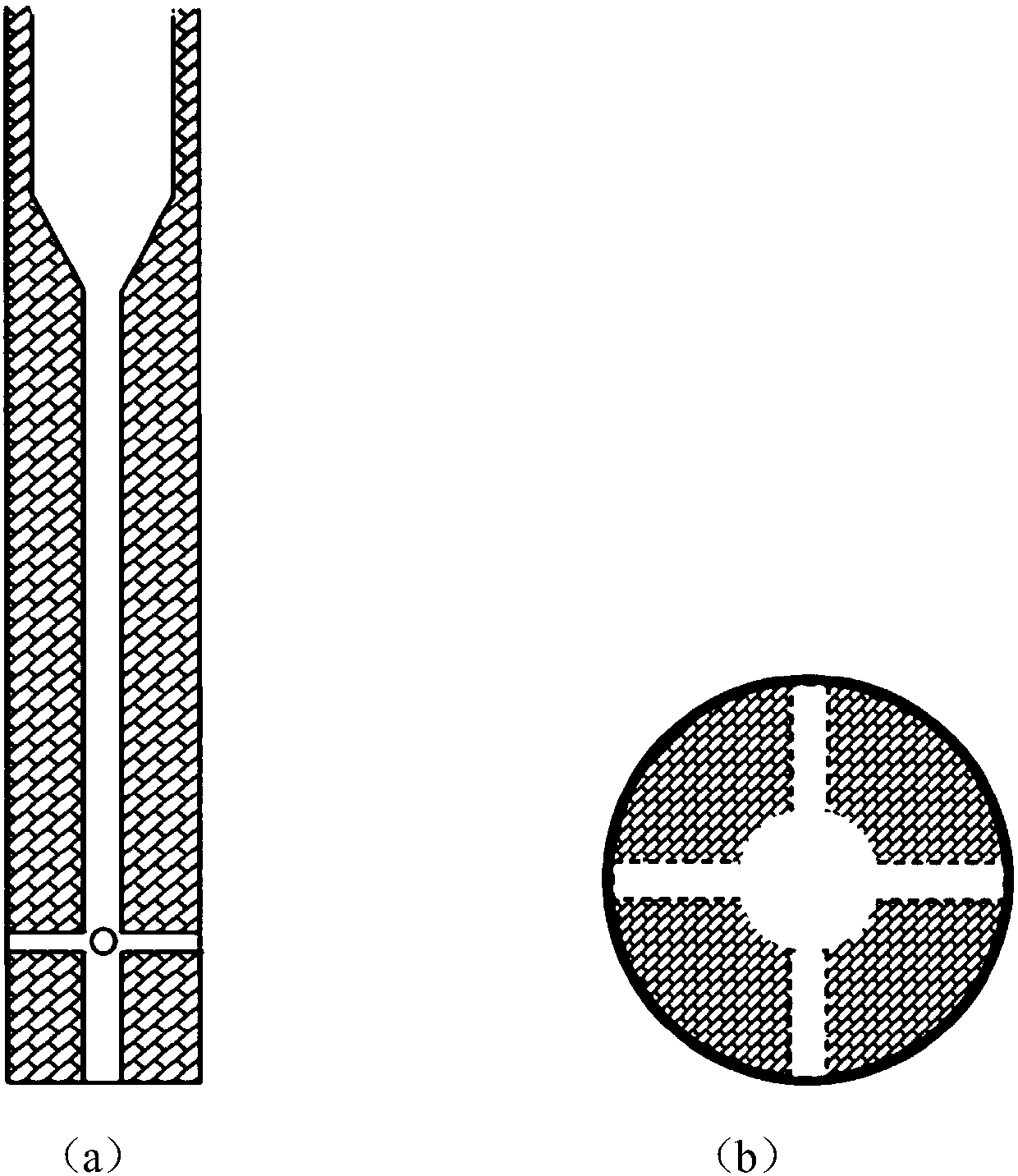

[0043] In the embodiment, the high-temperature-resistant lined airflow regulator is made of graphite. The reactor is a cylindrical hollow structure with an outer diameter of 39.5 mm, which precisely matches the inner diameter of the furn

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap