High temperature resistance filter cloth

A technology of high temperature resistance and filter cloth, which is applied in the fields of air protection and purification, purifiers, and filter elements. It can solve the problems of not being able to use high temperature fields and limit the application of carbon cloth, and achieve high-efficiency and long-lasting antistatic performance, simple structure, and high temperature resistance. good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the drawings and specific implementations. The terms "upper", "lower", "left", "right", "middle" and "one" quoted in the preferred embodiment are only for the convenience of description and are not intended to limit the scope of the present invention. The scope of implementation, and the change or adjustment of the relative relationship, shall also be regarded as the scope of the implementation of the present invention without substantial changes to the technical content.

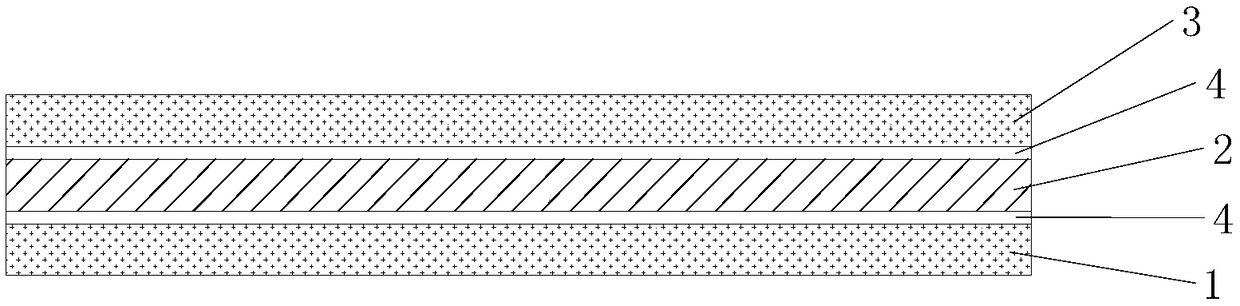

[0027] See figure 1 The present invention designs a high-temperature resistant filter cloth, which in turn includes: a first support layer 1, a functional layer 2, and a second support layer 3, between the first support layer 1 and the functional layer 2, and between the functional layer 2 and the second The supporting layers 3 are tightly bonded by the adhesive layer 4. The overall thickness of the filter cloth of this scheme is 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap