Enhancement of agitation by an innovative blender

a technology of agitation and blender, applied in the direction of mixers, chemistry apparatus and processes, mixing, etc., can solve the problem of low efficiency and achieve the effect of less energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

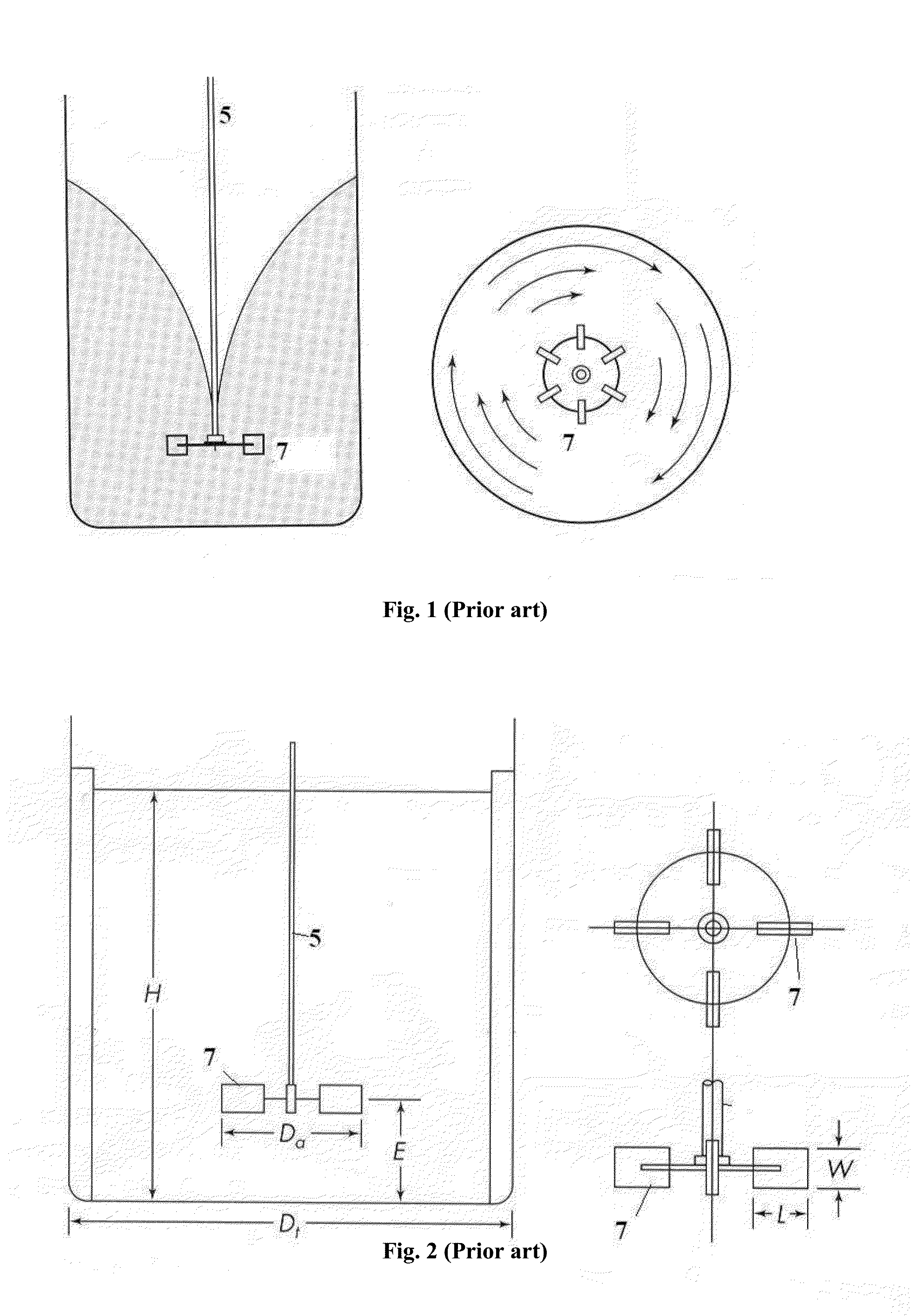

[0019]Blenders are implemented for various uses, such as in home for mixing of different types of food such as eggs, juices, and so on; and in chemical industries for mixing of chemical matters, or in water and wastewater treatment plants for mixing of chemical matter such as alum and chlorine and for good sedimentation of colloidal matter.

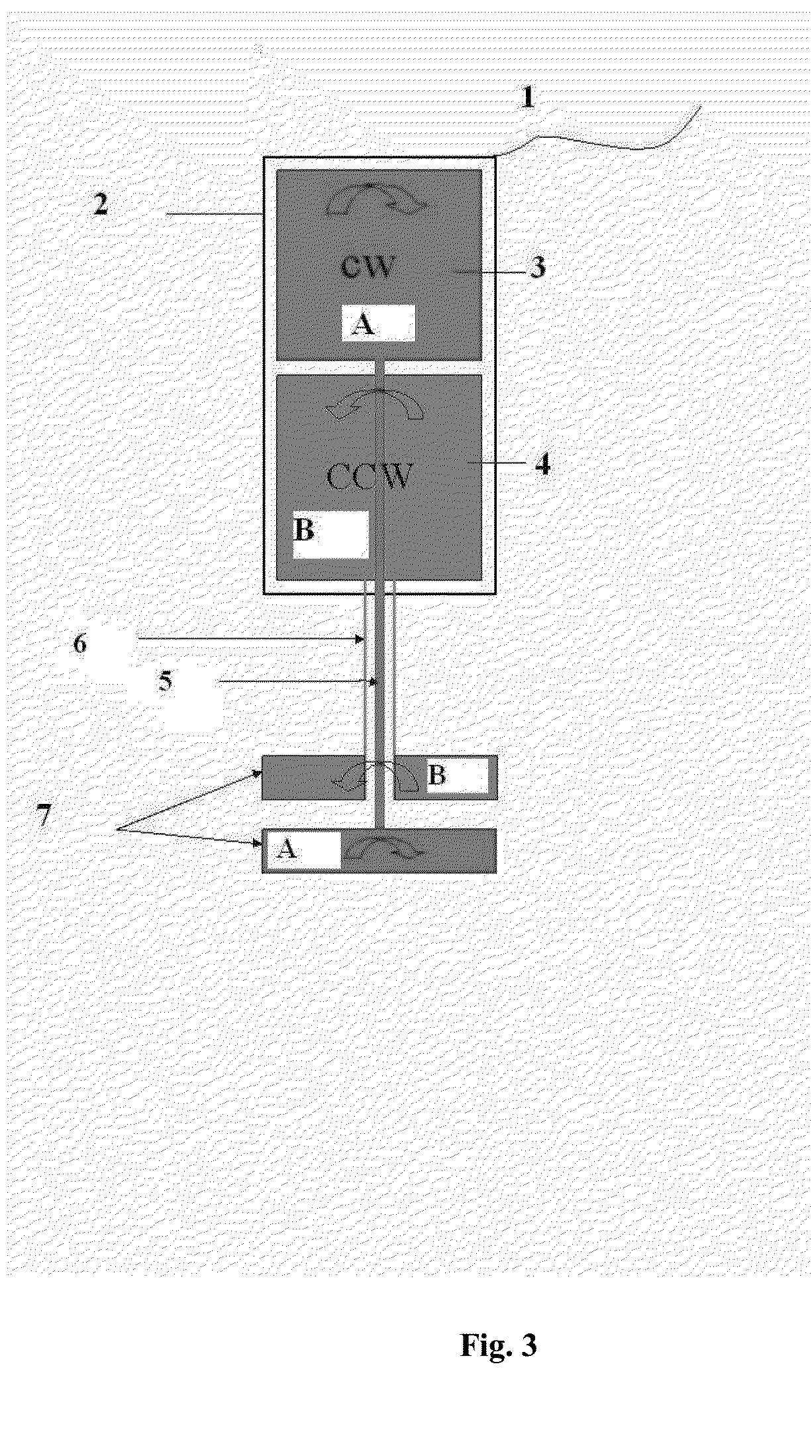

[0020]This innovative blender solves the swirling issue and low efficiency by increasing turbulence and velocity and therefore working more rapidly than its counterpart one blade blenders. Therefore energy consumption is reduced to a great extent and efficiency is high than conventional blender.

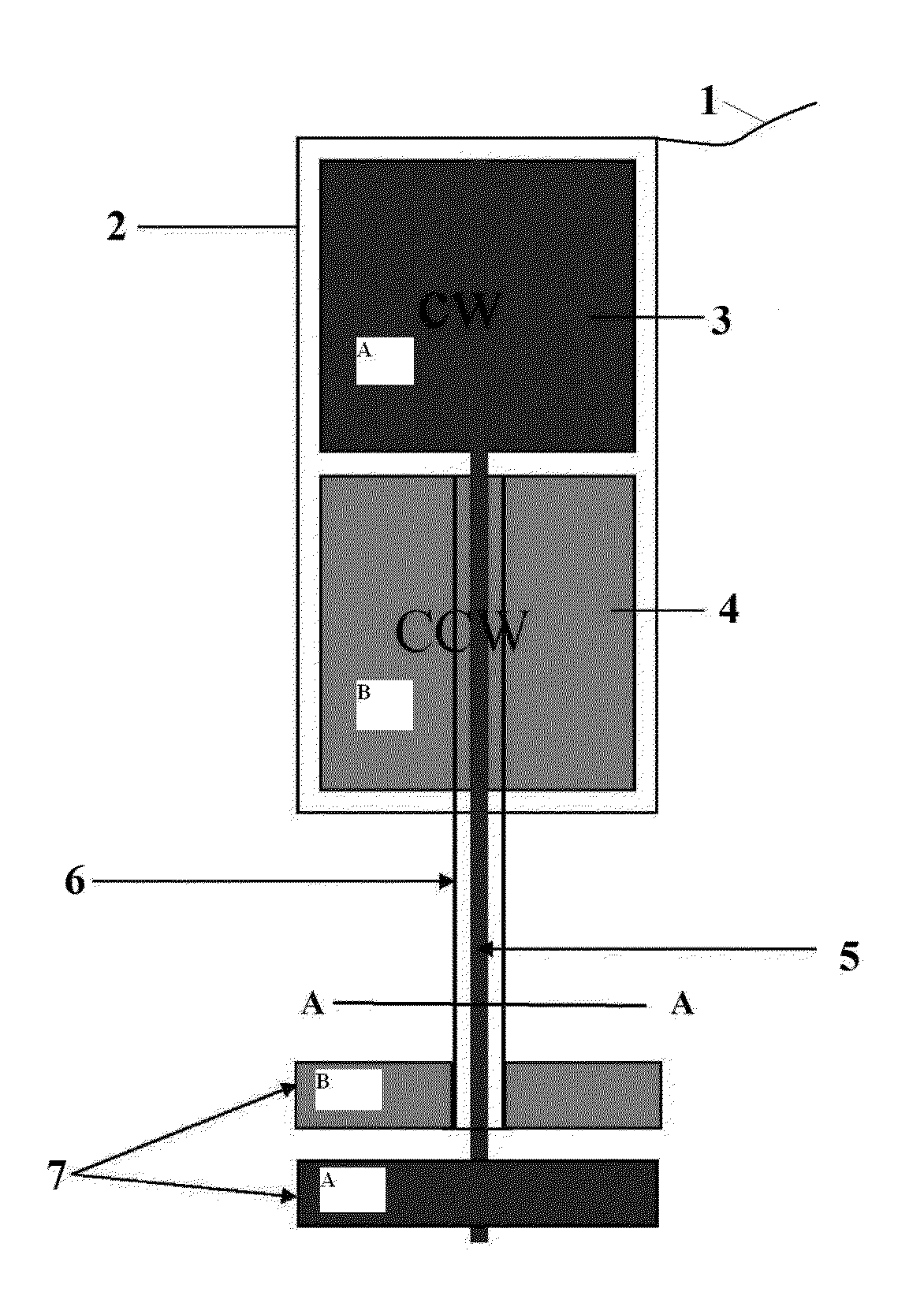

[0021]As displayed in FIG. 3, the current innovative blender has two coaxial and concentric rotors (A and B) that are connected to two blades 7 by a shaft 5 and a casing 6. Rotors A and B rotate in opposite direction with regards to each other, so if rotor A rotates in Clockwise (CW) direction rotor B rotates in counter clockwise (CCW). Each rotor is attached

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap