Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4 results about "Plastics extrusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plastics extrusion is a high-volume manufacturing process in which raw plastic is melted and formed into a continuous profile. Extrusion produces items such as pipe/tubing, weatherstripping, fencing, deck railings, window frames, plastic films and sheeting, thermoplastic coatings, and wire insulation.

Extruder screw for a multi-screw extruder for plastics extrusion

ActiveUS20200282369A1Shorten the timeIncrease contact areaRotary stirring mixersTransportation and packagingPolymer scienceEngineering

An extruder screw for a multi-screw extruder for plastics extrusion includes: a feeding and metering zone for melting and homogenizing the plastic and an evacuating zone for carrying away gaseous constituents and a compressing and / or discharging zone; a multi-screw section, which has a plurality of planetary screws, which lie open on the outer circumference of the extruder screw, at least over part of their length; and a driving zone, in which the planetary screws engage by way of a toothing in an external toothing on a central shaft or in an internal toothing in a stator ring or in the inner wall of an extruder bore of the multi-screw extruder. The feeding and metering zone extends into the multi-screw section, wherein the respective part of the planetary screws that is lying in the metering zone is at least partially enclosed.

Owner:GNEUSS GMBH

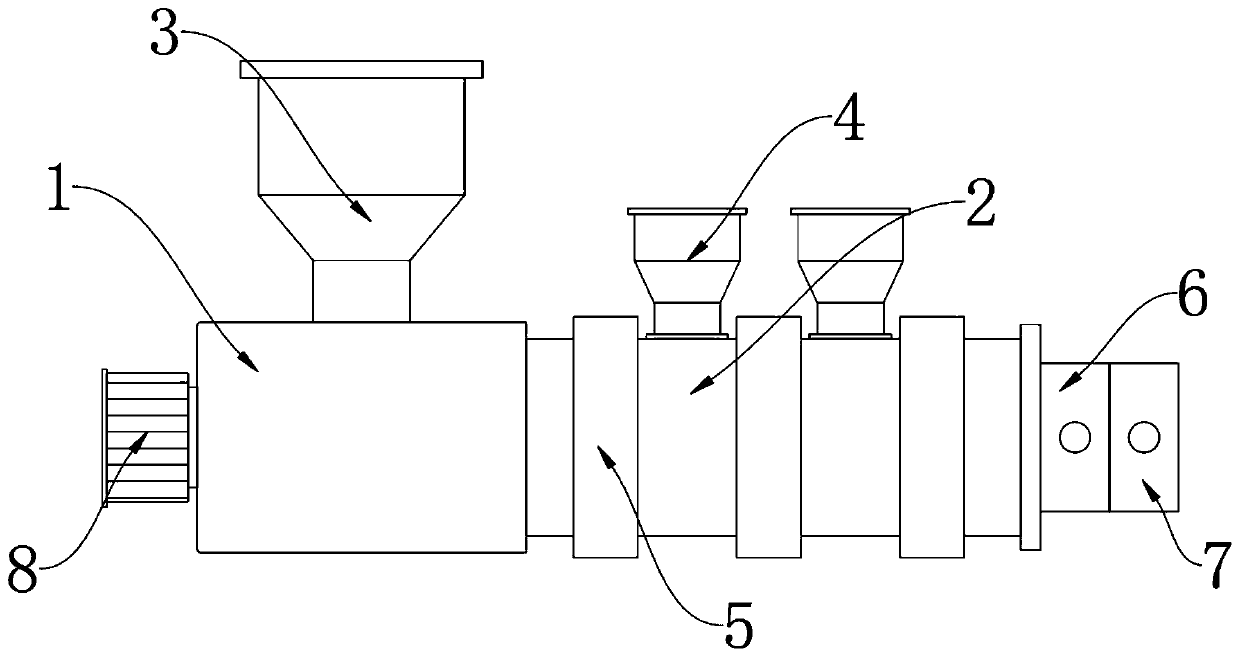

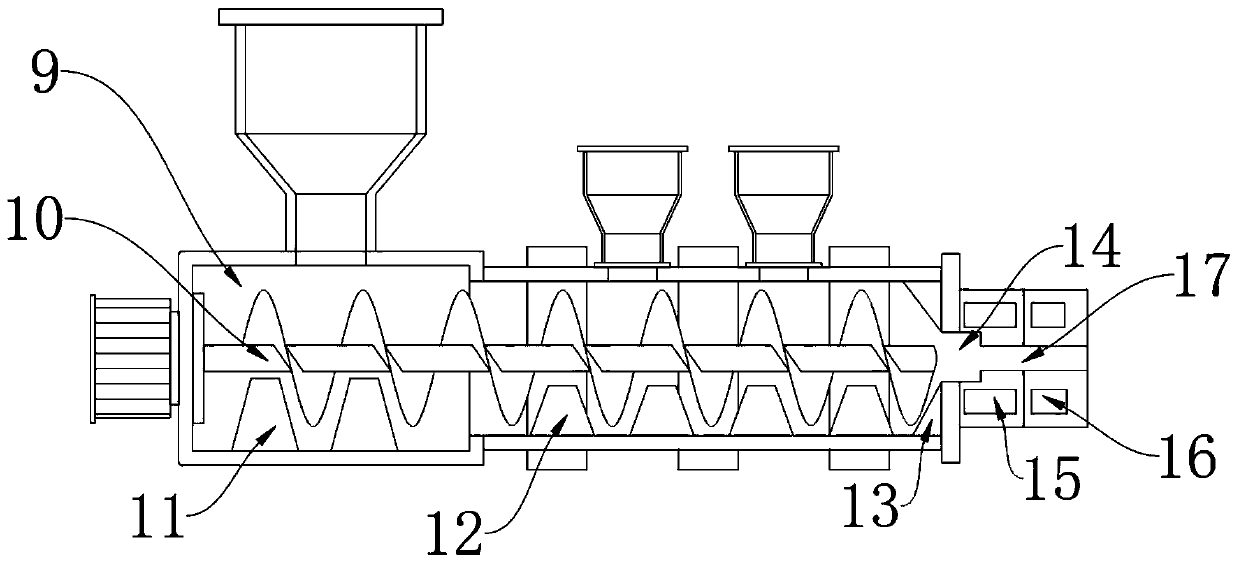

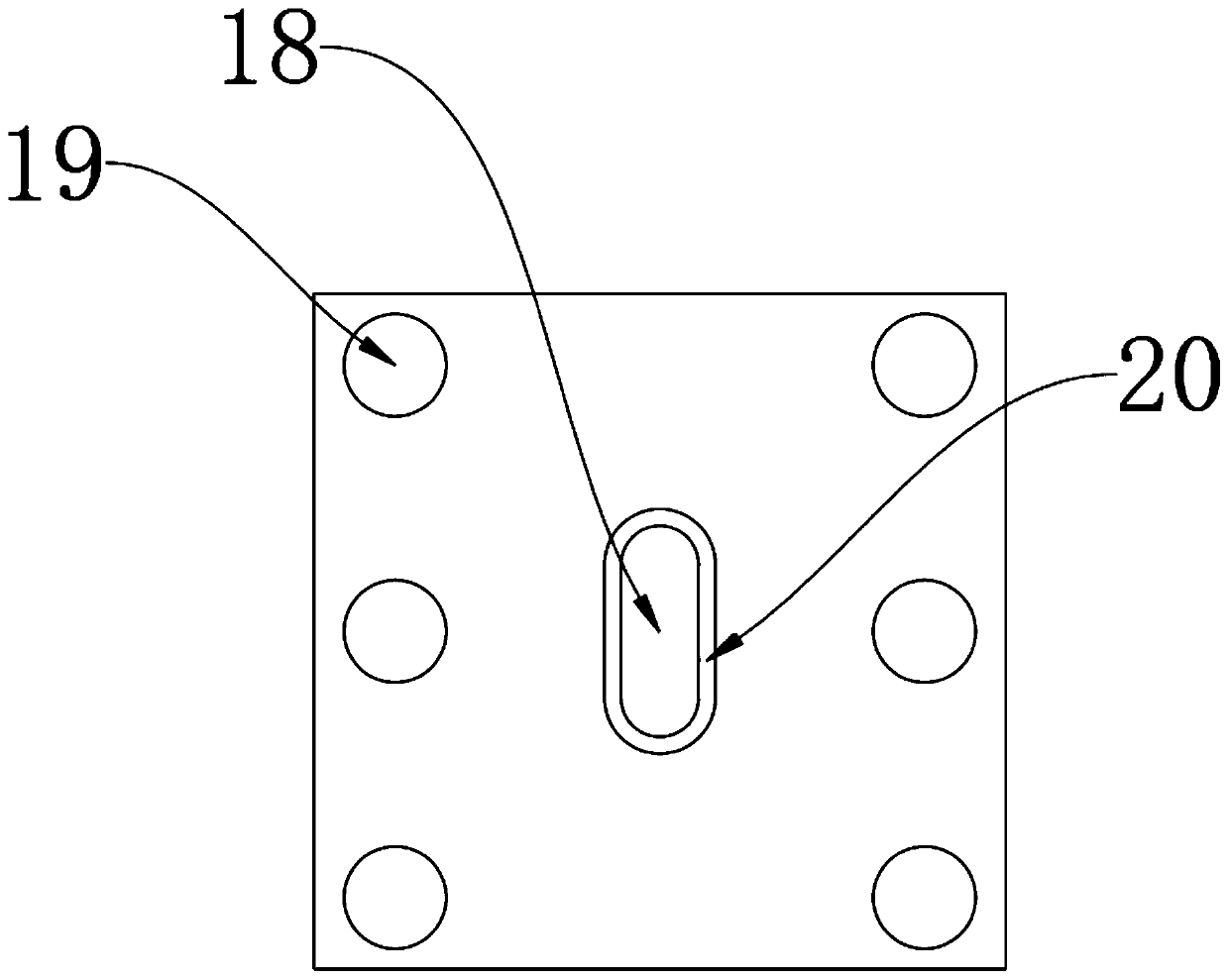

Extrusion device for mold production

Owner:苏州巨模模具有限公司

Crushing type plastic extruder

The invention discloses a crushing type plastic extruder. A main crushing device is composed of a motor, a first rotating shaft, a driving gear, a plurality of first stirring blades and a pressing plate. The motor is installed on the middle part of the upper end of a box body, the output end of the motor is connected with the first rotating shaft, and the other end of the first rotating shaft penetrates through the top wall of the box body and reaches the inside of an extrusion device. The multiple first stirring blades are connected to the side wall of the section, located in the box body, ofthe first rotating shaft at equal distances in the circumferential direction. The extrusion device includes an extrusion box, a filter plate and a spiral rod. The upper end of the extrusion box fixedly penetrates through the middle part of the lower end of the box body. The upper end of the inner side wall of the extrusion box is fixedly connected with the filter plate. The spiral rod is movablyconnected to the filter plate in an inserted mode, and the upper end of the spiral rod is fixedly connected with the lower end of the first rotating shaft. The crushing type plastic extruder has the characteristics that the crushing effect is good and the work efficiency is improved, and is high in practicability.

Owner:NANJING LINGYA AUTOMOBILE TECH RES INST

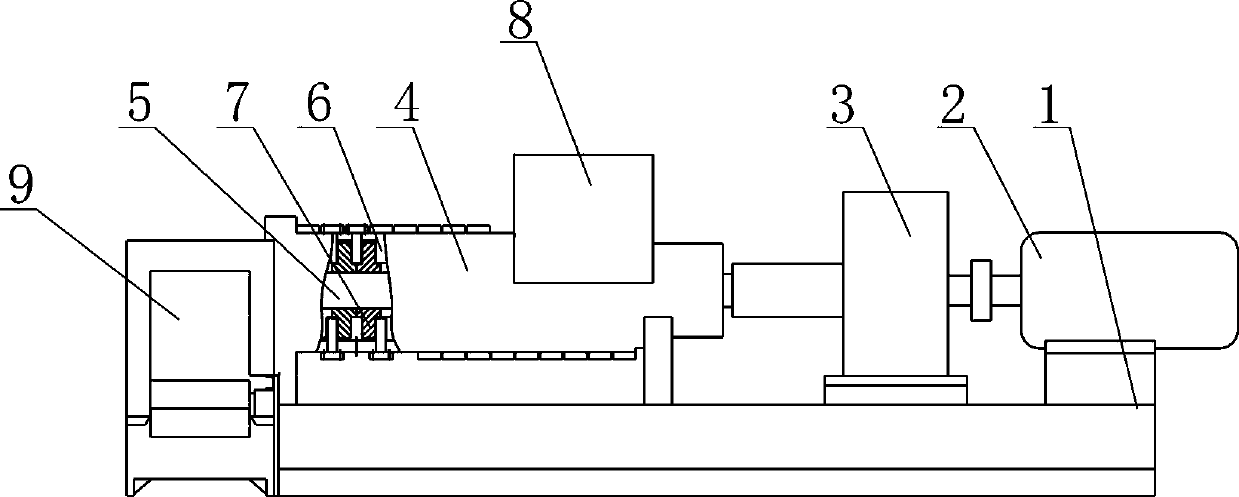

Plastic extruder

InactiveCN107553868AIncrease squeezeHelp stirringHelical lineReduction drive

Owner:徐国峰

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap