Plastic extruder

A technology of plastic extruder and frame is applied in the field of plastic extruder, which can solve the problems of entrapment and uneven mixing, and achieve the effect of uniform mixing and increasing extrusion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

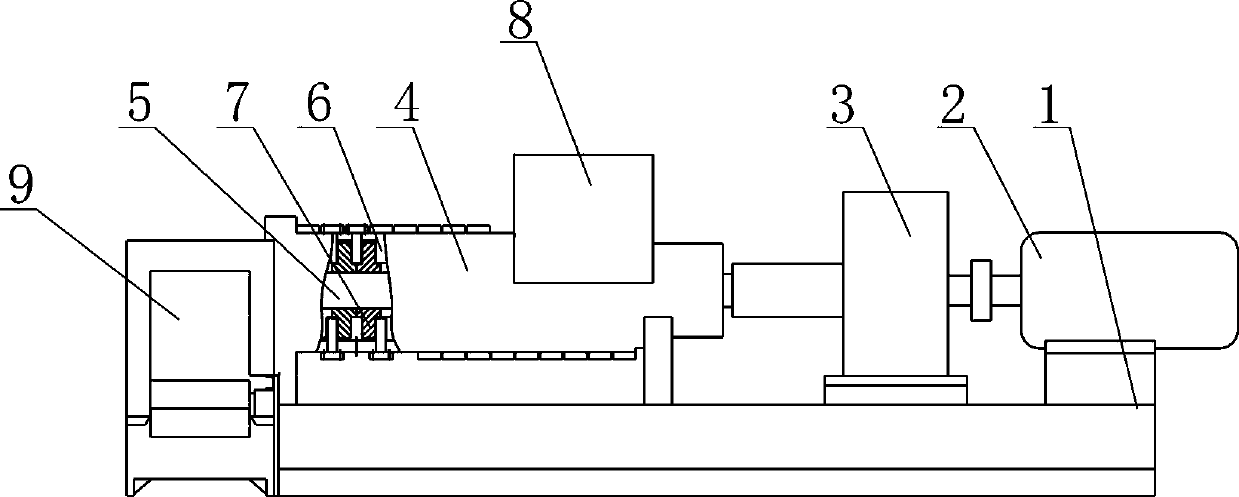

[0010] Such as figure 1 As shown, a plastic extruder includes a main shaft 5, a fixed knife group 6, a moving knife group 7, a frame 1, and a main motor 2, a reducer 3 and a heating and curing cylinder 4 arranged on the frame 1. The top of the heating and curing cylinder 4 is provided with a feed hopper 8, and the moving knife group 7 is composed of a plurality of moving knives, and the plurality of moving knives are arranged on the surface of the main shaft 5 and distributed at intervals along the direction of the helix. 5 is arranged in the heating and aging cylinder 4, and the fixed knife group 6 is composed of a plurality of fixed knives. The main motor 2 drives the main shaft 5 to rotate through the reducer 3, and the moving knife group 7 rotates together with the main shaft 5. The mixed material is pushed to the discharge end of the heating and aging cylinder 4, and the discharge end is provided with a discharge hopper 9.

[0011] The above description is only a preferred

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap