Constant-speed harmonic speed reducer

A technology of harmonic reducer and harmonic generator, applied in the direction of belt/chain/gear, mechanical equipment, transmission device, etc., which can solve unreasonable design, unstable speed of harmonic generator, uncontrollable speed of servo motor, etc. problem, to achieve the effect of stable speed and controllable state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings will be used for a detailed description, as follows:

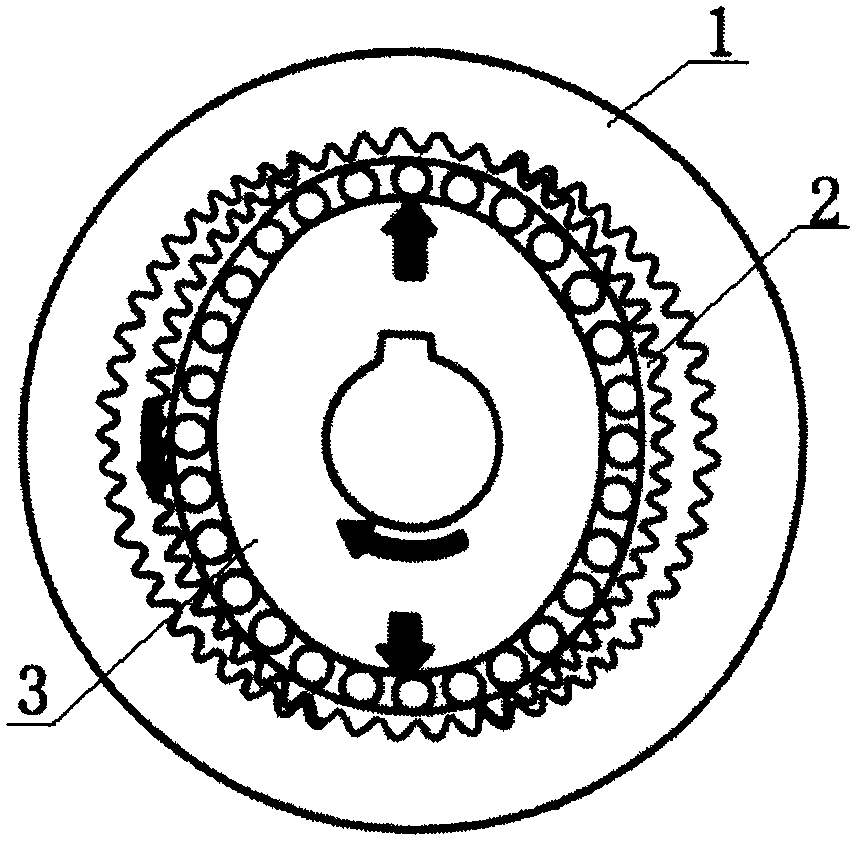

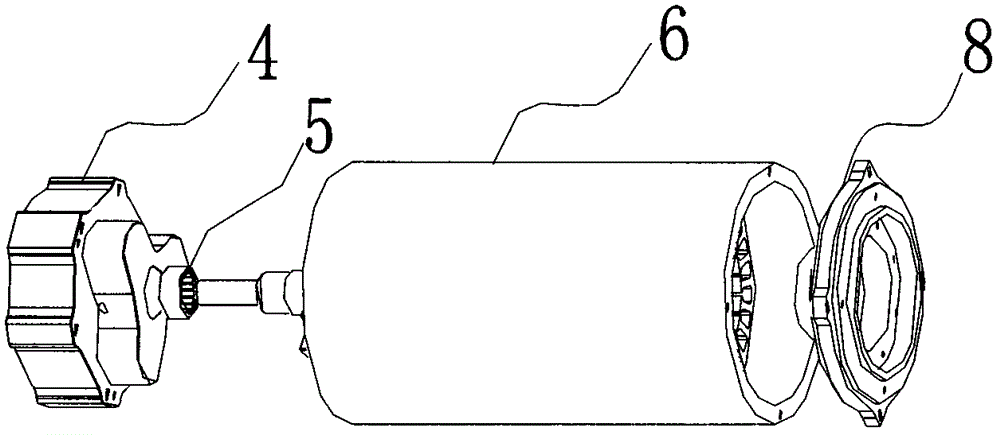

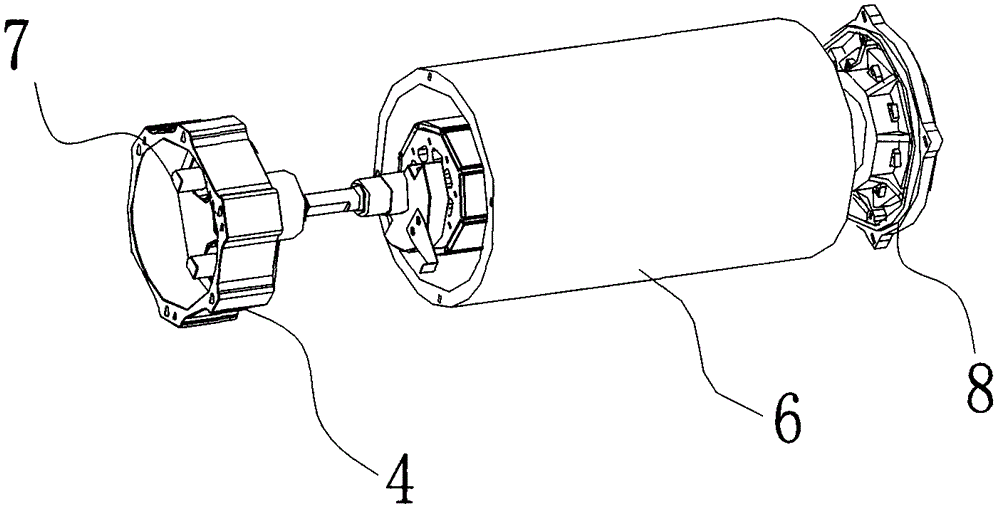

[0016] Such as Figure 1 to Figure 3 As shown, a steady-speed harmonic reducer includes a rigid wheel 1, the rigid wheel 1 is connected with a flexible wheel 2, and the flexible wheel 2 is connected with a harmonic generator 3 connected to a servo motor for rotation, and the harmonic generation One side of the generator 3 is provided with a generator end cover 4, and the generator end cover 4 is provided with a connection hole, and the connection hole is connected with the output shaft of the servo motor 6 through a needle bearing 5; the tail of the servo motor 6 is provided with a Hall Control system 8, the Hall control system 8 includes a drive board with a signal acquisition module, a logic processing module and a motor drive modu

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap