Four-container liquid level system dead-beat model prediction control method considering set disturbance

A model predictive control and dead-beat technology, applied in liquid level control, non-electric variable control, control/regulation system, etc., can solve problems such as large system influence, threat to system stability, and influence on accurate tracking of the system to achieve high efficiency The effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0022] The present invention is described in further detail below in conjunction with the accompanying drawings and specific embodiments:

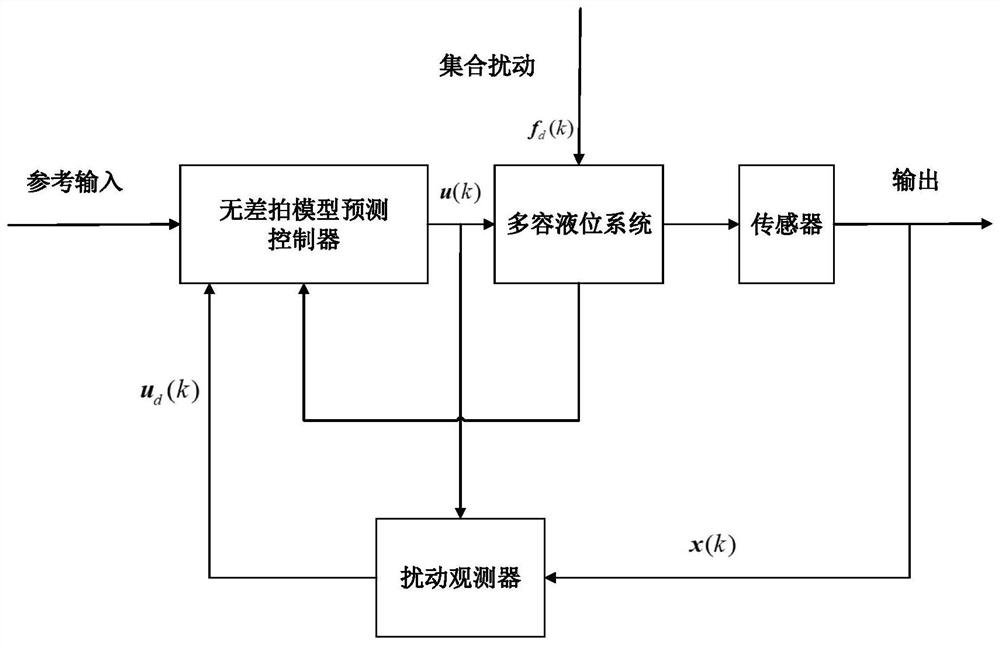

[0023] combine figure 1 As shown, this embodiment describes a deadbeat model predictive control method for a four-volume liquid level system considering collective disturbances, so as to solve the liquid level control problem of a specific type of four-volume liquid level system.

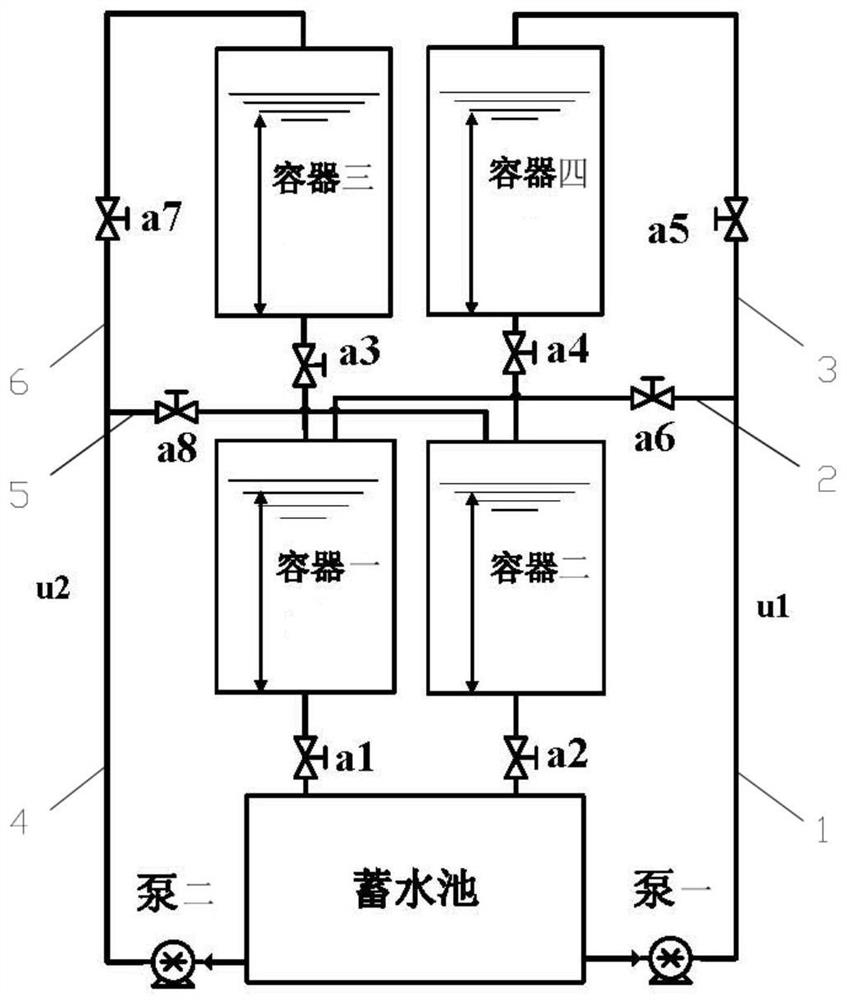

[0024] like figure 2 As shown, the four-volume liquid level system includes a reservoir, two pumps, four vessels, and eight manual adjustment valves.

[0025] Define two pumps as pump one and pump two.

[0026] Define four containers as container one, container two, container three and container four.

[0027] The eight manual regulating valves are defined as manual regulating valve 1, manual regulating valve 2, manual regulating valve 3, manual regulating valve 4, manual regulating valve 5, manual regulating valve 6, manual regulating valve 7 and manual regula

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap