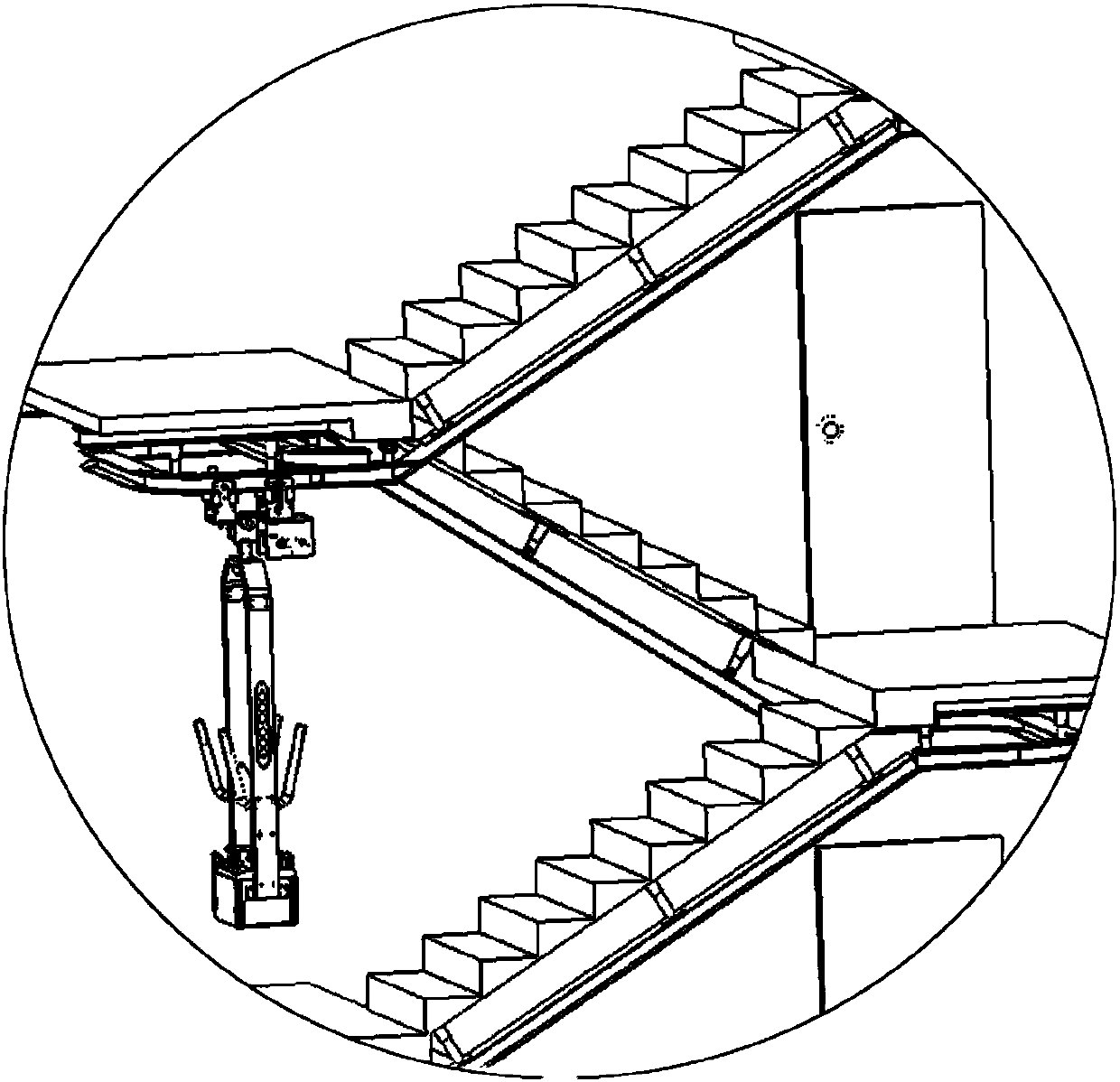

Drive device matched with hanging rail

A technology of driving wheels and driven wheels, which is applied in the direction of transportation and packaging, elevators and lifts in buildings, etc. It can solve the problems of blocking seats, affecting the lighting of low-rise residents, and high installation and maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

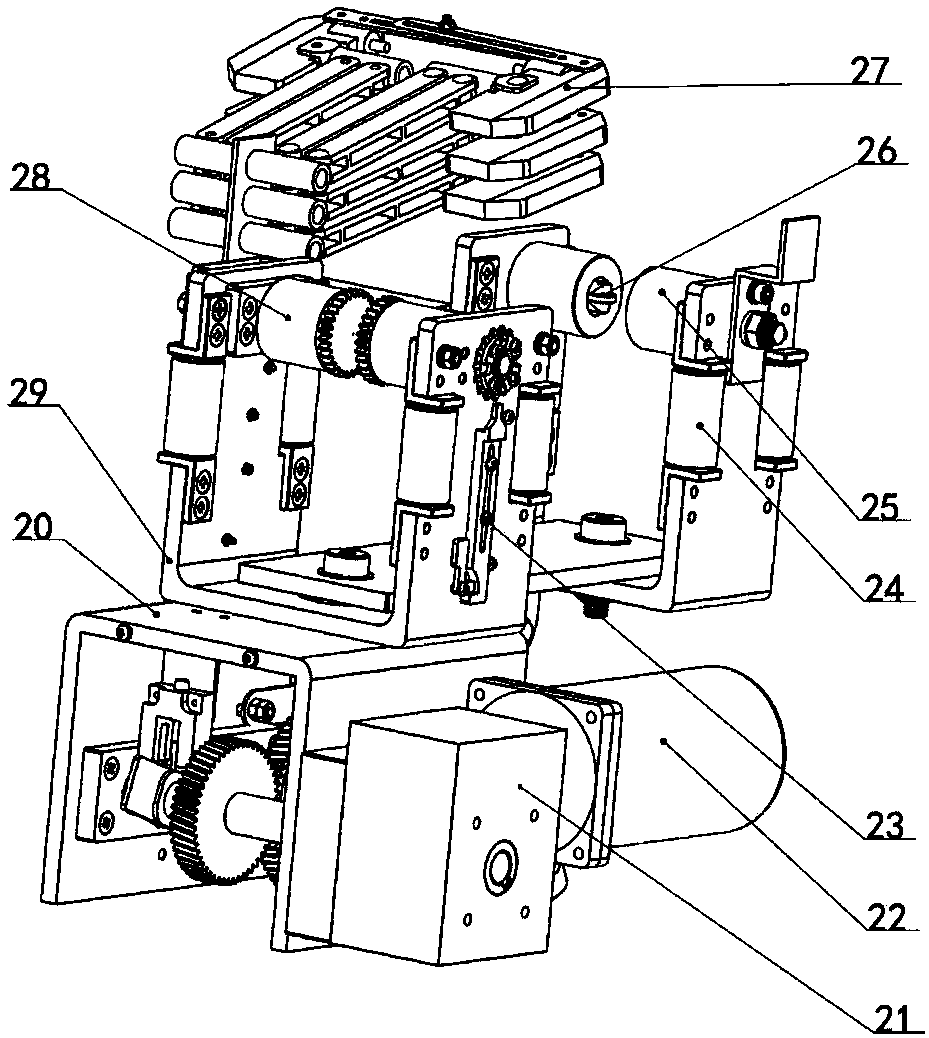

[0020] combine Figure 2 to Figure 7 , The driving device includes a U-shaped upper box body 29, a lower box body 20, a driving wheel 28, a speed reducer 21, a motor 22, and a transmission gear set. The upper box body 29 is fixedly connected with the lower box body 20 . The reducer 21 and the motor 22 are arranged on the lower casing 20, the reducer 21 is connected with the output shaft of the motor 22, and the driving wheels 28 have two and are symmetrically arranged on the two inner wall surfaces of the U-shaped upper casing 29 and are positioned on the guide rails. On the nylon pad 15 between the upper guide rail plate and the lower guide rail plate. The driving wheel 28 is axially arranged on a gear matched with the rack 14 . The output shaft of the speed reducer 21 is connected with the driving wheel 28 through the transmission gear set.

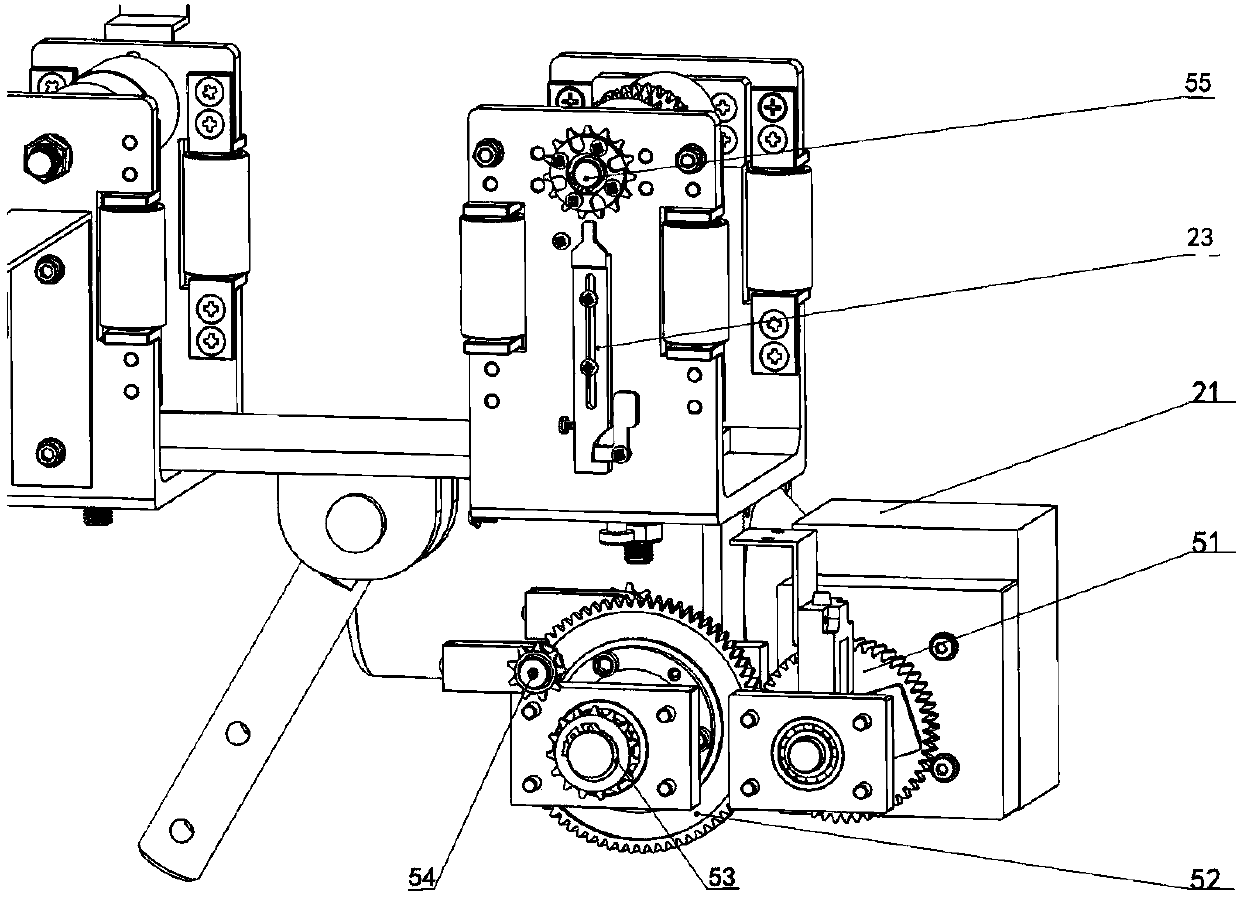

[0021] combine Figure 8 The transmission gear set includes a first helical gear 51 and a second helical gear 52 meshing with each ot

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap