Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2 results about "Impact area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Device and Method for Admixing Liquids into Flowable Bulk Material

ActiveUS20080144425A1High energyEfficient mixingMixing/kneading structural elementsFlow mixersSpray nozzleImpact area

A device for admixing a liquid into flowable dry materials has a housing with a mixing chamber having an inner wall with an impact area and an exit opening at a bottom end of the mixing chamber. Dry material is supplied from above into the mixing chamber and falls downwardly toward the impact area in front of the inner wall of the mixing chamber and exits through the exit opening. A nozzle generates a pressurized high-speed jet of a liquid impacting on the inner wall of the mixing chamber in the impact area and wetting the dry material with the liquid as the jet passes through the dry material and impacts against the inner wall. An opening inside the housing is provided for supplying liquid and pasty additives, wherein the opening is directed toward an area of the mixing chamber between the nozzle and the impact area.

Owner:DIERKS & SOHNE GMBH & CO KG

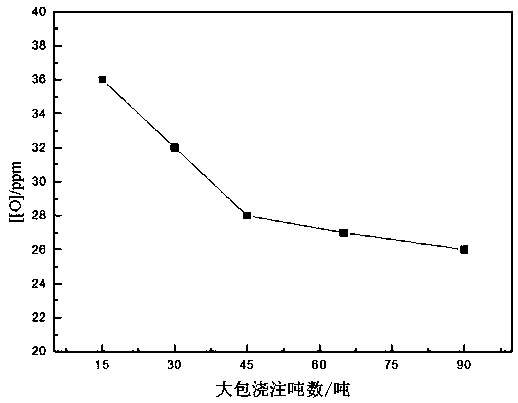

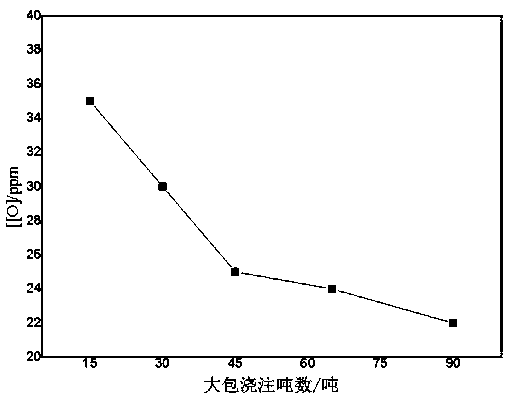

Method for adding tundish covering agent for continuous casting

Owner:TANGSHAN STAINLESS STEEL +1

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap