Method for adding tundish covering agent for continuous casting

A continuous casting pouring and tundish technology, which is applied in the field of adding tundish covering agent, can solve the problems of low alkalinity covering agent with low content of alkaline oxide, slab quality that cannot meet the requirements, and cannot be fully absorbed, etc., to achieve Improve the quality of continuous casting pouring blanks and the qualified rate of finished products, reduce the content of secondary oxidation and non-metallic inclusions, and increase the effect of adsorption and inclusion capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: The method for adding the tundish covering agent used for continuous casting and pouring adopts the following process.

[0023] The mass percentage of the main components of the tundish covering agent used is: SiO 2 3.2%, CaO 47.3%, MgO0.3%, Fe 2 o 3 0.4% and Al 2 o 3 35.0%, alkalinity 12.3.

[0024] Use the above method to add, start to add after 5 seconds of pouring, after adding five batches of covering agent, add a total of 25 bags, weighing 250kg.

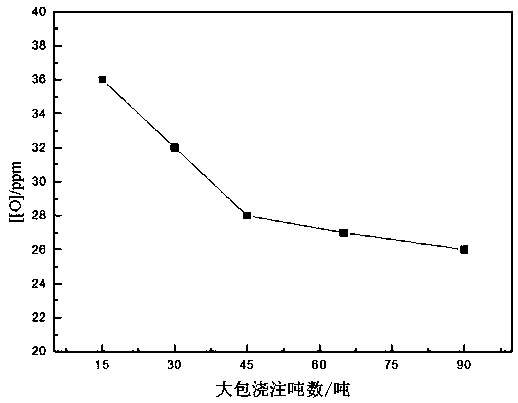

[0025] During the casting process, the protection of the molten steel surface in the tundish can be clearly seen. After the tundish covering agent is added, the liquid level rises steadily as the casting progresses. After the molten steel is immersed in the protective sleeve, the liquid steel level does not fluctuate. The change trend of the sub-oxygen level in the pouring furnace is as follows figure 1 shown by figure 1 It can be seen that the oxygen content level in the first molten steel of the

Embodiment 2

[0026] Embodiment 2: The method for adding the tundish covering agent used for continuous casting and pouring adopts the following process.

[0027] The mass percentage of the main components of the tundish covering agent used is: SiO 2 3.0%, CaO 42.6%, MgO 0.2%, Fe 2 o 3 1.0% and Al 2 o 3 37.4%, alkalinity 10.7.

[0028] Use the above method to add, start to add after 5 seconds of pouring, after adding five batches of covering agent, add a total of 25 bags, weighing 250kg.

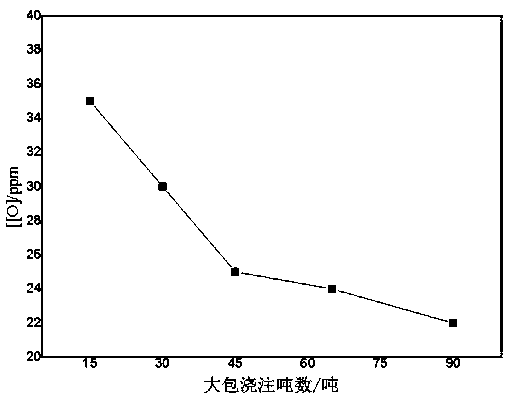

[0029] During the casting process, the protection of the molten steel surface in the tundish can be clearly seen. After the tundish covering agent is added, the liquid level rises steadily as the casting progresses. After the molten steel is immersed in the protective sleeve, the liquid steel level does not fluctuate. The change trend of the sub-oxygen level in the pouring furnace is as follows figure 2 shown by figure 2 It can be seen that the oxygen content level in the first molten steel of t

Embodiment 3

[0030] Embodiment 3: The method for adding the tundish covering agent used for continuous casting and pouring adopts the following process.

[0031]The mass percentage of the main components of the tundish covering agent used is: SiO 2 2.5%, CaO 43.7%, MgO0.2%, Fe 2 o 3 0.8% and Al 2 o 3 40.0%, alkalinity 11.3.

[0032] Use the above method to add, start to add after 6 seconds of pouring, after five batches of covering agent are added, a total of 25 bags are added, weighing 250kg.

[0033] During the casting process, the protection of the molten steel surface in the tundish can be clearly seen. After the tundish covering agent is added, the liquid level rises steadily as the casting progresses. After the molten steel is immersed in the protective sleeve, the liquid steel level does not fluctuate. The oxygen content level in the first molten steel of the pouring furnace will decrease rapidly, indicating that the addition of the high-alkalinity tundish covering agent durin

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap