Dying device

A technology of equipment and dyes, which is applied in solid materials, mixers, types of packaging items, etc., can solve the problems of large quantitative operation error, high labor intensity, low efficiency, etc., and achieves high degree of automation, reduced labor intensity, and simple device structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

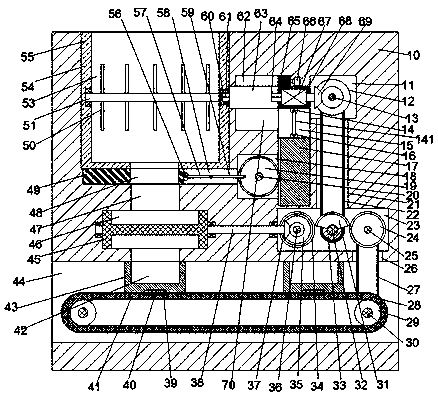

[0015] Such as figure 1 As shown, a kind of dyeing equipment of the present invention includes a body 10, a first installation cavity is arranged in the top end surface of the body 10, a stirring box 55 is fixed in the first installation cavity, and a stirring box 55 is arranged in the stirring box 55. There is a stirring chamber 53 with an upward opening, and the body 10 on the right side of the first installation chamber is provided with a second installation chamber 11, and the first installation chamber and the second installation chamber 11 are communicated with each other. There is a first sliding groove 63, a sliding block 68 is slidably installed in the first sliding groove 63, a driving motor 67 is fixed in the sliding block 68, and a spline shaft 64 is installed on the left side of the driving motor 67, A first bevel gear 69 is installed on the left side of the driving motor 67, and a first rotating shaft 13 is rotatably installed in the front and rear end walls of the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap