Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about "Solid material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

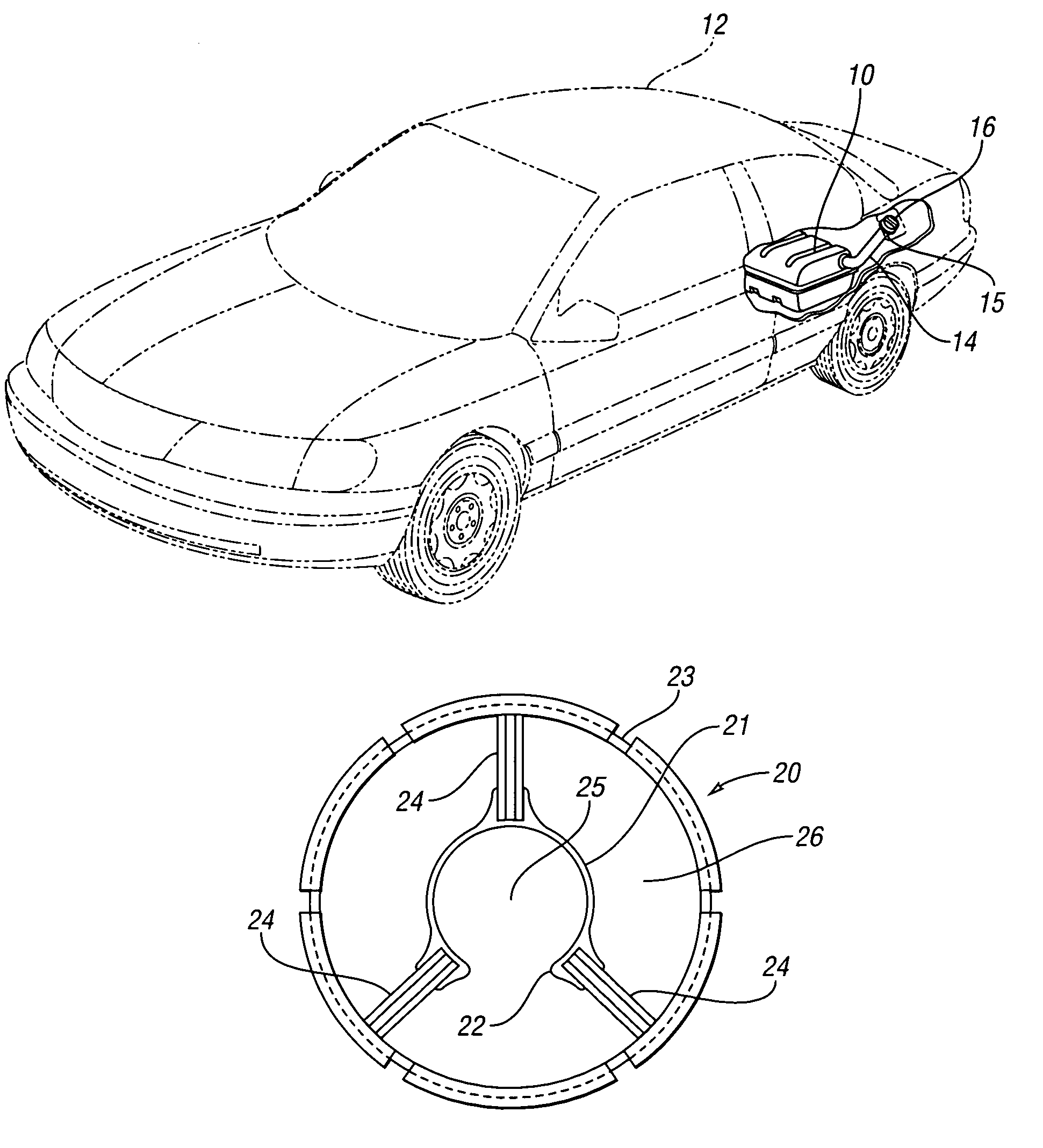

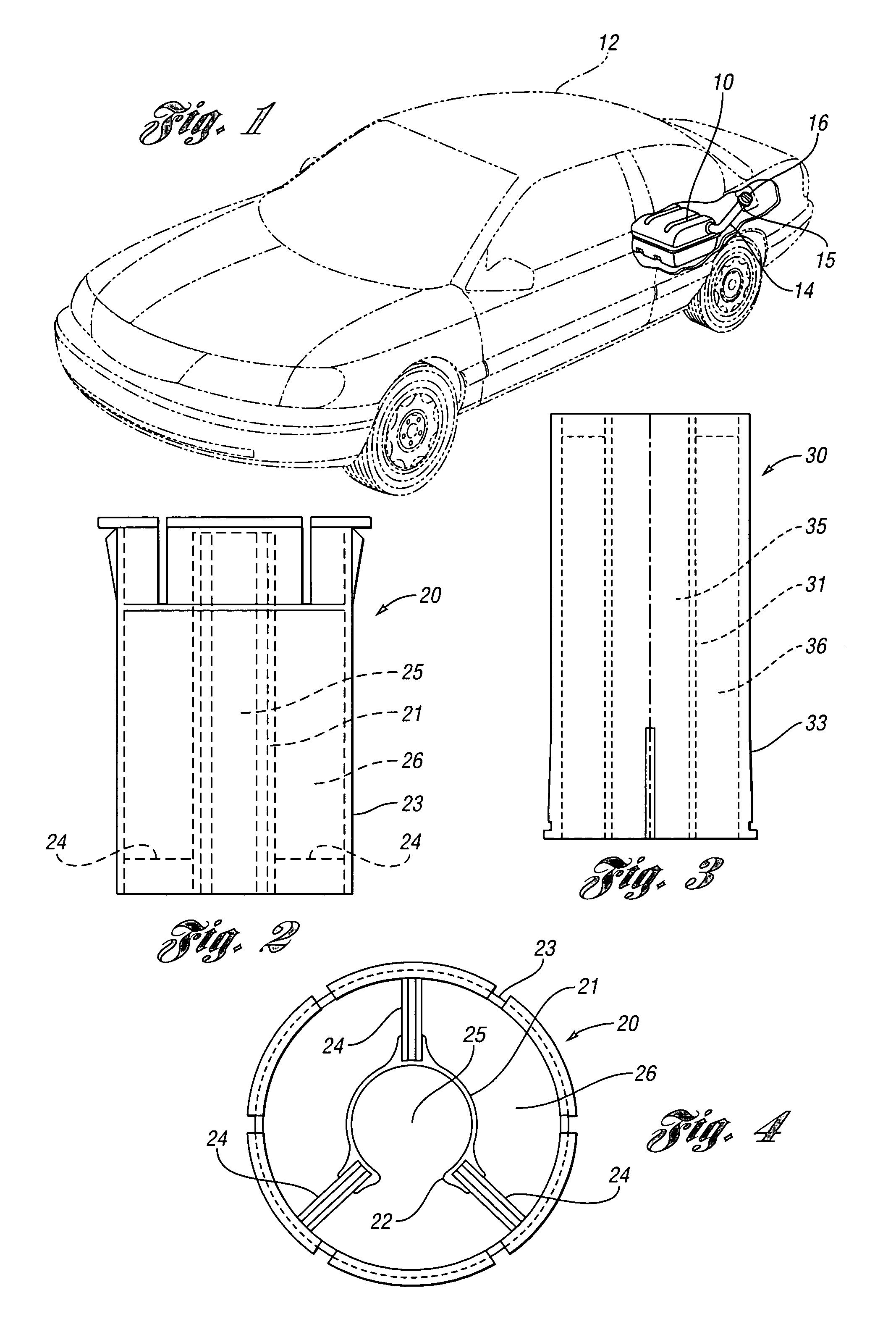

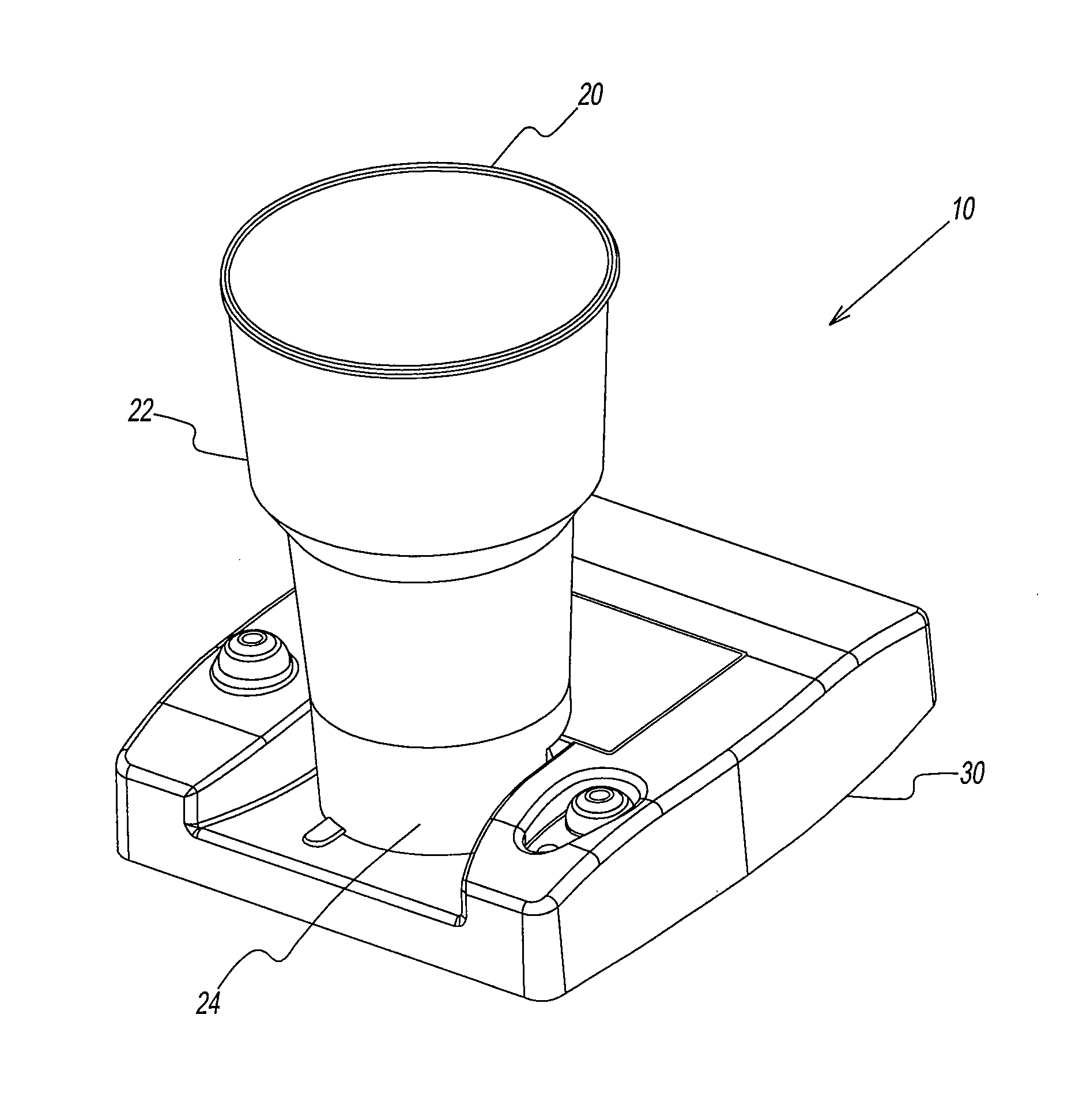

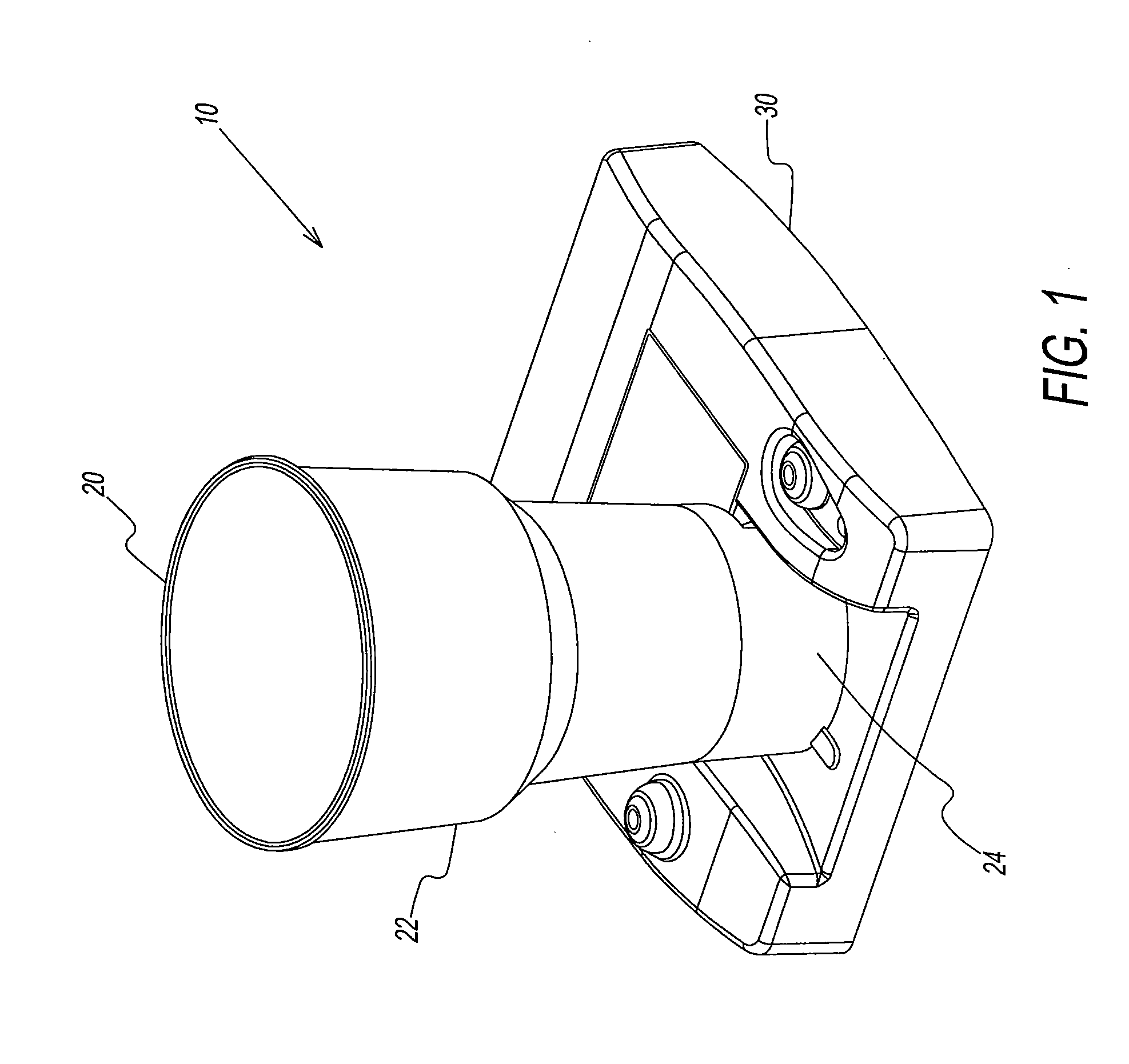

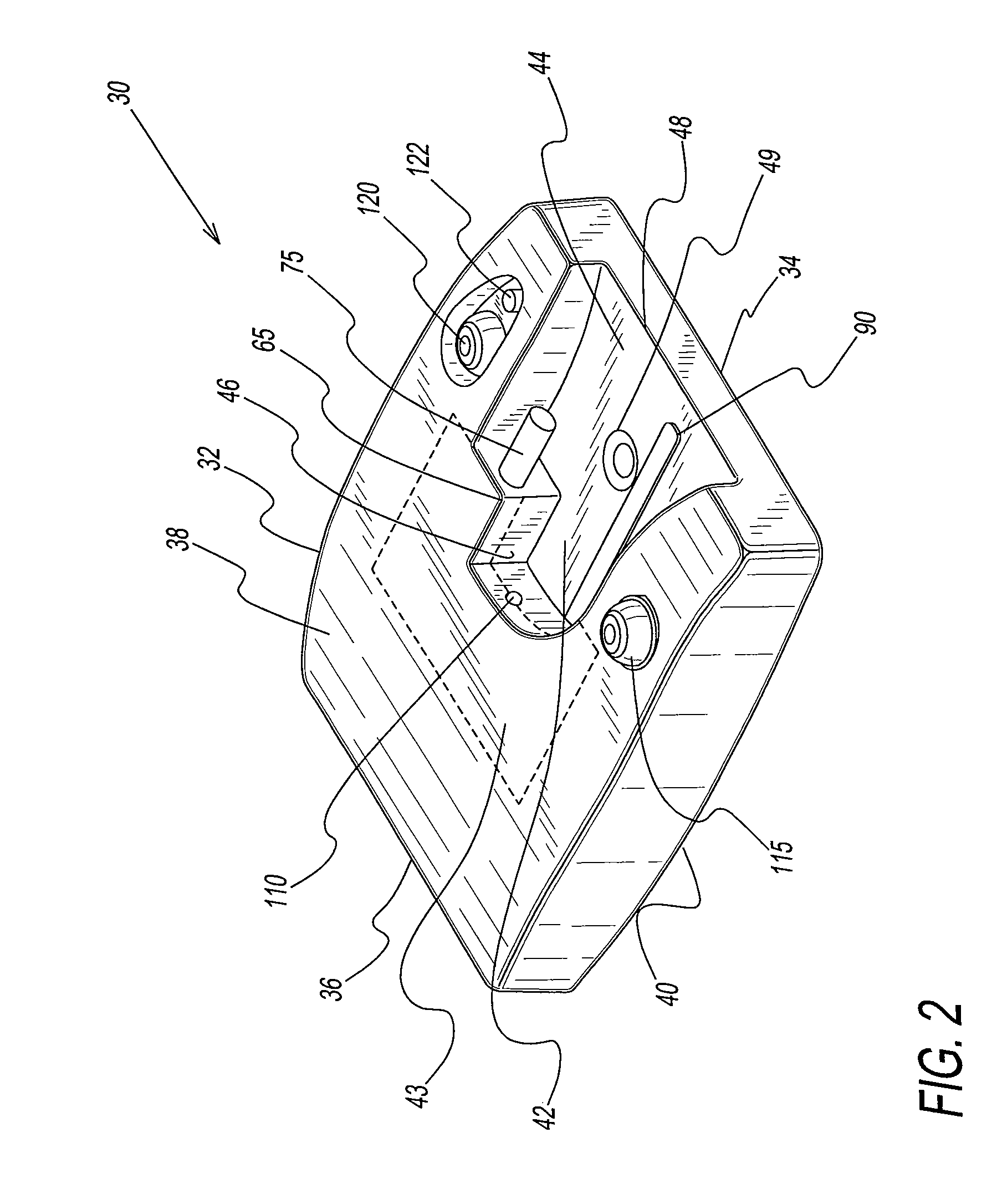

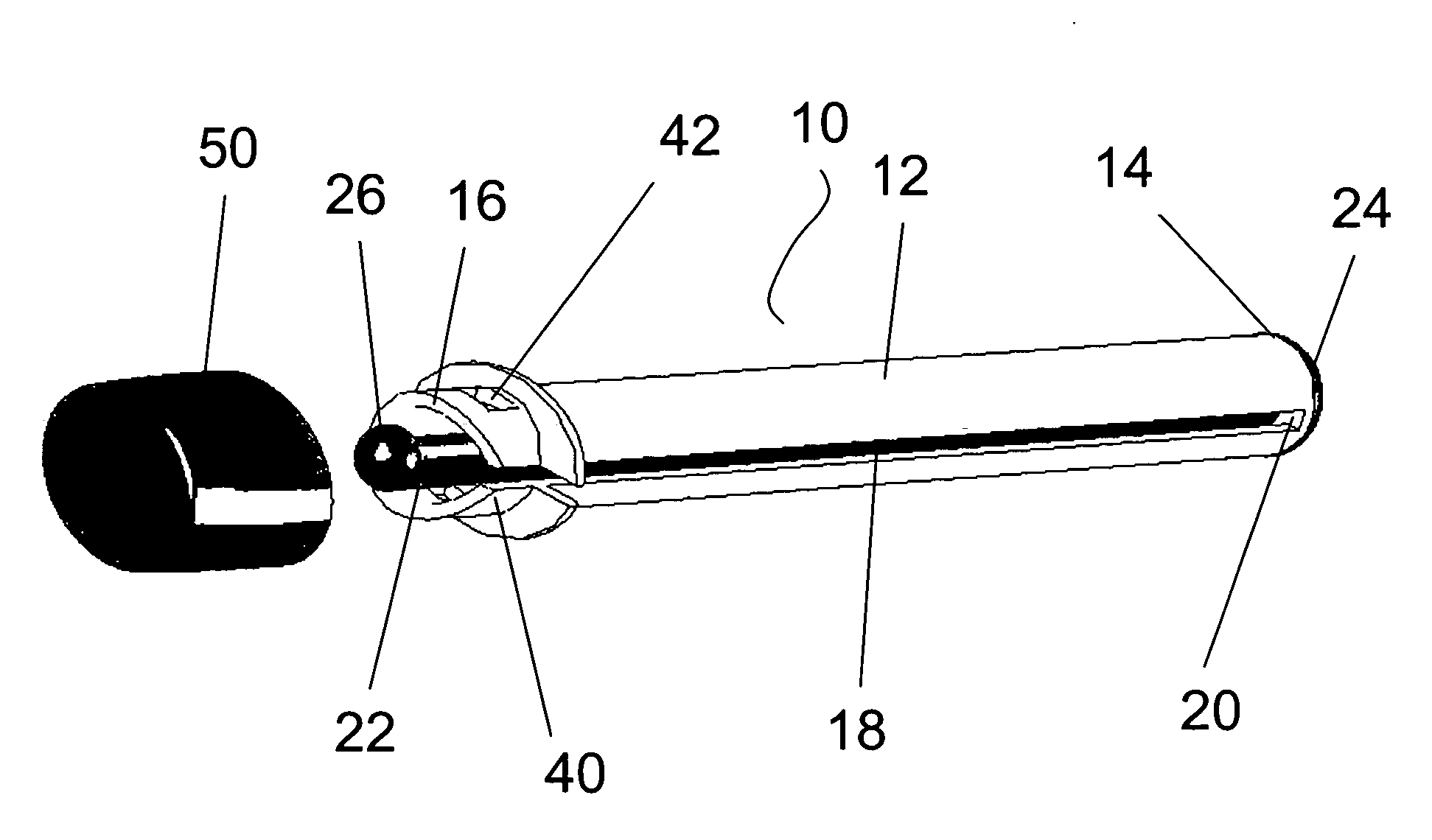

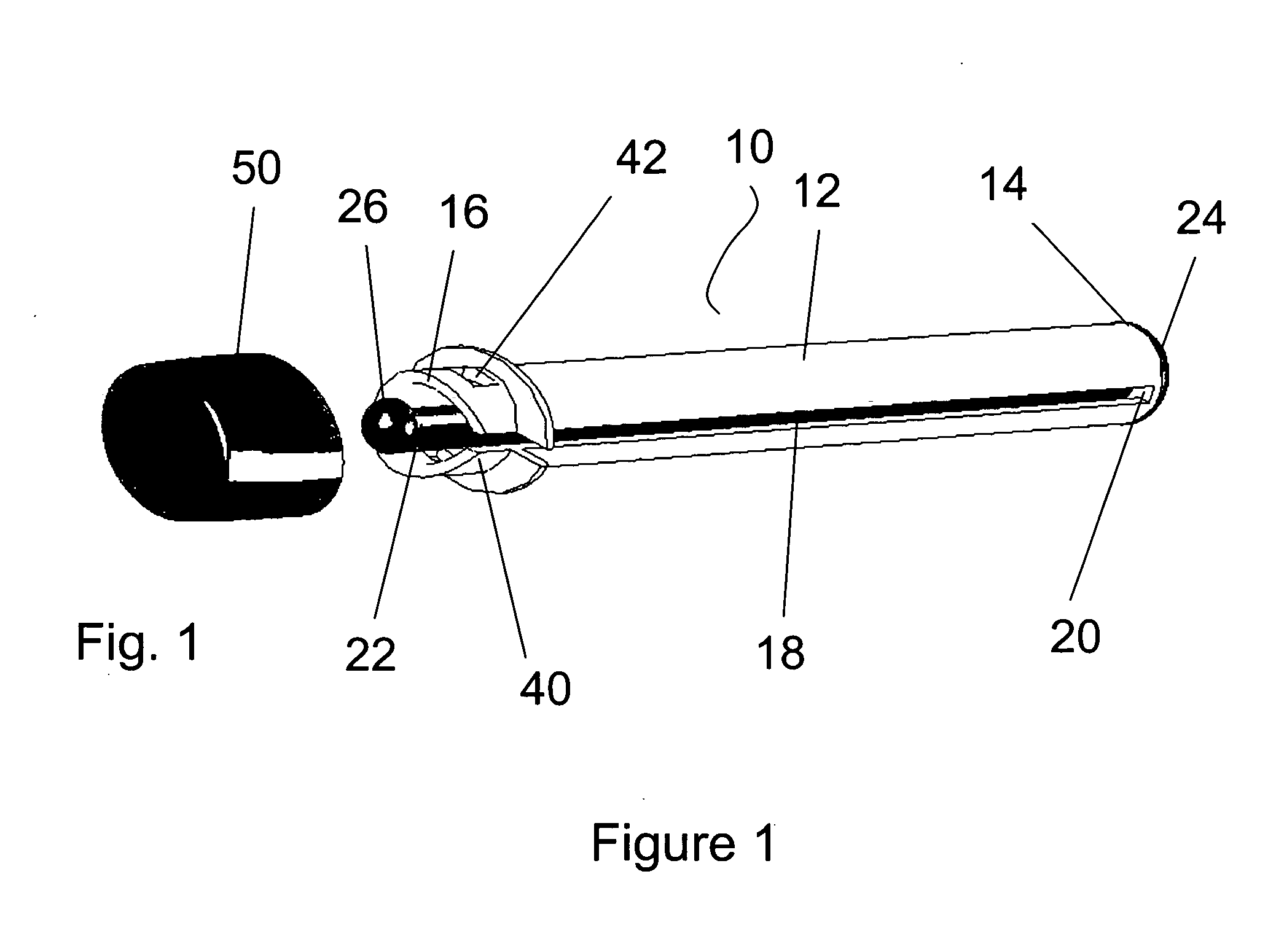

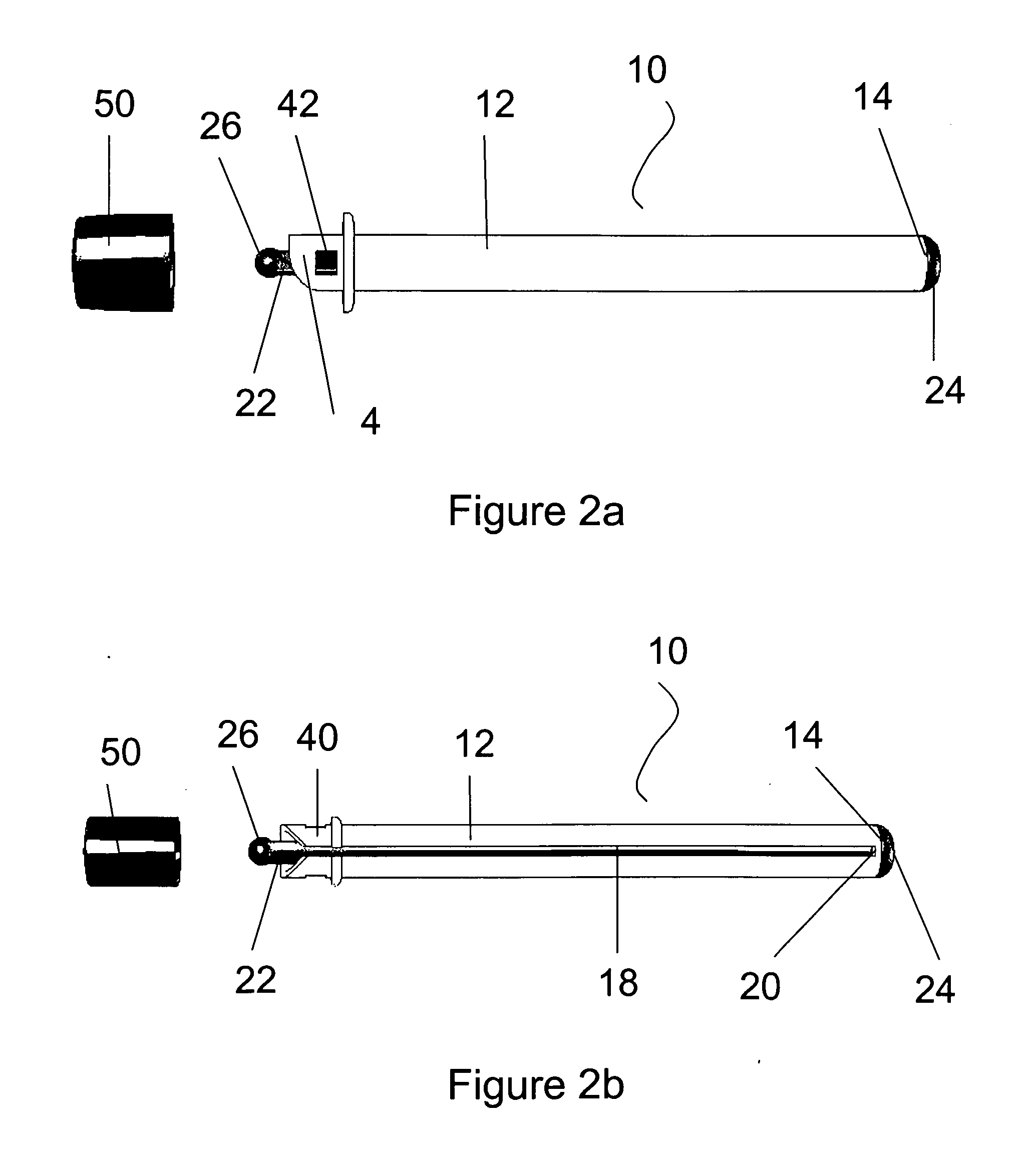

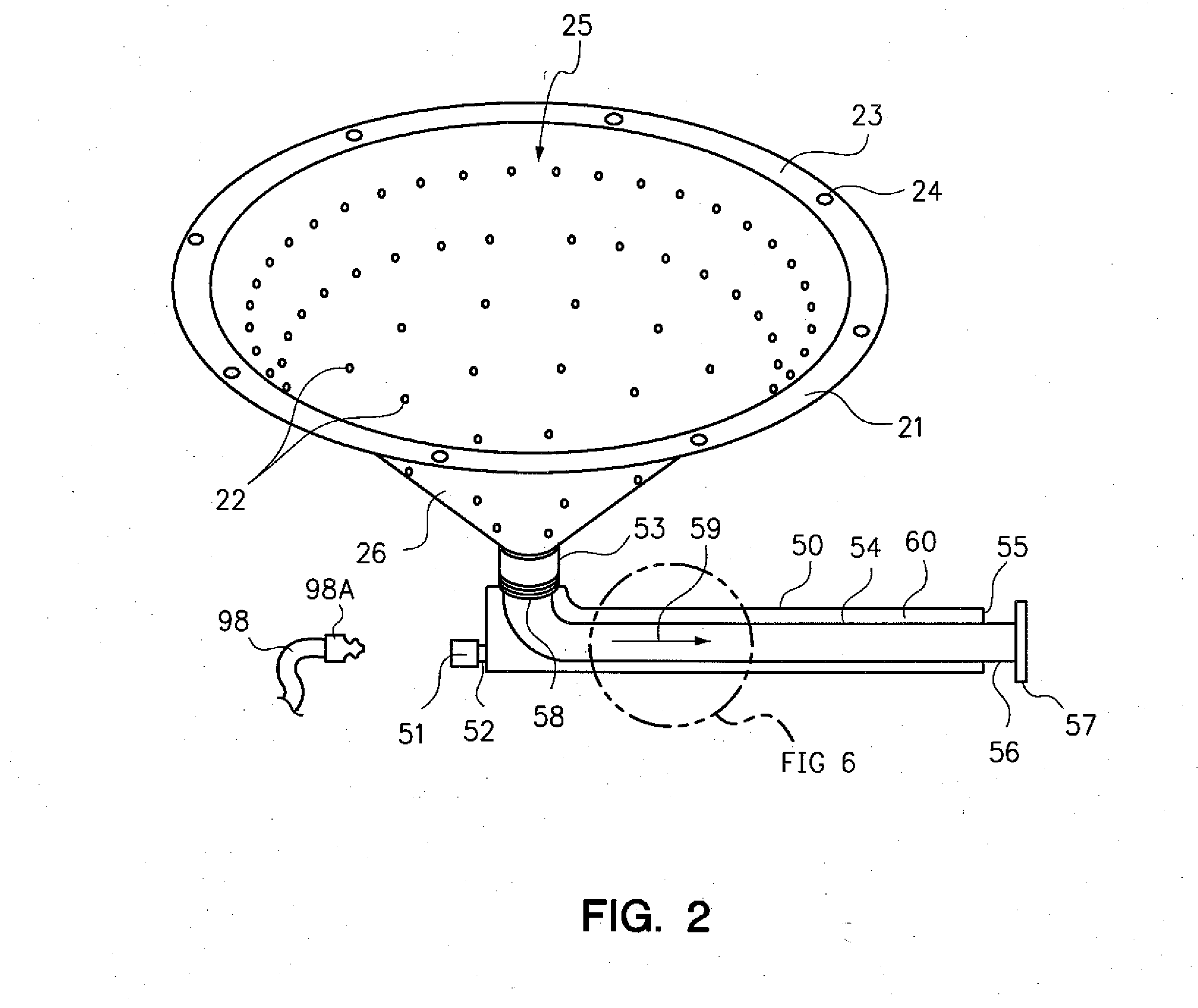

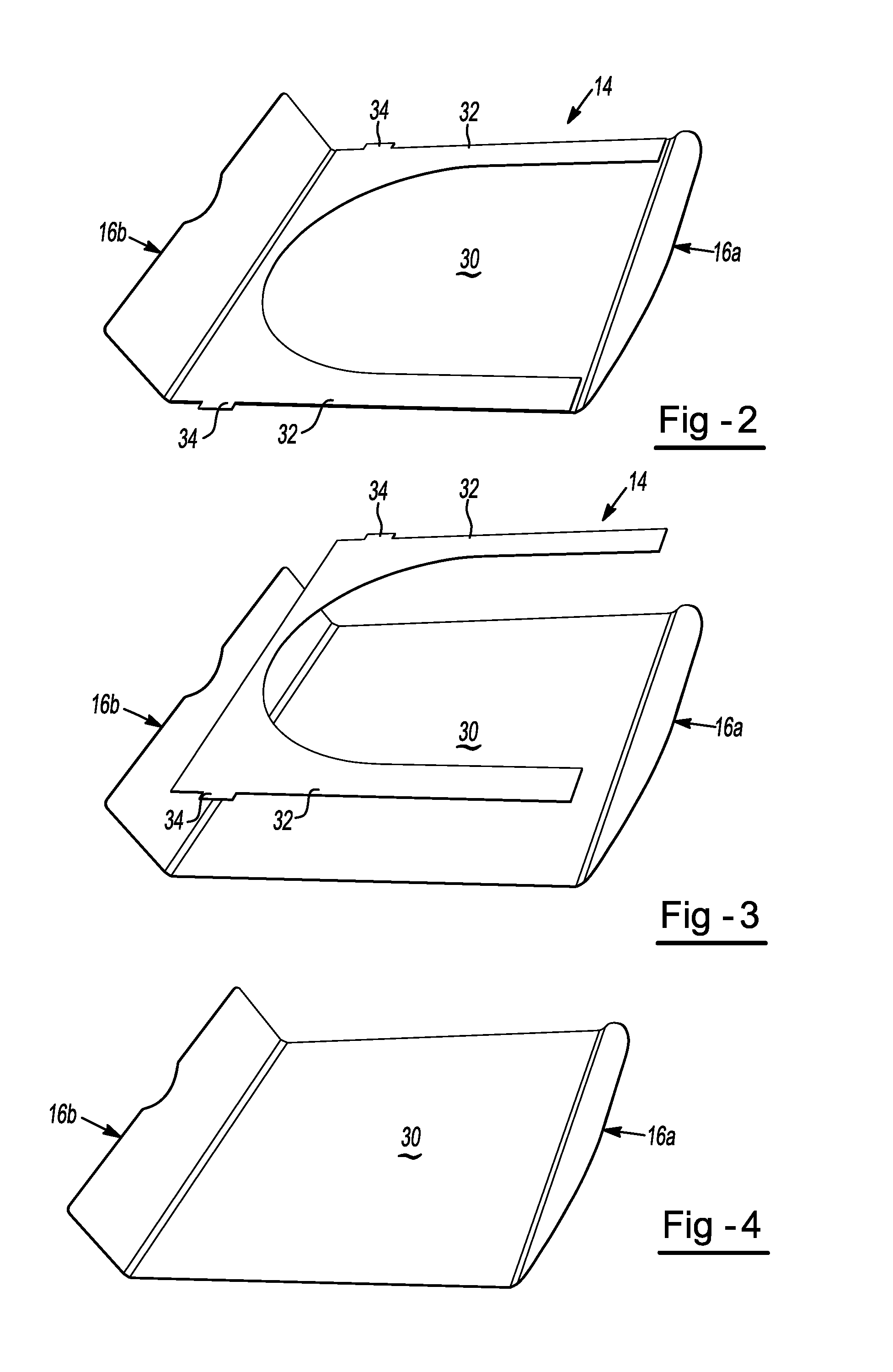

Misfueling prevention device

InactiveUS6966349B1Simple and reliable processEasy to operateSolid materialClosures to prevent refillingFuel tankEngineering

Owner:LADUKE INNOVATIONS

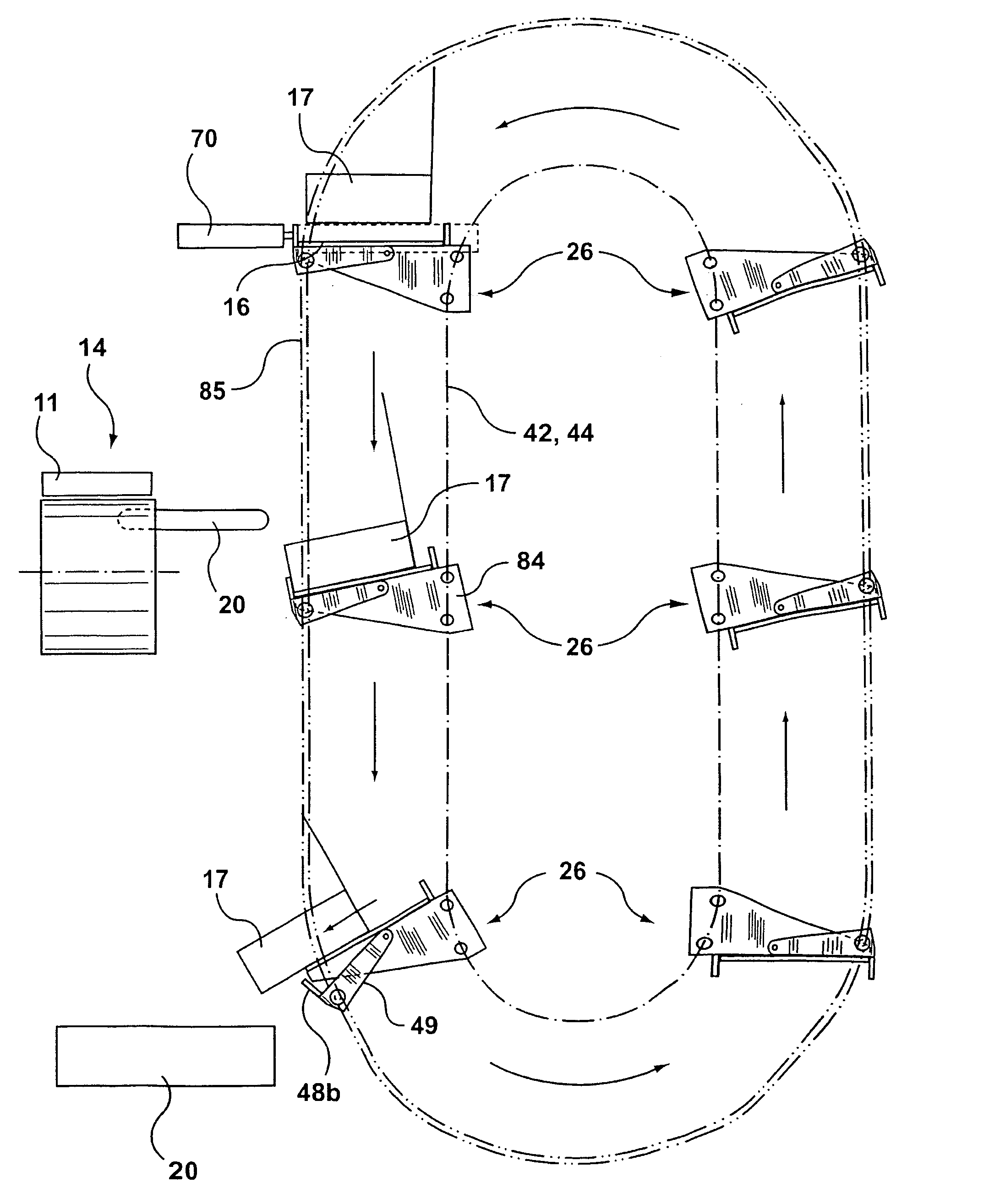

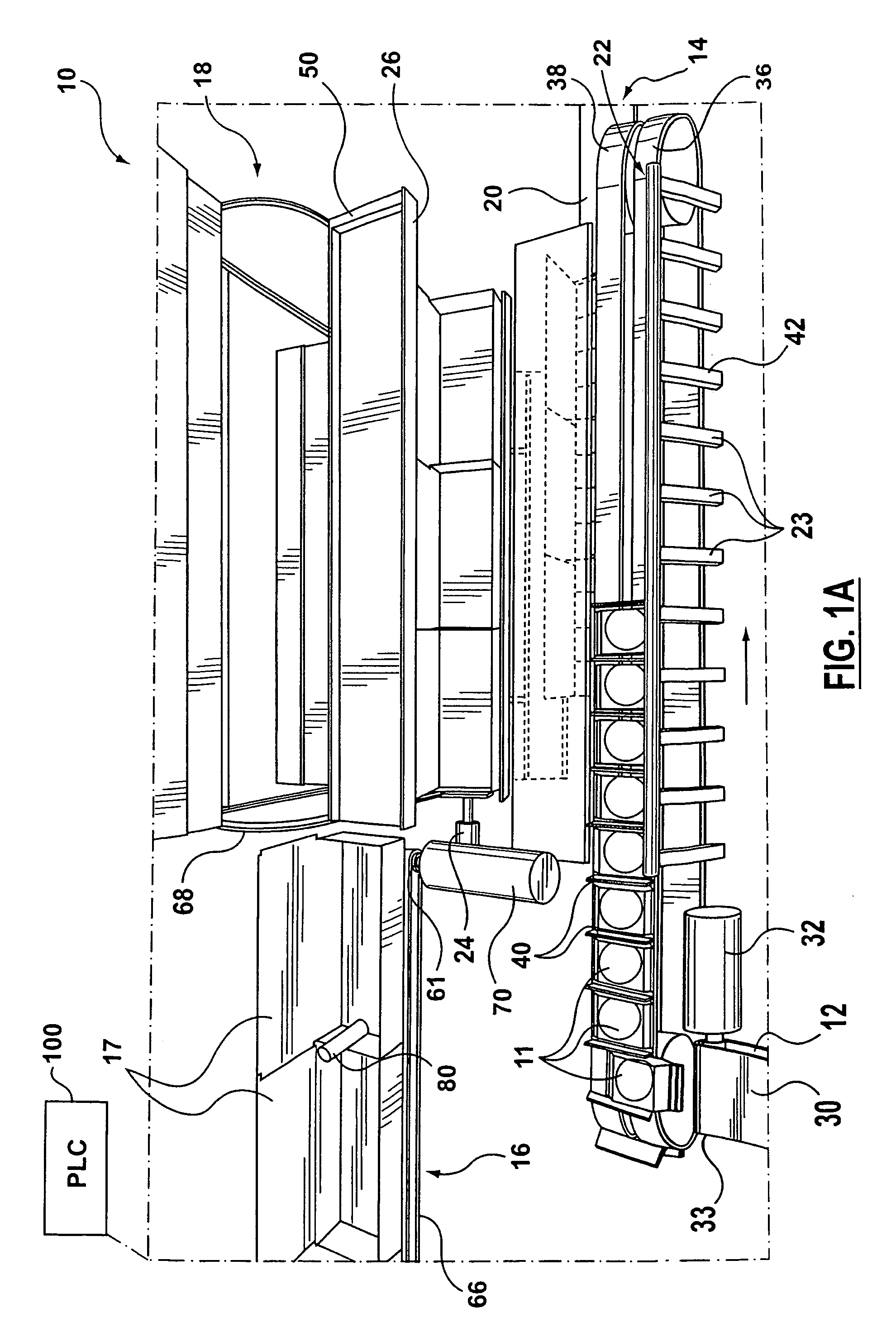

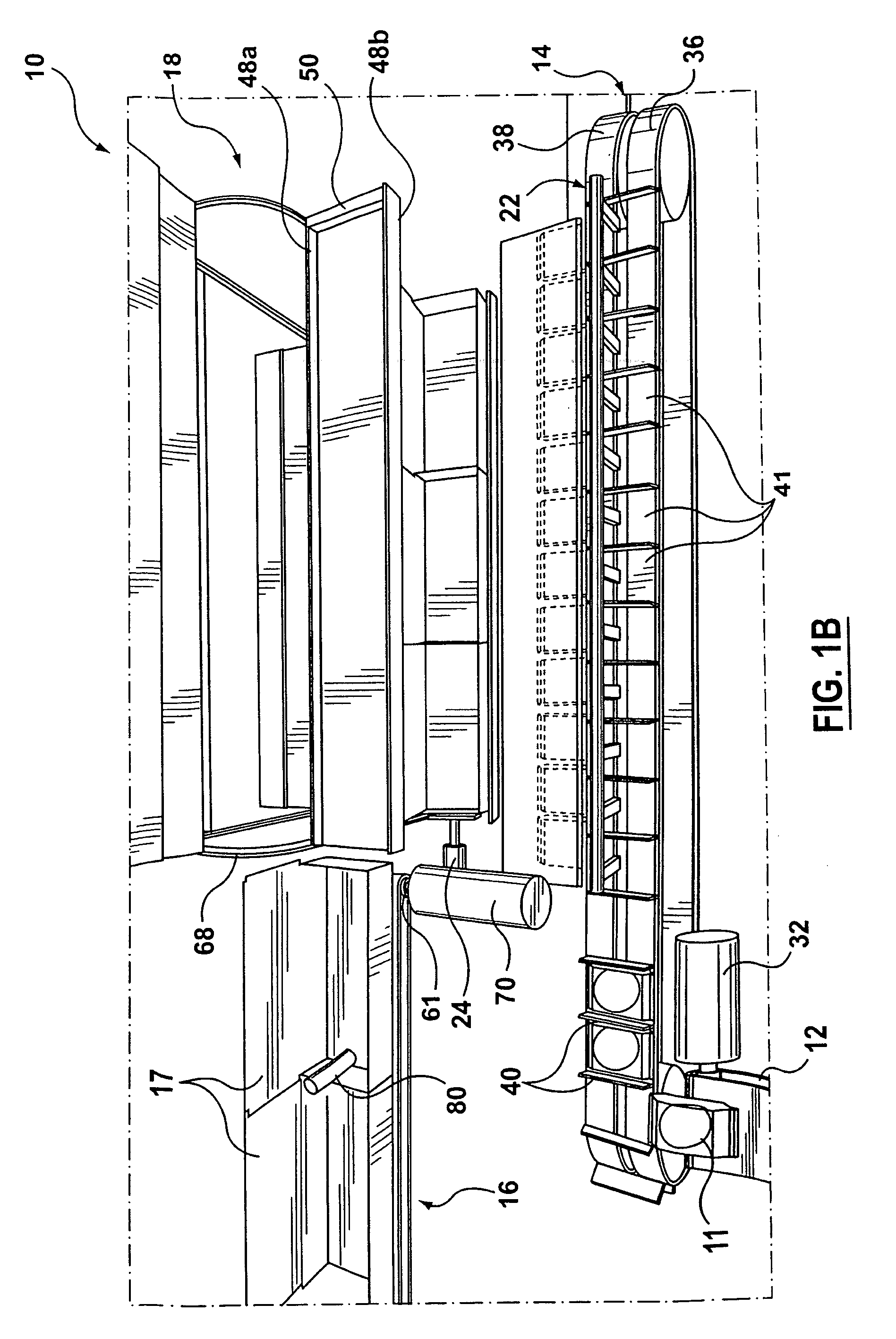

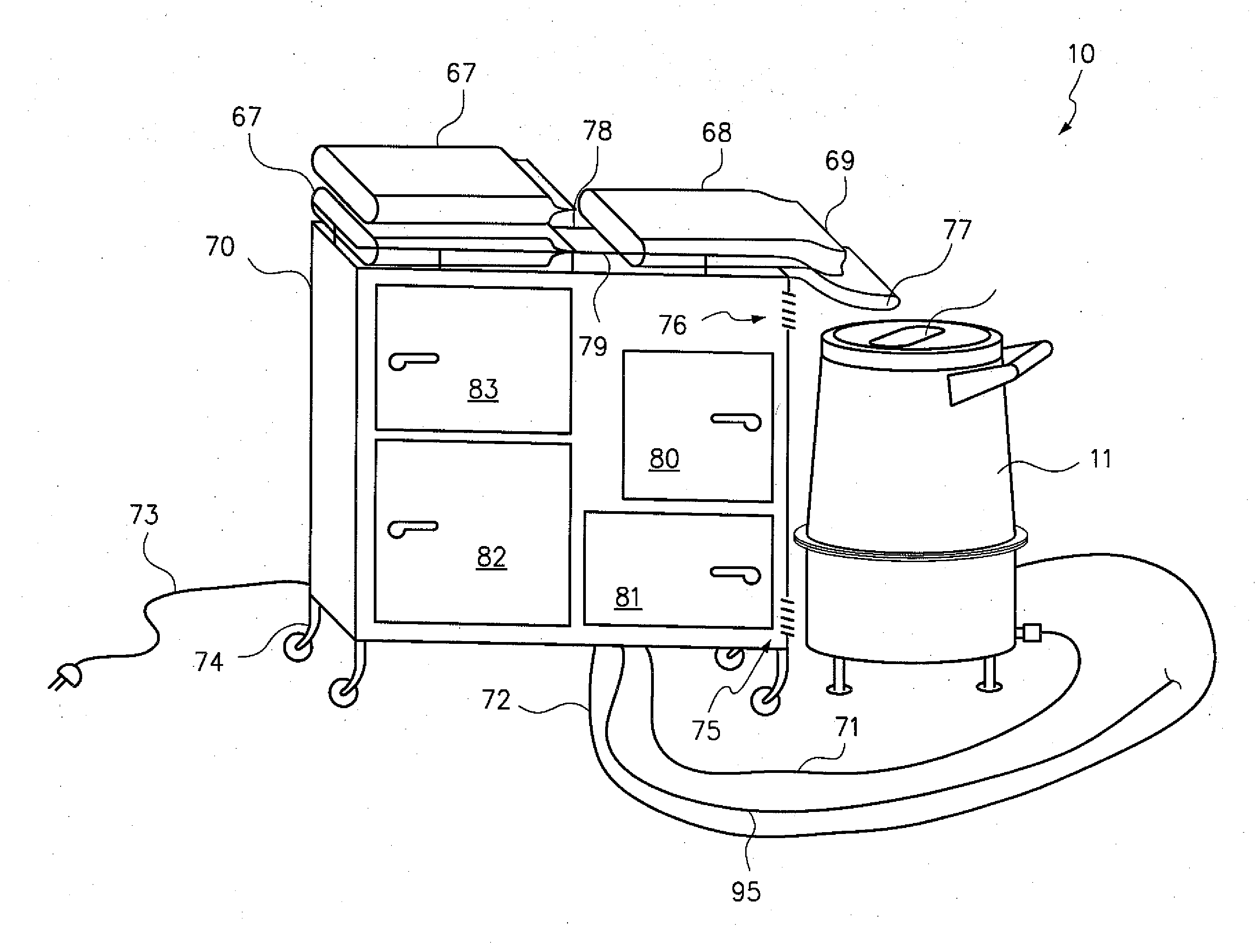

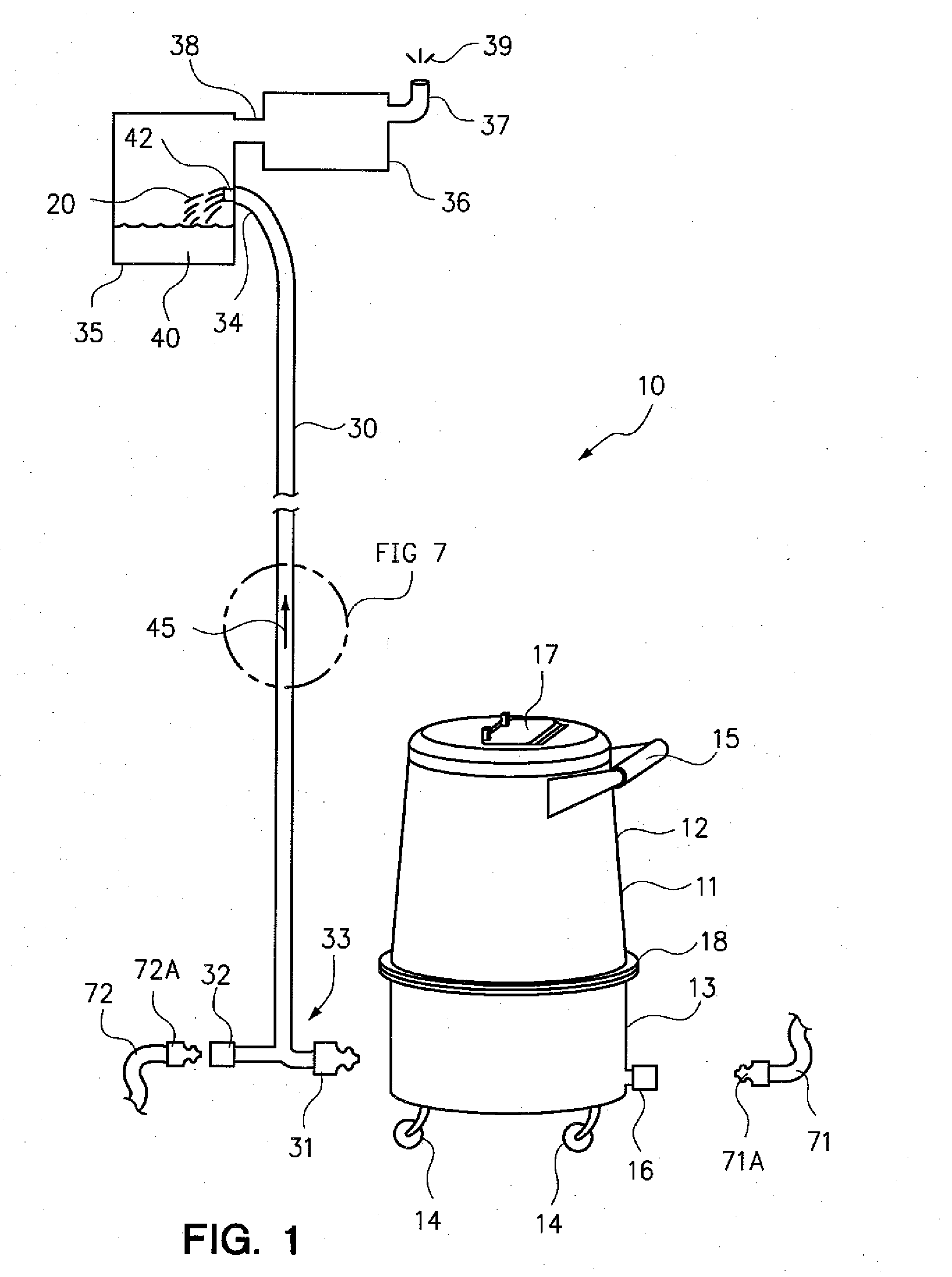

Dispensing system and method of controlling the system

InactiveUS20110240170A1Minimal foamingMinimal fobbingLiquid fillingLiquid flow controllersControl systemWaste management

Owner:MANITOWOC BEVERAGE SYST

Method for the preparation of samples

Owner:METTLER TOLEDO GMBH

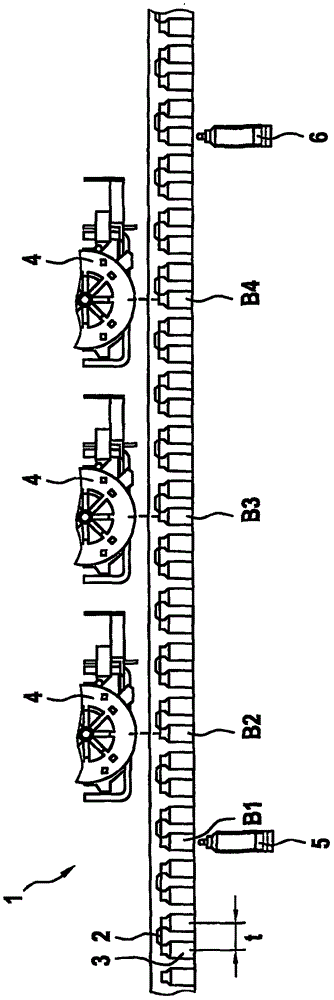

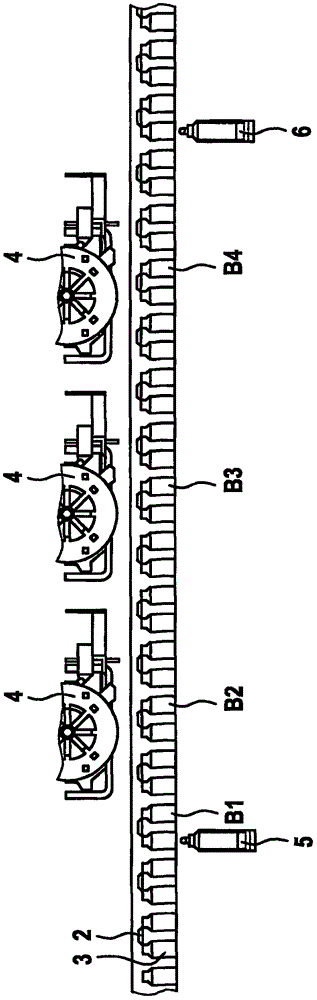

Tray loader

Owner:LANGEN PACKAGING

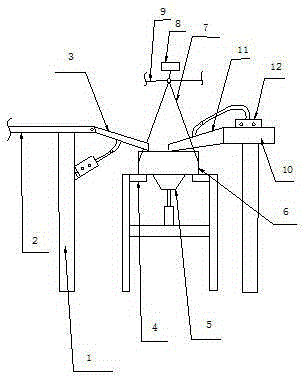

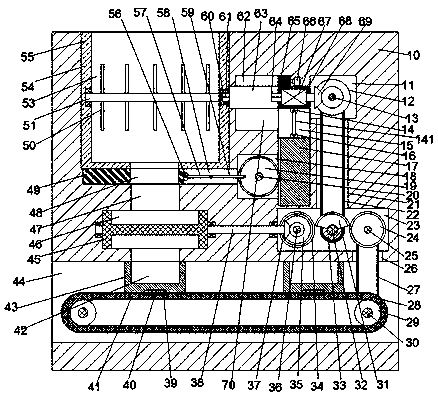

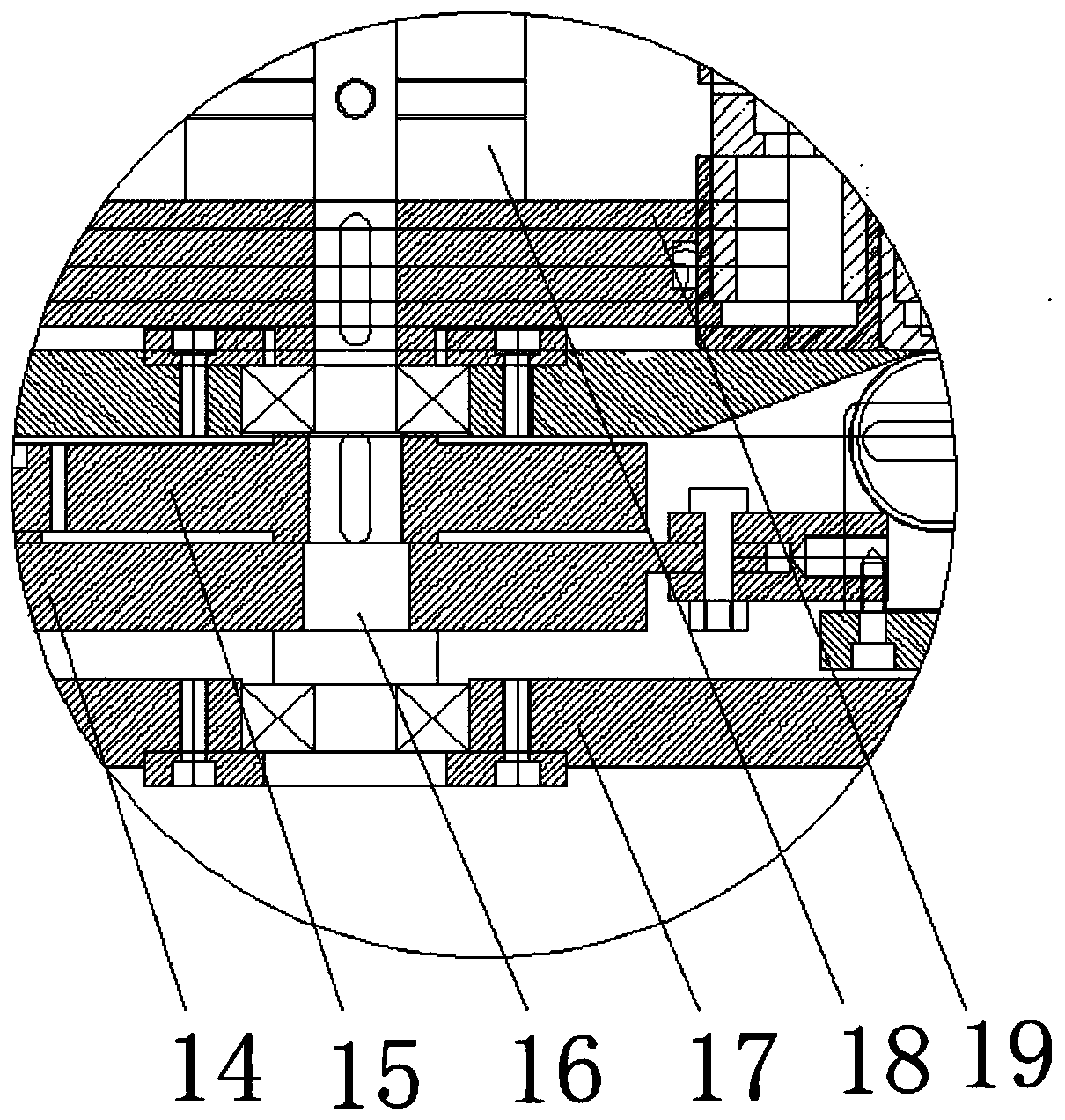

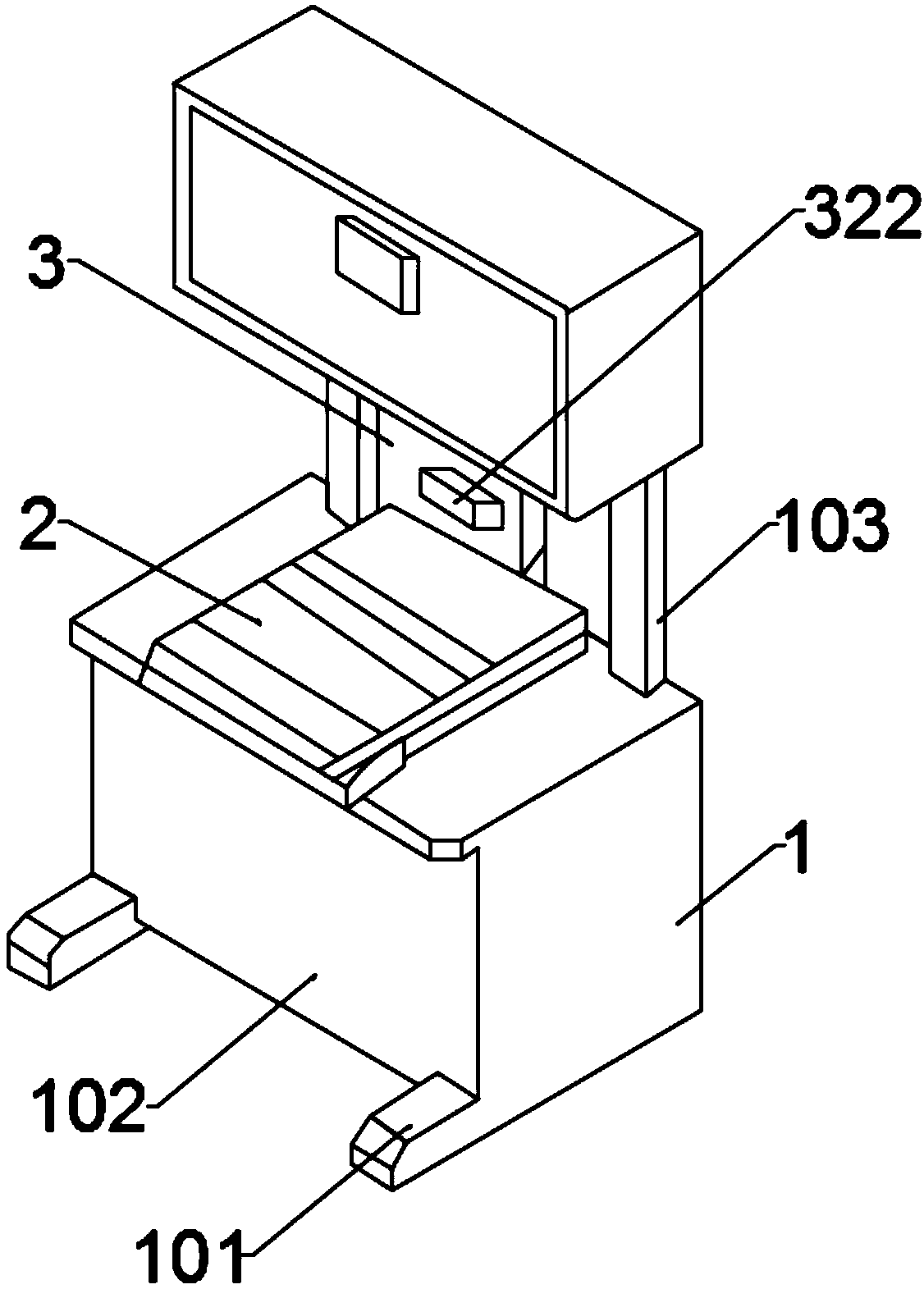

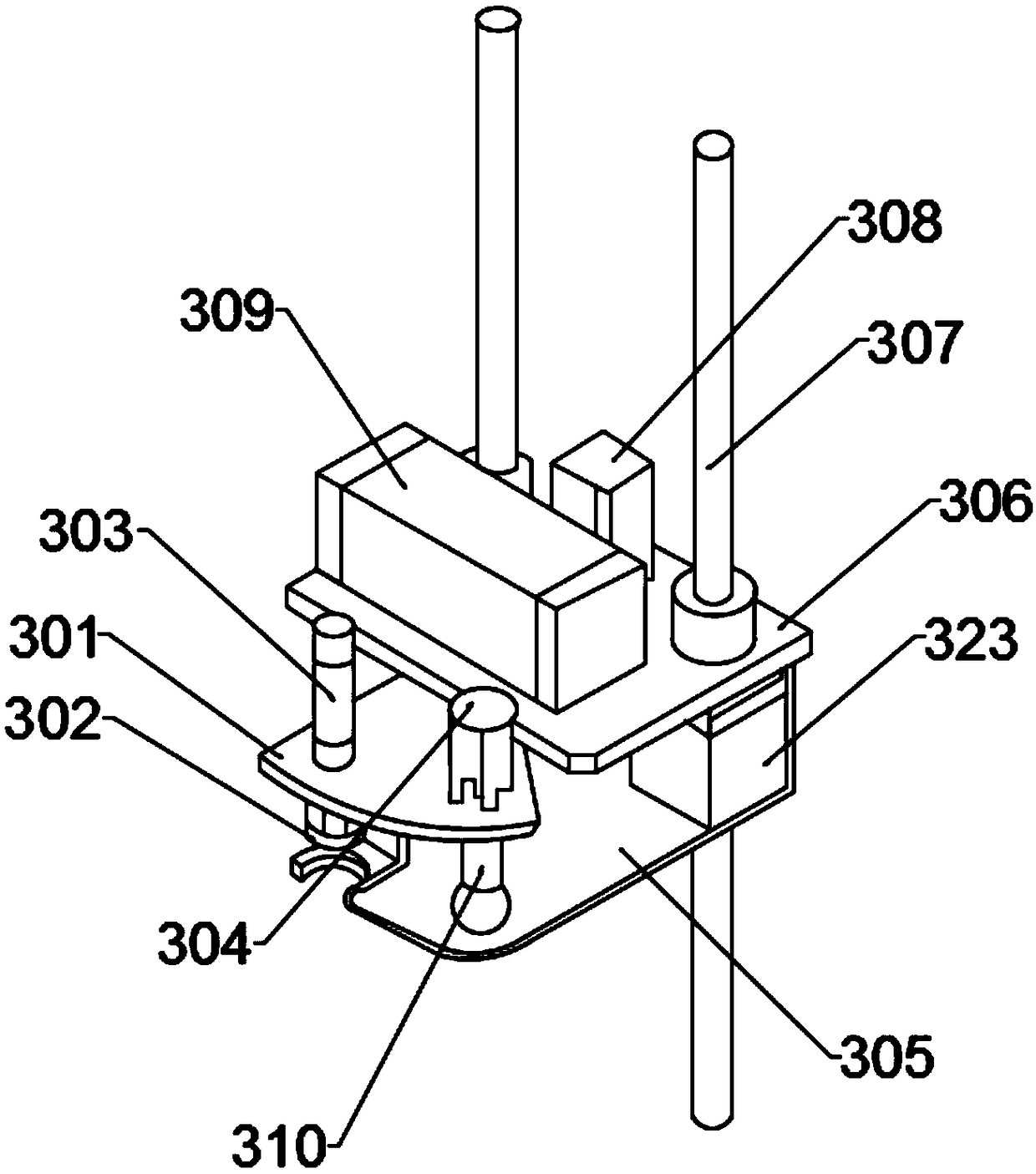

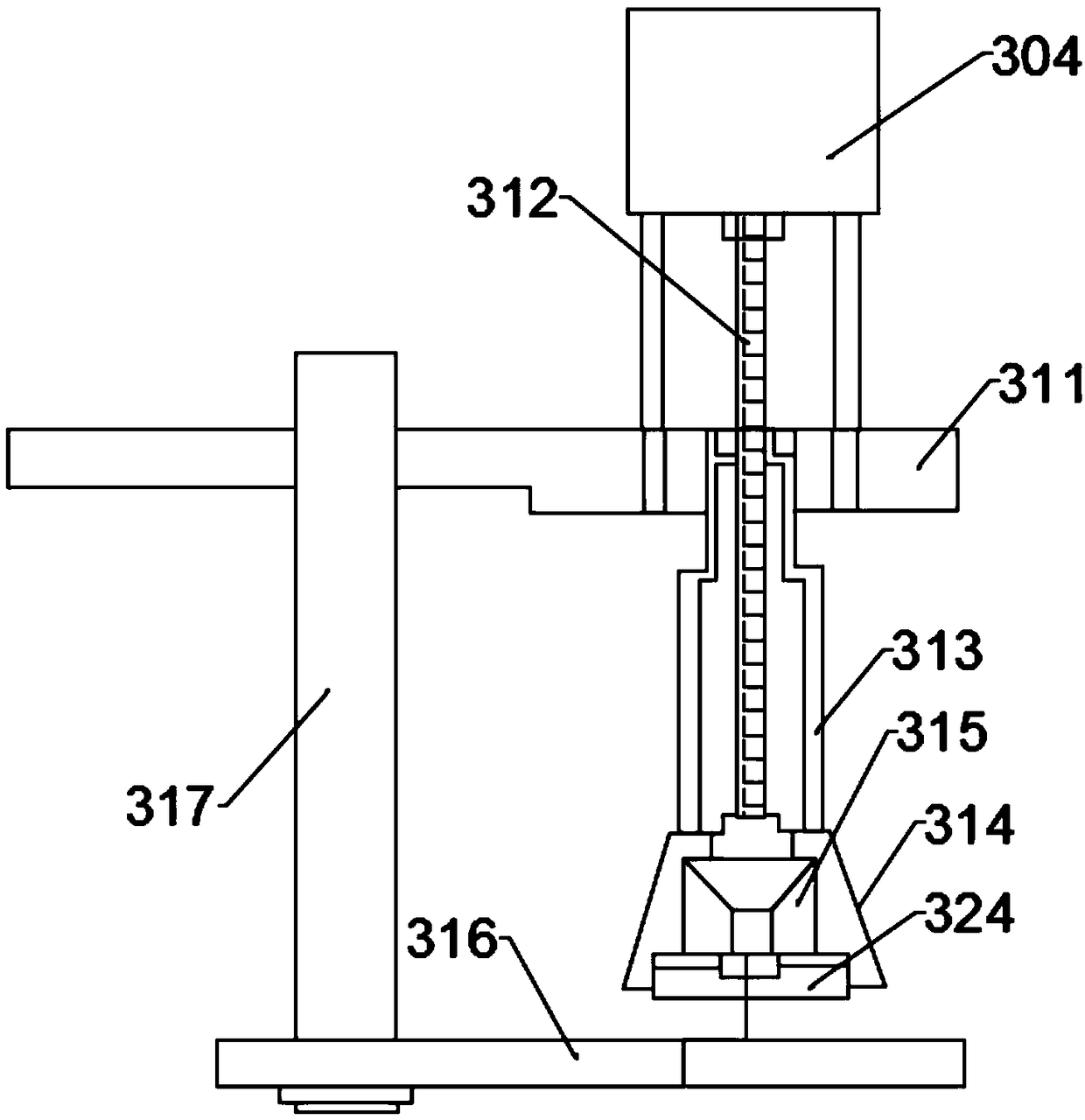

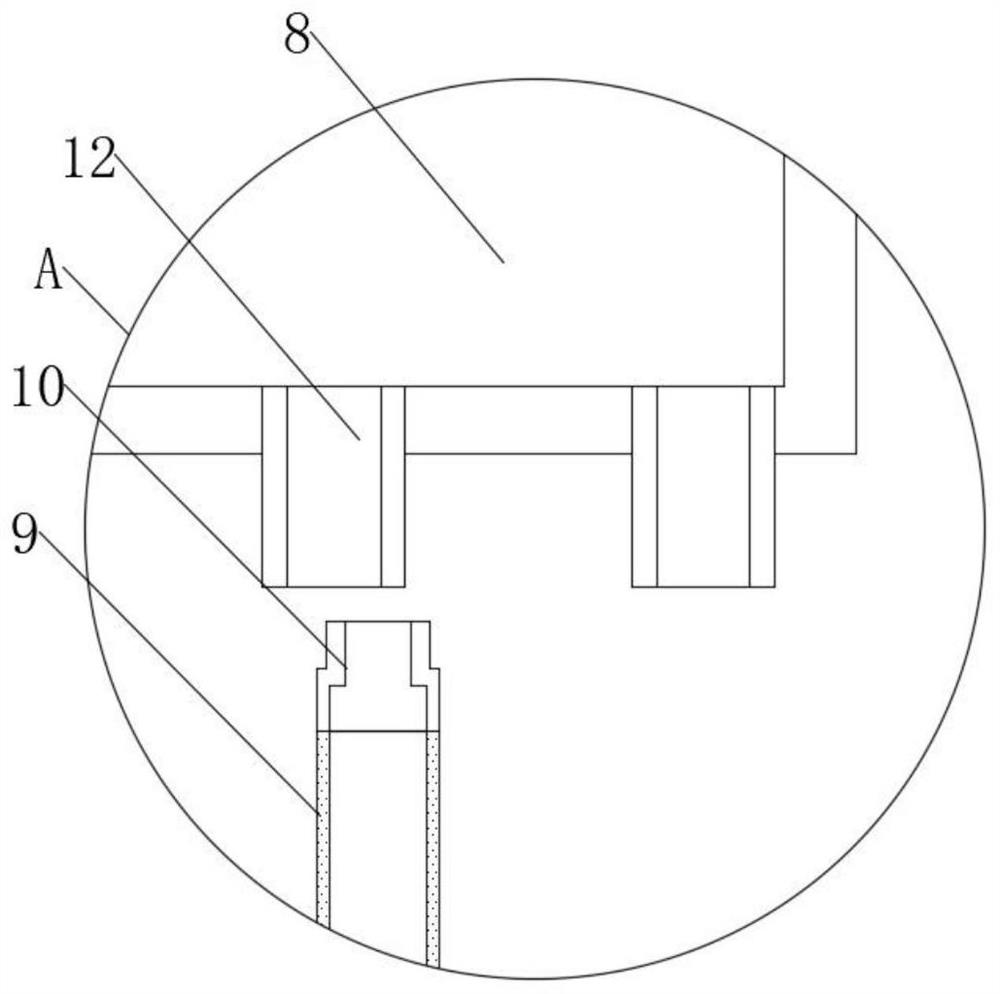

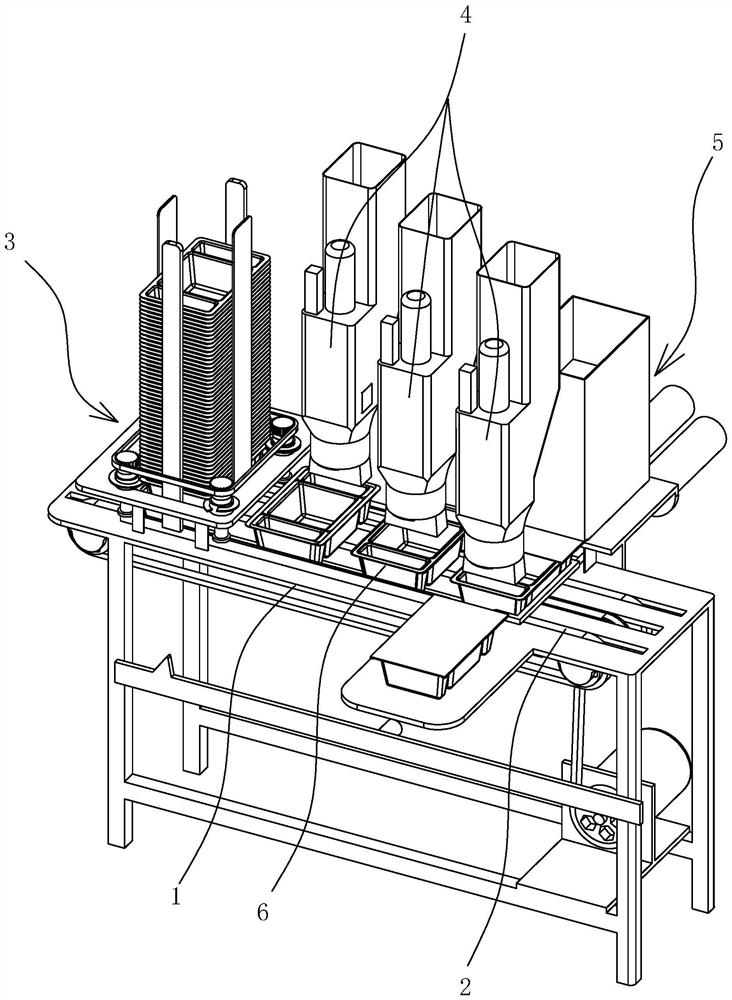

Traditional Chinese medicine tablet filling device

ActiveCN112960201AGuaranteed storage securityGuaranteed sealing performanceCapsThreaded caps applicationSolenoid valveEngineering

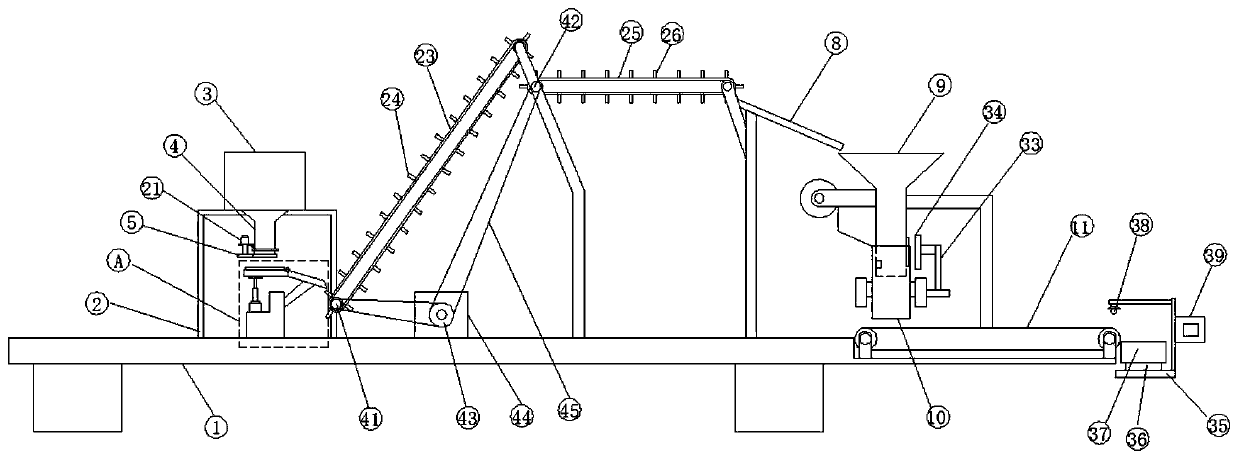

The invention relates to the technical field of traditional Chinese medicine processing, in particular to a traditional Chinese medicine tablet filling device which comprises an X-axis conveying mechanism, a filling mechanism, medicine bottles and bottle caps, wherein the filling mechanism and a Z-axis conveying mechanism are installed above the X-axis conveying mechanism; the filling mechanism comprises a first supporting frame, and a tablet tank is fixed to the top end of the first supporting frame; a solenoid valve is fixed to the bottom end of the tablet tank, and the Z-axis conveying mechanism comprises a second supporting box; a second conveyor belt is movably connected to the interior of the second supporting box, and the bottle caps are evenly distributed on the second supporting box; an X-axis driving mechanism is arranged behind the right side of the Z-axis conveying mechanism, and comprises a second supporting frame; and an X-axis sliding table is fixed to the top end of the second supporting frame, and the front end of the X-axis sliding table is slidably connected with a Y-axis driving mechanism. According to the filling device, a screw cap and sealing detection integrated structure is adopted, therefore the sealing detection can be carried out while the caps are sealed, and the storage safety of tablets is ensured.

Owner:YANTAI KANGGUTANG MEDICAL TECH CO LTD

Packaged food packaging equipment

Owner:JIANGSU LEATER GREEN PACKAGING CORP LTD

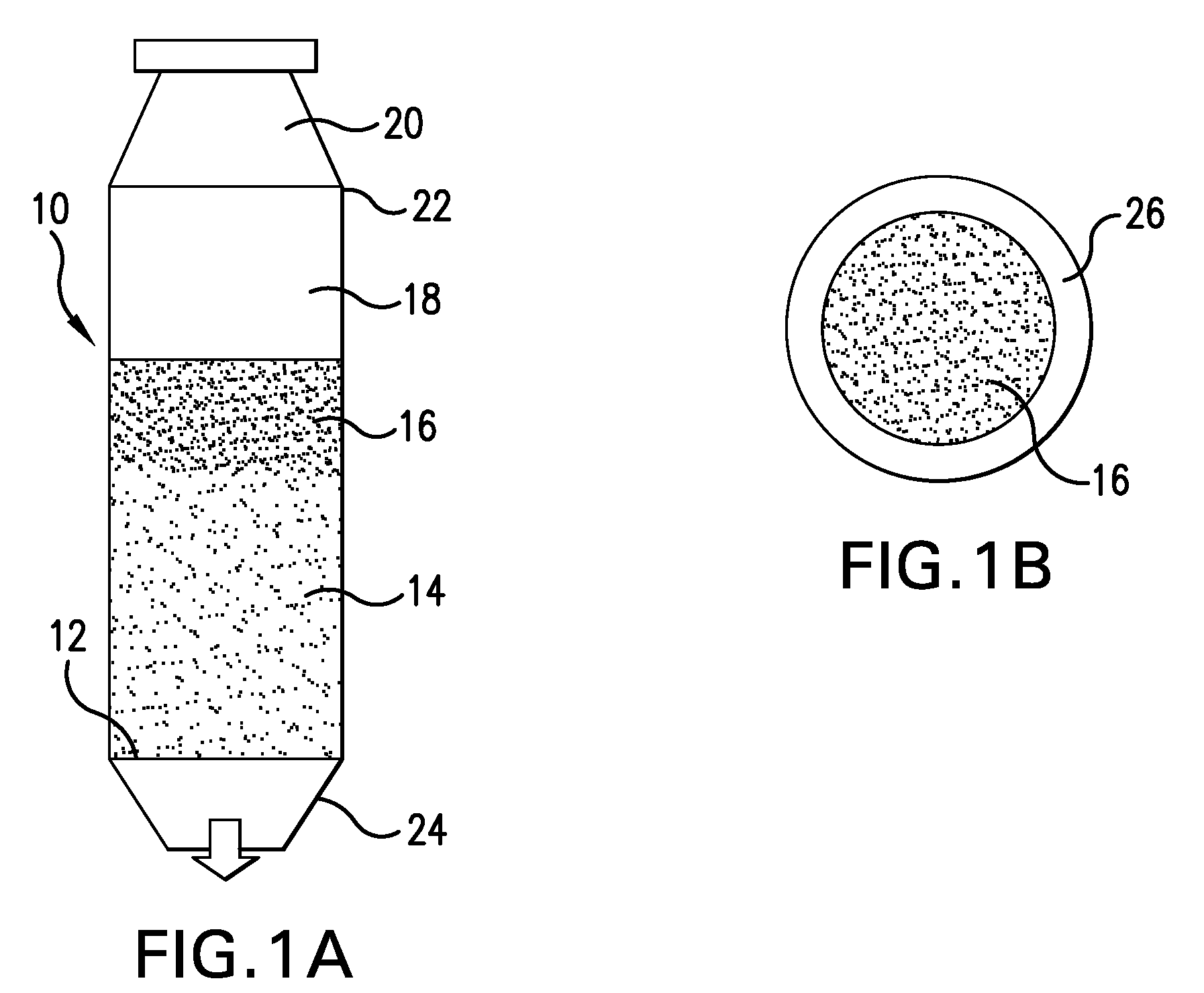

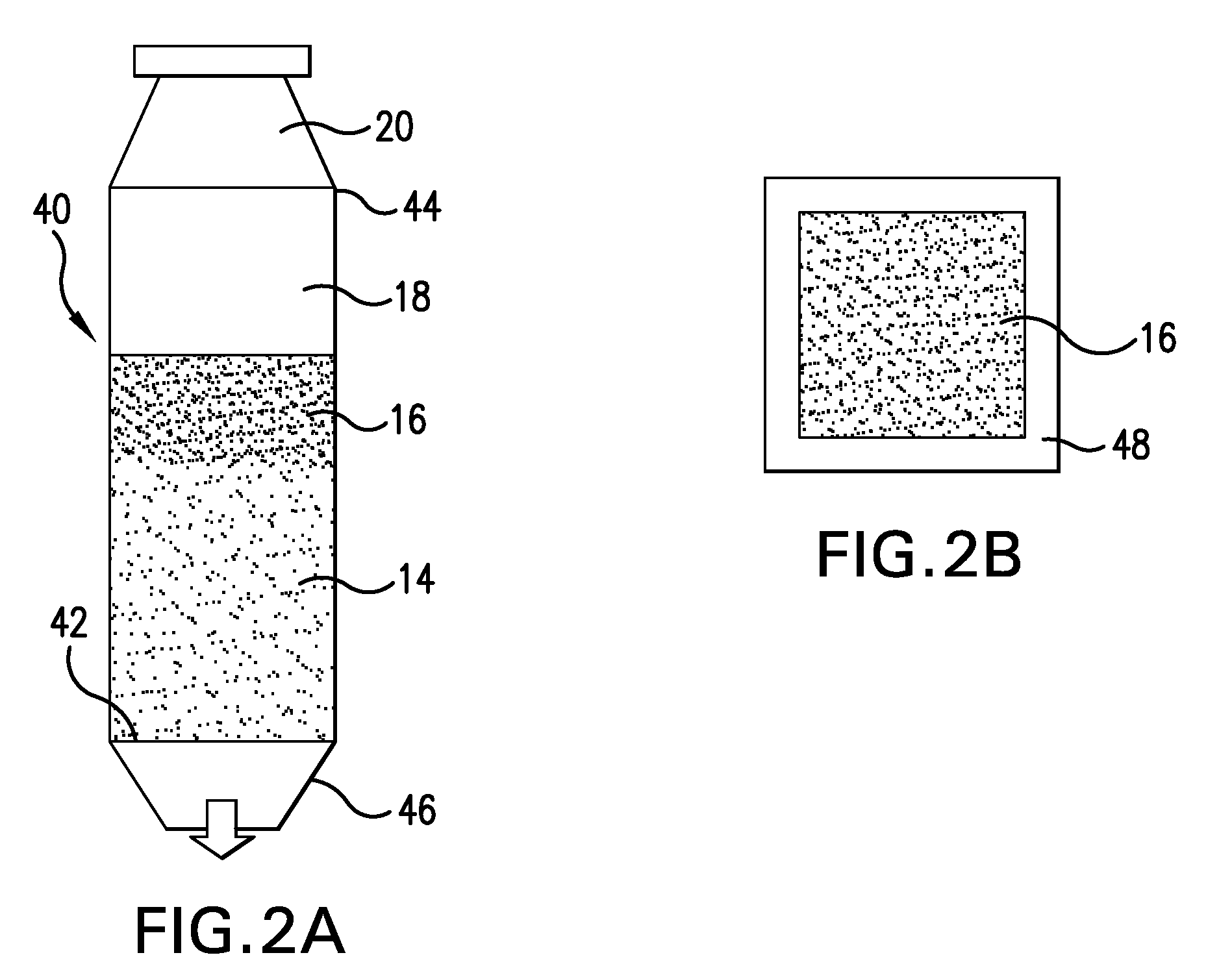

Mixing and packing of particles

InactiveUS20090272078A1Well mixedLower the volumeShaking/oscillating/vibrating mixersPackaging by pressurising/gasifyingParticulatesVolumetric Mass Density

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY +1

Dying device

InactiveCN109279053ASimple structureHigh degree of automationRotary stirring mixersMixer accessoriesPower modeGear wheel

Owner:岑浩明

Method for filling receptacles

Owner:SYNTEGON TECHNOLOGY GMBH

Closure for pouches

Owner:BAYER CONSUMER CARE

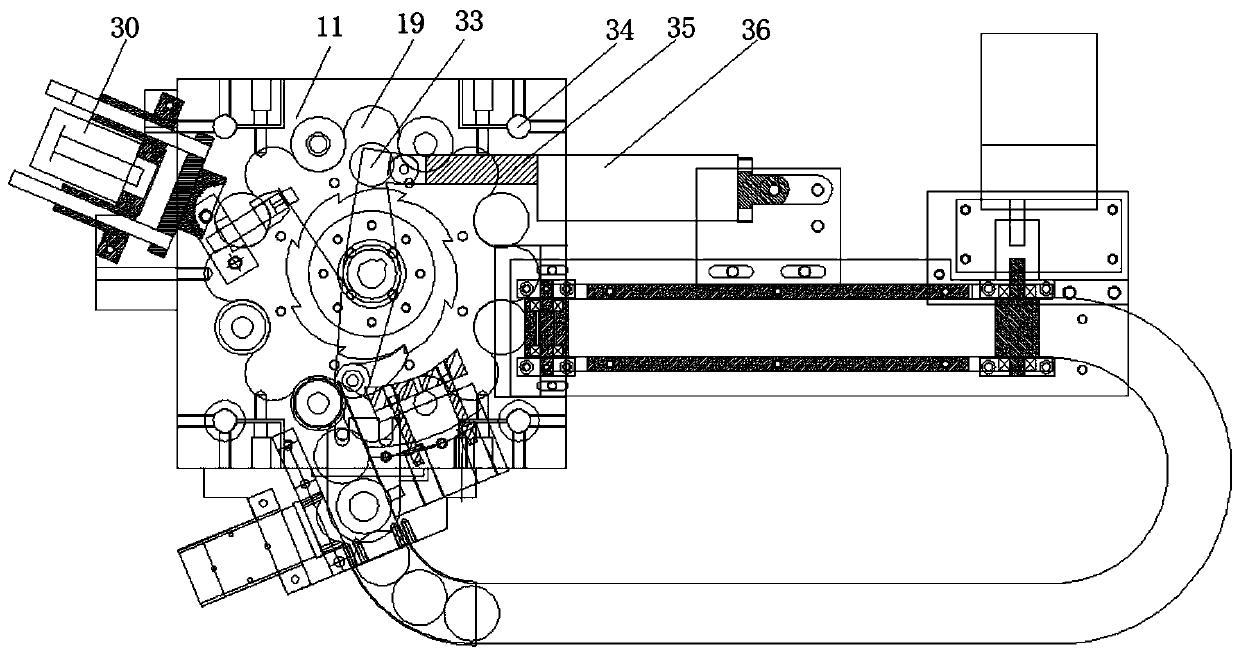

Carbon bag filling machine for lithium battery

ActiveCN110406703ACompact structureEasy to operatePrimary cell manufactureAssembling battery machinesElectrical batteryPulp and paper industry

Owner:双洎能源(洛阳)有限公司

Medicine supply apparatus

There is disclosed a medicine supply apparatus that can effectively solve medicine lodgment or blocking within a nozzle that discharges a medicine into packing paper. The medicine supply apparatus includes a nozzle for discharging a medicine discharged from a tablet case and a shutter rotatably provided in the nozzle for opening / closing a medicine drop path in the nozzle. The shutter includes a first shutter plate that has a size capable of closing the inside of the nozzle and is rotated, a second shutter plate swingably connected to the tip of the first shutter plate, and a guide for swinging the second shutter plate in a direction opposite to a direction of rotation of the first shutter plate in a final stage where the first shutter plate is opened. The tip of the second shutter plate is located in a position to narrow an outlet of the medicine drop path when the first shutter plate is opened.

Owner:PHC HLDG CORP

Tea leaf storage device

Owner:谢长溪

Wet food canning device for pet cat food production

Owner:滨州殿歌生物科技有限公司

Efficient organic fertilizer homogenizing device and homogenizing method thereof

PendingCN114749084AAvoid secondary agglomerationPromote homogenizationRotary stirring mixersSolid materialAgricultural scienceAgricultural engineering

Owner:翁立义

Food seasoning replenishment system and apparatus

Owner:HEAT & CONTROL

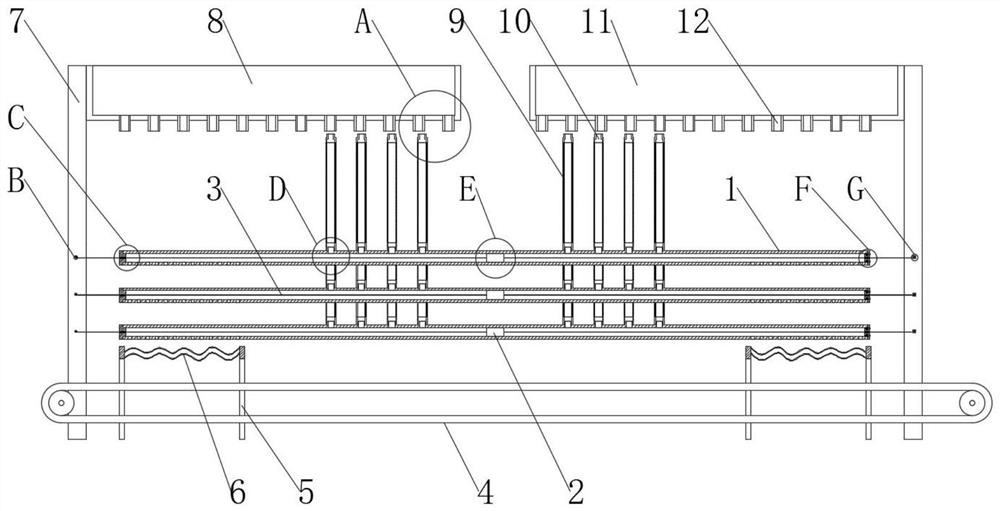

Filling mechanism of tea filling machine

InactiveCN109178374ASolve the problem of lax valve closingSolve the problem of pinched tea leavesSolid materialForeign matterSurface type

Owner:芜湖市春满壶茶业有限公司

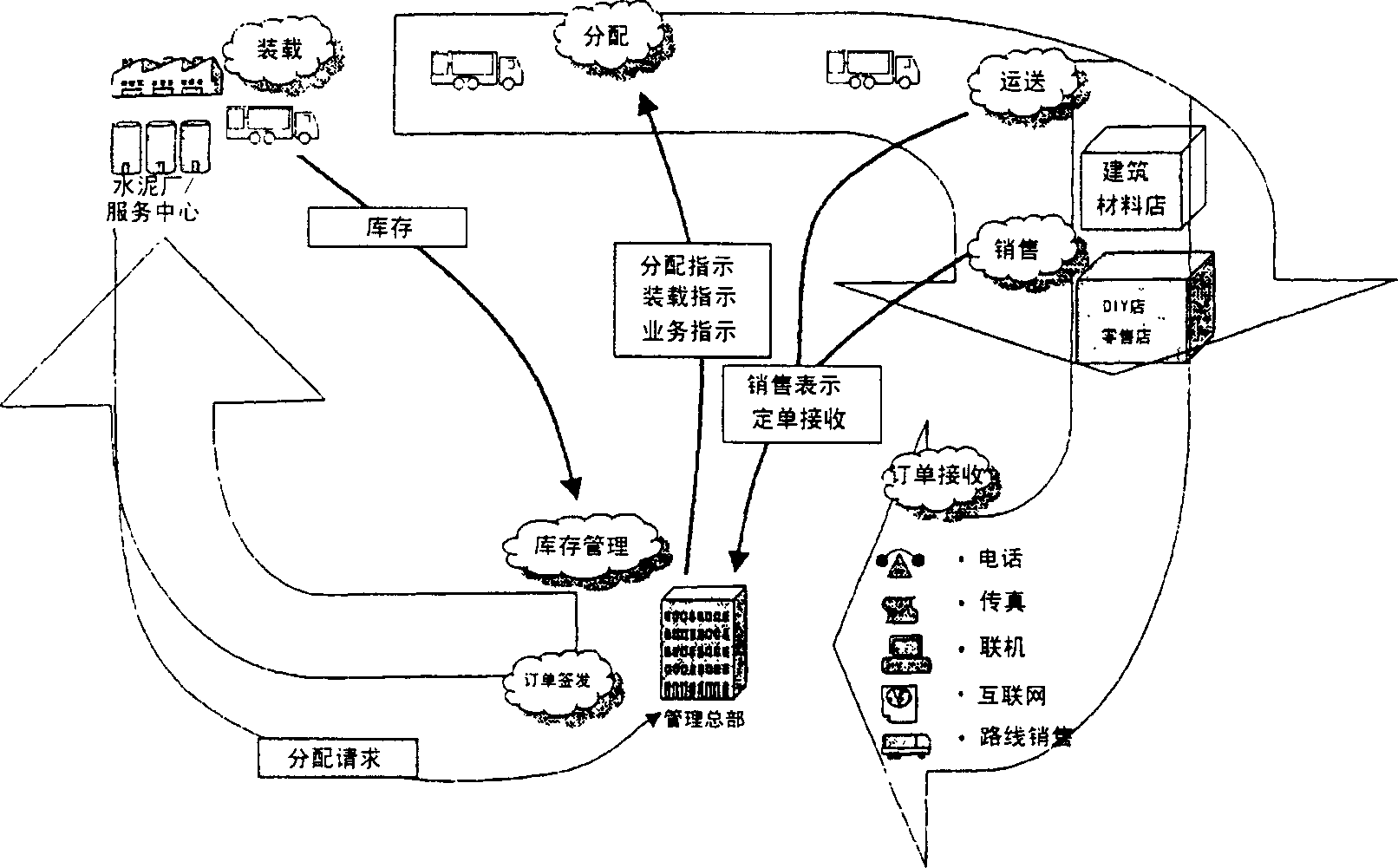

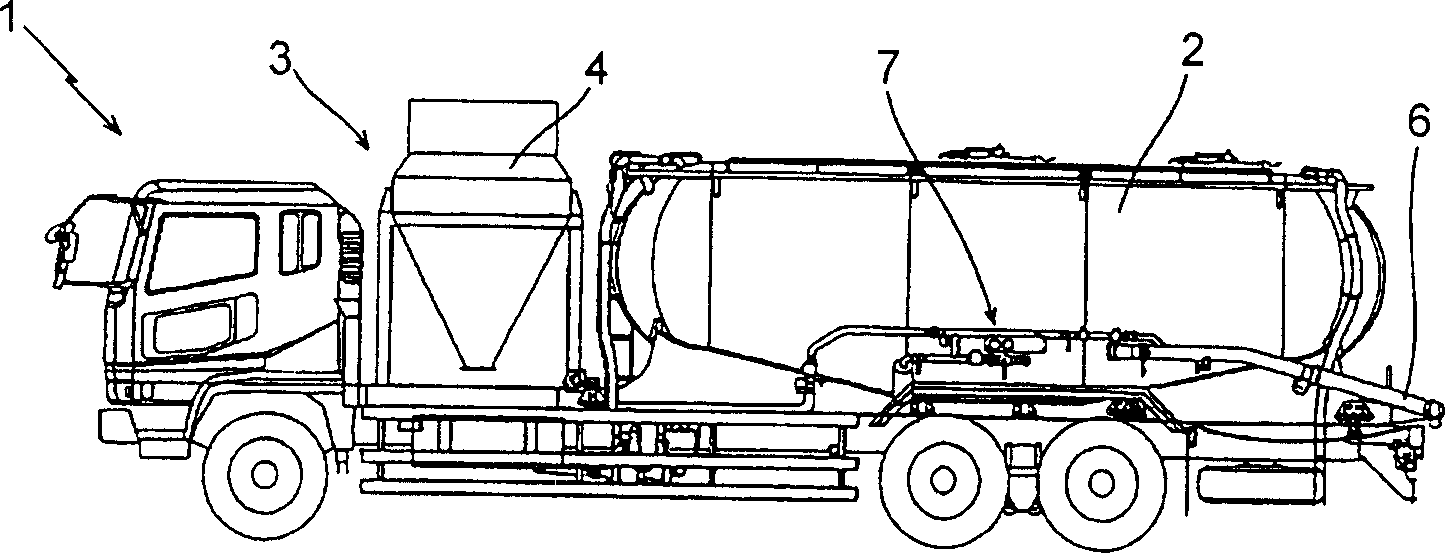

Cement distributing system

Owner:MITOMO

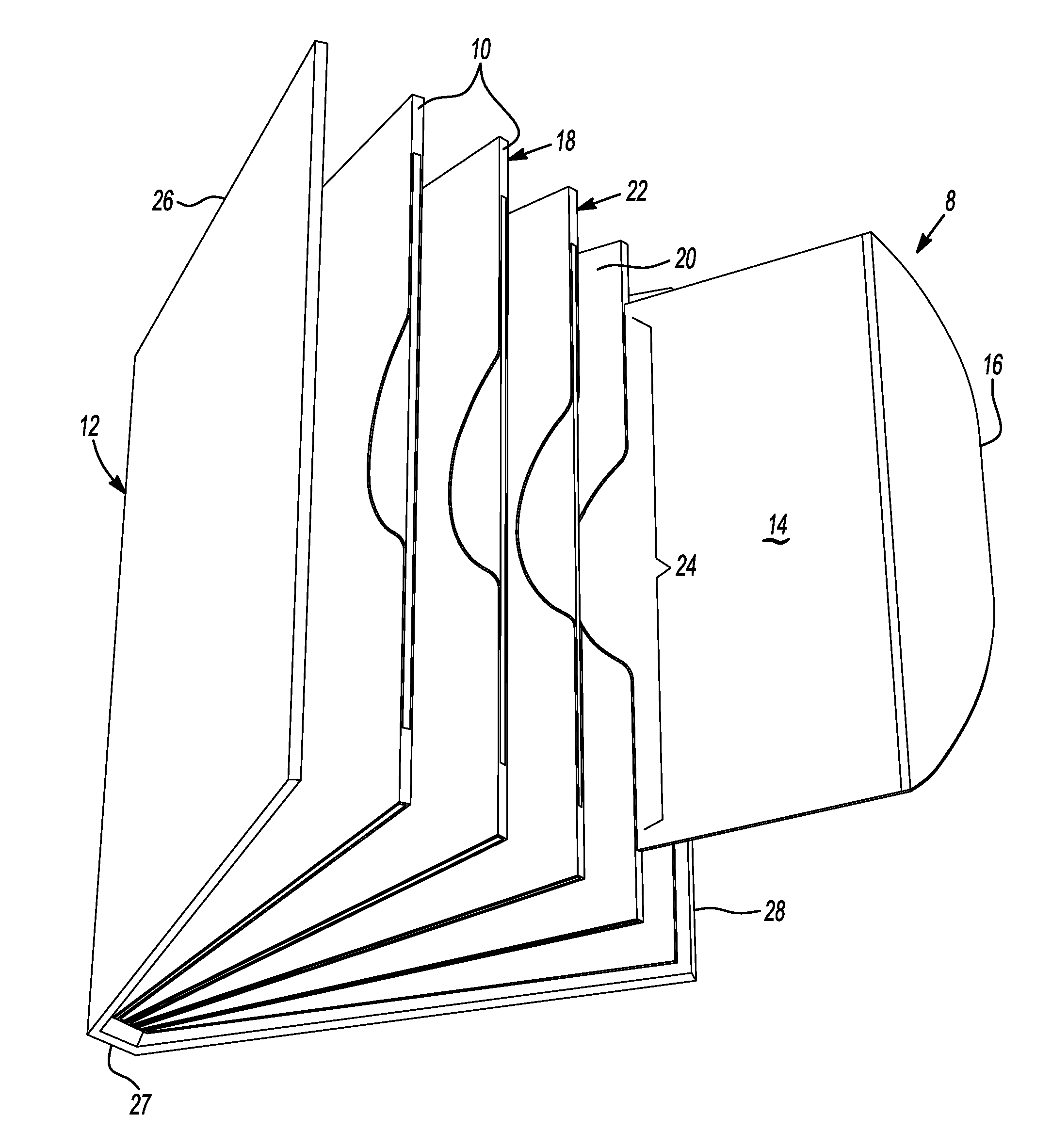

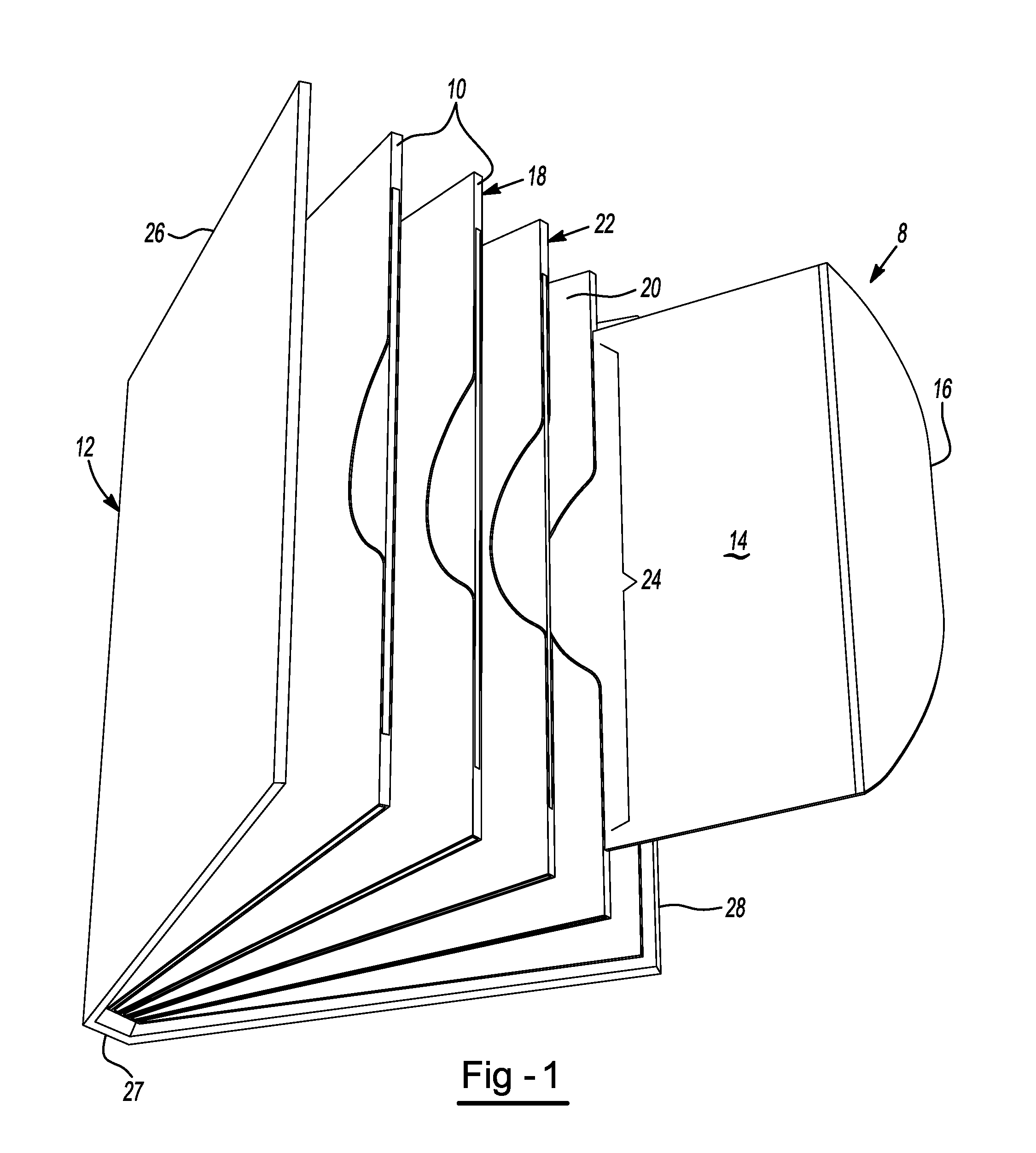

Storage and packaging device

InactiveUS20120062090A1Prevent removalMinimal damageRecord information storageFiling appliancesPaperboardBiomedical engineering

Owner:MULTI PACKAGING SOLUTIONS

Device for unloading and bagging grinding body of ball mill

Owner:仁寿县汪洋建宝水泥有限公司

Packaging production line

Owner:梁梅芹

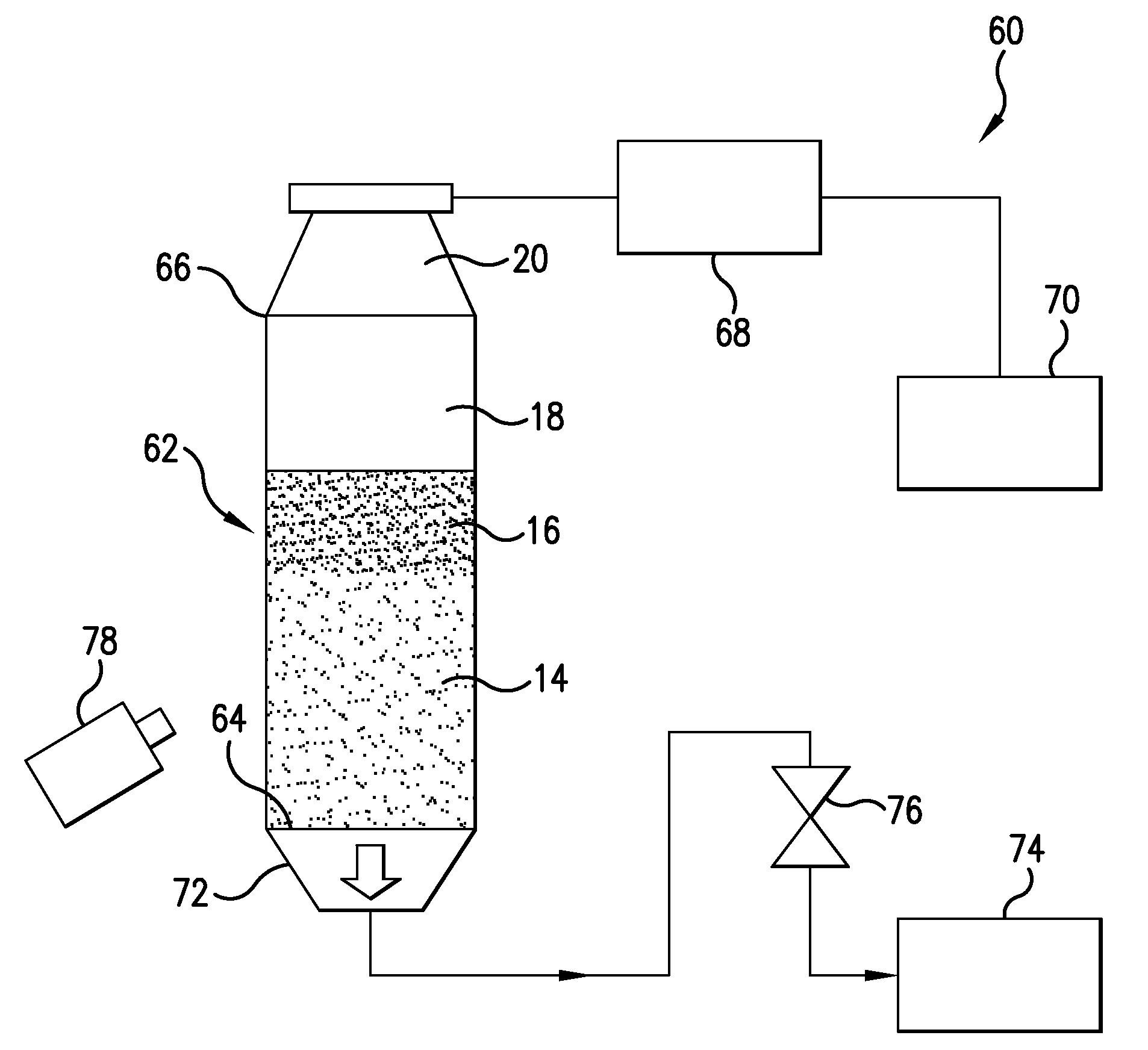

Cyclone type automatic adsorbent filling device

Owner:山西皆利气体科技有限公司

Granular powder metering and packaging machine

Owner:JINGMI MACHINERY SHANGHAI

Anti-collision electronic scale device in metering filling machine

InactiveCN111619888AEasy to disassembleEasy to installSolid materialLiquid bottlingElastic componentControl engineering

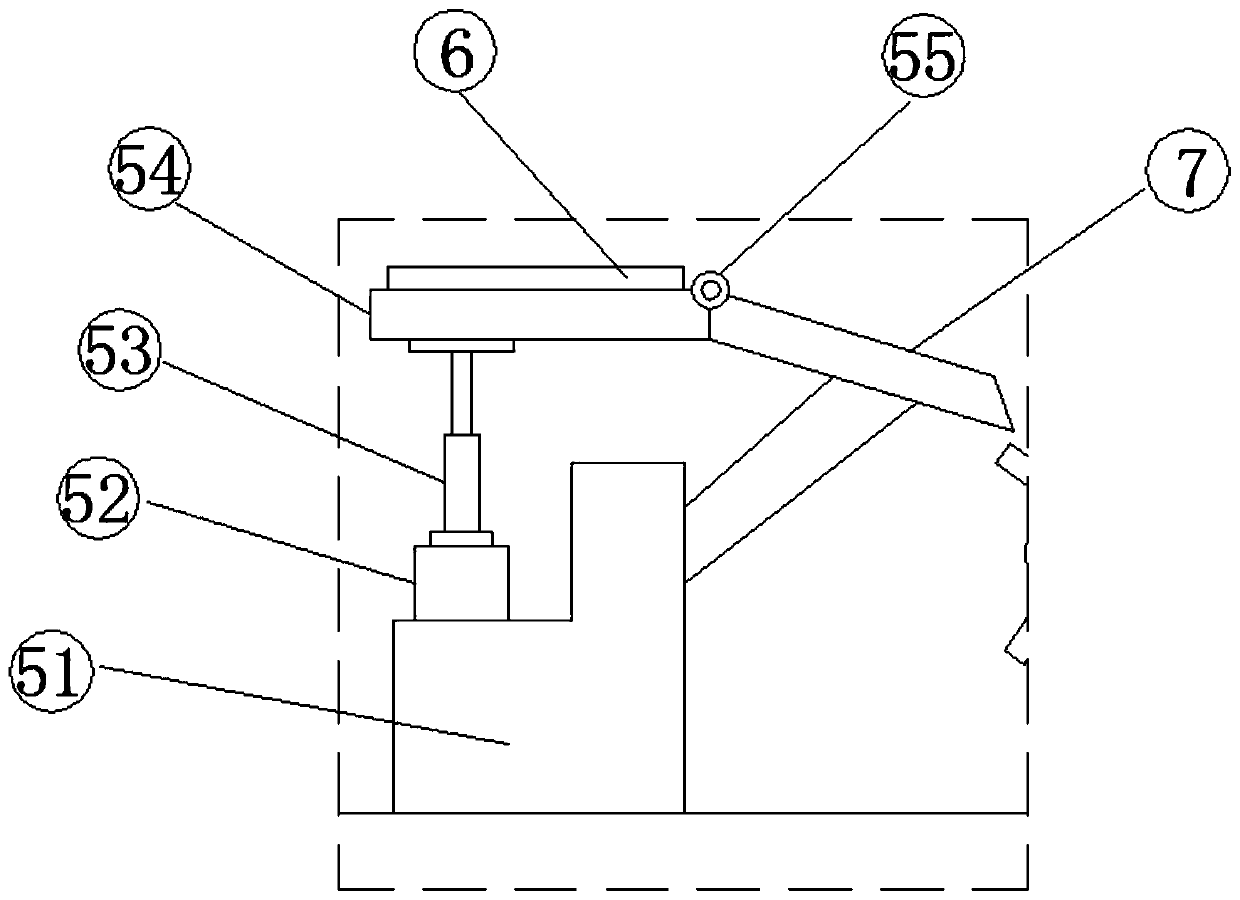

The invention discloses an anti-collision electronic scale device in a metering filling machine. The device comprises a weighing platform which is provided with an installation rack, the installationrack is sequentially provided with a bottle body protection plate and a bottle clamp from the bottom to the top, and the installation rack comprises an upper installation rack and a lower installationrack; the lower installation rack comprises a first lower guide column and a second lower guide column, and the upper installation rack comprises a first upper guide column and a second upper guide column; and the lower ends of the first upper guide column and the second upper guide column are hinged to the upper ends of the first lower guide column and the second lower guide column respectively,an elastic component is arranged between the upper installation rack and the weighing platform, and the first upper guide column and the second upper guide column are in an upright state and abut against a limiting mechanism under the action of elastic force of the elastic component. When the upper installation rack rotates towards the rear of the weighing platform under the action of external force until the acting force of the elastic component is located below the hinged position, an upper supporting frame completely topples towards the rear of the weighing platform. The device has the advantages that the device is elastically connected, and damage caused by impact is avoided.

Owner:JIANGSU NEWAMSTAR PACKAGING MACHINERY

Expandable Pocket

InactiveUS20120067010A1Variable thicknessEnvelopesFiling appliancesProtection systemMechanical engineering

Owner:ENGLAND ANTHONY

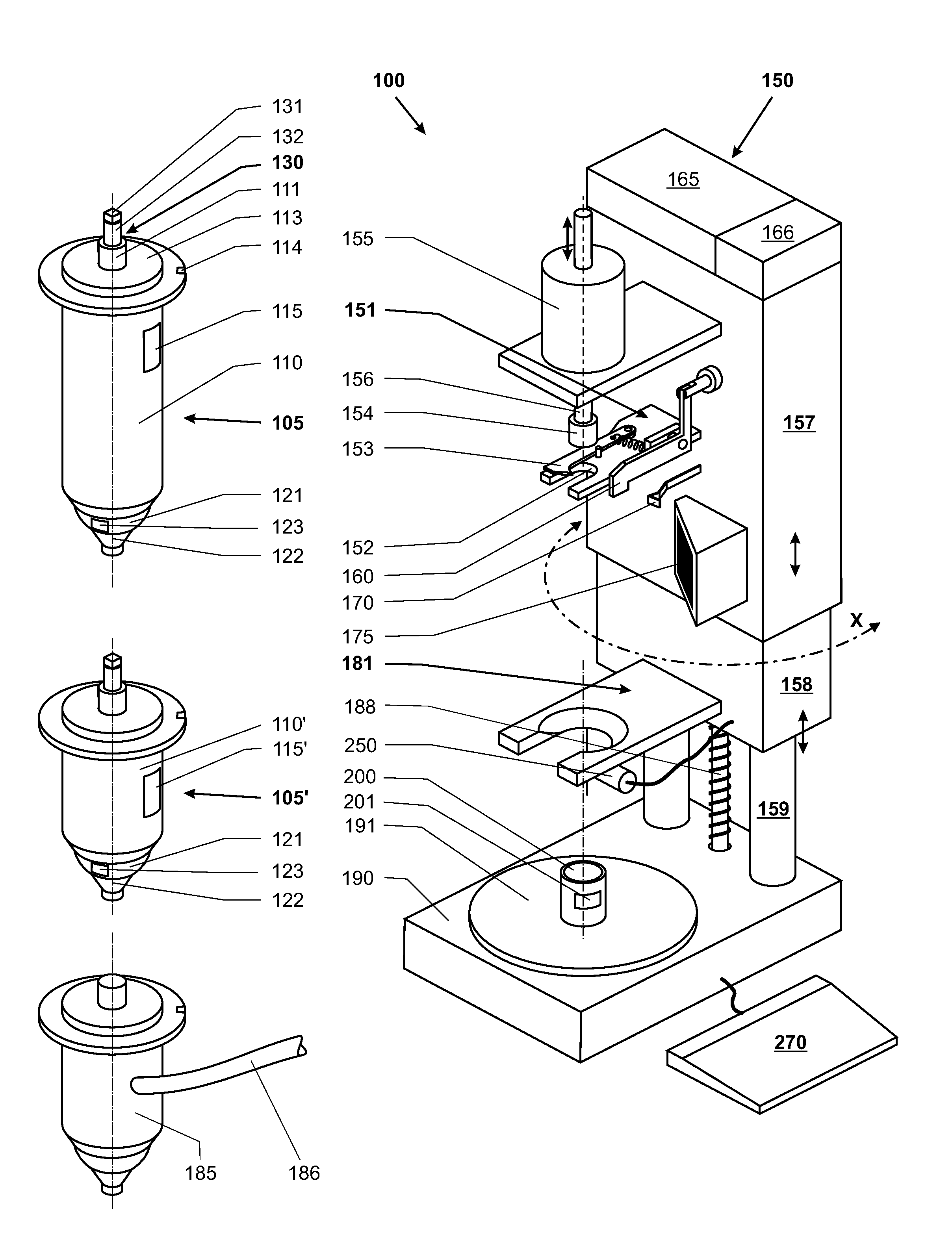

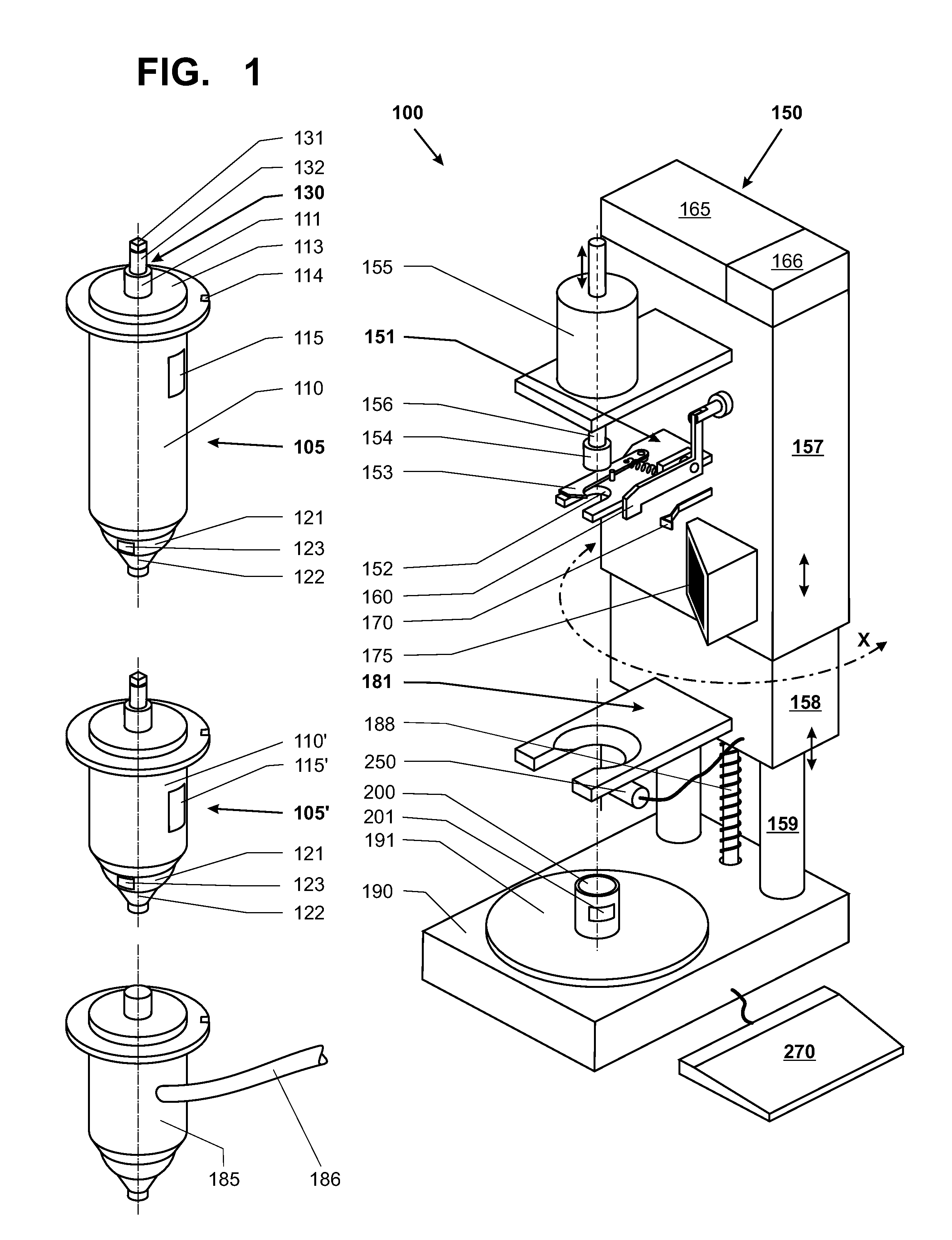

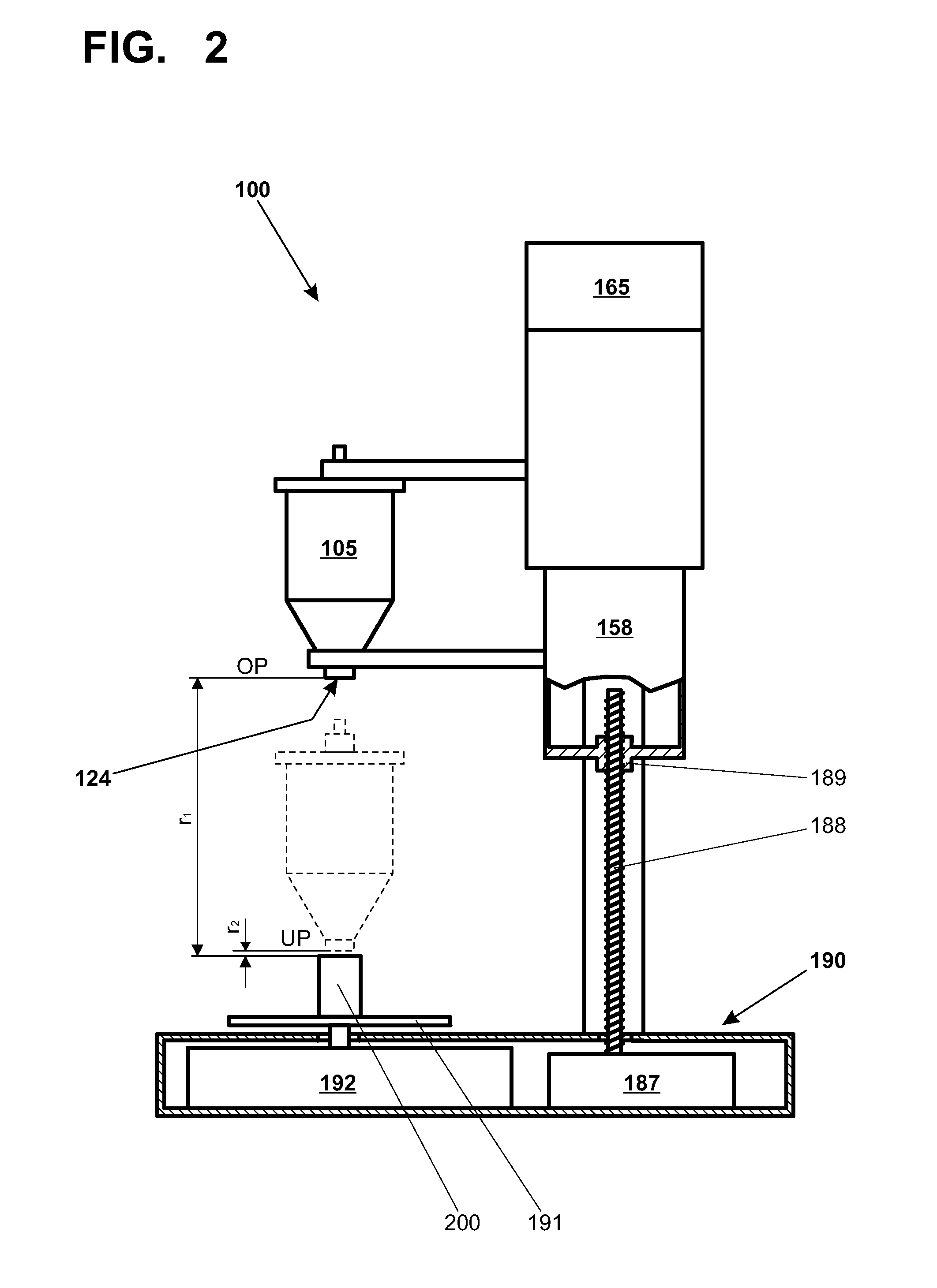

Device, system and method for filling packages with solid food product

ActiveCN111169677AStandardization of volume measurementsEasy to handleSolid materialPackaging foodstuffsEngineeringSolid food

Owner:TETRA LAVAL HLDG & FINANCE SA

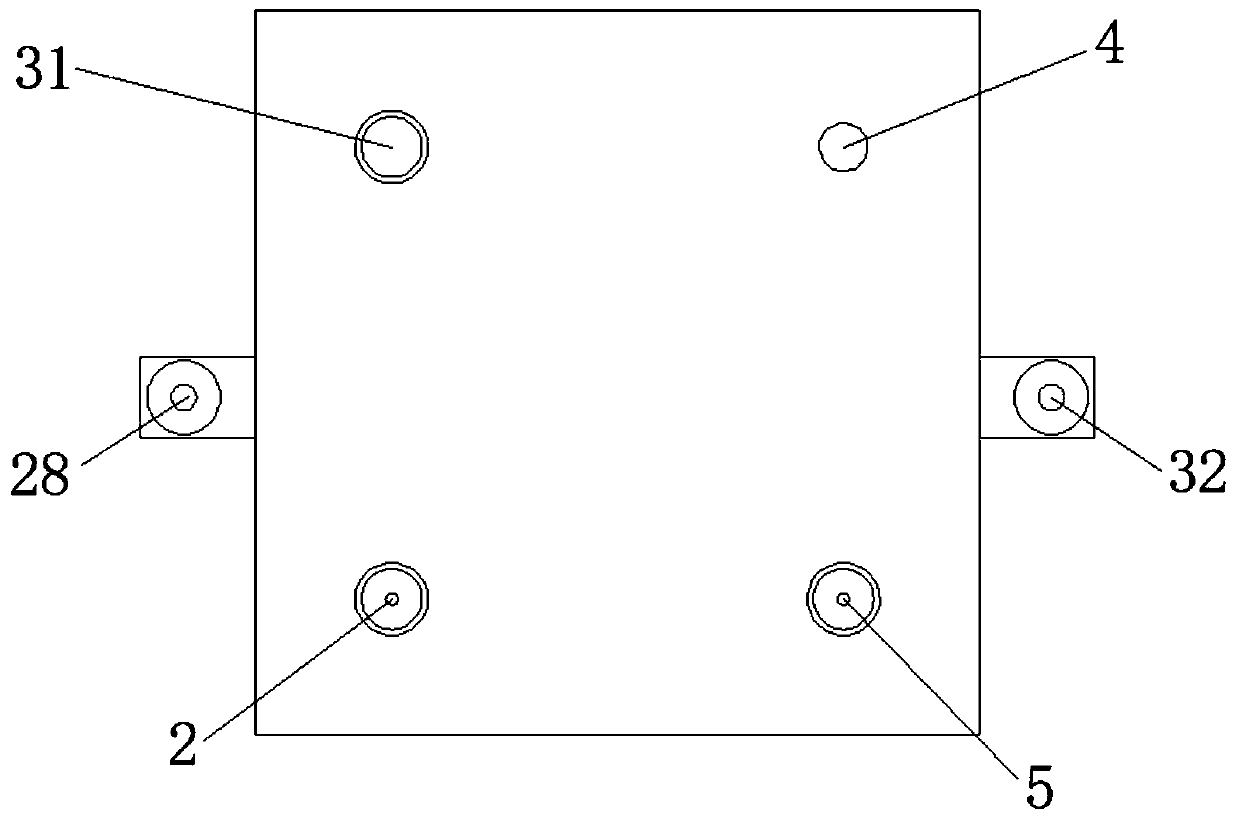

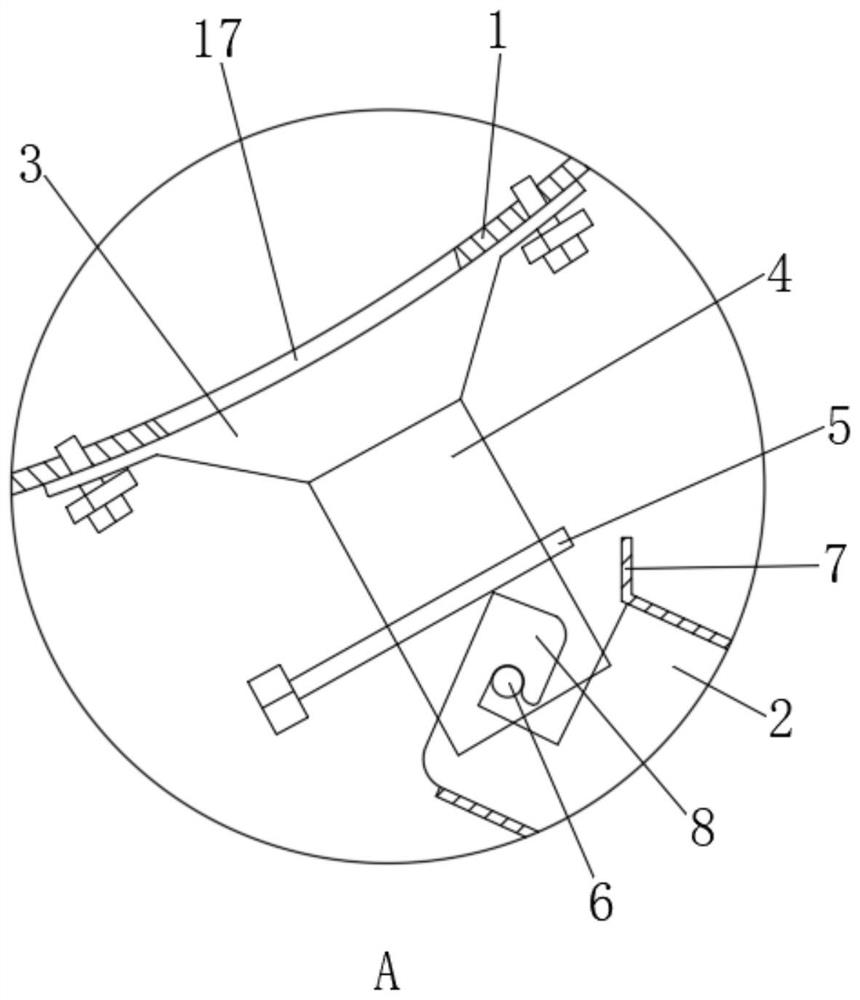

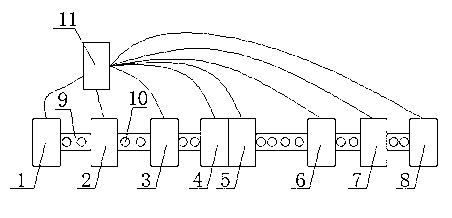

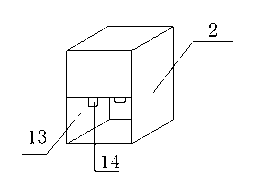

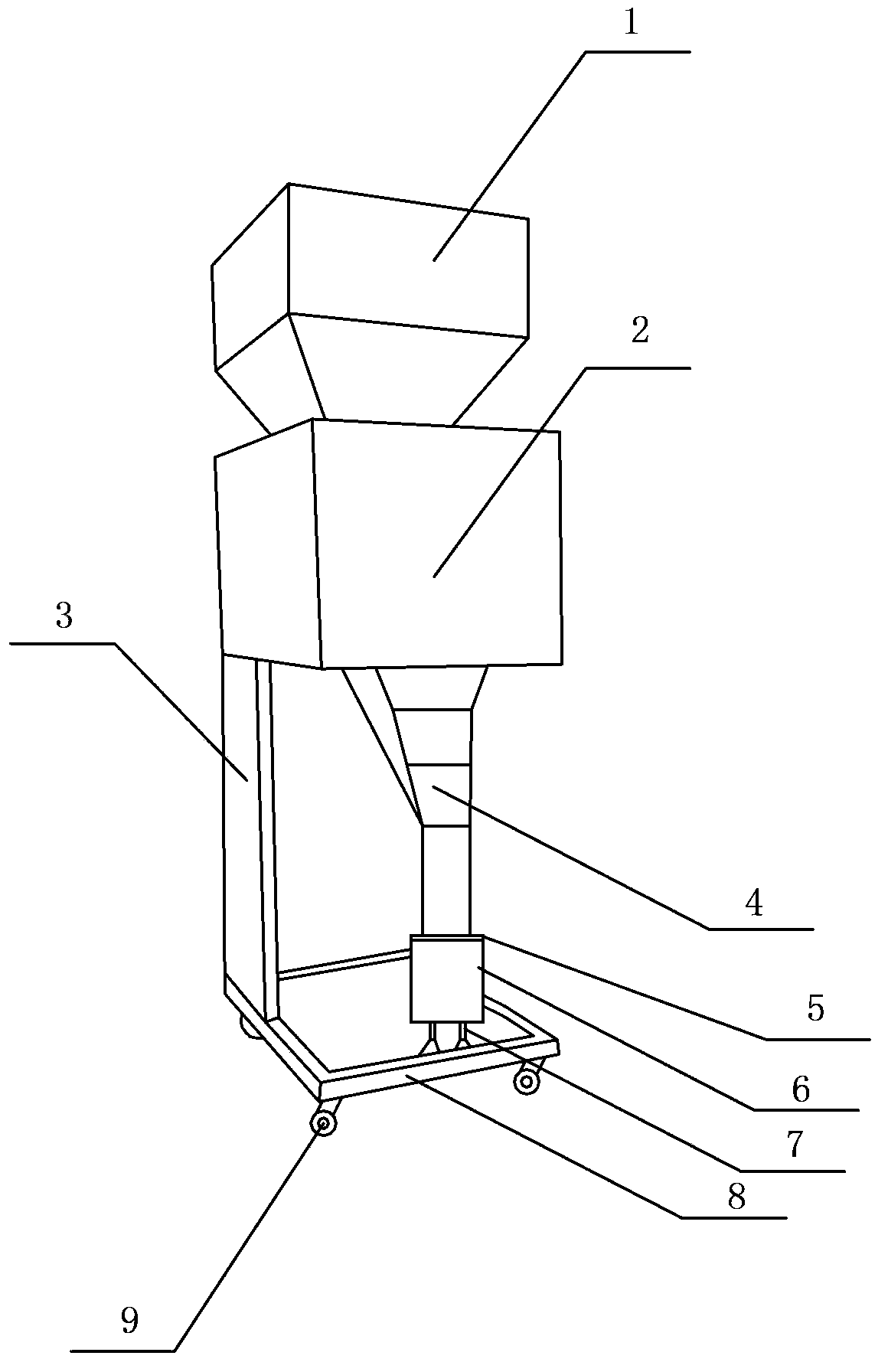

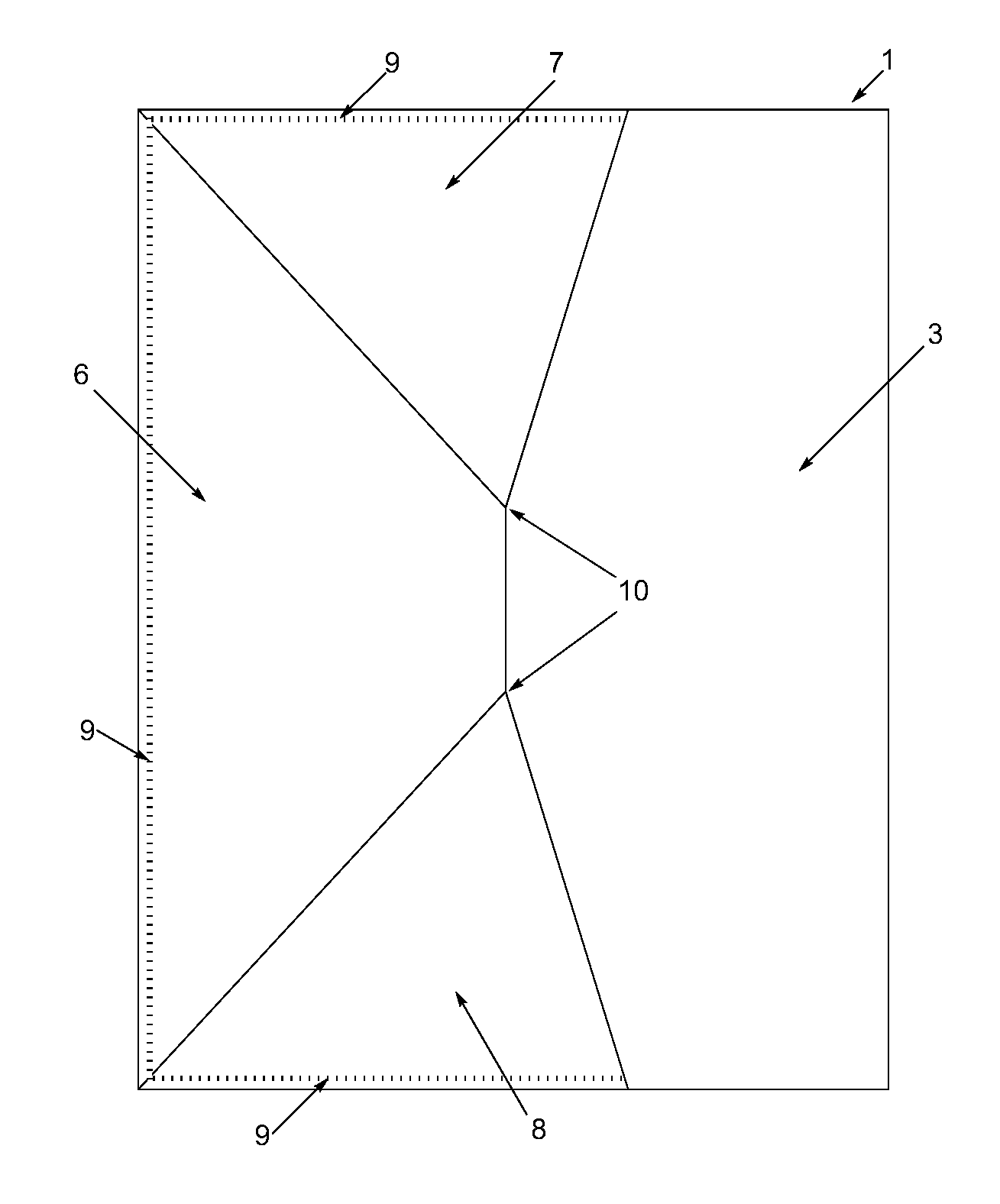

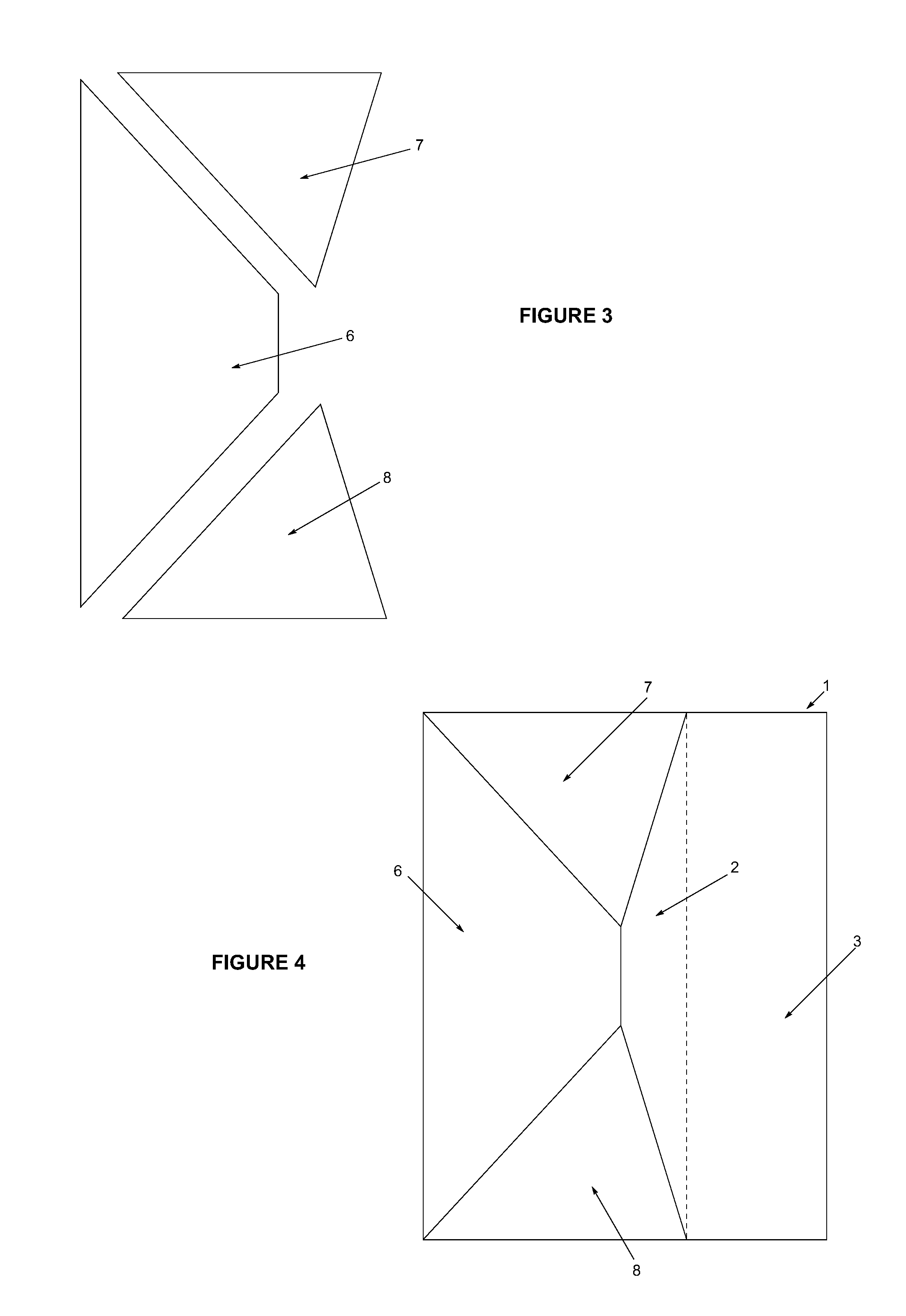

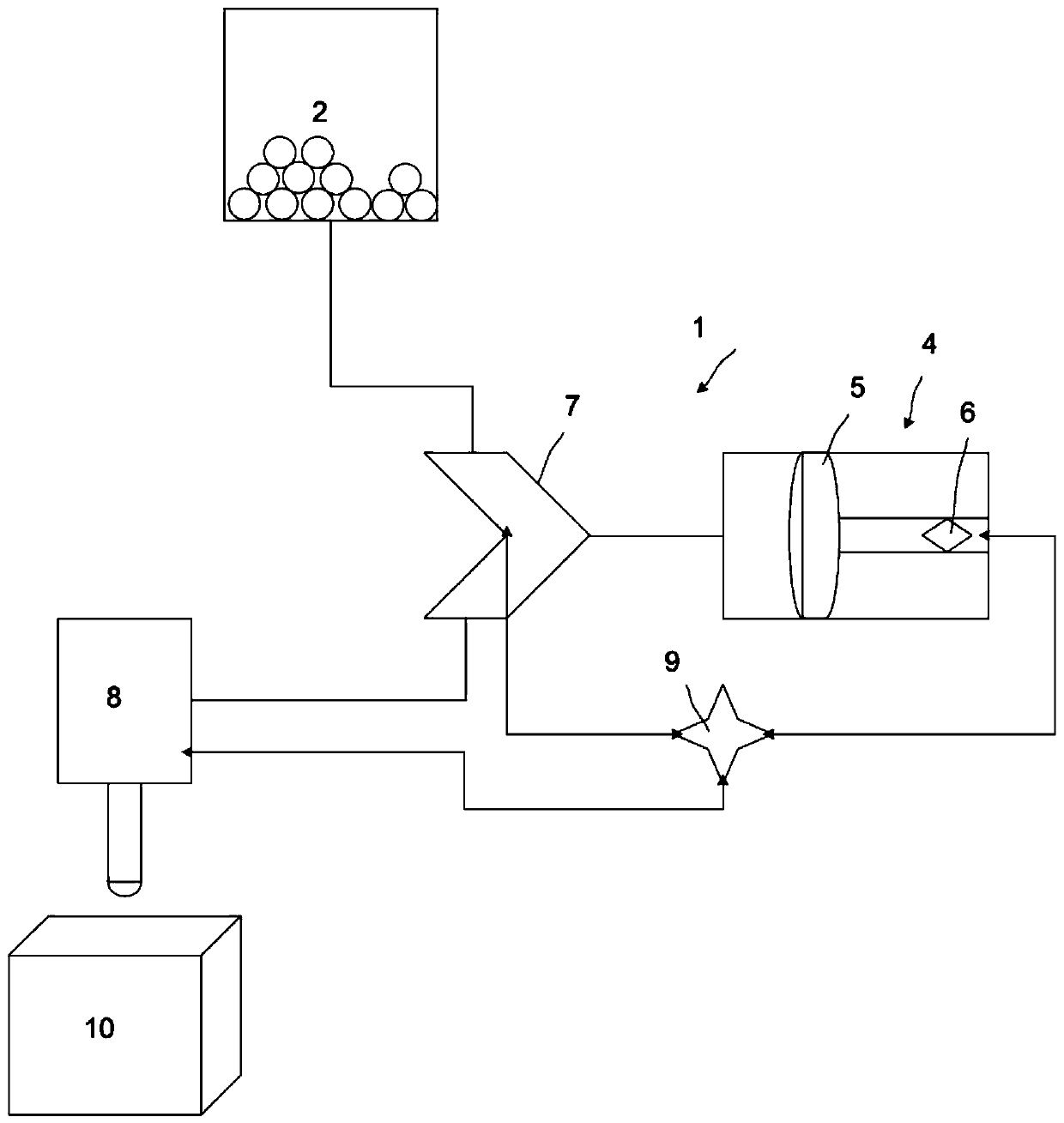

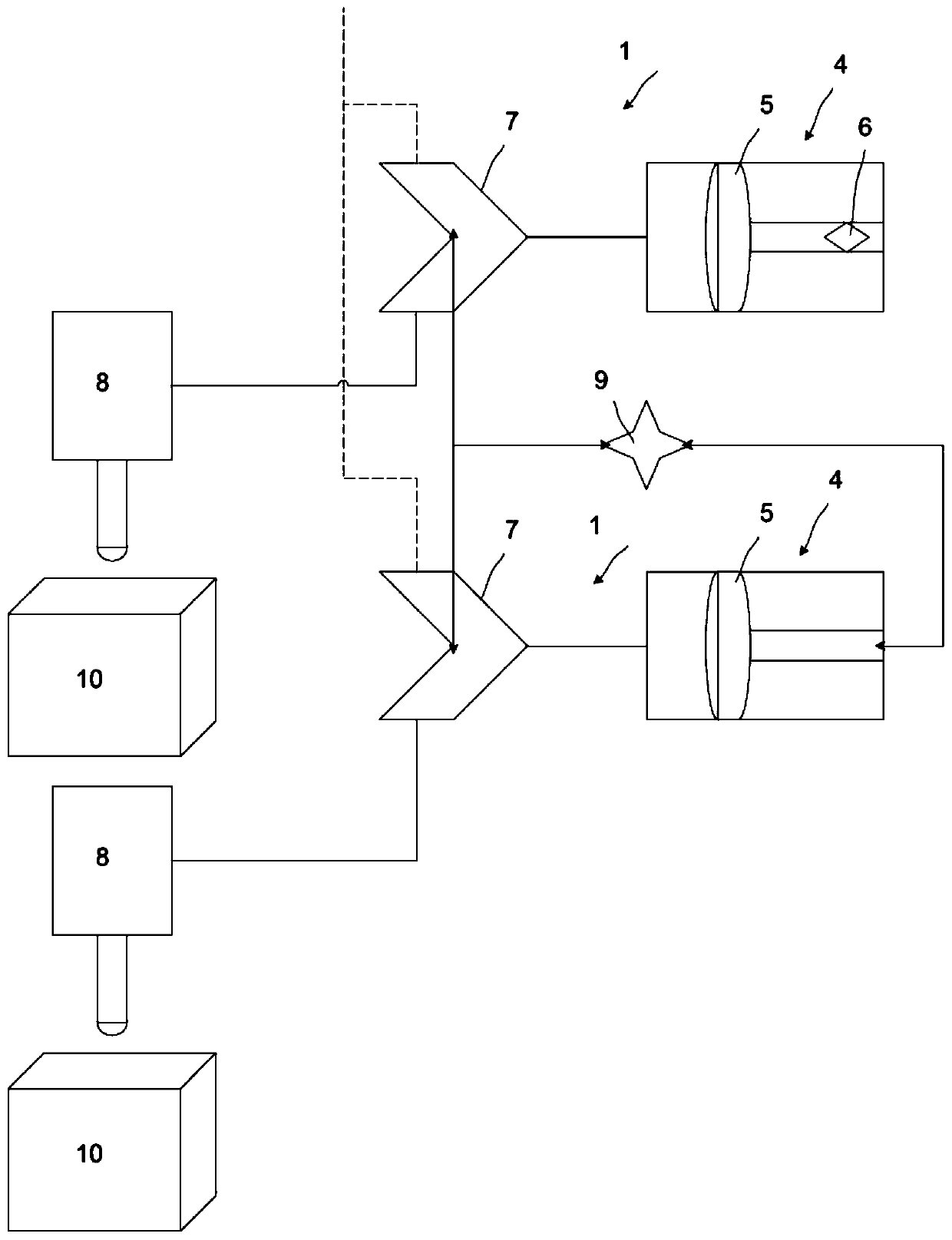

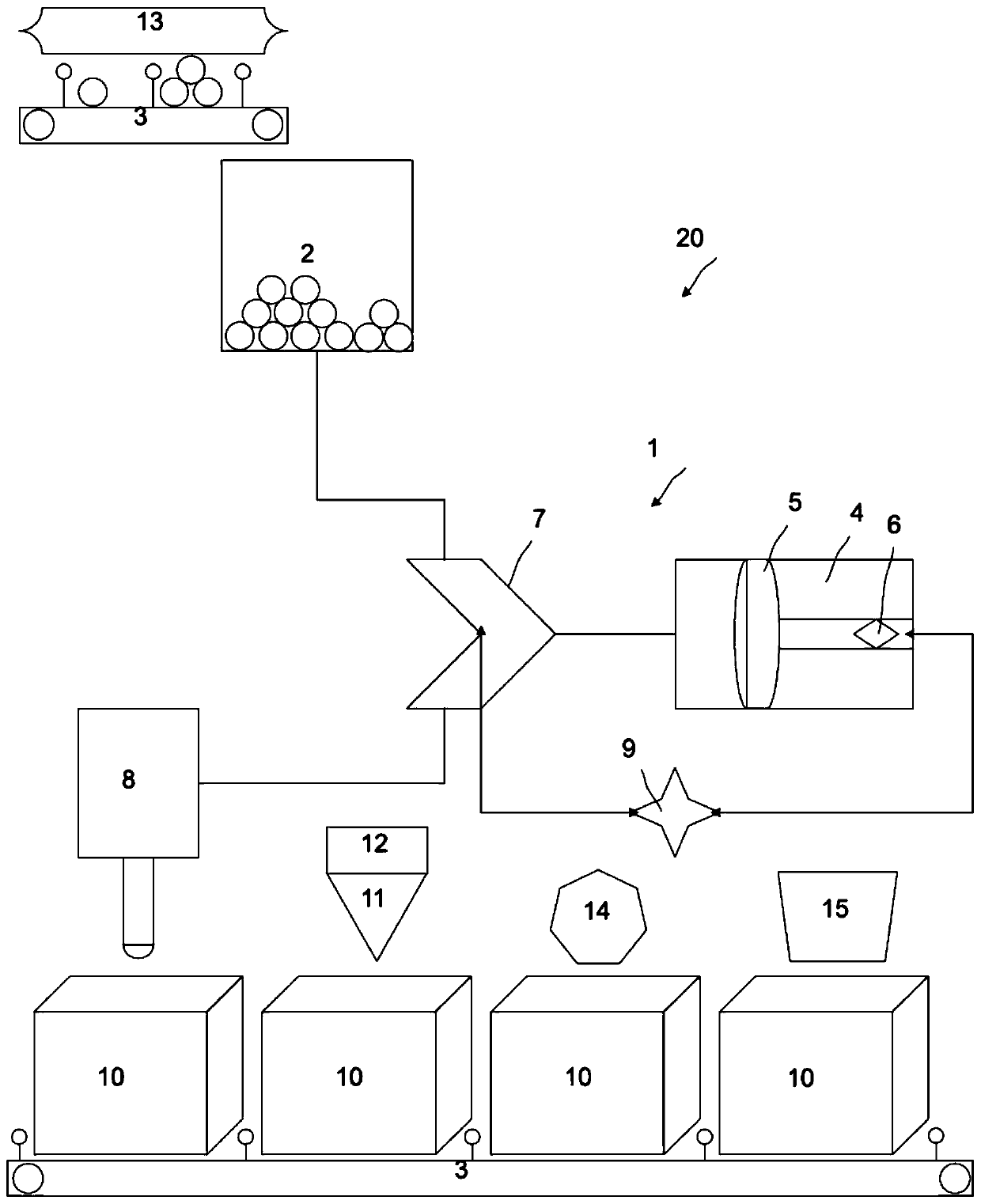

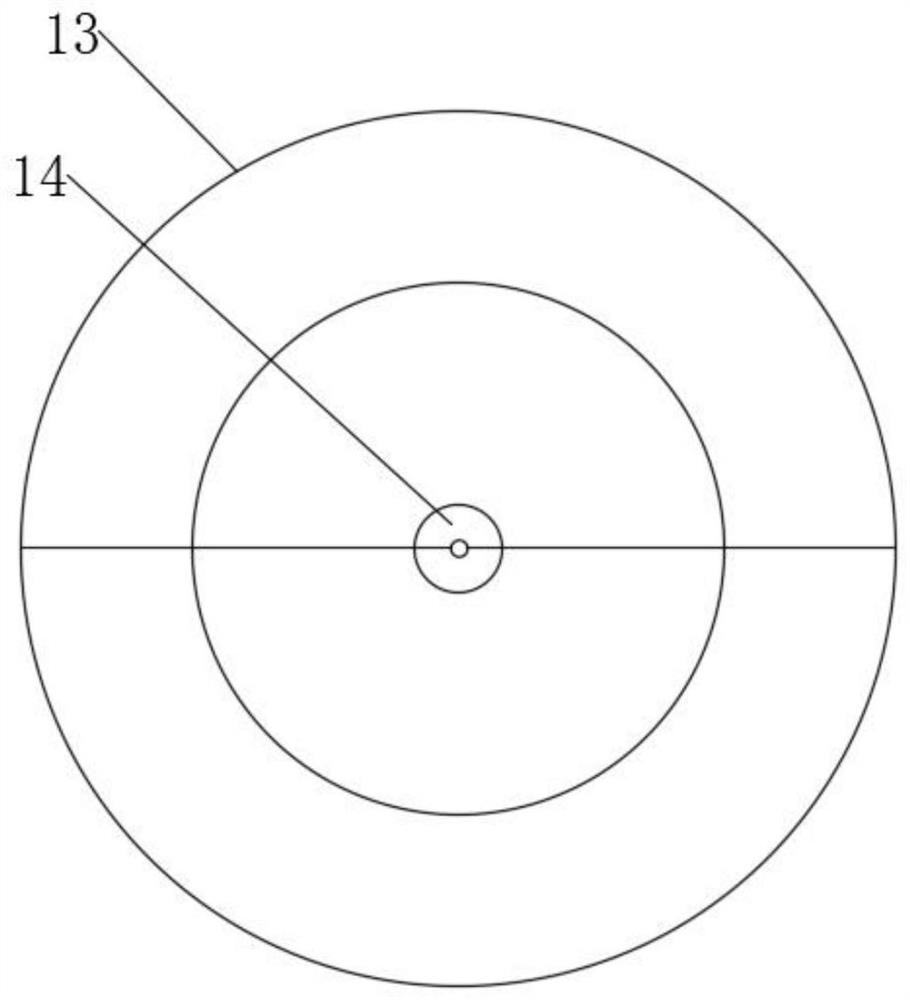

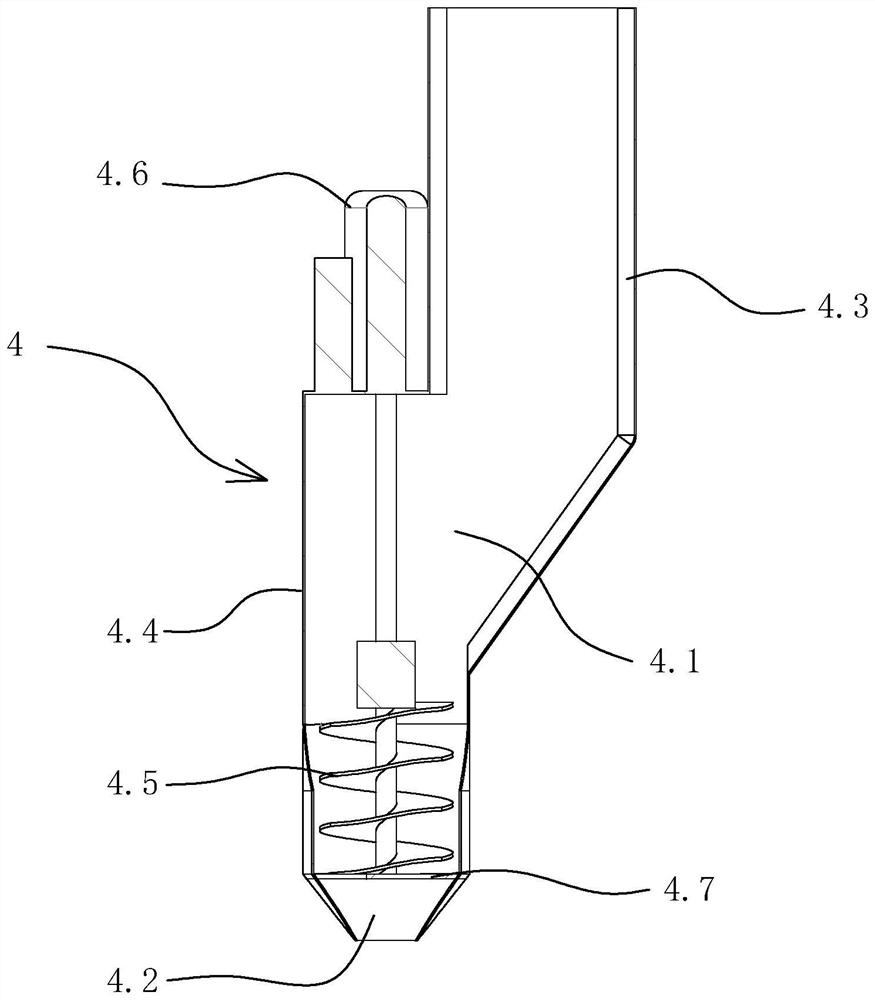

Multi-channel seed source automatic blanking high-speed counting device

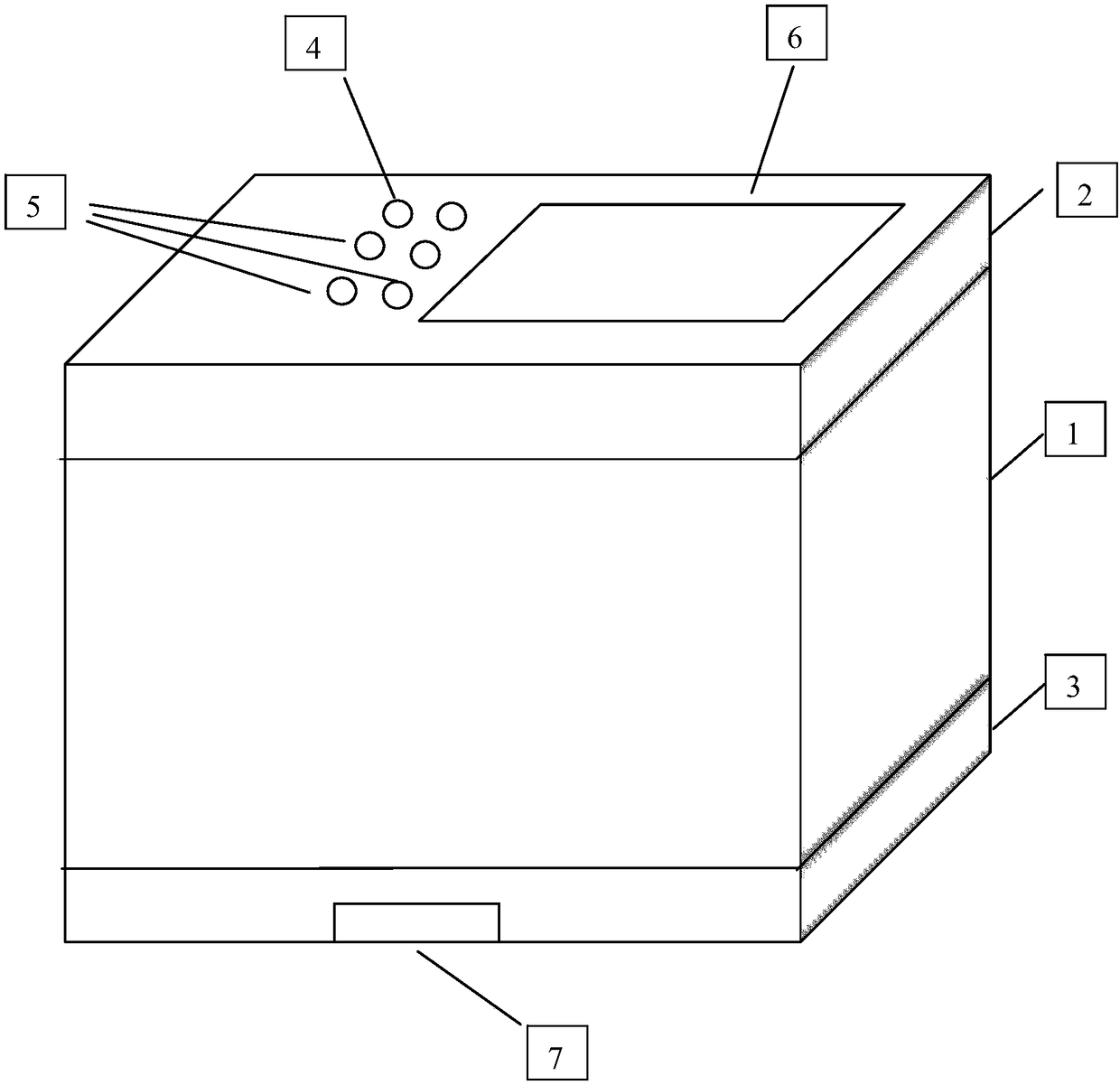

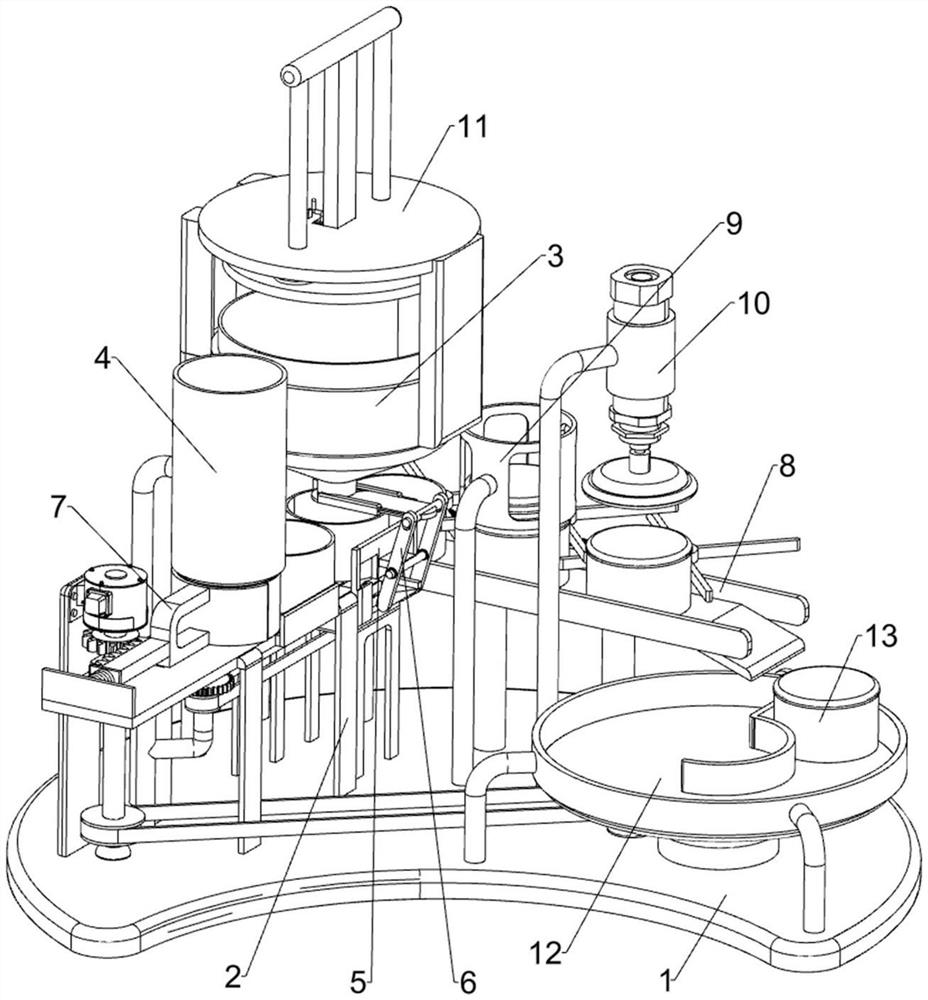

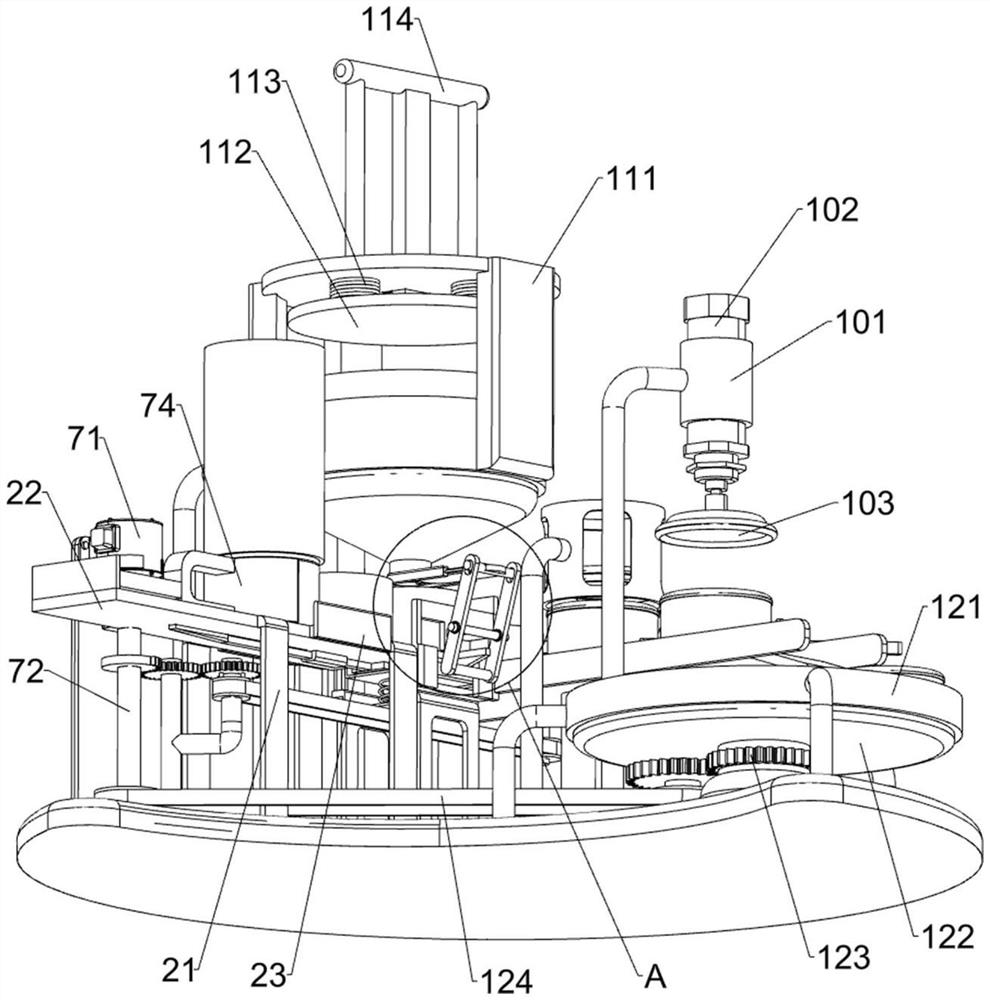

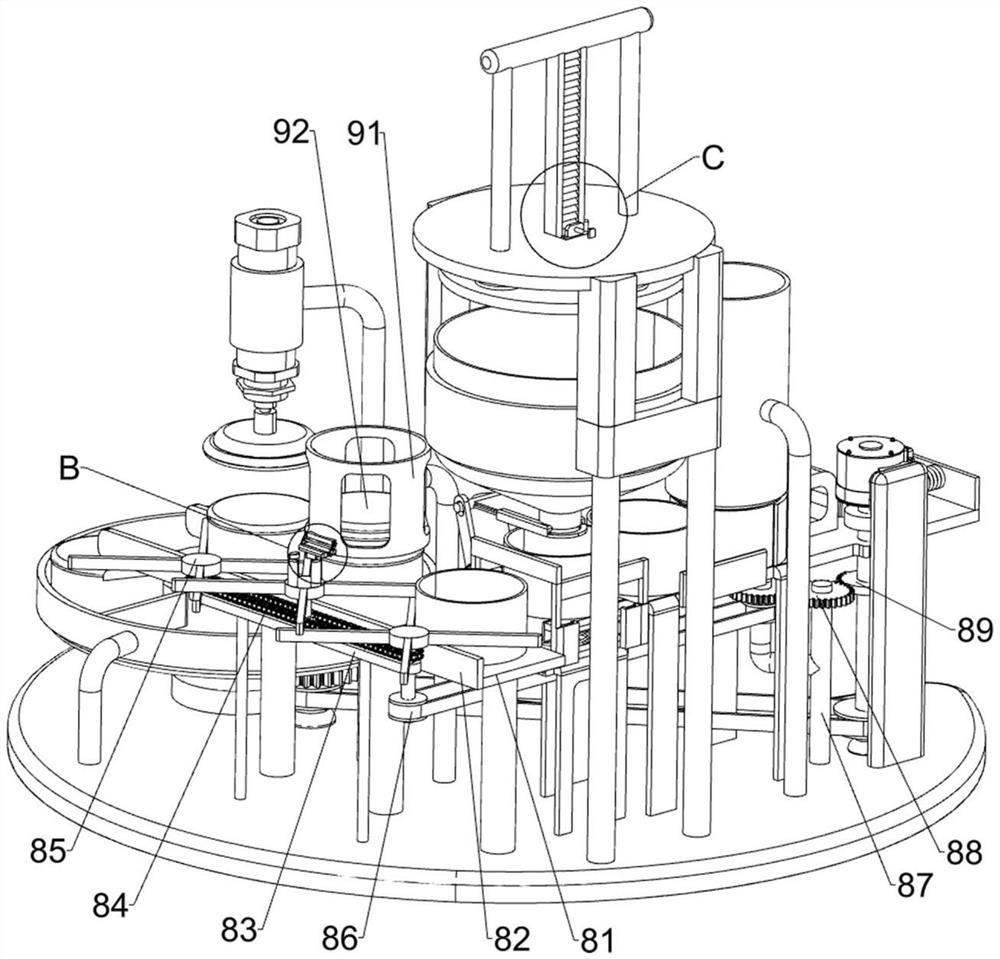

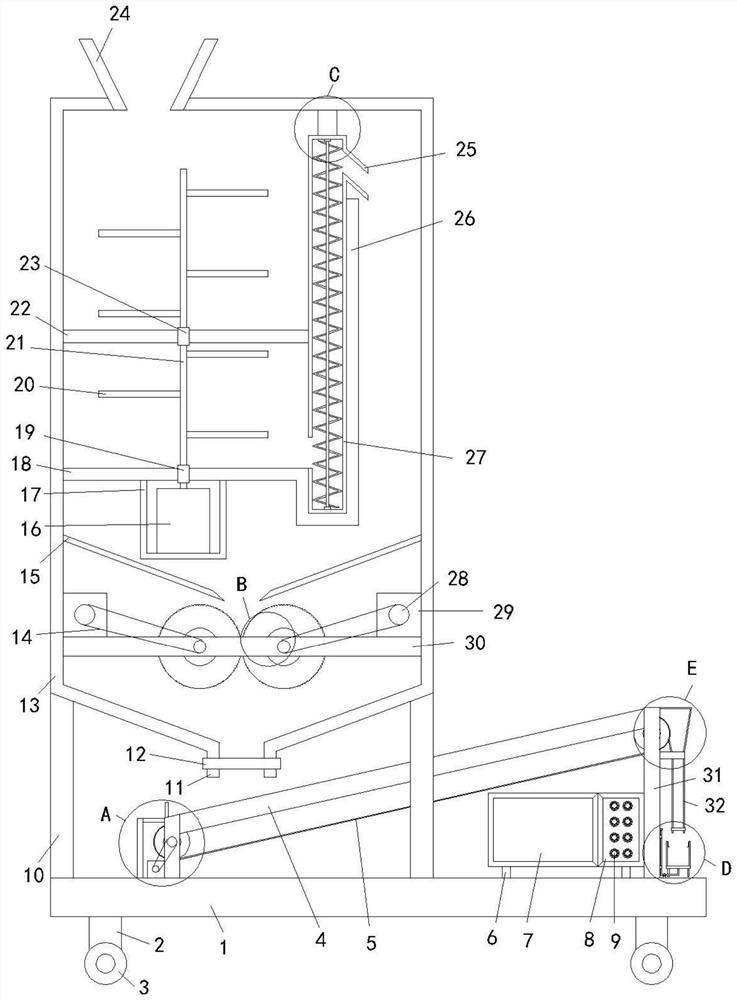

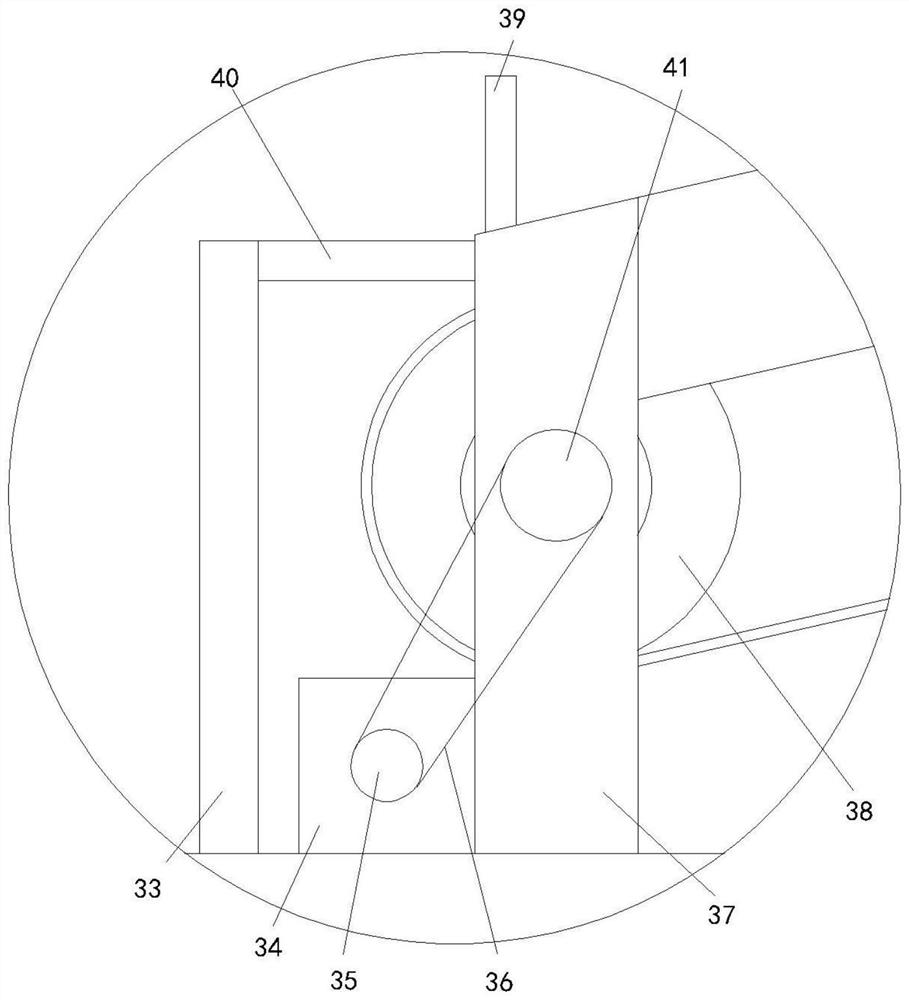

PendingCN114394296AAccurate countAdjustable blanking speedPackaging automatic controlSolid materialSeeds sourceRadiation Dosages

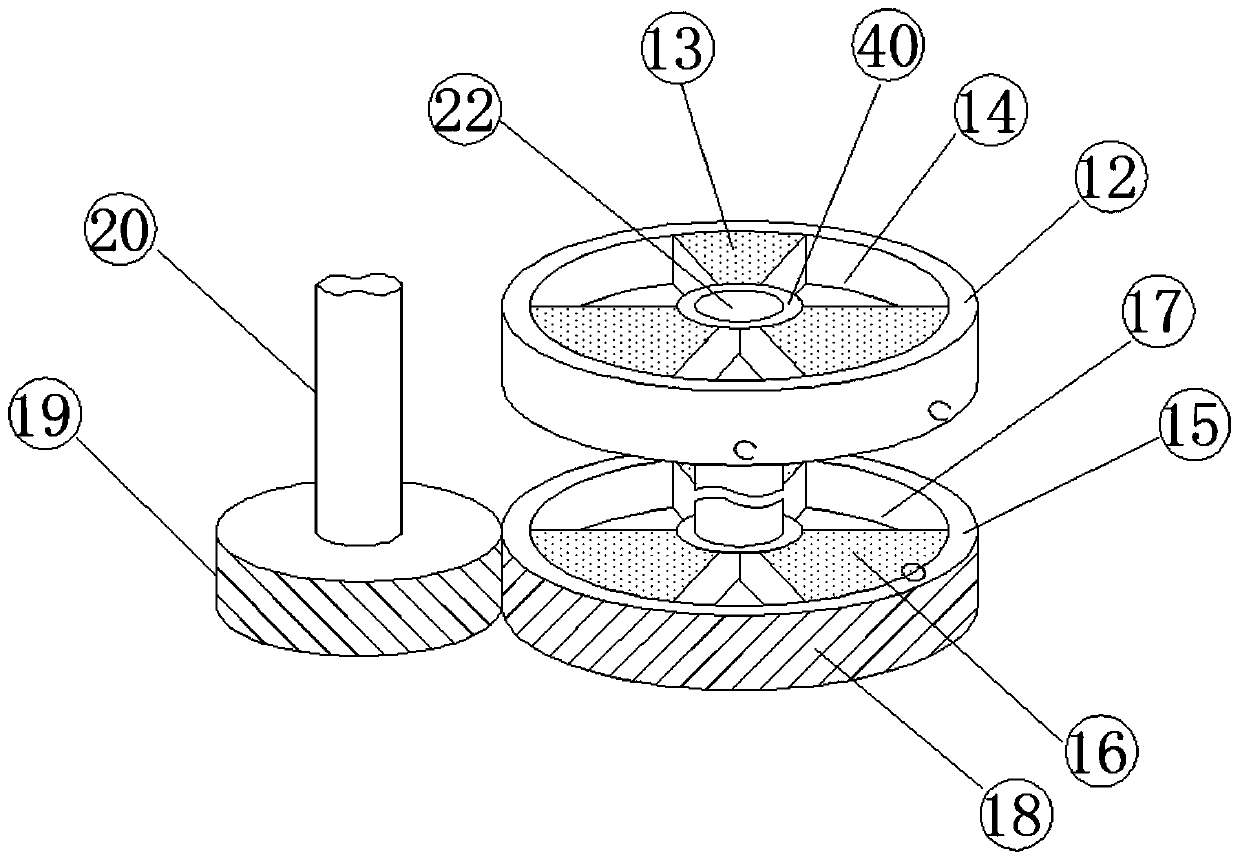

The invention belongs to the field of tiny material conveying and counting, and particularly relates to a multi-channel seed source automatic blanking high-speed counting device. Comprising a cabinet body, a blanking system and a control mechanism, and the blanking system and the control mechanism are arranged in the cabinet body. And the blanking system comprises a seed source arranging and filling mechanism and a seed source conveying and counting mechanism. The multi-channel automatic blanking device has the advantages that multi-channel automatic blanking of the sealed seed source can be completed; seed source blanking counting in each seed source channel can be performed independently or simultaneously, and the blanking speed is adjustable; seed source blanking in each channel can be counted continuously or quantitatively; according to seed source counting, accurate counting of seed sources is ensured in a multi-path sensor monitoring and rechecking mode, counting is accurate, efficiency is high, adjustable seed source blanking speed, quantitative and accurate counting are achieved, and batched and quantitative subpackaging of the seed sources can be achieved; when the seed source is counted, the contact between a person and a radiation source is reduced, the radiation dose of the seed source to a human body is effectively reduced, and the safety is high.

Owner:CNNC LIXIN (BEIJING) TECH CO LTD

Intelligent material mixing, processing and bagging equipment

Owner:阜阳市杨洁涛农业科技有限公司

Automatic boxing equipment for food materials

Owner:ZHEJIANG AISHIDA ELECTRIC CO LTD +1

Packaging machine with weighing and counting function

InactiveCN110949760AImprove accuracyImprove convenienceWrapper twisting/gatheringSolid materialStress sensorsElectrical and Electronics engineering

Owner:嘉善精田精密机械股份有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap