Dispensing system and method of controlling the system

a technology of a pouring system and a control system, applied in the direction of liquid handling, packaging goods, transportation and packaging, etc., can solve the problems of reducing the rate at which a beverage can be dispensed, the top pouring system cannot support the dispense rate required at many high-demand venues, and the fobbing or foaming rate is increased. , to achieve the effect of reducing the amount of foaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

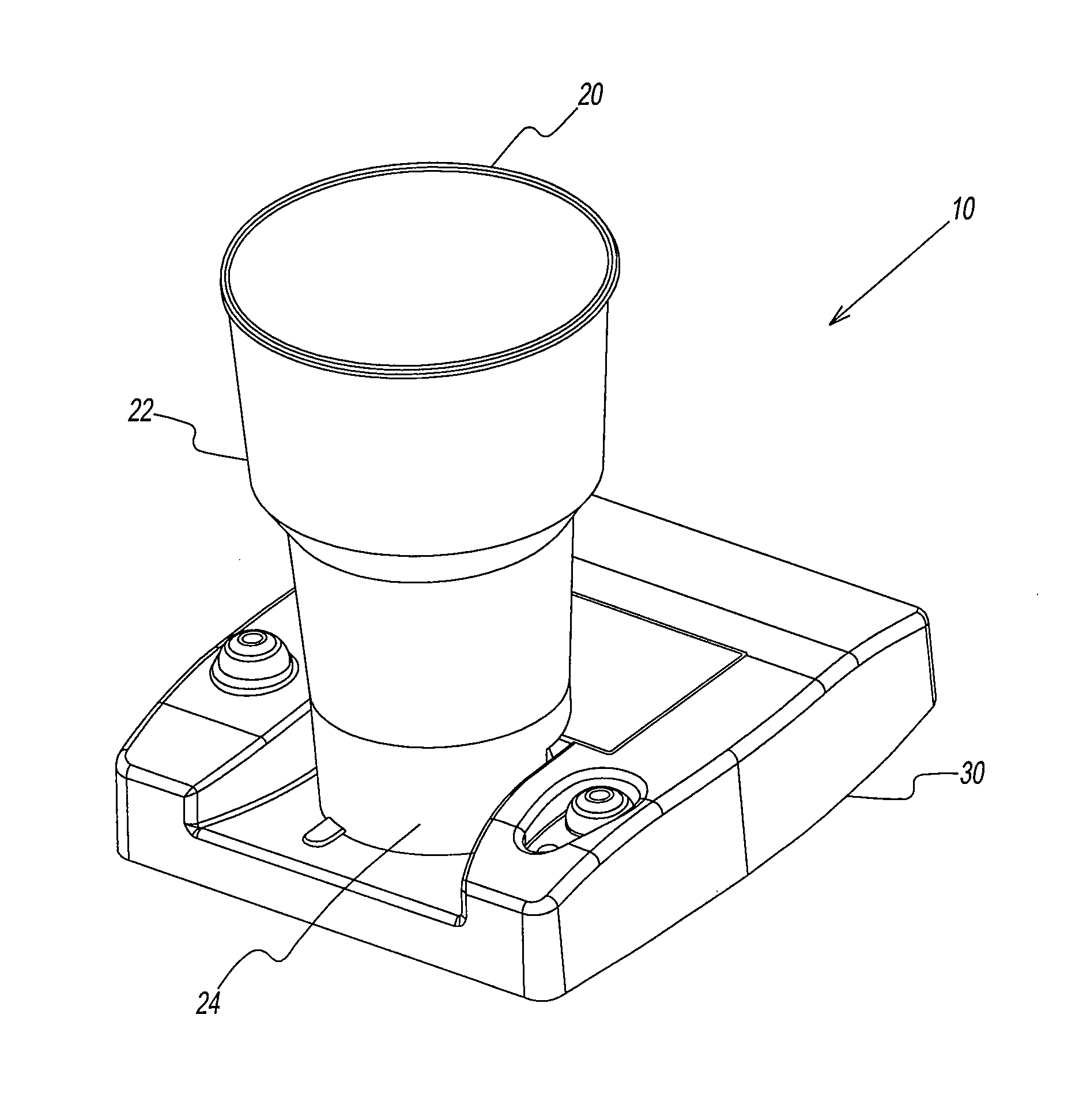

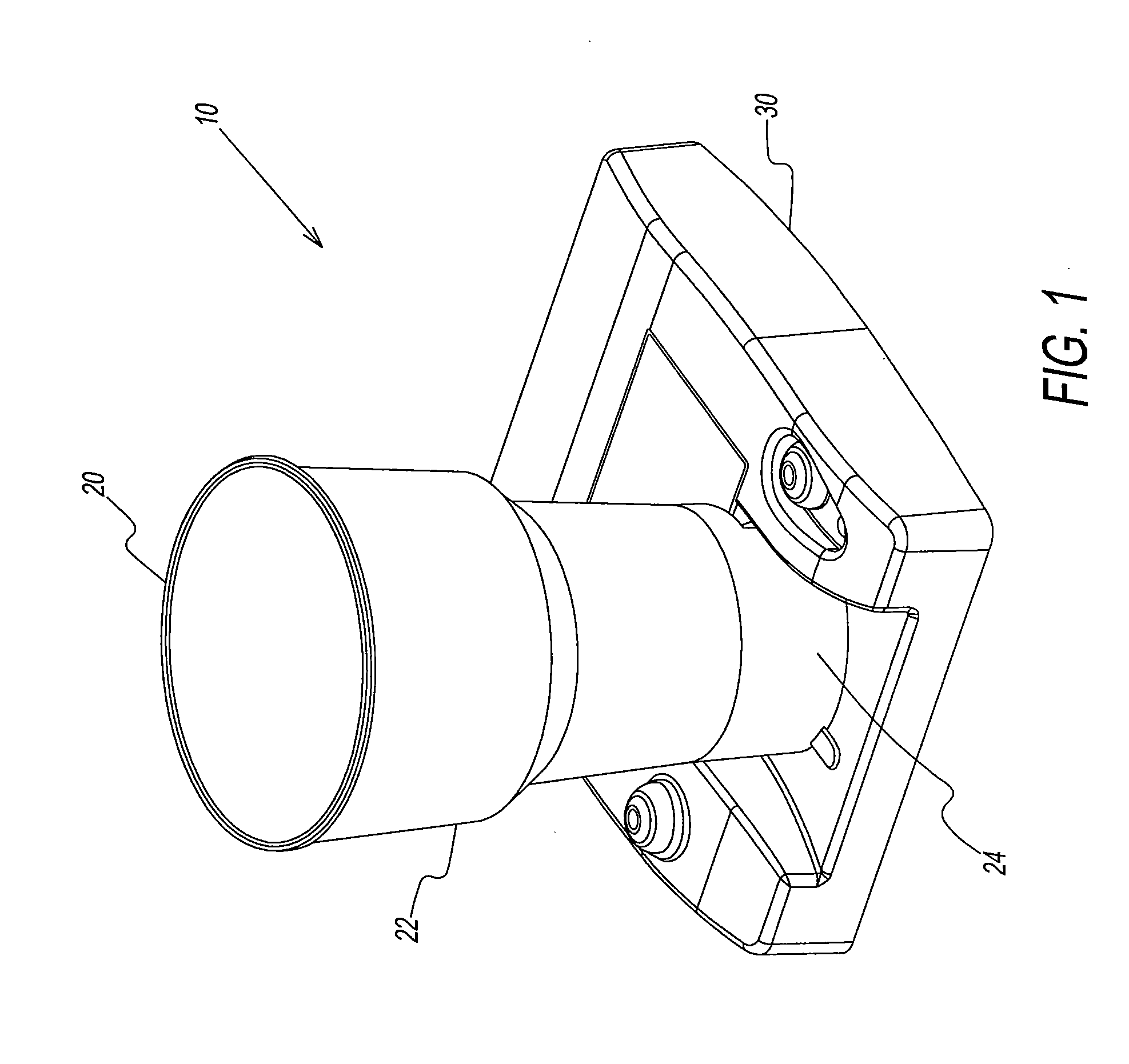

[0067]Referring to the drawings, a beverage dispensing system according to the present disclosure is shown and generally referenced to by numeral 10. Beverage dispensing system 10 includes a vessel 20 that can be removably disposed on a dispenser 30, as shown in FIG. 1. Vessel 20 is designed to contain a liquid received from dispenser 30. Dispenser 30 may contain a control system to regulate the use of dispensing system 10. Beverage dispensing system 10 can effectively control the flow of any type of liquid, carbonated or non-carbonated, such as water, beer, soft drinks, smoothies or other beverage, through dispenser 30 and into vessel 20. Thus, beverage dispenser system 10 can provide for the rapid dispensing of liquids in a very short period of time.

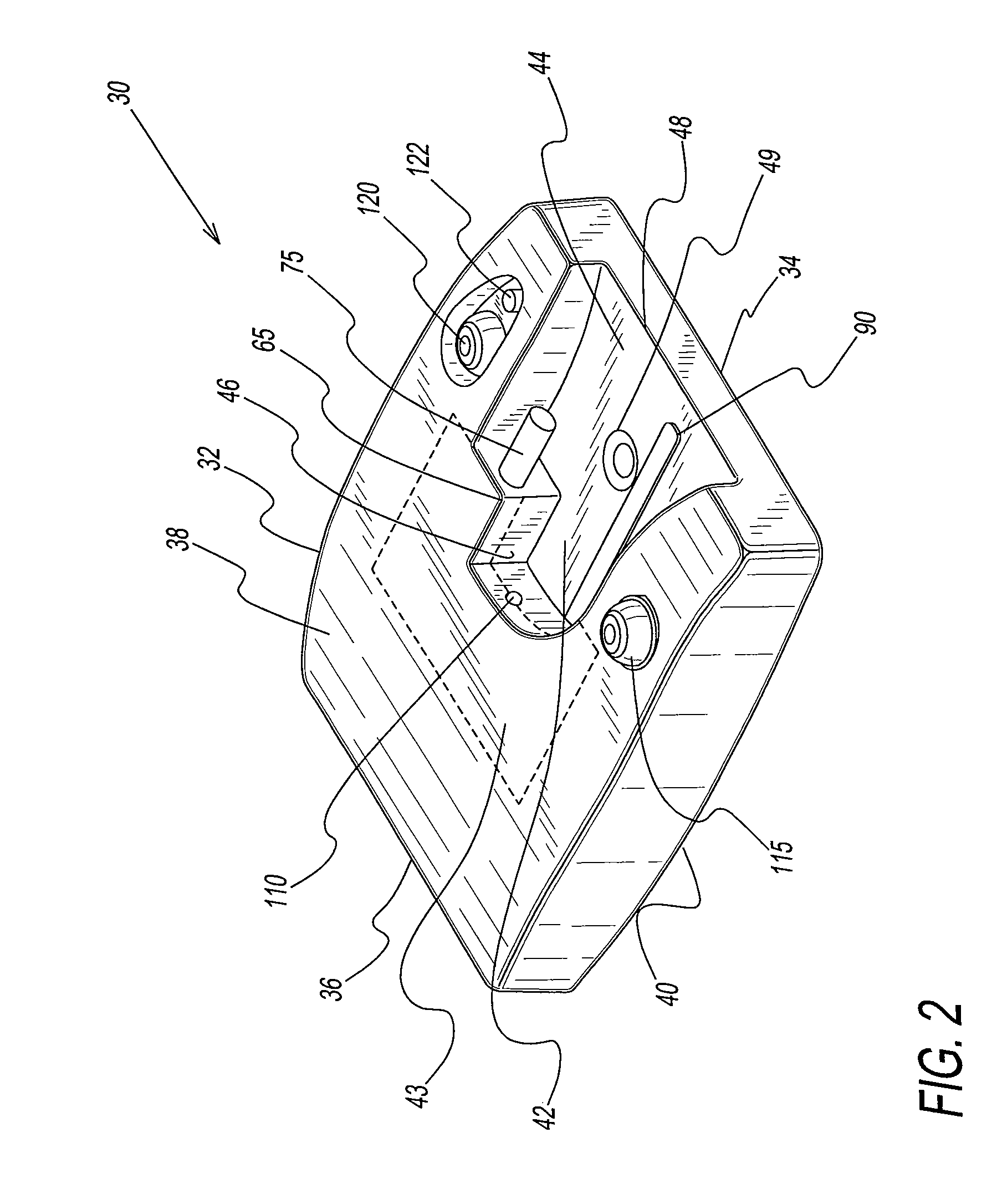

[0068]As shown in FIGS. 2-5, dispenser 30 contains a housing 32 having at least a first end 34, a second end 36, an upper panel 38 and a lower panel 40. Housing 32 can be made out of any durable material, such as, but not limited to plast

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap