Efficient stirring device for paint production

A stirring device and high-efficiency technology, applied in the field of paint, can solve the problems of difficult to observe internal mixing, long time for complete stirring and mixing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

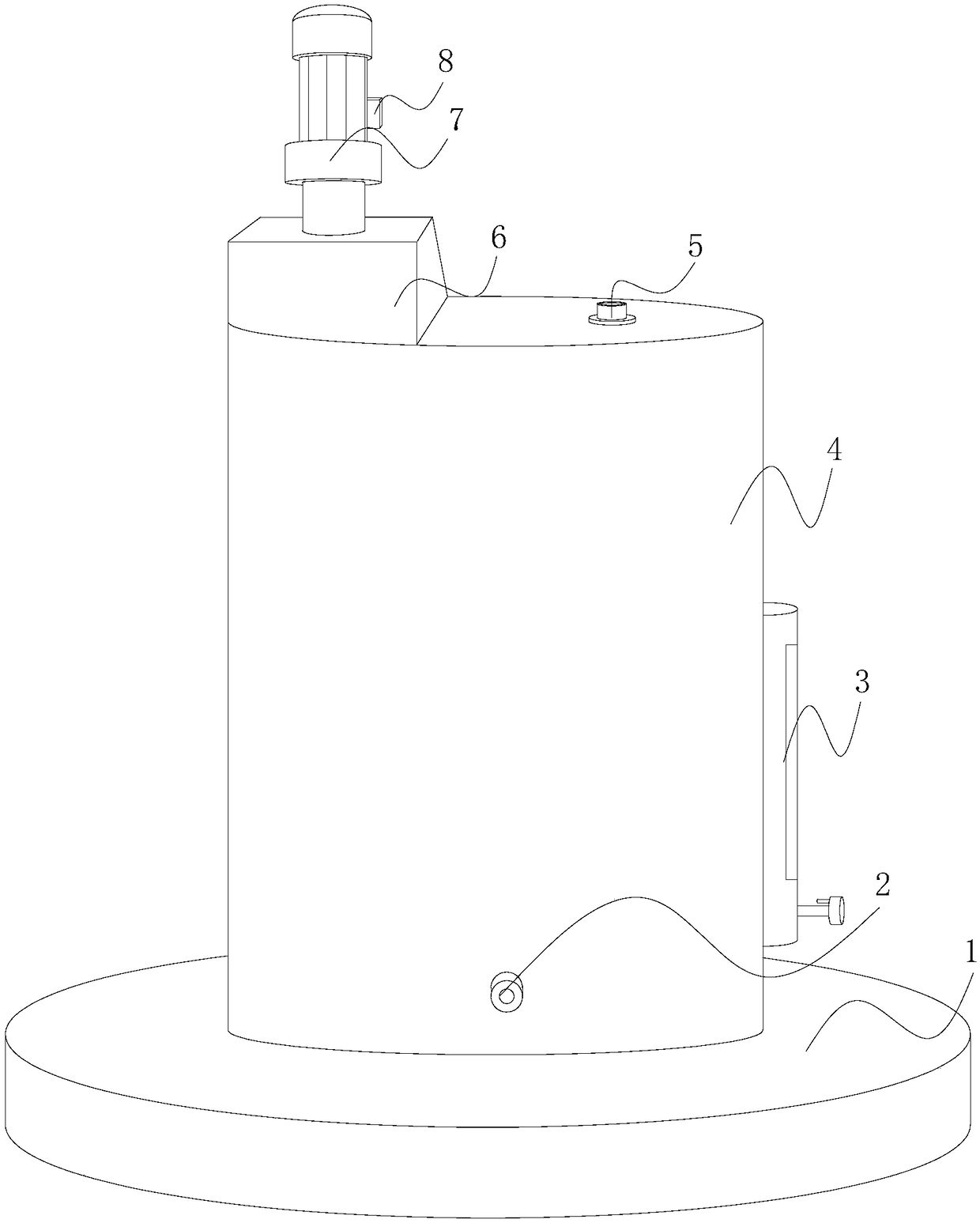

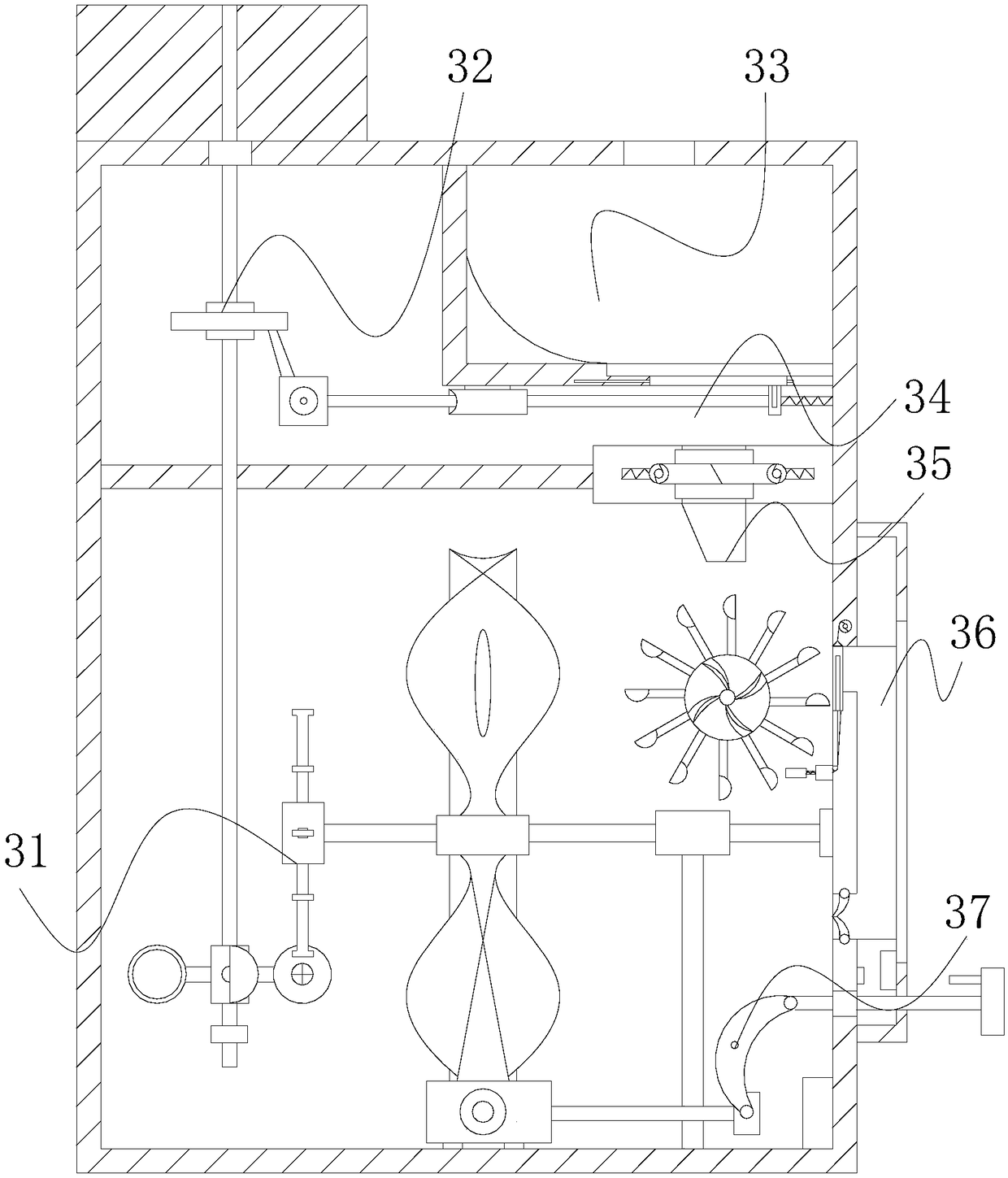

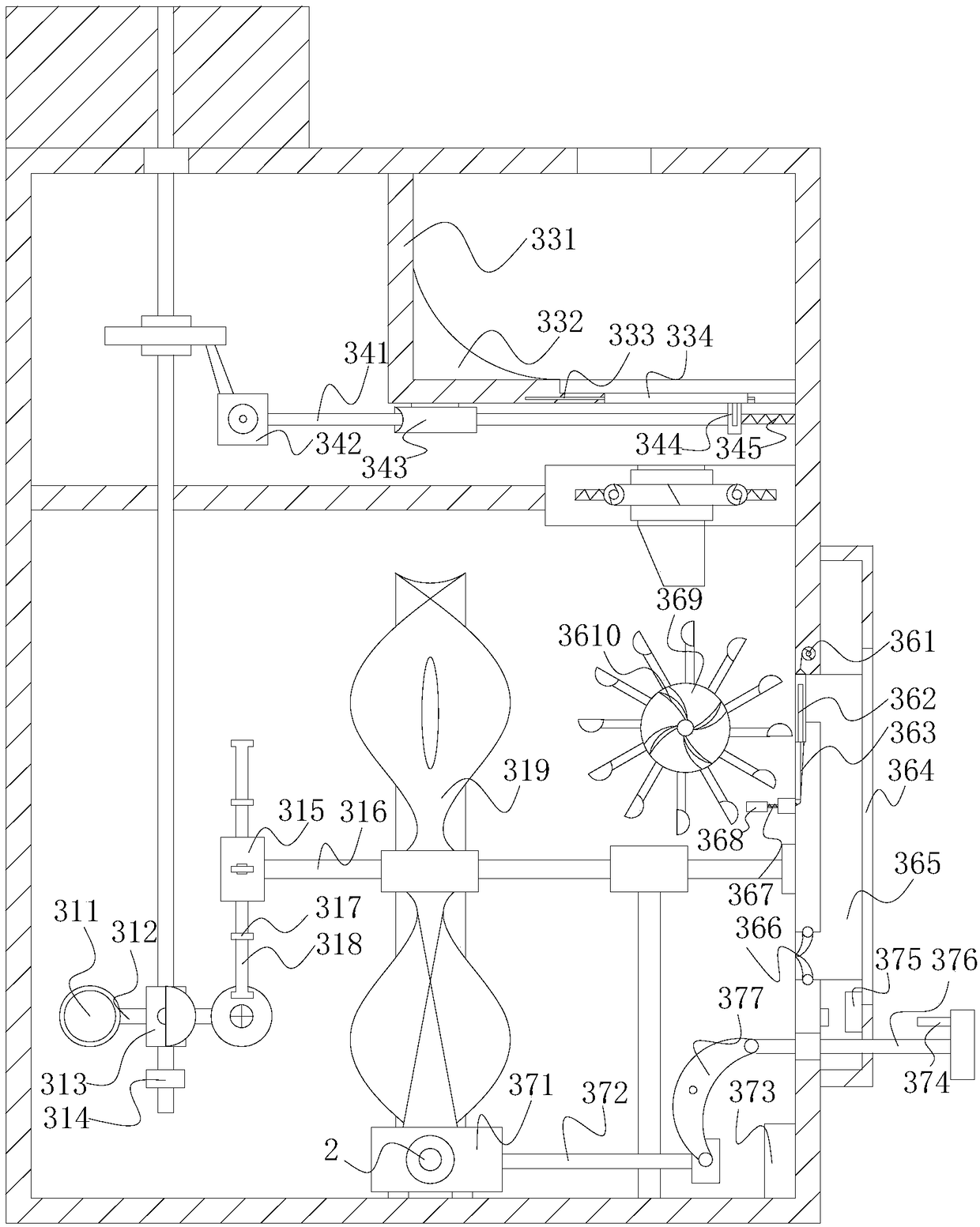

[0023] see Figure 1-Figure 5, the present invention provides a high-efficiency stirring device for paint production, and its structure includes a base 1, a discharge port 2, an observation-type high-efficiency stirring device 3, a stirring outer barrel 4, a feeding end 5, a fixed seat 6, a motor 7, and a junction box 8. The top of the base 1 is fixedly connected to the bottom of the mixing tub 4 by means of electric welding, the back of the outlet 2 is installed at the bottom of the left end of the mixing tub 4 by means of embedding, and the feeding end 5 The bottom end is installed on the top of the mixing tub 4 away from the fixed seat 6 by means of embedding, and one end of the junction box 8 is fixedly connected to the middle of the outer surface of the motor 7 by means of electric welding, and the bottom end of the motor 7 is installed by means of embedding At the top of the fixed seat 6, the bottom end of the fixed seat 6 is fixedly connected to the top end of the stirring

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap