Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4 results about "Fluidization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluidization (or fluidisation) is a process similar to liquefaction whereby a granular material is converted from a static solid-like state to a dynamic fluid-like state. This process occurs when a fluid (liquid or gas) is passed up through the granular material.

Fluidized-bed reaction device and fluidization reaction method for hydrogenation of nitrobenzene

ActiveCN111298727AImprove fluidization qualityReduce the presence of air bubblesOrganic compound preparationAmino compound preparationPtru catalystGas phase

The invention relates to a fluidized-bed reaction device and a fluidization reaction method for hydrogenation of nitrobenzene. The invention mainly aims to solve the problems of low gas-solid contactefficiency, large bubble size, low fluidization quality and the like in a fluidized bed. According to a technical scheme in the invention, at least one group of composite components are arranged in afluidized-bed reactor, so when gas and catalyst particles pass through the components, bubbles and particle clusters are broken, fluidization quality is effectively improved, and the above technical problems are well solved; and the device and the method can be applied to industrial production of gas-phase catalytic hydrogenation of nitrobenzene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Device for preparing double-shell microcapsules

PendingCN108160014AEasy to manufactureEfficient manufacturingMicroballoon preparationMicrocapsule preparationSolubilityPeristaltic pump

A device for preparing double-shell microcapsules comprises a core material liquid inlet, a wall material liquid inlet, a vibrating system, a concentric nozzle, a collector, a stirrer, a peristaltic pump I, a second layer coating chamber, a rotatable screen, a coating liquid inlet, a peristaltic pump II, an atomizing nozzle, an air compressor, a temperature control system and the like. The deviceis simple; through control over the liquid inlet speeds of the core material liquid inlet and the wall material liquid inlet and the vibrating frequency of the vibrating system, the sizes of microcapsule cores are controlled, so that the microcapsules with uniform sizes are prepared and damage during microcapsule preparation is reduced; through hardening liquid filtration and hot air fluidization,rapid moulding of first-layer microcapsules is achieved; through control over the atomizing pressure and the coating liquid solubility, the shell thickness of second-layer coating is controlled. A preparation technology is simple, the reaction condition is mild, the control is easy, and the repeatability is relatively good; in addition, because of a sealing property of the device, influence of the environment on the microcapsules is greatly reduced, so that the double-shell microcapsules can be effectively prepared and the preparation time is greatly shortened.

Owner:NANCHANG UNIV

Fly ash hollow microsphere pulsation solid-liquid fluidization sorting recovery device and method

The invention discloses a fly ash hollow microsphere pulsation solid-liquid fluidization sorting recovery device and method. The device comprises an overflow barrel, an overflow material discharging pump, an overflow opening, a water flow distributor, a water inlet, a first water jacking opening, a second water jacking opening, a first electromagnetic butterfly valve, a first throttle valve, a second throttle valve, a high-level water tank, a sorting bed body, a first internal component, a second internal component, a vertical cylinder, an obconical sleeve, a material inlet, a material inlet pump, a material inlet stirring barrel, a material outlet, a second electromagnetic butterfly valve, a pulsation electromagnetic butterfly valve, an underflow material discharging pump, and an underflow barrel. Through joint action of the pulsation electromagnetic butterfly valve and the underflow material discharging pump, a top-to-bottom pulsation water flow is formed inside the sorting bed body,fly ash magma is sorted by density under the action of the pulsation water flow, and sorted fly ash enters the overflow barrel or the underflow barrel via the material discharging pump, so the sorting recovery operation of hollow microsphere in fly ash is completed. The device is simple, the operation is convenient, and the device can be used for continuous sorting recovery operation of the fly ash hollow microsphere.

Owner:HENAN POLYTECHNIC UNIV

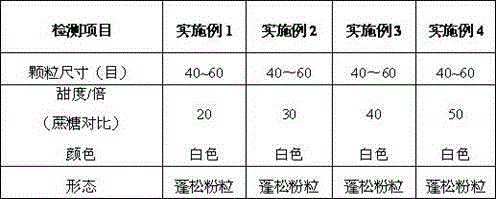

Compound sweetener suitable for refreshing neutral beverage and preparation method thereof

InactiveCN102940236AHighlight substantive featuresSignificant progressFood preparationSucroseCyclodextrin

Owner:苏州工业园区尚融科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap