Compound sweetener suitable for refreshing neutral beverage and preparation method thereof

A compound sweetener and refreshing technology, which is applied in the field of compound sweetener and its preparation, can solve the problems of post-sweetness, raw material loss, and limitation of use range, and achieve improved sweetness dispersion, scientific and reasonable matching, and shortened sweetness. The effect of the processing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The preparation process of the compound sweetener: first put isomalt, xylitol, β-cyclodextrin and glucose accounting for 60~70% of the total amount into the multidimensional mixer, and mix 20 ~50 minutes, the particle size of the mixed material is controlled at 80~130 mesh, and the mixed material of isomalt, xylitol, β-cyclodextrin and glucose is obtained; then the sucralose, maltodextrin and the remaining amount of Glucose is dissolved in deionized water to obtain a mixed aqueous solution of sucralose, maltodextrin and glucose; then the mixed material is put into the spray fluidized bed equipment, so that the mixed material enters the fluidized bed from the bottom of the spray fluidized bed under positive pressure The bed is accelerated from bottom to top, and the upper part of the spray fluidized bed is subjected to negative pressure and vibrates from top to bottom to make the mixed material boil up and down in the fluidized bed. Small sugar alcohol particles; through th

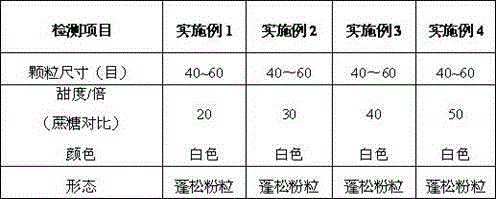

Embodiment 1

[0023] Example 1: 20

[0024] (1) Put 12 kg of isomalt, 5 kg of xylitol, 8 kg of β-cyclodextrin and 46.5 kg of glucose into a multidimensional mixer, control the number of stages of the multidimensional mixer to 8000rpm, and mix for 40 minutes to obtain A mixture of isomalt, xylitol, β-cyclodextrin and glucose, with a particle size between 80 and 130 mesh;

[0025] (2) Mix 3.33 kg of sucralose, 3 kg of maltodextrin, and 22.17 kg of remaining glucose with deionized water, heat up and stir to dissolve, and obtain a mixed aqueous solution of sucralose, maltodextrin and glucose;

[0026] (3) Put the mixed material obtained in step (1) into the spray fluidized bed equipment, so that the mixed material enters the fluidized bed from the bottom of the sprayed fluidized bed with positive pressure and accelerates from bottom to top, and the sprayed fluidized bed Negative pressure is applied to the upper part of the fluidized bed to vibrate from top to bottom to make the mixed material boi

Embodiment 2

[0027] Example 2: 30

[0028] (1) Put 15 kg of isomalt, 6.5 kg of xylitol, 10 kg of β-cyclodextrin and 39 kg of glucose into a multidimensional mixer, control the number of stages of the multidimensional mixer to 800 rpm, and mix for 40 minutes to obtain A mixture of isomalt, xylitol, β-cyclodextrin and glucose, with a particle size between 80 and 130 mesh;

[0029] (2) Mix 5 kg of sucralose, 3.5 kg of maltodextrin, and 21 kg of remaining glucose with deionized water, heat up and stir to dissolve, and obtain a mixed aqueous solution of sucralose, maltodextrin and glucose;

[0030] (3) Put the mixed material obtained in step (1) into the spray fluidized bed equipment, so that the mixed material enters the fluidized bed from the bottom of the sprayed fluidized bed with positive pressure and accelerates from bottom to top, and the sprayed fluidized bed Negative pressure is applied to the upper part of the fluidized bed to vibrate from top to bottom to make the mixed material boil up

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap