Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

9 results about "Catalytic hydrogenation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalytic hydrogenation is hydrogenation in presence of catalysts. Addition of hydrogen to alkenes is an exothermic (releasing heat energy) reaction, requiring the use of a transition metal catalyst due to the high energy barriers to direct the reaction between alkenes and hydrogen gas.

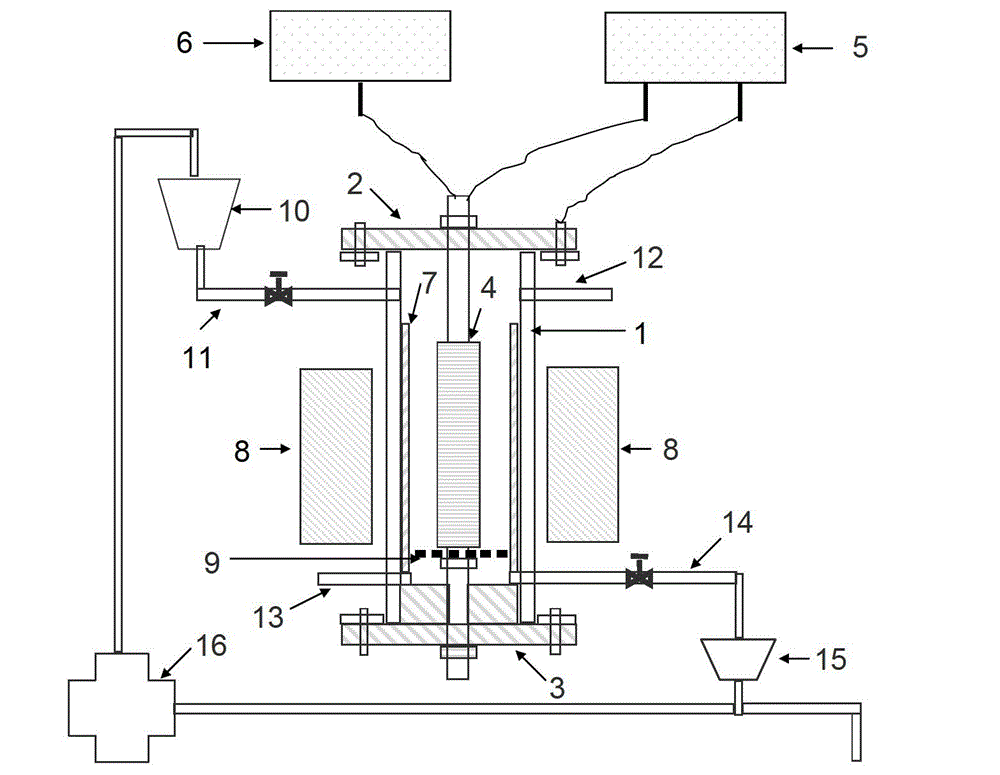

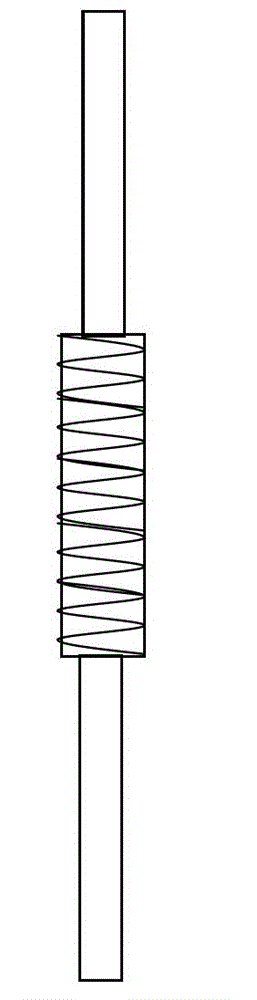

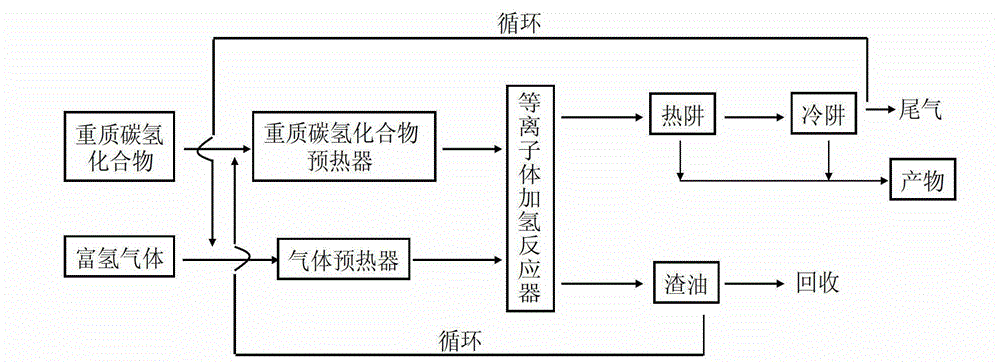

Method for updating heavy hydrocarbon to produce light oil and plasma hydrogenation reactor for method

ActiveCN102942950AAvoid separationReduce difficultyLiquid hydrocarbon mixture productionEnergy based chemical/physical/physico-chemical processesLow voltageHigh pressure

Owner:SYNFUELS CHINA TECH CO LTD

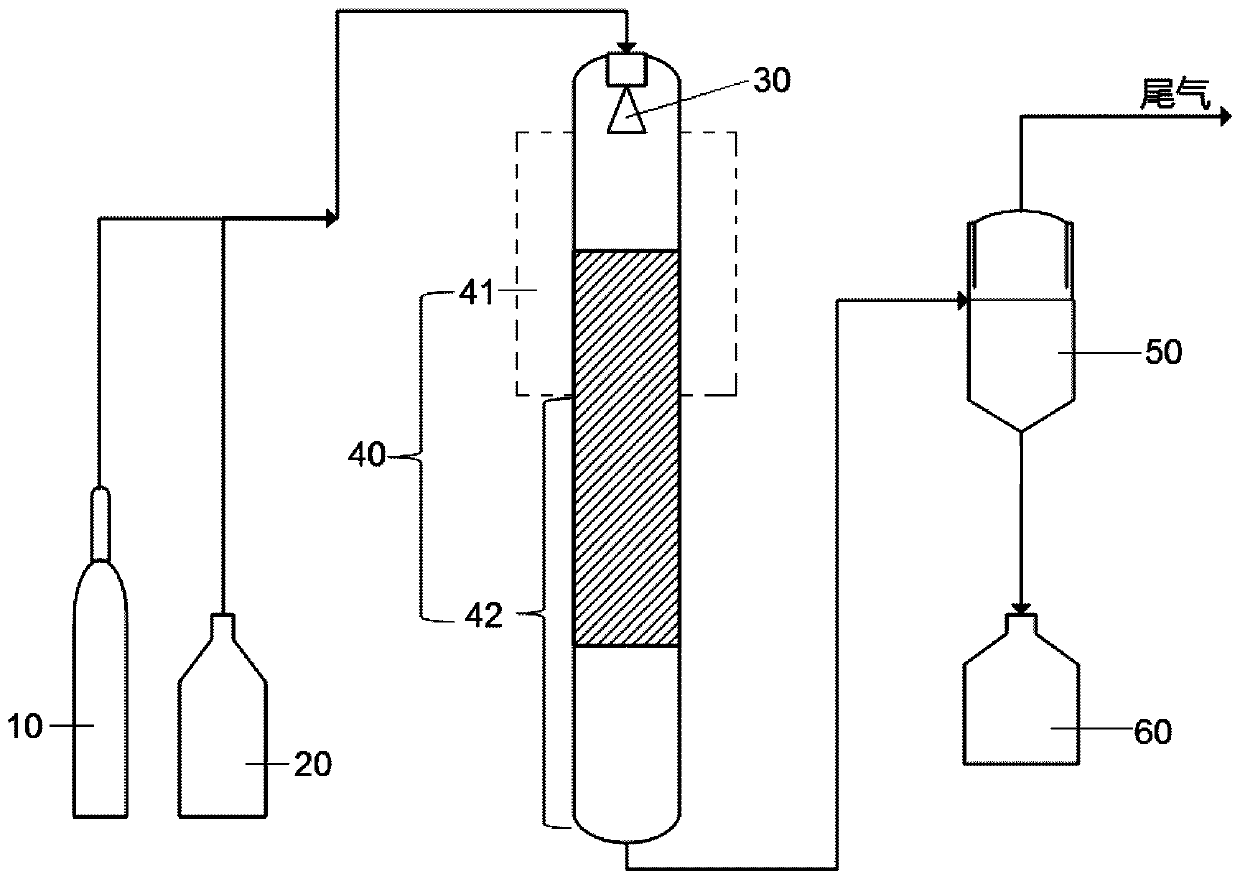

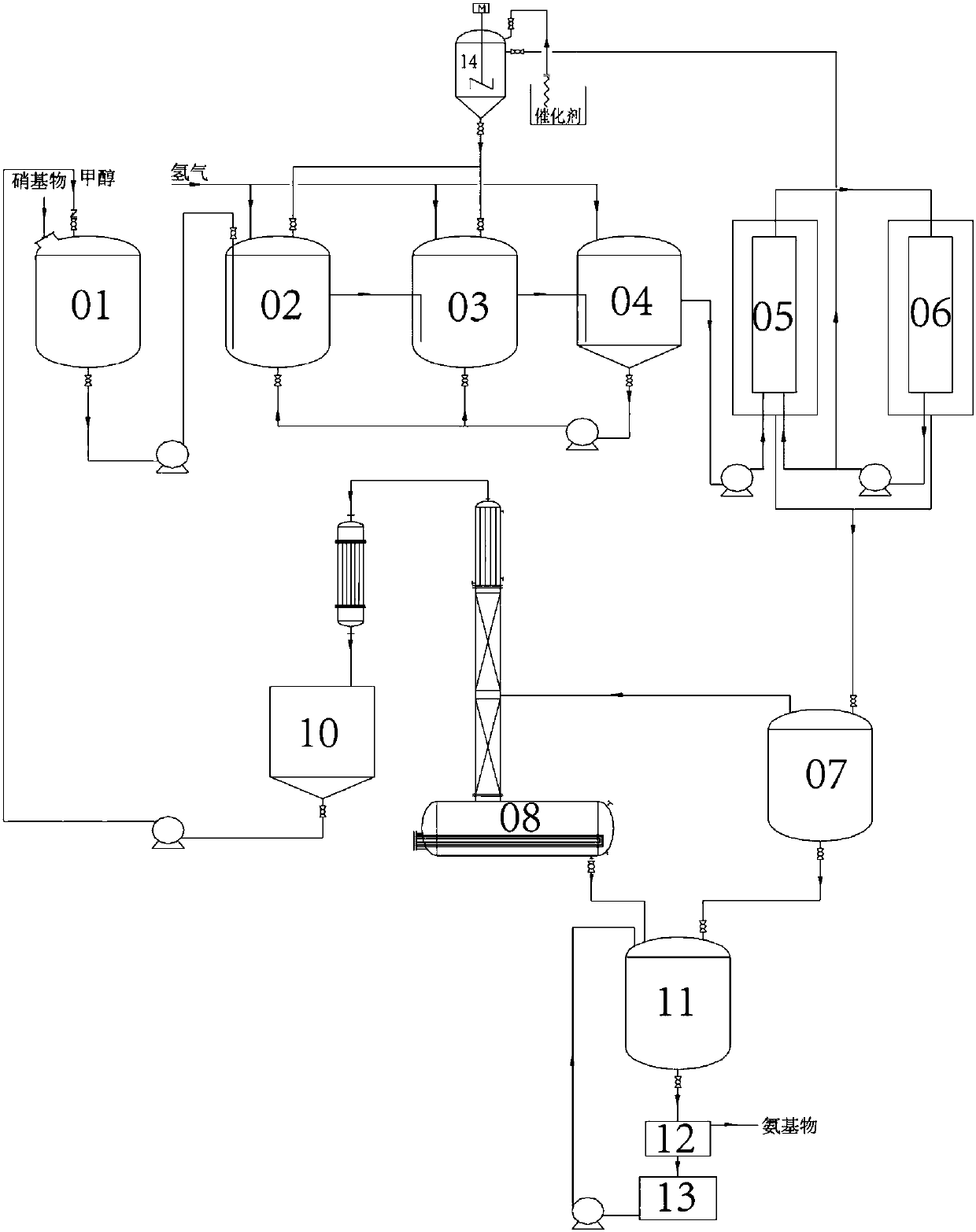

Fluidized-bed reaction device and fluidization reaction method for hydrogenation of nitrobenzene

ActiveCN111298727AImprove fluidization qualityReduce the presence of air bubblesOrganic compound preparationAmino compound preparationPtru catalystGas phase

The invention relates to a fluidized-bed reaction device and a fluidization reaction method for hydrogenation of nitrobenzene. The invention mainly aims to solve the problems of low gas-solid contactefficiency, large bubble size, low fluidization quality and the like in a fluidized bed. According to a technical scheme in the invention, at least one group of composite components are arranged in afluidized-bed reactor, so when gas and catalyst particles pass through the components, bubbles and particle clusters are broken, fluidization quality is effectively improved, and the above technical problems are well solved; and the device and the method can be applied to industrial production of gas-phase catalytic hydrogenation of nitrobenzene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Furfural catalytic hydrogenation method under supercritical carbon dioxide and method for preparing catalysts

InactiveCN104059035AAchieve conversionNo carbon depositsOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsPalladium on carbonLiquid product

Owner:ZHEJIANG UNIV

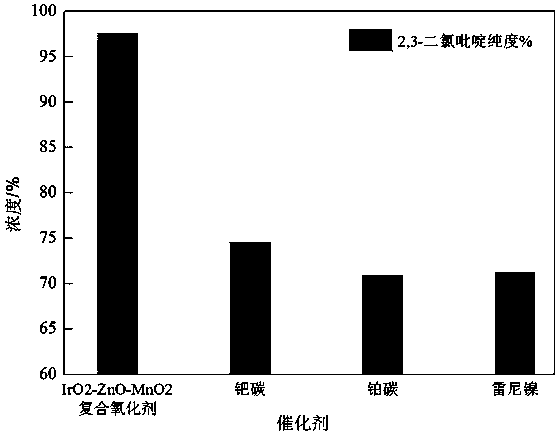

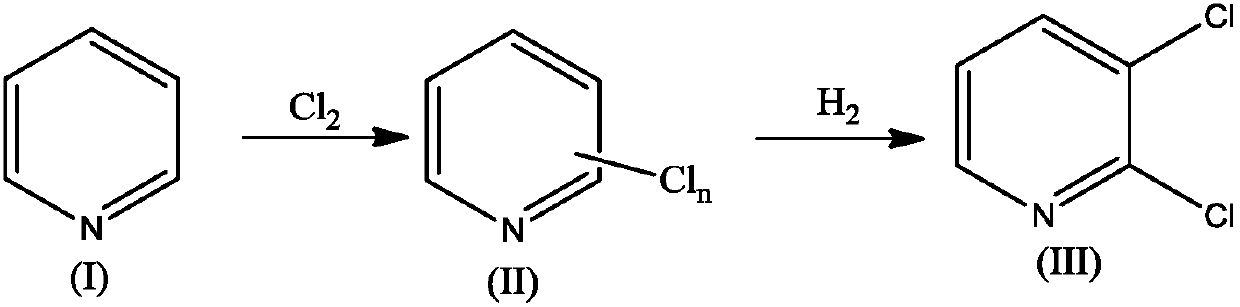

Method for synthesizing 2, 3-dichloropyridine

InactiveCN107628988AExcellent catalytic performanceHigh purityOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsHydrogenSynthesis methods

Owner:JIUJIANG SHANSHUI TECH +1

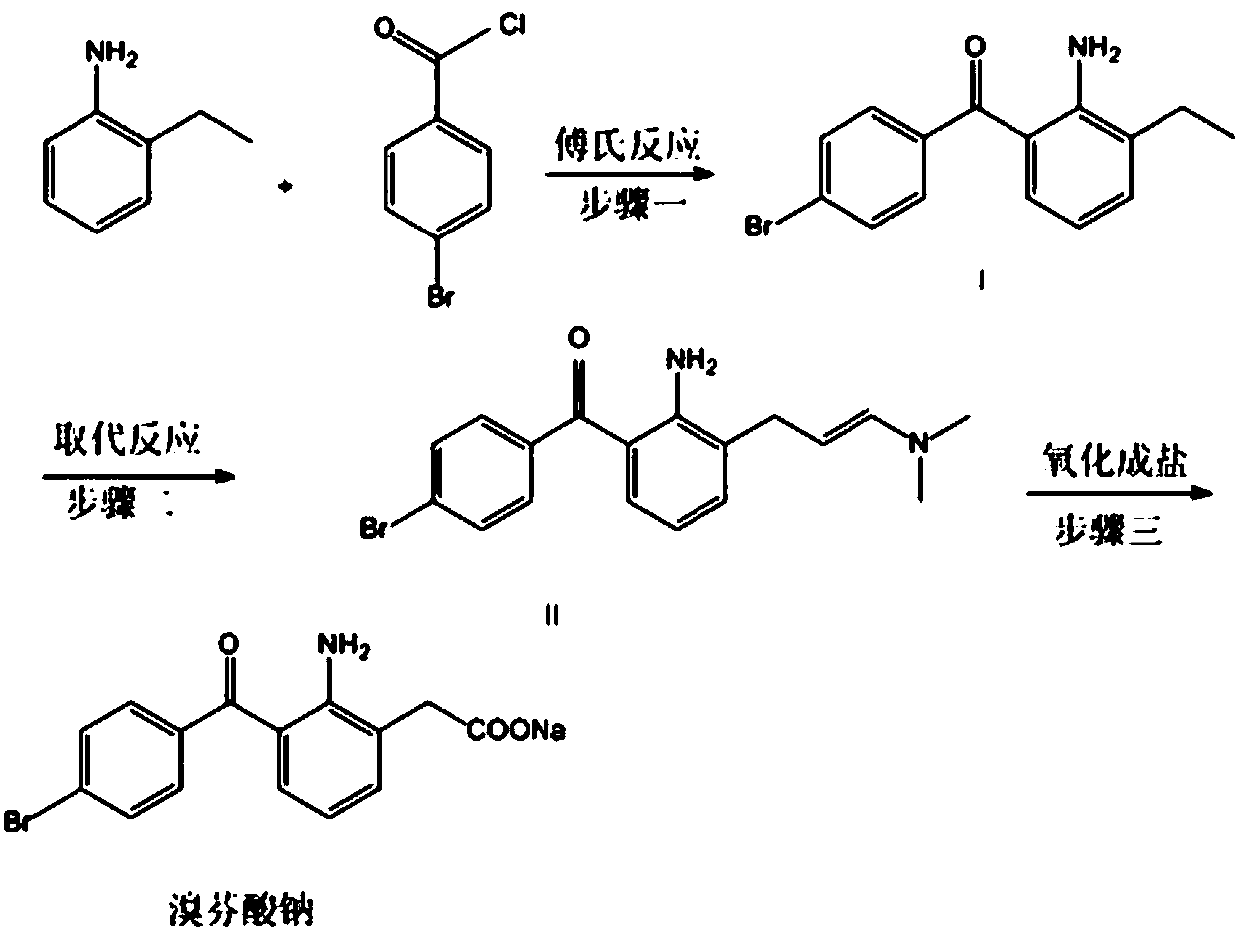

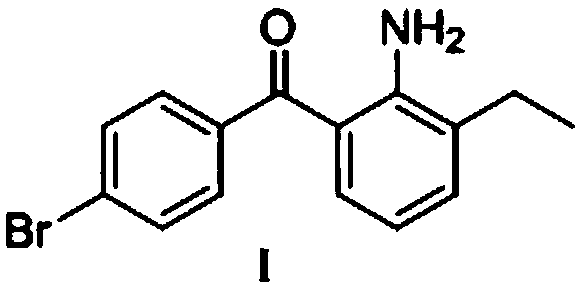

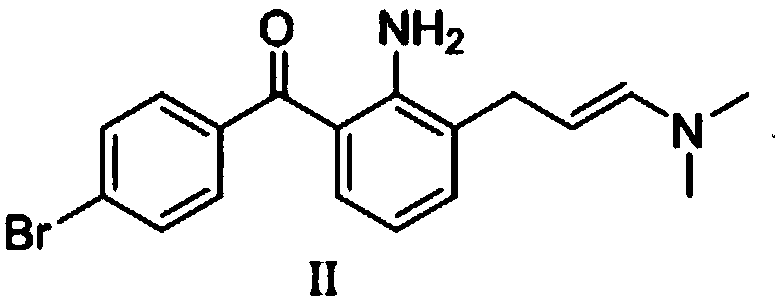

Preparation method of bromfenac sodium

PendingCN109988075AReduce usageSimple processOrganic compound preparationAmino-carboxyl compound preparationPhosphoric acidChloride

Owner:TIANJIN PHARMA GROUP CORP

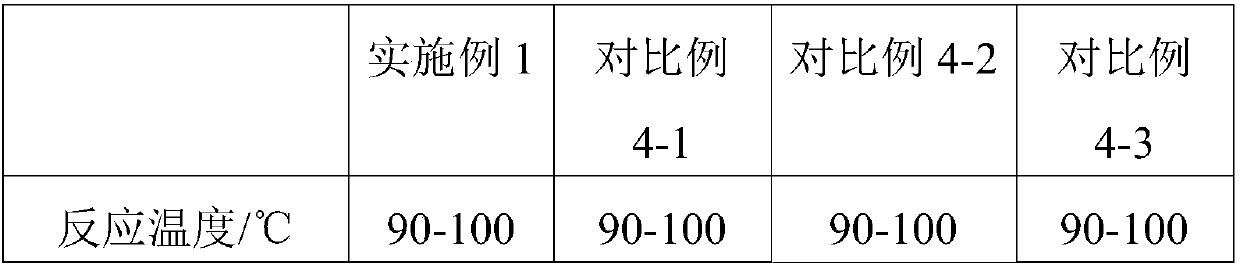

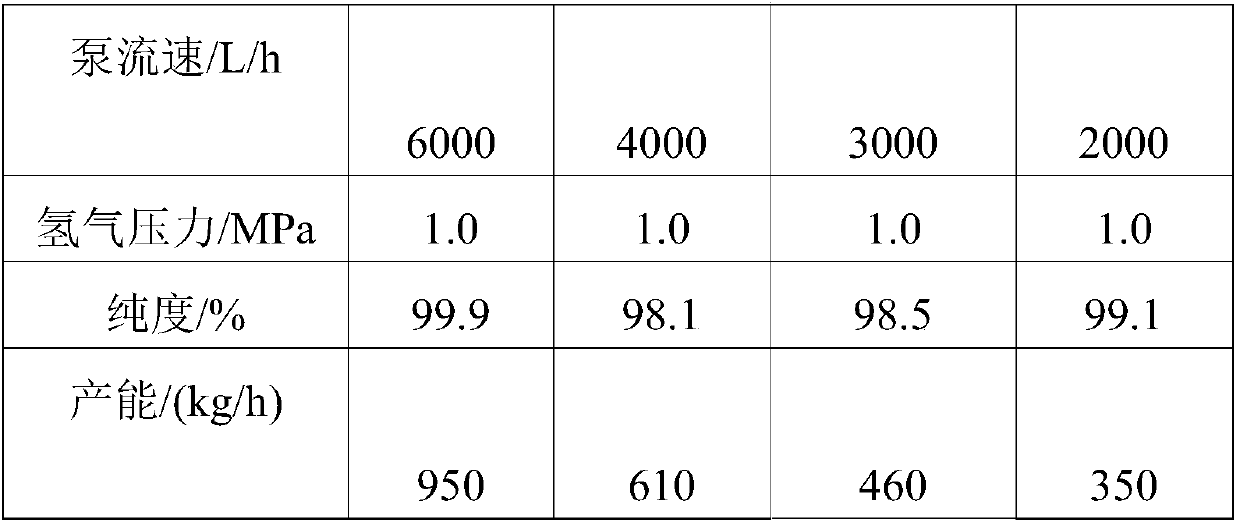

Continuous hydrogenation method and application of ethyl pyrazine-2-carboxylate

ActiveCN111559983ARaise the degree of adequate responseShort reaction timeOrganic chemistryTemperature controlPyrazine

Owner:ASYMCHEM LIFE SCI TIANJIN

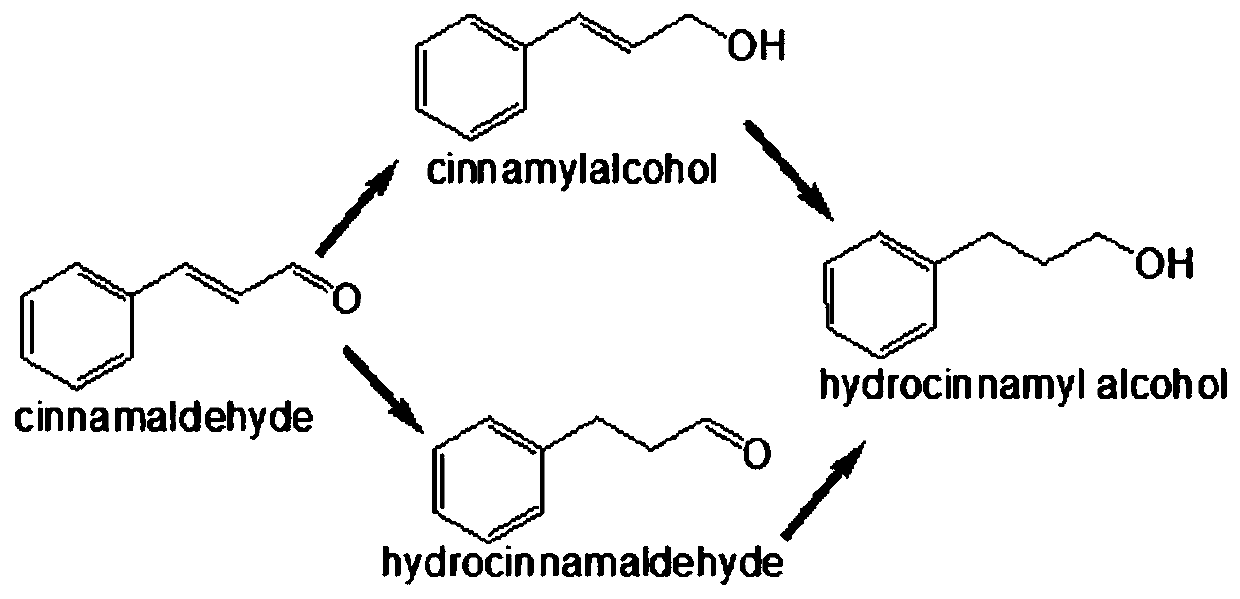

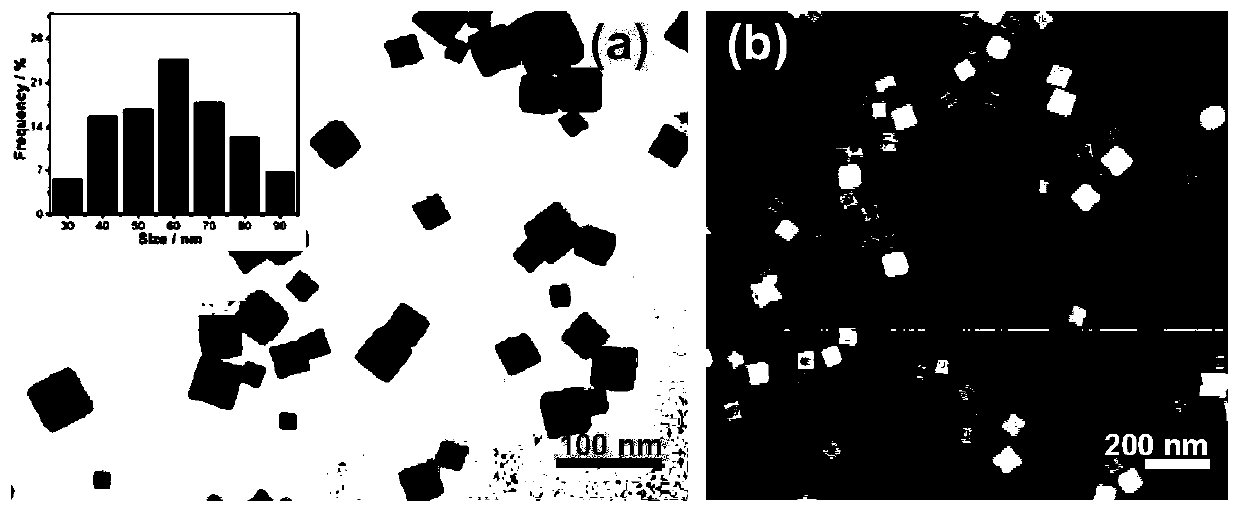

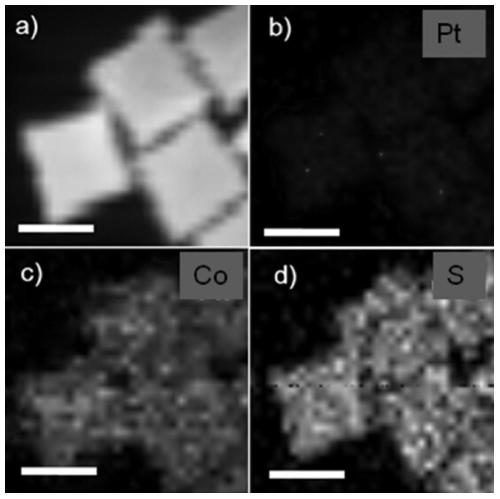

Method for improving cinnamyl alcohol production yield and selectivity

InactiveCN111298810AGood selection of hydrogenation performanceAvoid passivationPhysical/chemical process catalystsOrganic compound preparationPtru catalystSulfite salt

Owner:王冲

Method for preparing fuel oil by taking waste lubricating oil as raw material

InactiveCN103756725ASolve the disadvantages of landfill disposalReduce pollutionTreatment with hydrotreatment processesLubricant compositionPetrochemicalFuel oil

Owner:JINAN DEV ZONE XINGHUO SCI & TECH RES INST

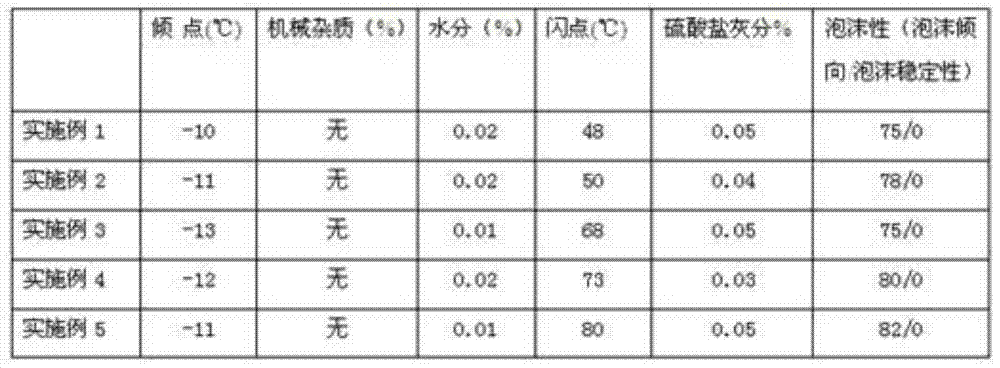

Preparation method of m-aminobenzole

InactiveCN108047067AOrganic compound preparationAmino-hyroxy compound preparationChemistryCatalytic hydrogenation

Owner:YANTAI ANOKY FINE CHEM CO LTD +4

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap