Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

28 results about "Circulating pump" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A circulating pump – a device that causes the flow of liquid in circuits of heating or cooling installations. The circulating pumps are used only as centrifugal pumps. The basic elements of the centrifugal pump are coiled housing with two ports, suction and discharge, and what is more, blade rotor mounted on a shaft driven be an electric motor. The ports of the circulating pump can be arranged in one axis or suction axis that can be perpendicular to the axis of discharge port. The mechanical energy delivered to the circulating pump via motor is transmitted through the rotor to the liquid flow causing the increase in pressure and speed. The energy increase of the liquid occurs only in the circulating pump rotor, which is the only element of the energy transmission. However, in the remaining parts, one type of energy changes into another e.g. kinetic energy into pressure energy. For instance, in the coiled shaped housing, part of kinetic energy changes into potential energy, which causes a further increase in the fluid pressure. Pressure generated by the pump is used to overcome resistance of the liquid flow through the heating or cooling circuit.

3D printer

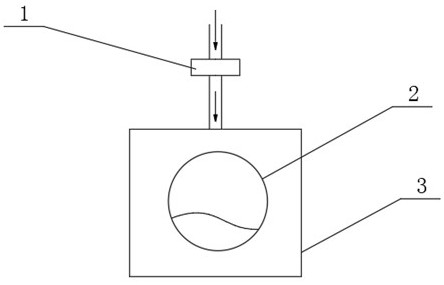

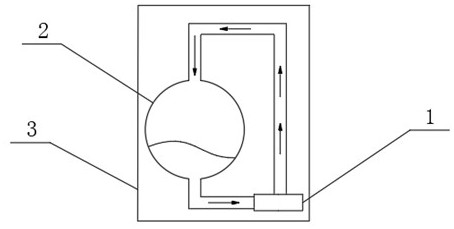

InactiveUS20170050389A1Improve liquidityImprove printing qualityManufacturing enclosuresManufacturing recyclingEngineering3d printer

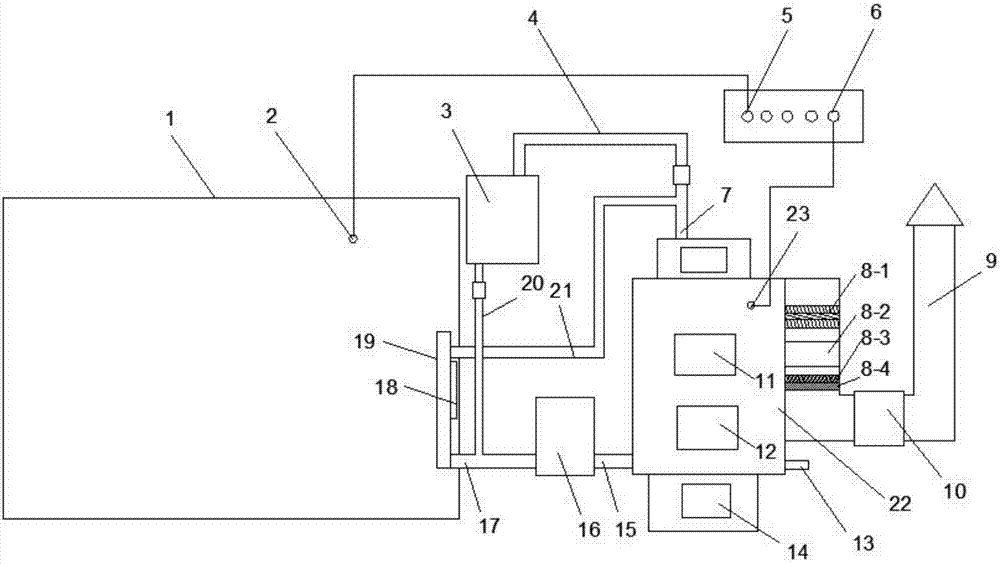

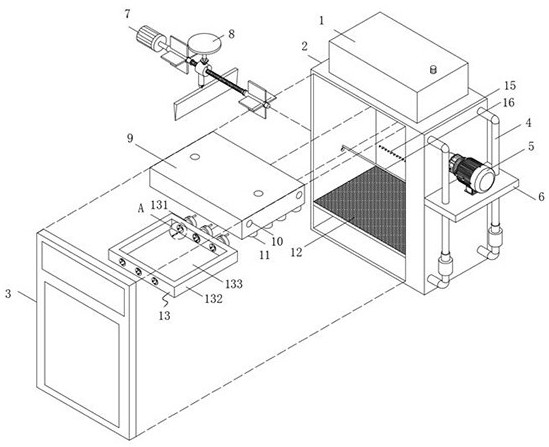

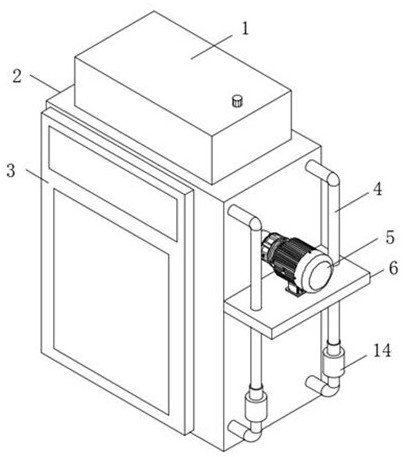

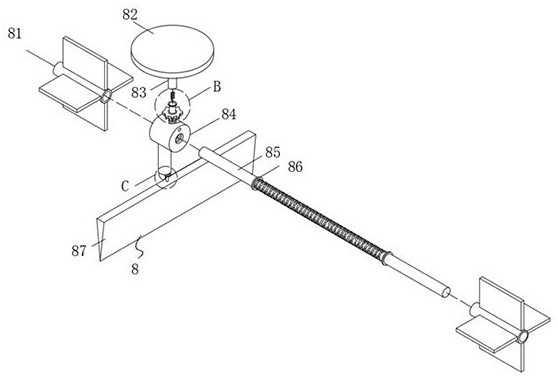

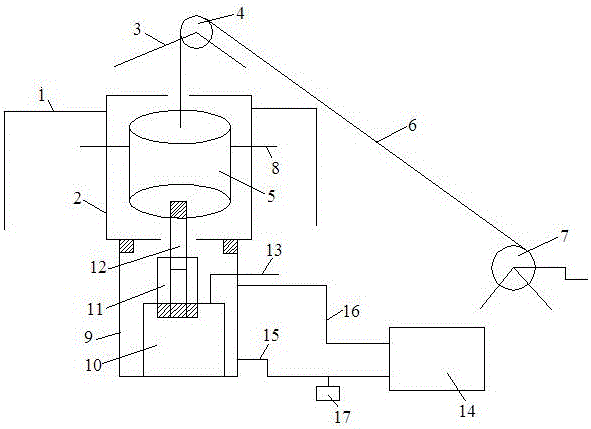

Disclosed is a 3D printer including a resin container which is filled with a photocurable liquid resin; a circulating pipe which forms a circulating channel through which the liquid resin is drained out of the resin container and then returned to the resin container; a circulating pump which circulates the liquid resin in the circulating channel; a heating unit which heats the liquid resin; and a filter which filters out impurities from the liquid resin in the circulating channel. According to the present invention, there is provided a 3D printer, in which cured floaters are easily removed by increasing fluidity of a liquid resin, a printed object is improved in quality, and the liquid resin is automatically replenished.

Owner:LEE BYUNG KEUK

System and method for producing hydrogen by directly electrolyzing urea-containing wastewater with renewable energy

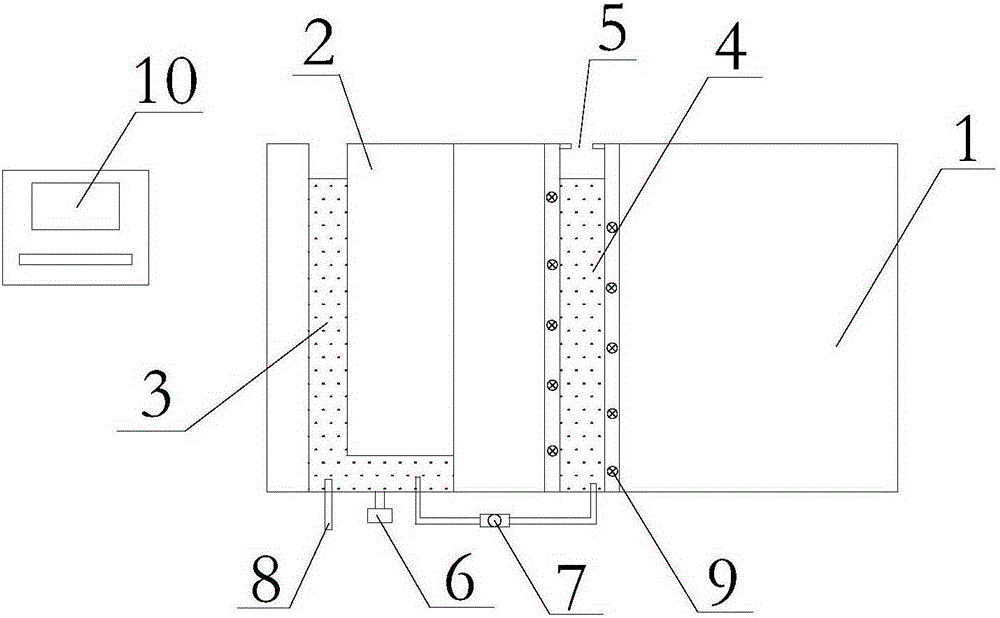

The invention discloses a system and method for producing hydrogen by directly electrolyzing urea-containing wastewater with renewable energy. The system comprises a renewable energy generation module, a power conditioning module, a urea-containing wastewater pretreatment module, an alkaline urea electrolytic hydrogen production module, a gas / liquid separation, drying and purifying module, an alkaline liquor circulating pump, a hydrogen storage tank and an anode product storage module, wherein an output end of the renewable energy generation module is connected with an input end of the power conditioning module, and an output end of the power conditioning module is connected with the alkaline urea electrolytic hydrogen production module. By means of the system, nearby in-time consumption of renewable energy power is facilitated, the hydrogen production cost is r educed, the tolerance of the hydrogen production system to the volatility and intermittence of a power supply is improved, a hydrogen production technology is combined with a water treatment technology, and while the hydrogen production energy consumption is reduced, environmental pollution is avoided; the applicability of the system is wide, the stability is high, the hydrogen produced by the system is high in purity, the process is simple, and industrial production is facilitated.

Owner:闫巍

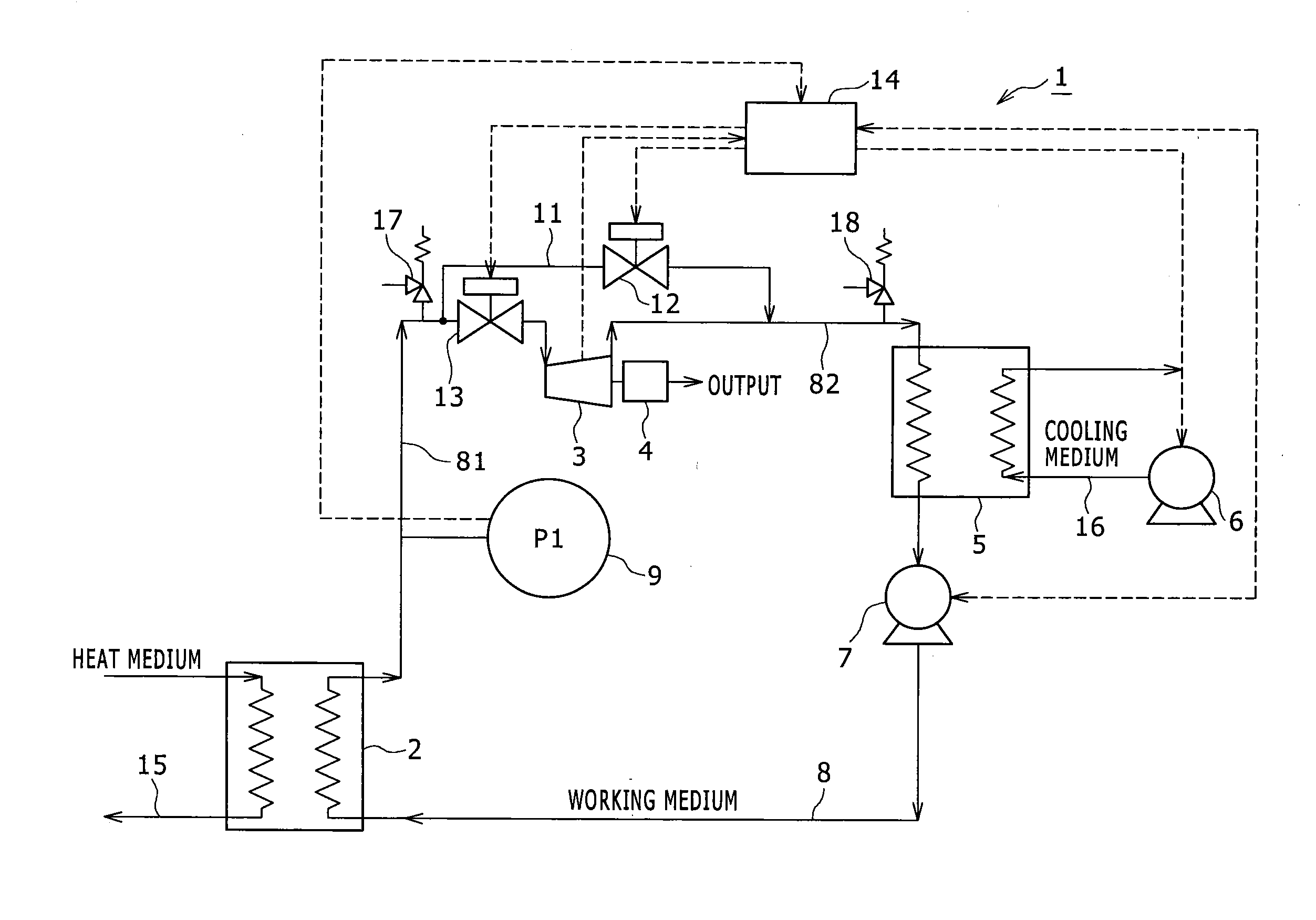

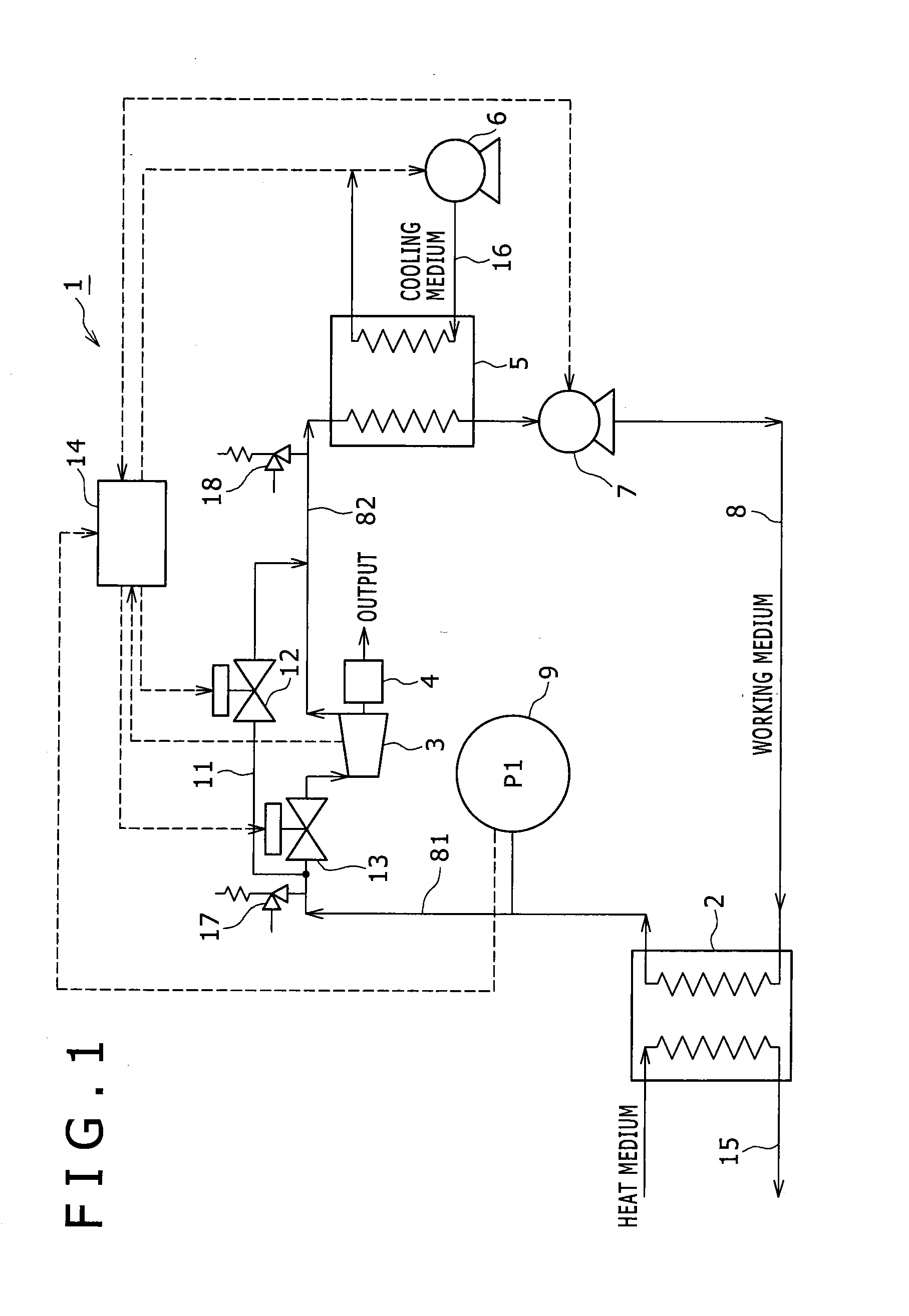

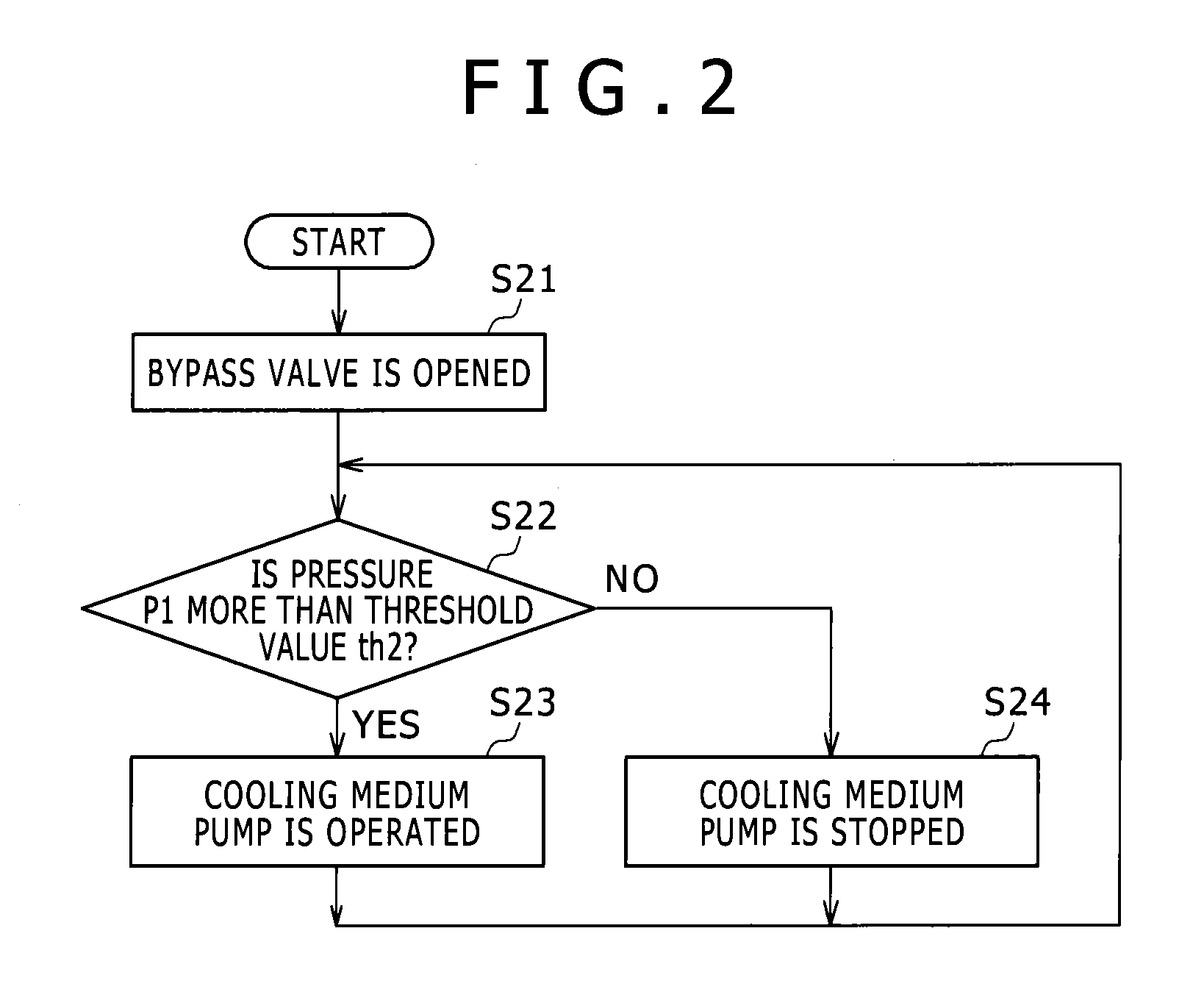

Thermal energy recovery device and control method

Owner:KOBE STEEL LTD

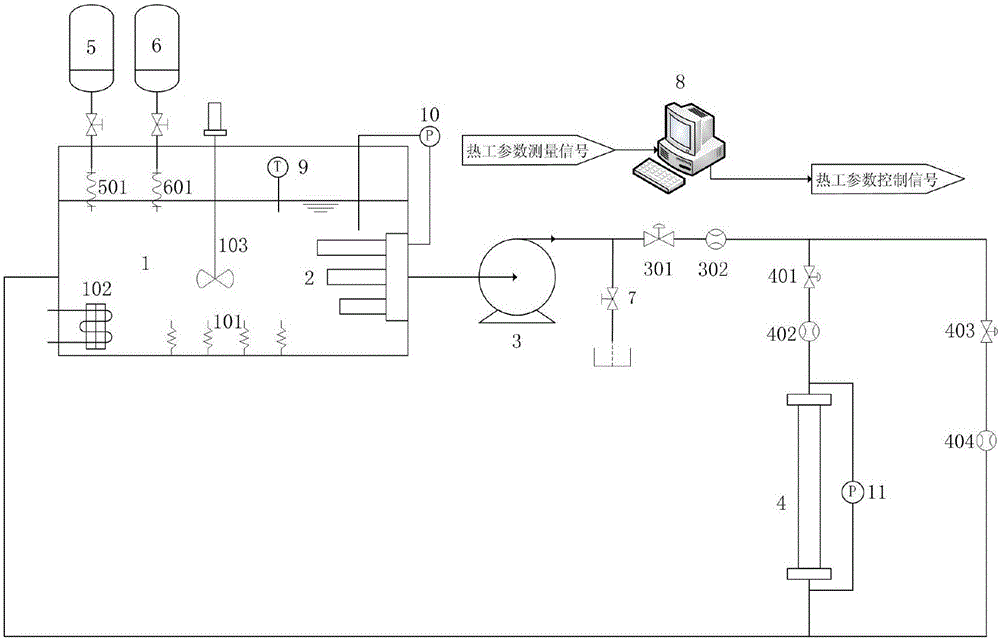

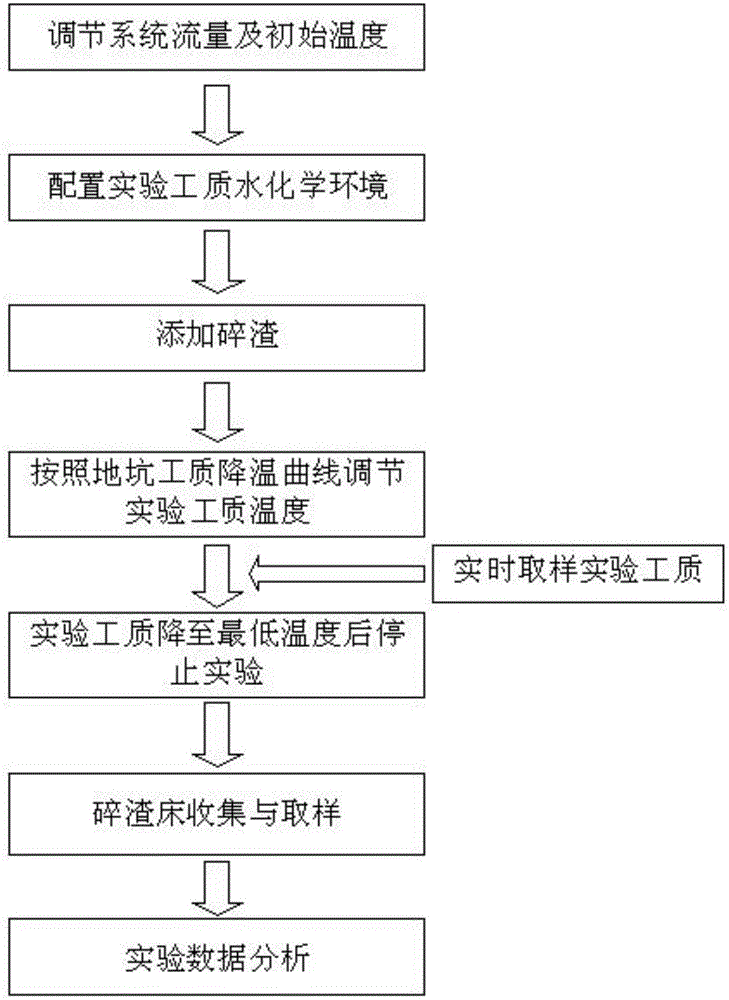

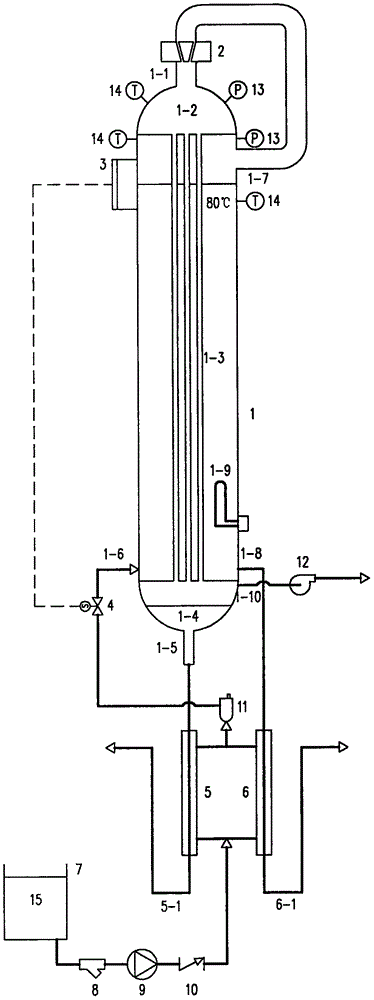

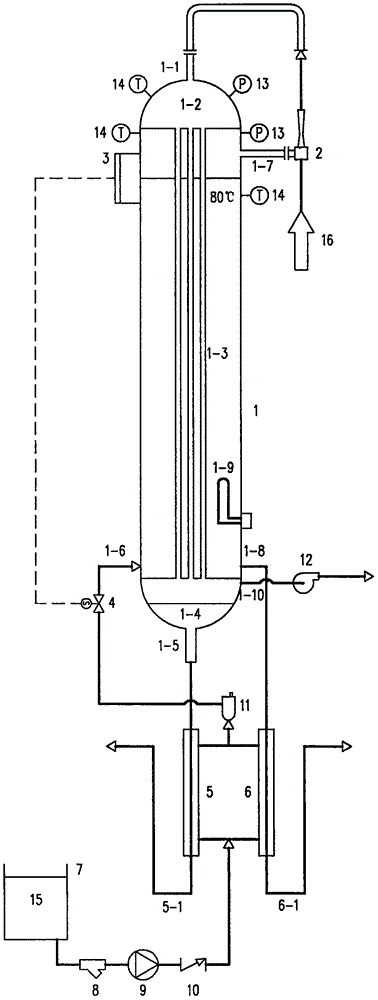

Containment pit strainer overall performance experimental system and method

ActiveCN106448760AClogged hydraulic properties gainHydraulic properties gainNuclear energy generationNuclear monitoringComputer moduleEngineering

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Human cell sample storage device for precision medical treatment

The invention relates to a human cell sample storage device for precision medical treatment. The human cell sample storage device comprises a bearing base, a protective wall, bearing cavities, circulating pumps, culture medium storage tanks, semiconductor refrigeration devices, electric heating wires, irradiation inactivation devices, a driving power supply and a control system, wherein the bearing base comprises protective side walls, bearing keels, a bearing platform and a positioning table; the bearing cavities are installed in the positioning table by locating holes; each bearing cavity and the corresponding locating hole are distributed in a coaxial way; connecting threads are arranged on the outer side face of the positioning table; the circulating pumps and the culture medium storage tanks are embedded in the bearing keels of the bearing base; the semiconductor refrigeration devices are embedded in the positioning table; the electric heating wires are evenly distributed on the walls of the locating holes and the outer surfaces of the culture medium storage tanks; the irradiation inactivation devices are respectively embedded in the bearing cavities. After the human cell sample storage device is used, a cell storage mode can be flexibly selected; the human cell sample storage device is good in universality and high in use safety, can avoid the pollution, caused by leakage and the like, to the surrounding environment, and can meet the demands of inactivated cell storage and cell activity preservation at the same time.

Owner:CHENGDU YUYA TECH

Siphon circulation, contraflow heat regeneration and vapor compression distillation device

InactiveCN105920863ASave investmentSave power consumptionEvaporation with vapour compressionSeawater treatmentSiphonWater vapor

Owner:侴乔力 +1

Continuous production equipment and process for hexafluoropropylene oxide oligomer

PendingCN111530383AContinuous operationReduce consumptionChemical recyclingCarboxylic acid halides preparationOligomerPtru catalyst

The invention provides continuous production equipment and a continuous production process for a hexafluoropropylene oxide oligomer. The continuous production equipment comprises a stirring kettle anda liquid phase separation kettle, wherein a stirrer is arranged in the stirring kettle; a discharge pipe is arranged at the bottom of the stirring kettle; a discharge pipe is arranged at the bottom of the liquid phase separation kettle; the discharging pipe is communicated with the discharge pipe through a feeding pipe; the feeding pipe is provided with a conveying pump; the top of the stirring kettle is communicated with the top of the liquid-phase separation kettle through a liquid-phase circulating pipe and a gas-phase circulating pipe respectively; the liquid-phase circulating pipe is provided with a circulating pump; the gas-phase circulating pipe is provided with a condenser; one end of the liquid-phase circulating pipe, which is positioned at the liquid-phase separation kettle, extends into the lower part of the liquid-phase separation kettle; and one end of the liquid-phase circulating pipe, which is positioned at the stirring kettle, is connected with a nozzle. The equipmentand the process have the advantages of continuous production, simplicity in operation, high production efficiency, stable product quality and the like, meanwhile, the catalyst, the solvent and byproducts can be recycled, and the process is low in cost and environmentally friendly.

Owner:JIUDING FLUORIN CHEM CO LTDZHANGPING FUJIAN

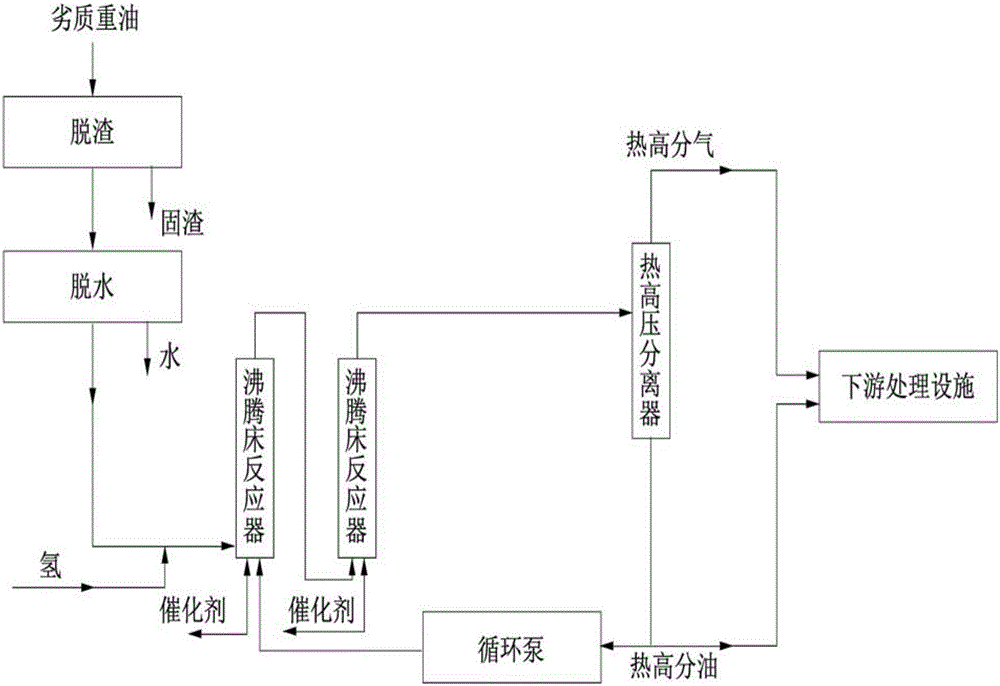

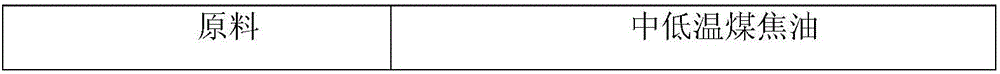

Coal tar all-fraction liquid-phase hydrogenation system and method

InactiveCN105087066AImprove internal space utilizationLess investmentTreatment with hydrotreatment processesHydrogenPre treatment

Owner:SHAANXI MEISILIN ENERGY SCI & TECH RES INST

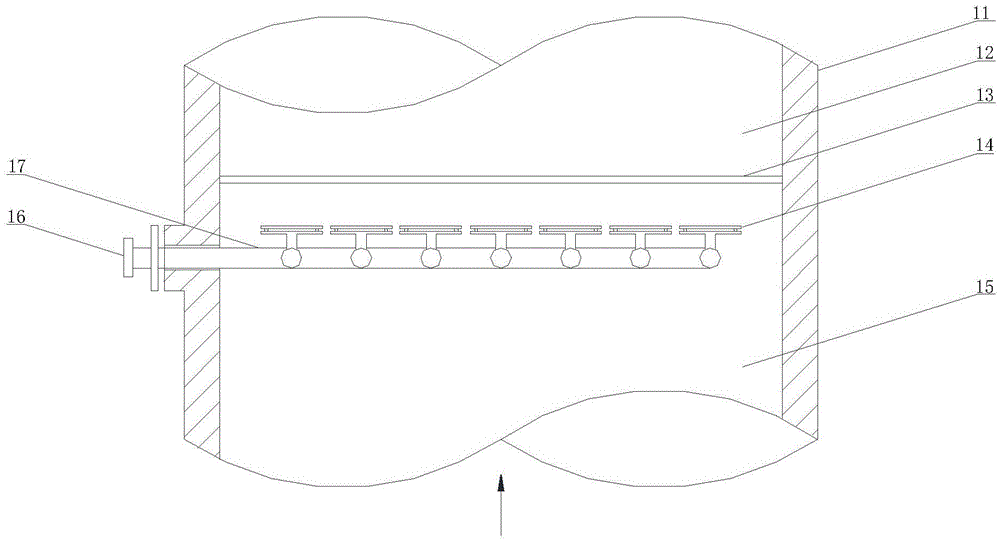

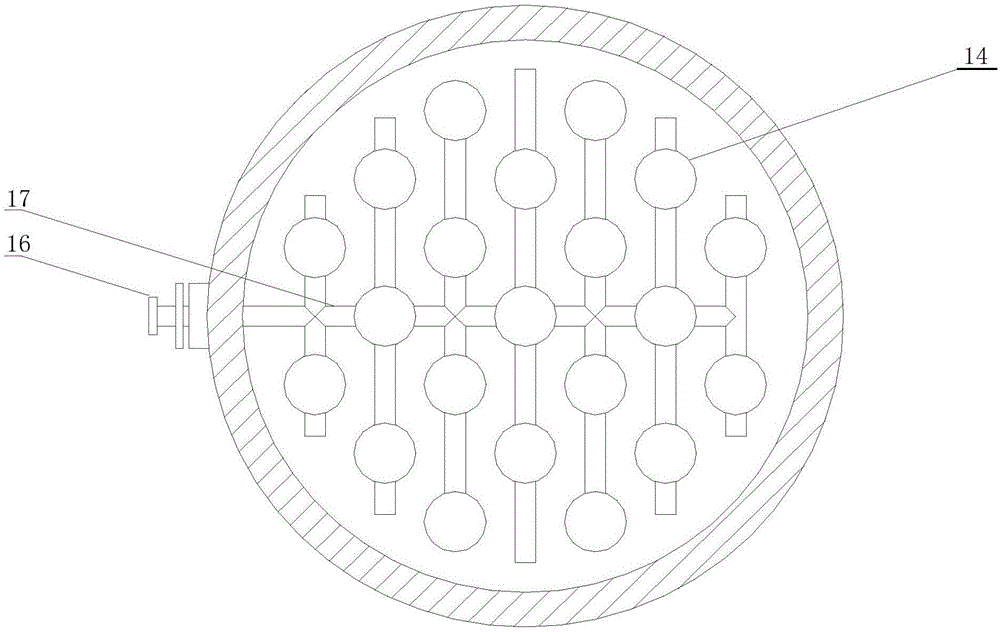

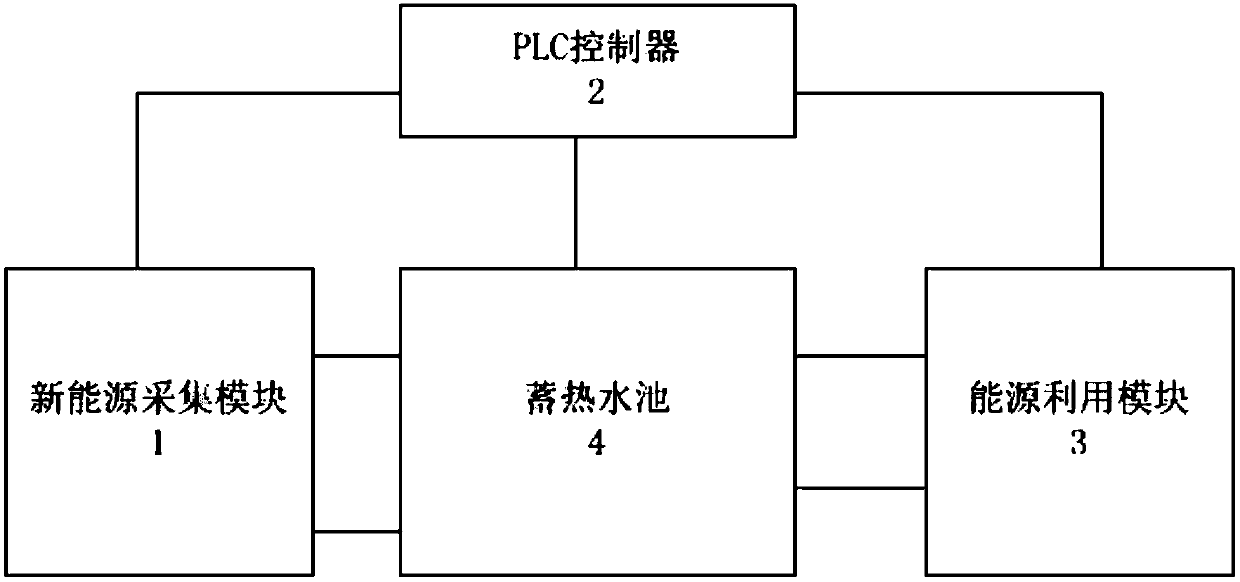

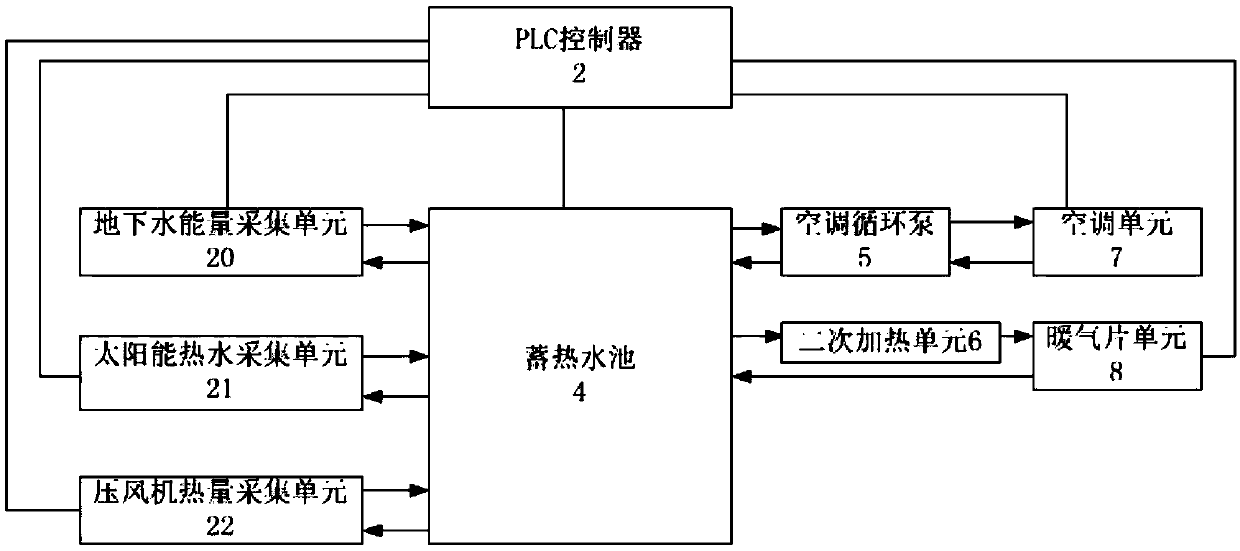

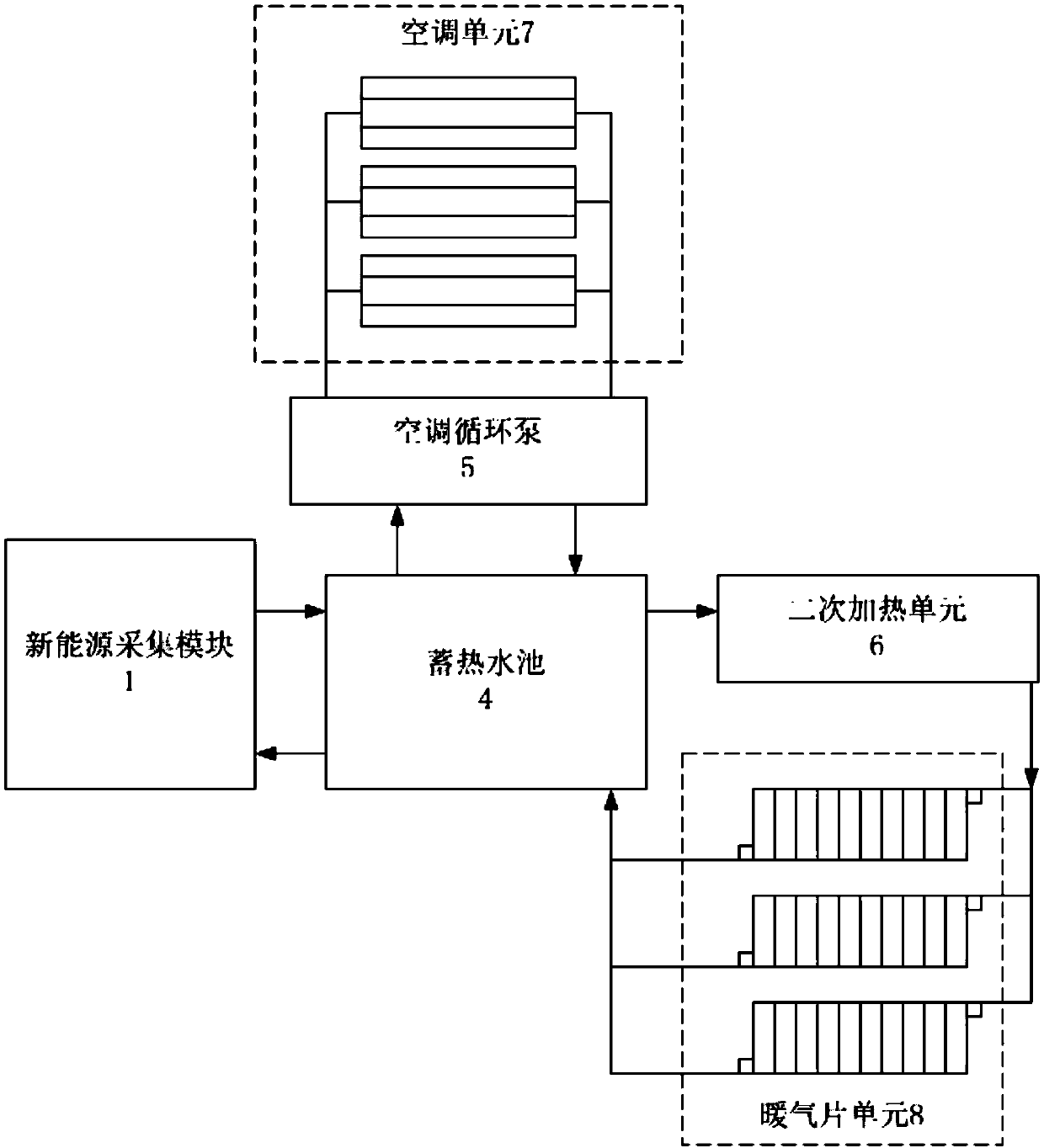

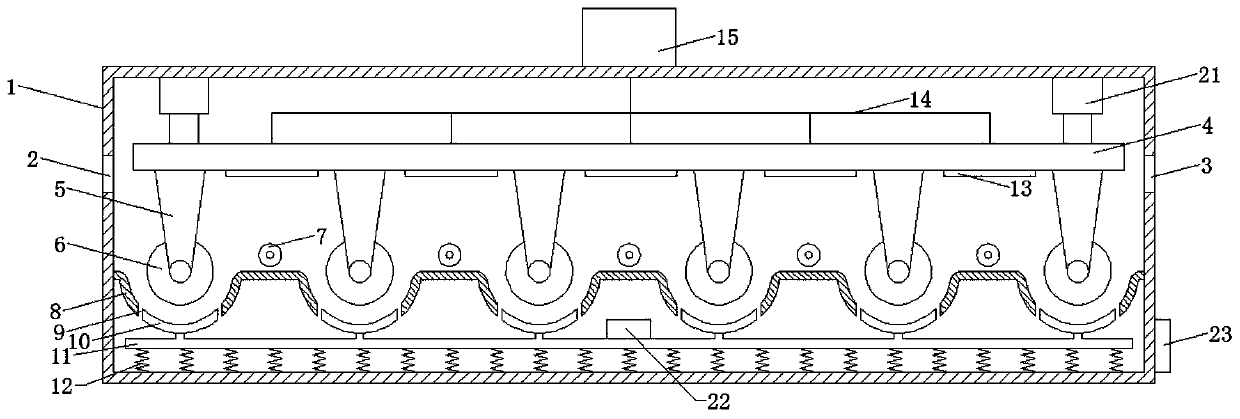

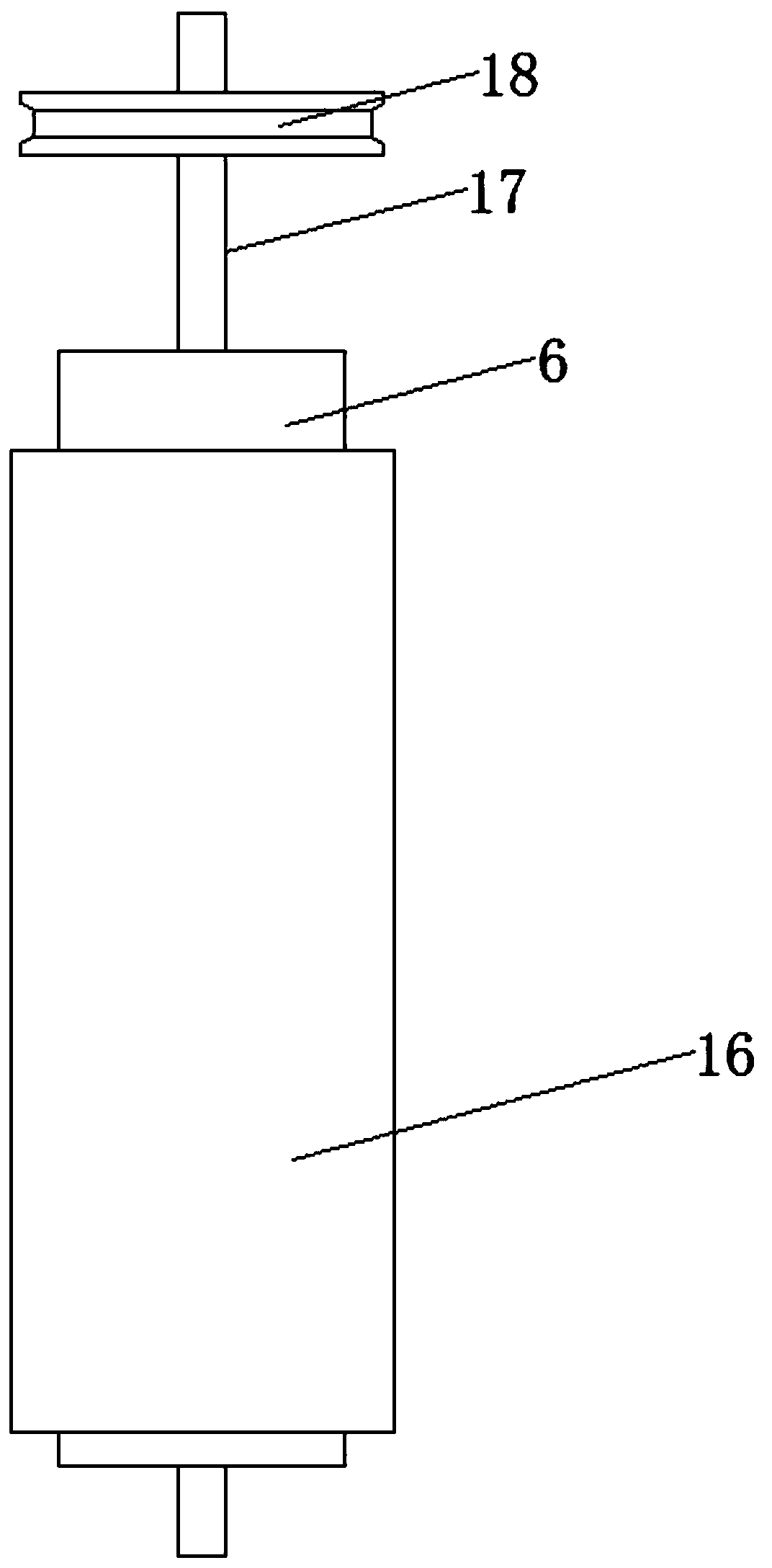

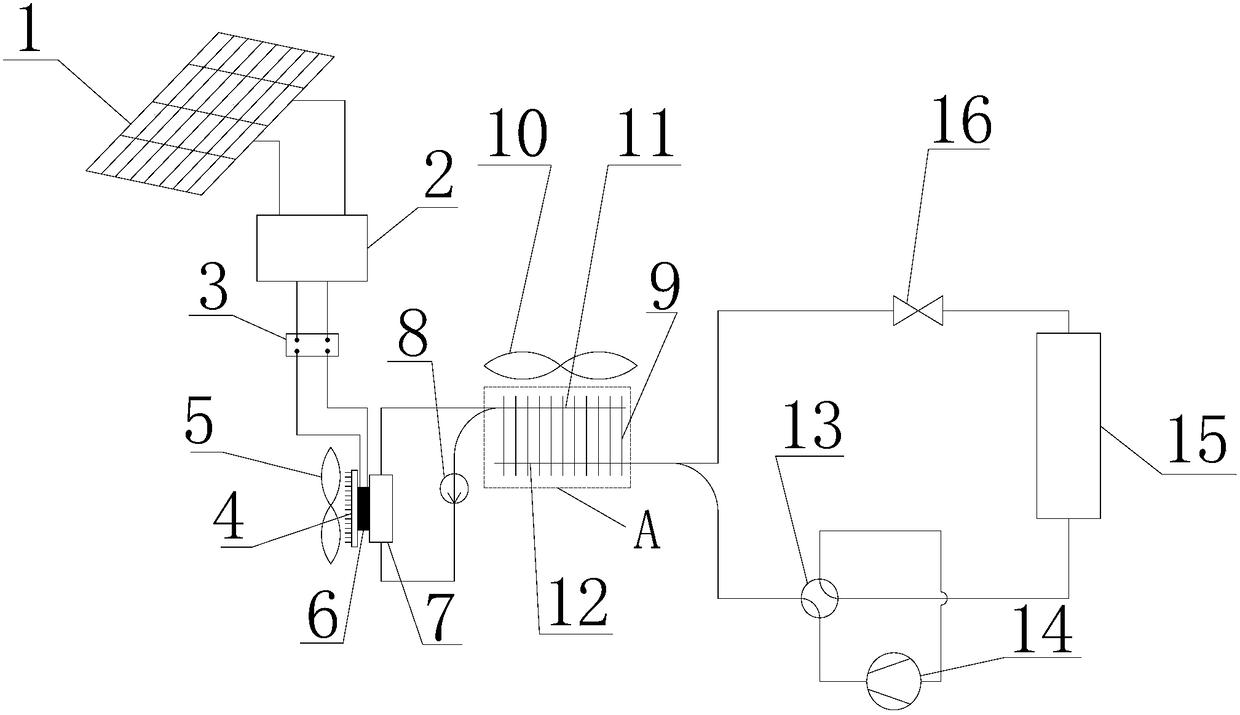

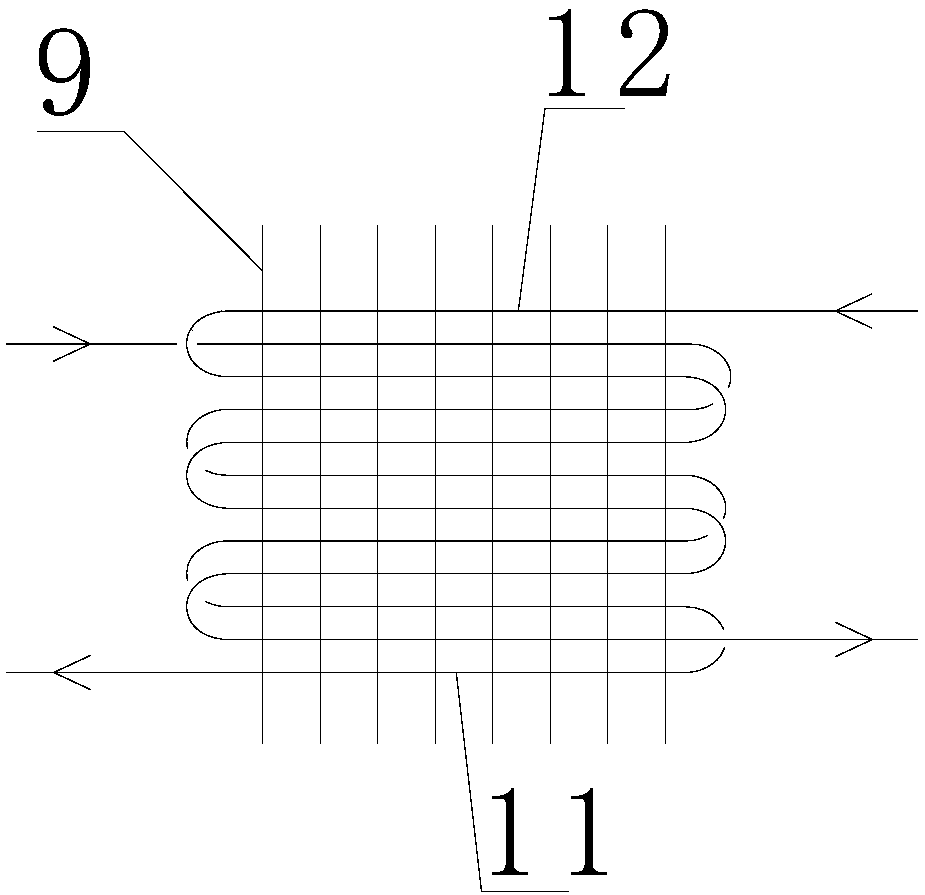

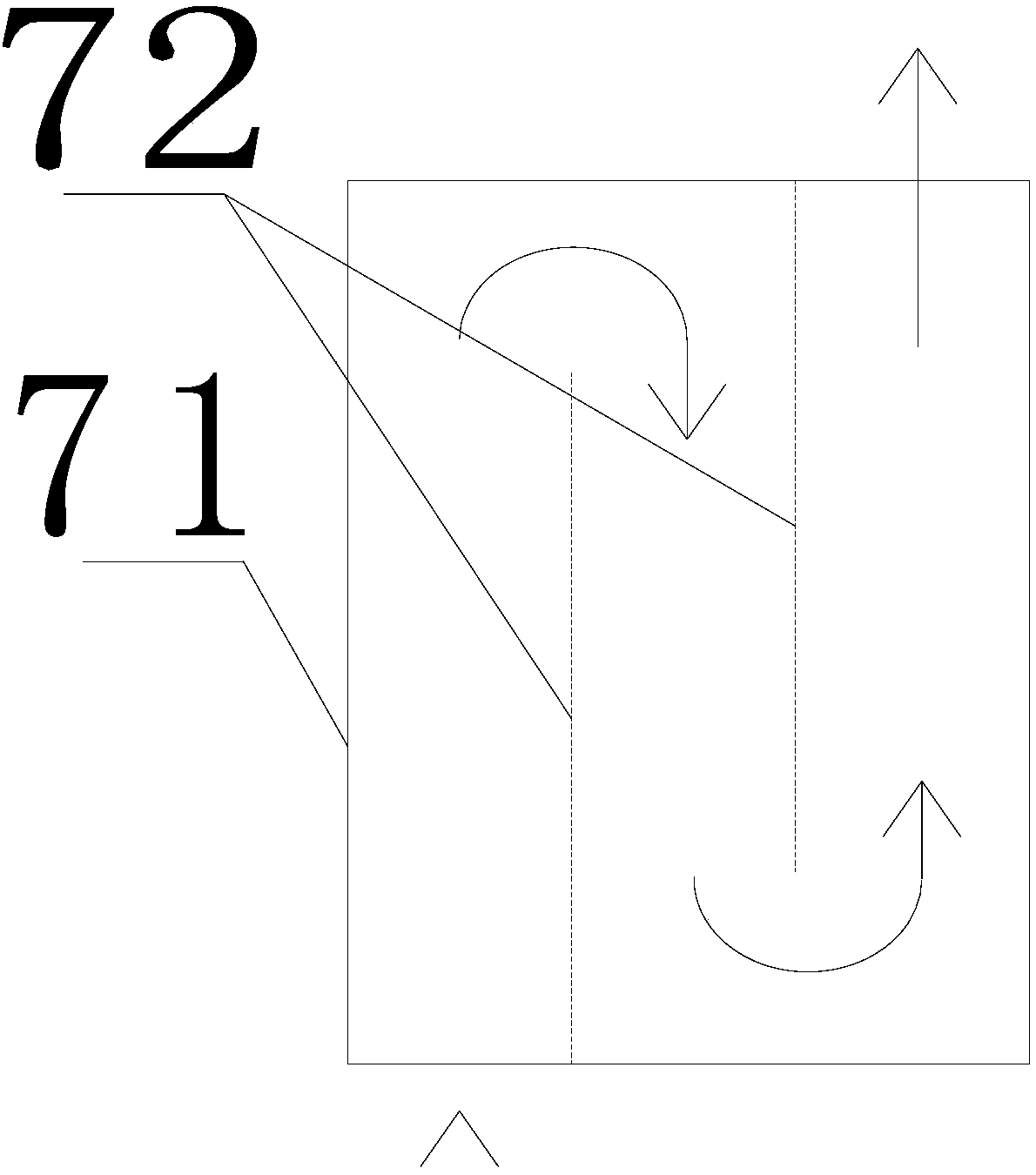

Mine new energy comprehensive utilization system and control method thereof

InactiveCN109611988AAvoid wastingAvoid pollutionSolar heating energyMechanical apparatusWater source heat pumpWater source

Owner:SHANDONG DONGSHAN MINING CO LTD ZHU BAI COAL MINING

Corrosive foil cleaning device

InactiveCN109939981ATimely supplementGuaranteed cleaning effectCleaning using toolsCleaning using liquidsBristleVibration of plates

Owner:JIANGSU LIFU ELECTRODE FOIL

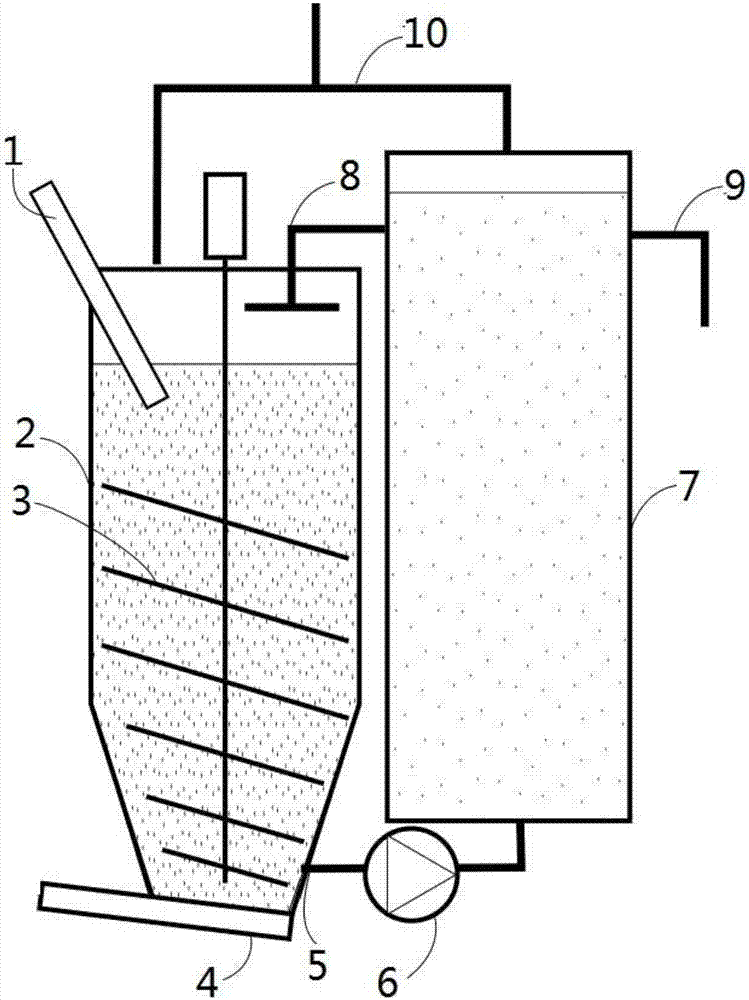

Device and method for fermenting organic matters

PendingCN107034126ABioreactor/fermenter combinationsBiological substance pretreatmentsInternal energyCirculating pump

Owner:ENWISE CO LTD

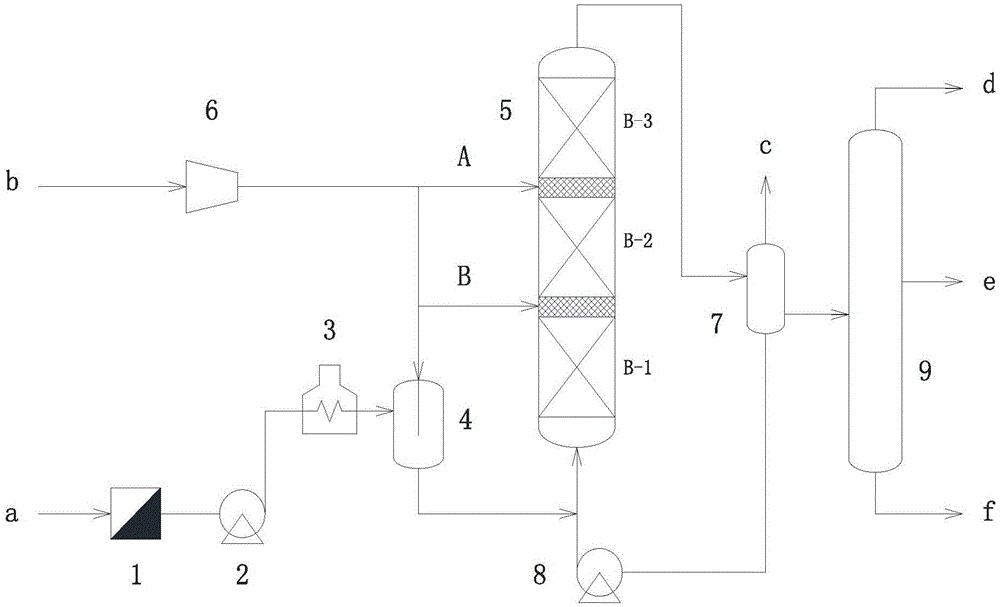

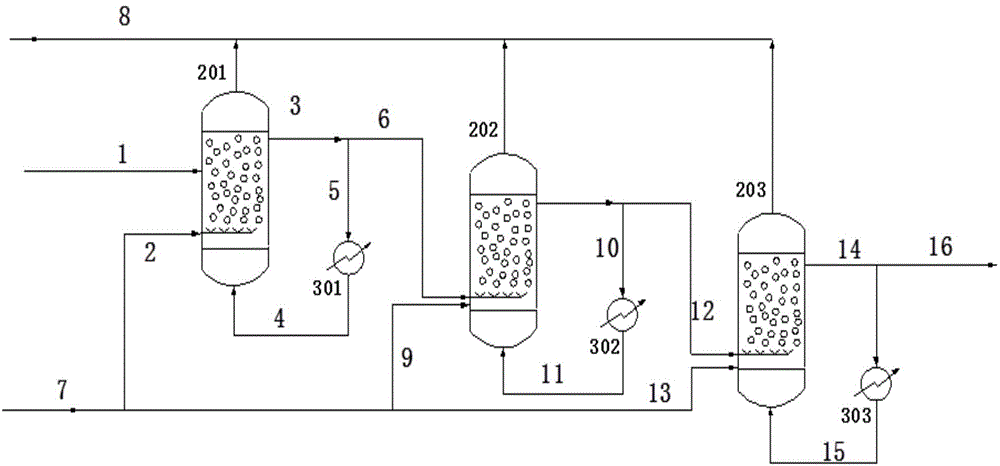

Method for arranging circulating pump in fluidized bed hydrogenation device

ActiveCN106701160AEfficient separationLess investmentHydrocarbon oils treatmentRefining to eliminate hetero atomsHydrogenEtching

Owner:上海竣铭化工工程设计有限公司

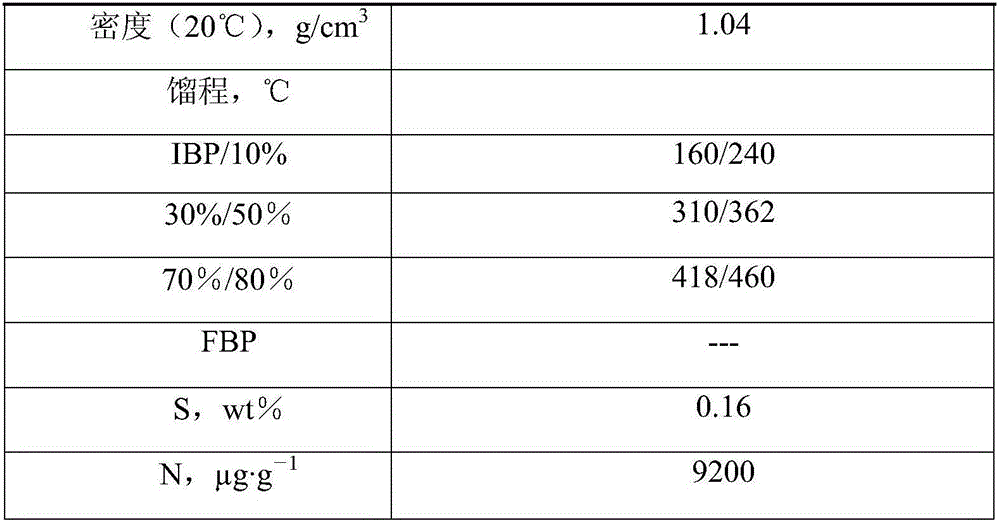

Method for removing low-boiling-point substance in polyether

ActiveCN105037704AMeet production requirementsHigh removal efficiency of low boilersBoiling pointNitrogen

Owner:JURONG NINGWU NEW MATERIAL CO LTD BY SHARES

Disinfection device

PendingCN112336889AExtension of timeEnsure hygiene and safetyLavatory sanitoryChemicalsAir IonizationPlasma generator

Owner:战洋

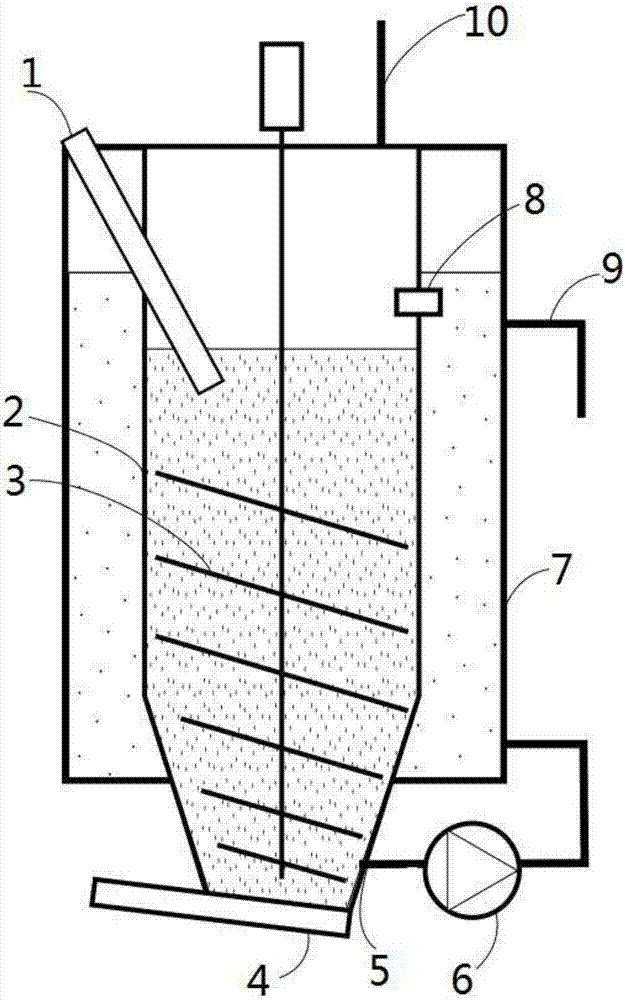

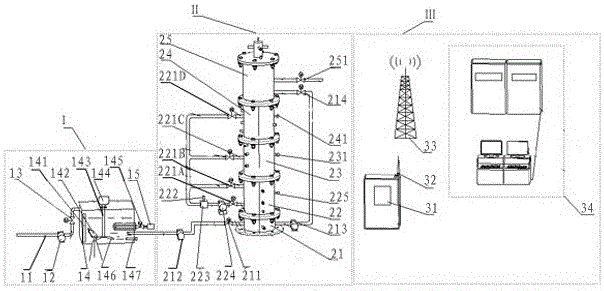

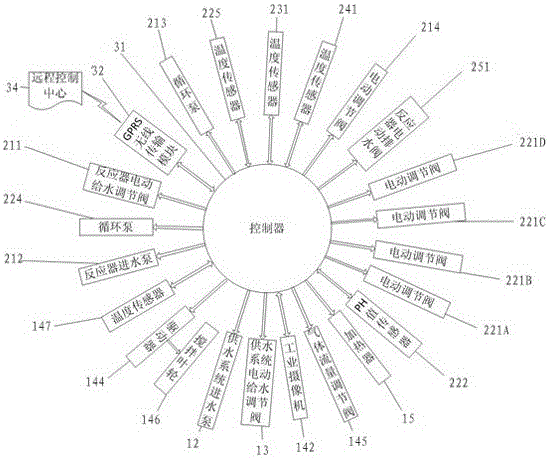

Automatic detection and control system for spiral symmetrical flow anaerobic reactor

ActiveCN105116945AReduce usageReduce manufacturing costTreatment with anaerobic digestion processesSimultaneous control of multiple variablesWireless transmissionRemote control

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

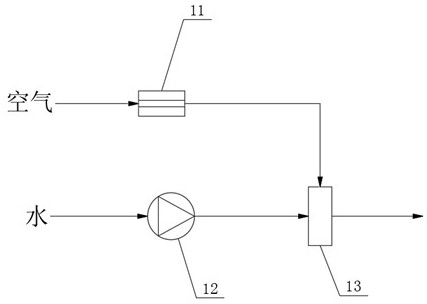

Efficient air source heat pump device

InactiveCN108204694AReduce summer condensing temperatureRaise the evaporation temperature in winterHeat pumpsMachines using electric/magnetic effectsBusiness efficiencyCondensation temperature

Owner:ZHEJIANG SCI-TECH UNIV

Hot press machine for bamboo wood veneering

InactiveCN105666601AExtended service lifePrevent adhesionLaminationLamination apparatusPulp and paper industryCirculating pump

Owner:ANHUI FUQIANG BAMBOO IND CO LTD

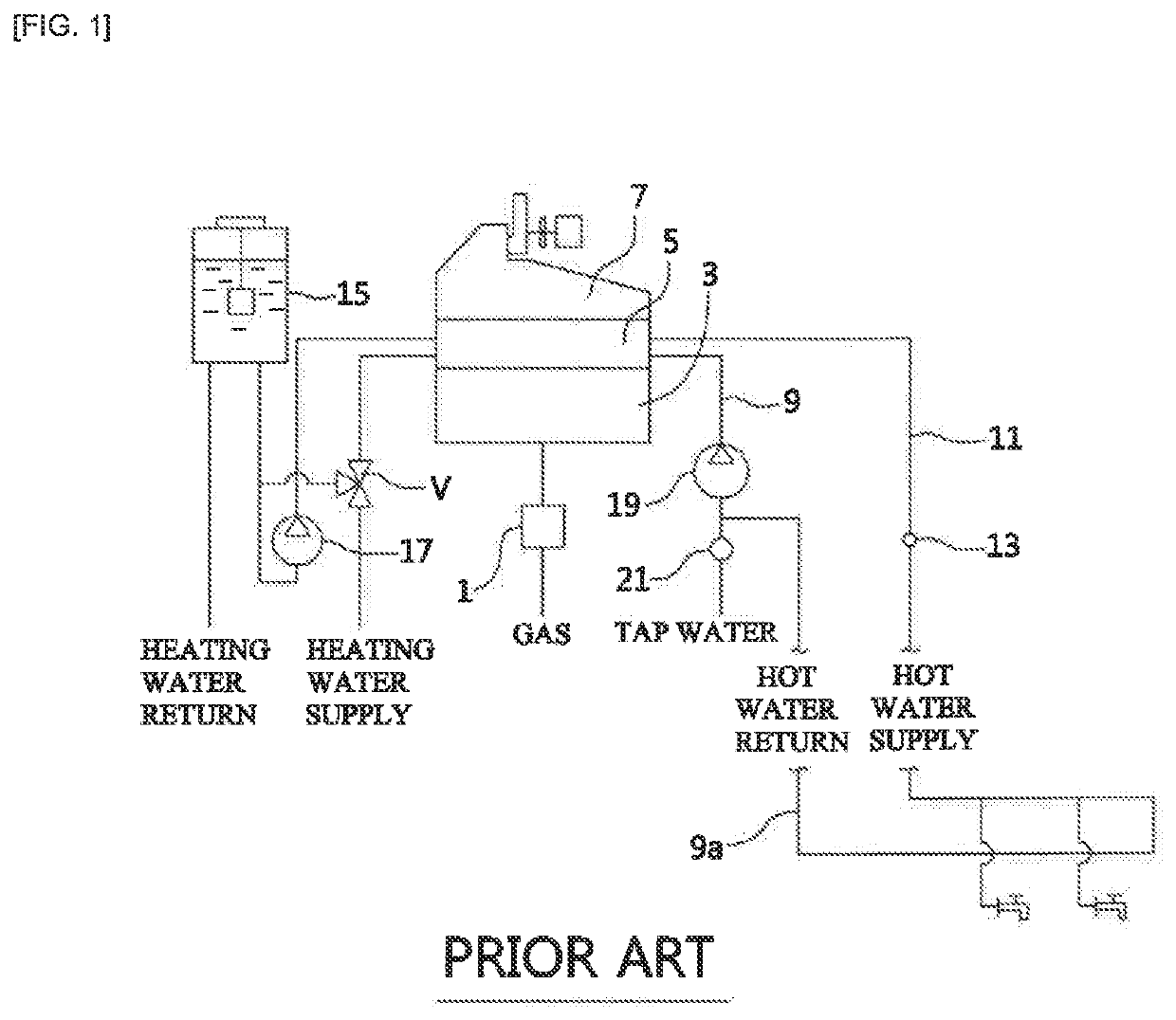

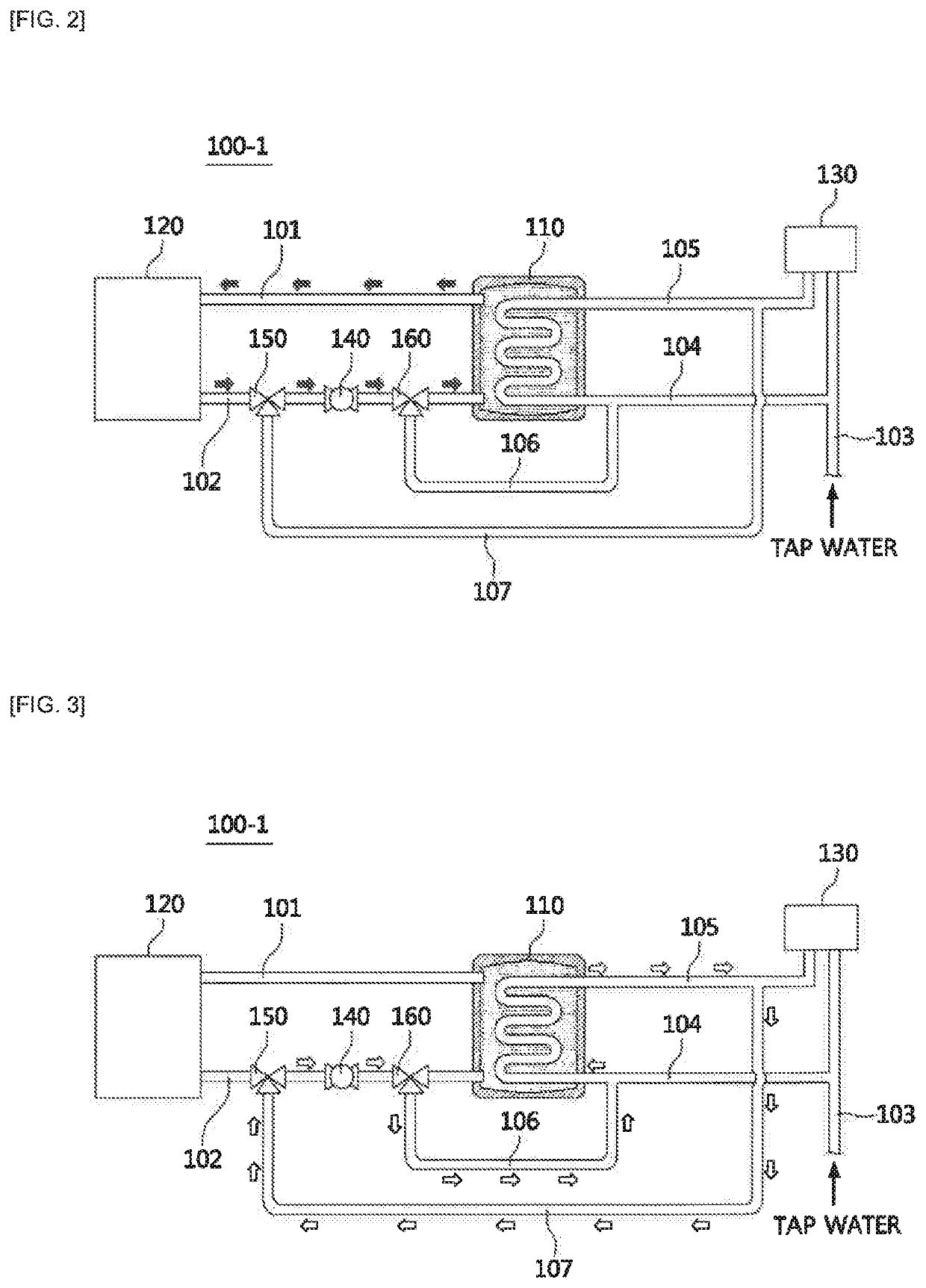

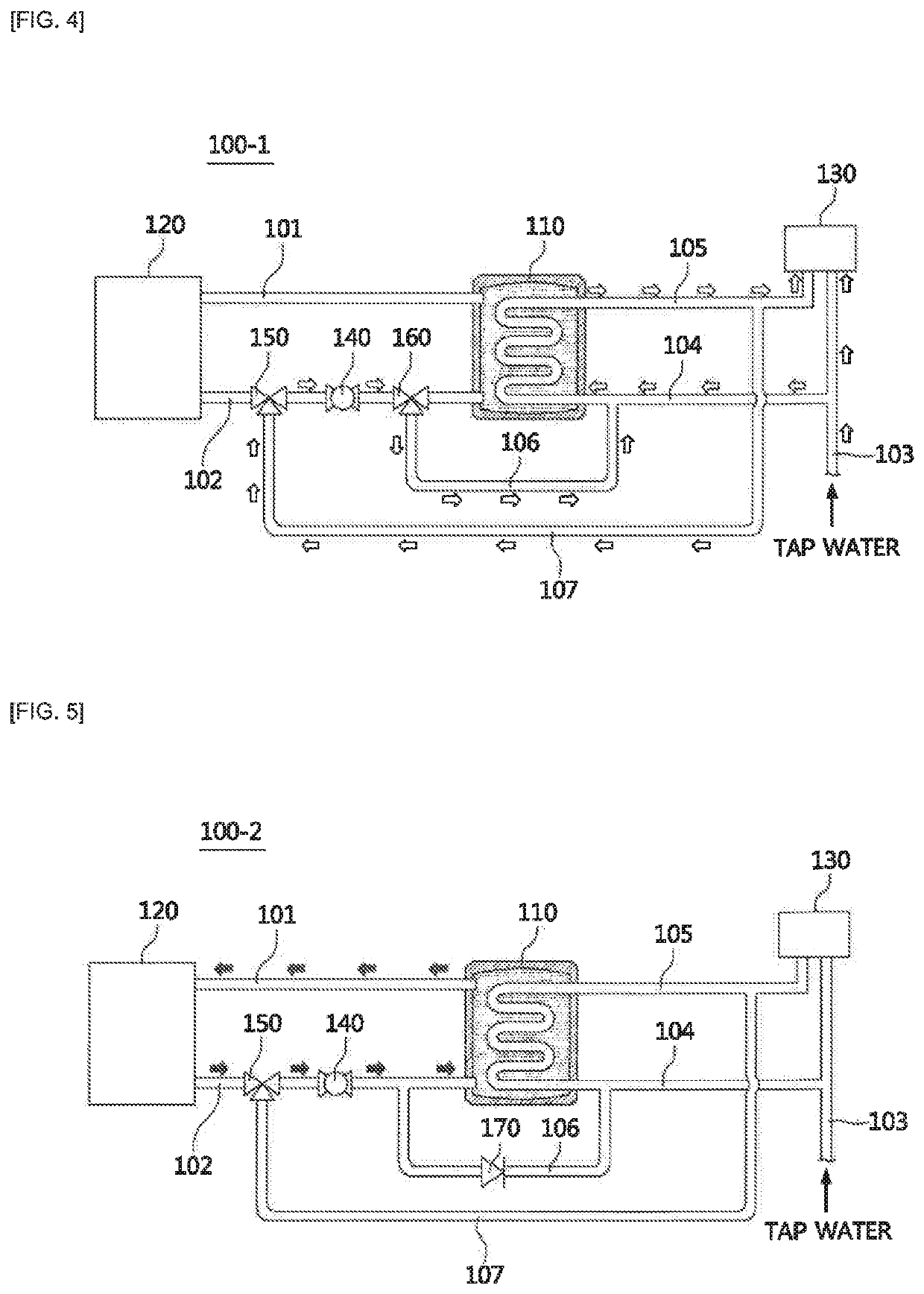

Boiler system for both heating and hot water

InactiveUS20200191412A1Lower purchase costIncreased ease of installationHeating fuelLighting and heating apparatusThermodynamicsTap water

Owner:KYUNGDONG NAVIEN

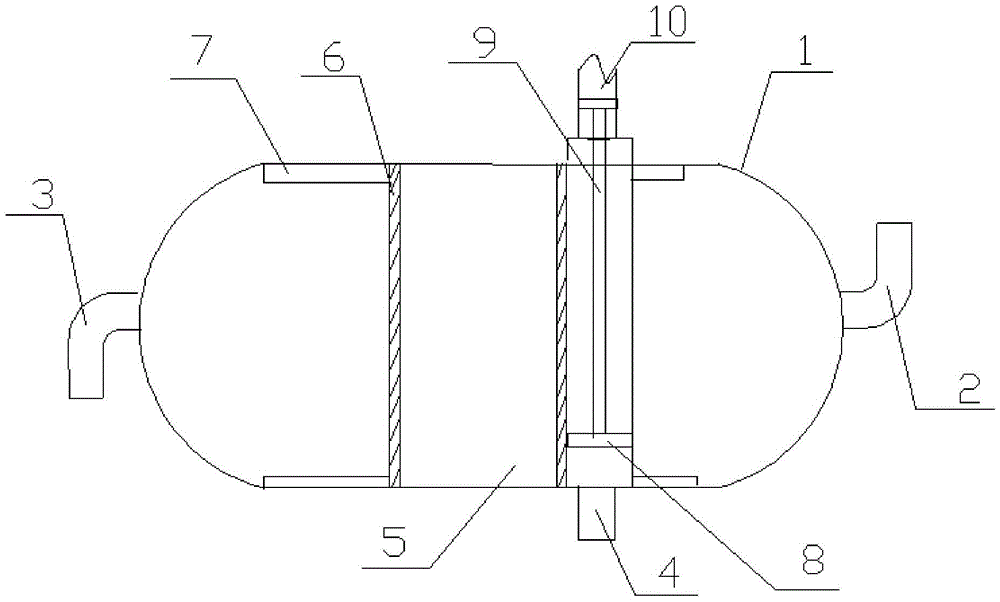

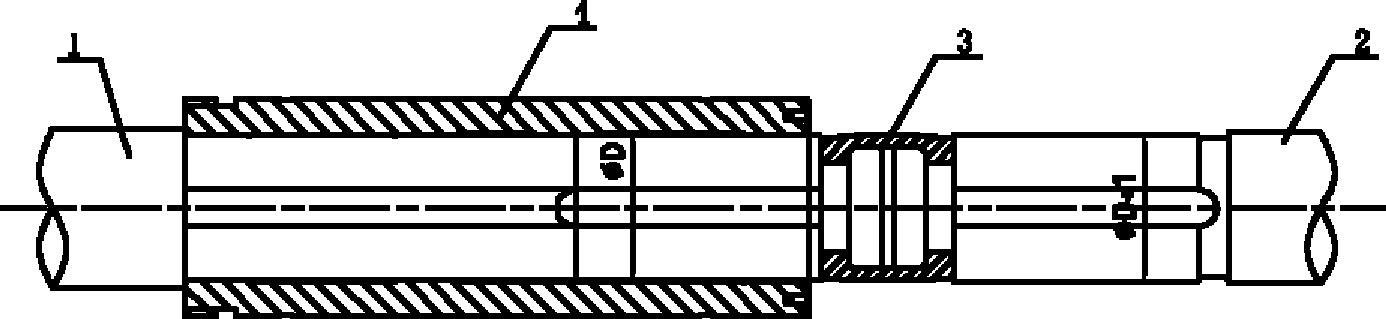

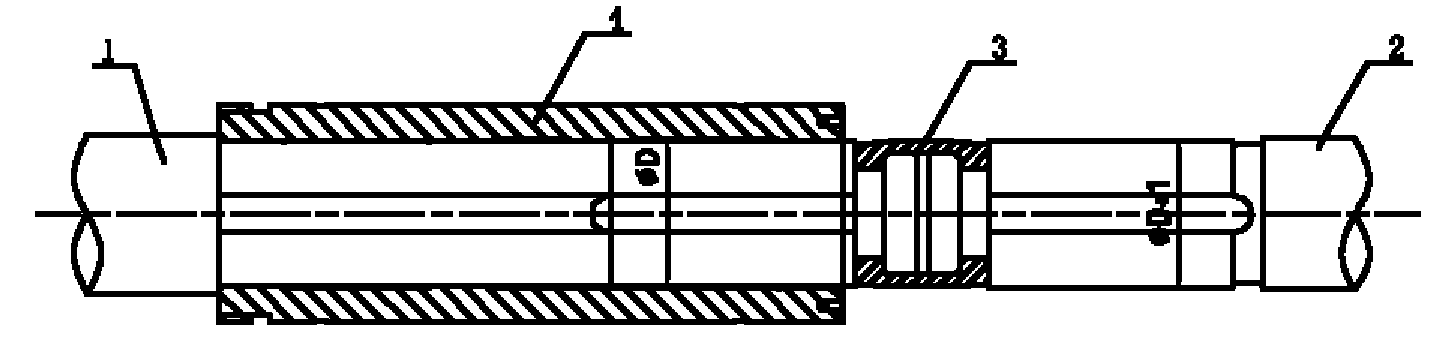

Improved pump shaft connecting structure of water circulating pump

Owner:HITACHI PUMP MFG WUXI

Circulating water pump motor maintenance device for nuclear power station

InactiveCN107872128AEasy to disassembleEasy to transportManufacturing dynamo-electric machinesSolid structureNuclear power

The invention relates to a maintenance device for a circulating water pump motor used in a nuclear power plant, which includes a body, the body is composed of an upper base, a lower bottom plate and a vertical plate, and the upper and lower ends of the vertical plate are respectively connected to the upper base, the lower The bottom plate is fixedly connected; the center of the upper base is provided with a through hole for placing the motor. Compared with the prior art, the invention maintains the vertical heavy-duty motor, and has the advantages of firm structure, stable center of gravity, safe maintenance, and convenient disassembly and transportation of the motor coupling and the lower guide bearing chamber of the motor.

Owner:CLP CHINA NUCLEAR POWER ENG TECH

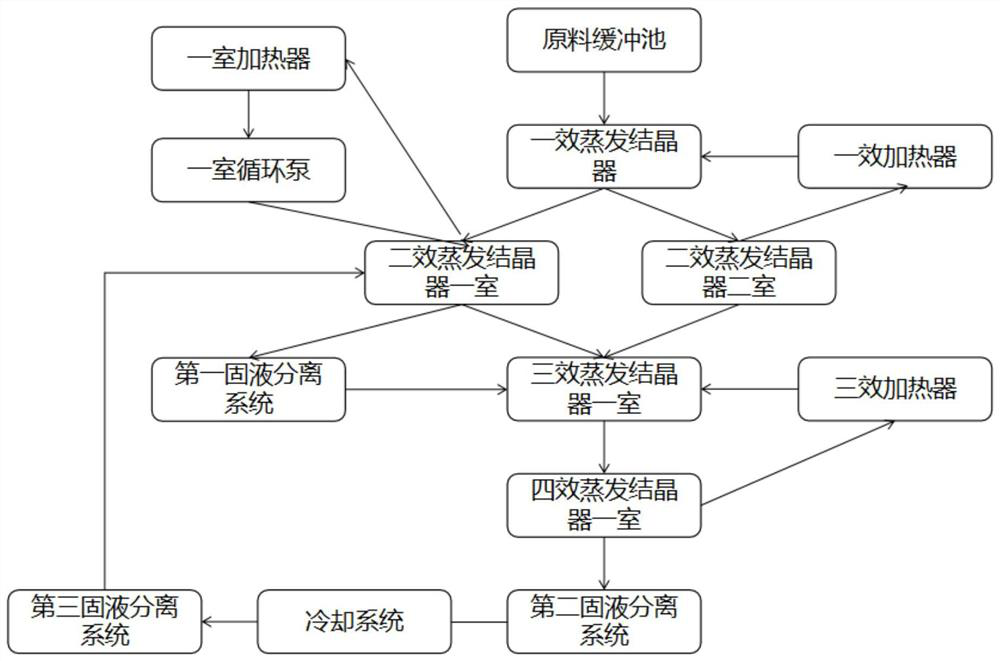

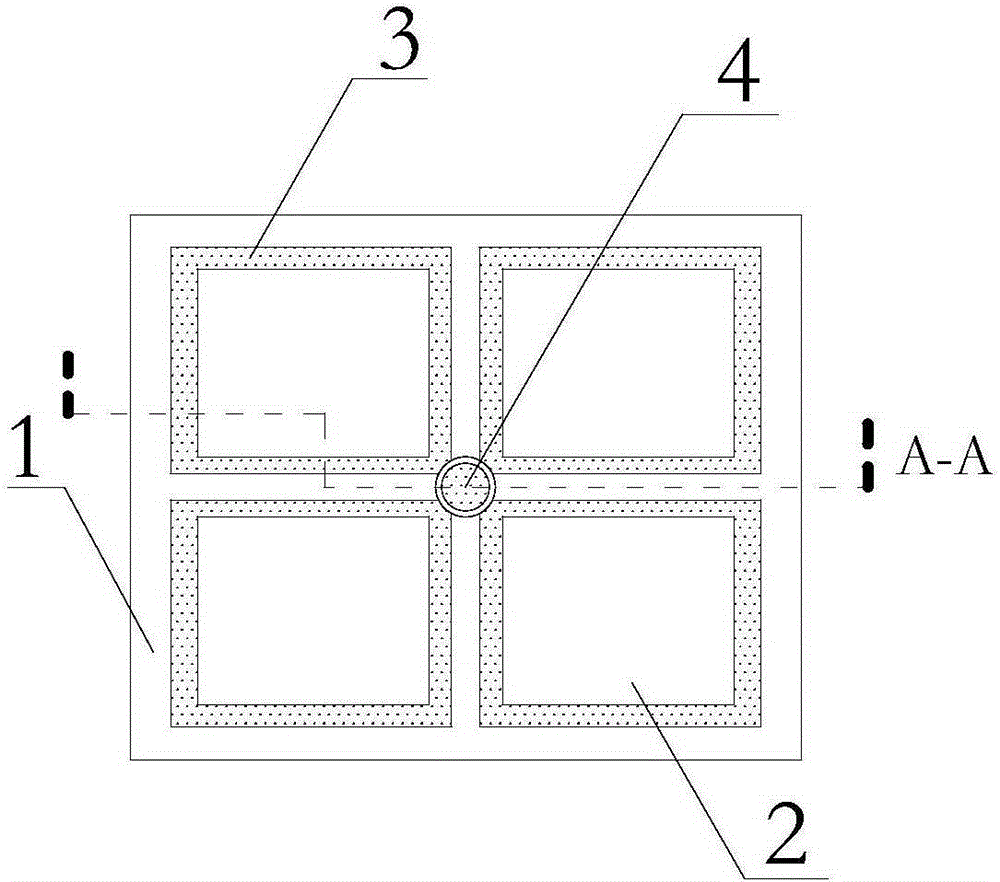

Shared multi-chamber evaporation crystallizer for non-similar electrolyte solutions

ActiveCN113476884ASimplify the difficulty of operationLow running costSolution crystallizationCrystallization by component evaporationThermodynamicsEngineering

Owner:SUZHOU JOYFA ENVIRONMENTAL TECH CORP LTD

Chemical material processing system and processing method

InactiveCN112782750AImprove reaction efficiencyRapid coolingRadiation measurementThermodynamicsElectric machinery

Owner:黄忠军

Method for reducing energy consumption of oxidation unit of epoxy propane device

Owner:SINOPEC SHANGHAI ENG +1

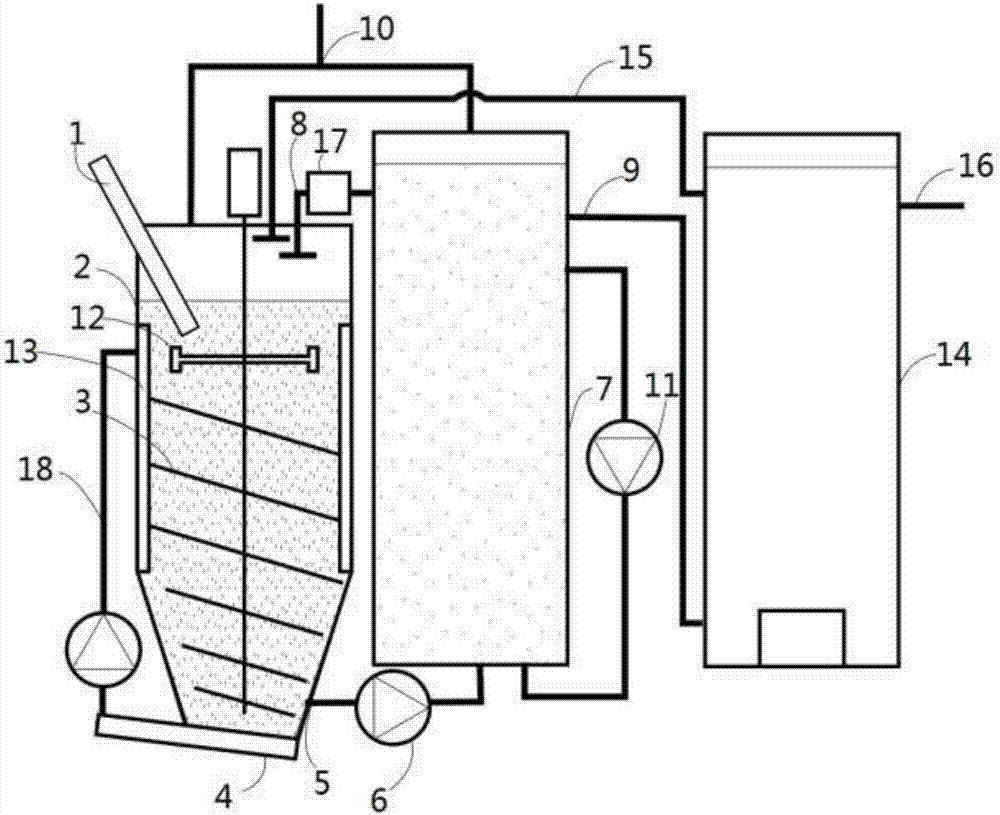

Agricultural seed soaking device

InactiveCN108934282ADissolve fastGuaranteed stabilitySeed immunisationAgricultural engineeringMetallic materials

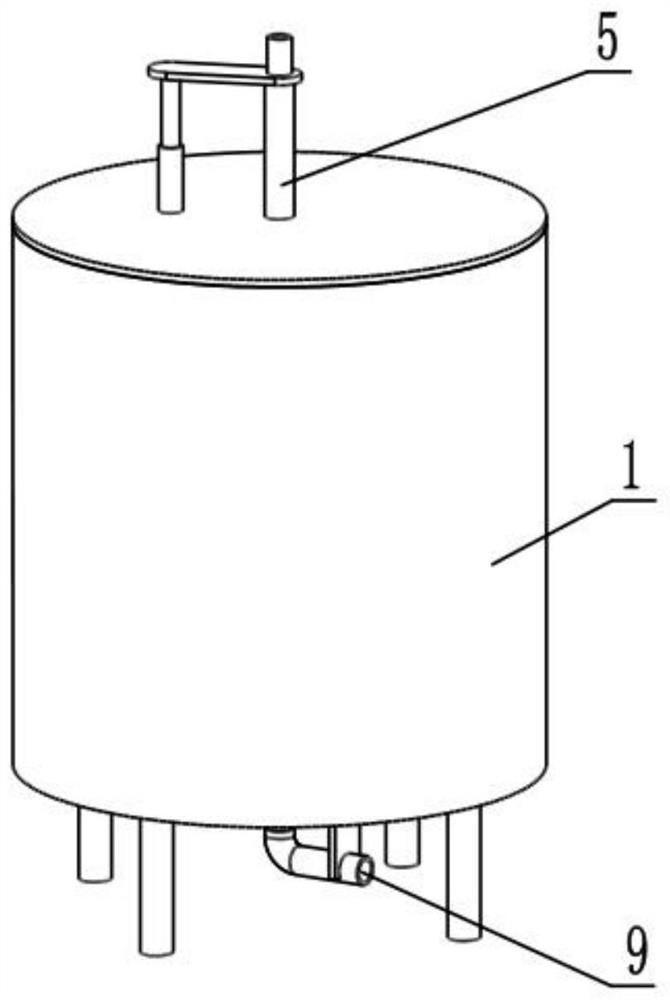

The invention discloses an agricultural seed soaking device, which comprises a dosing tank, a soaking tank and a circulating pump. The dosing tank and the circulating pump are communicated by a firstduct, the circulating pump and the soaking tank are communicated by a second duct, a third duct is installed between the second duct and the dosing tank, and electromagnetic valves are installed on both the second duct and the third duct. The top of the dosing tank is equipped with a water sealed slot communicated with the same, and a water seal cover matching the shape of the water sealed slot isinstalled above the water sealed slot. The device is reasonably designed, and adopts the circulating pump for liquid stirring, and dissolved reagents do not contact metals, thus effectively avoidingcorrosion of reagents to metal materials. At the same time, the water seal structure of the device can prevent outward diffusion of odor in the dosing tank and has good sealing performance.

Owner:TAIZHOU BIAOMENG INTPROP AGENCY

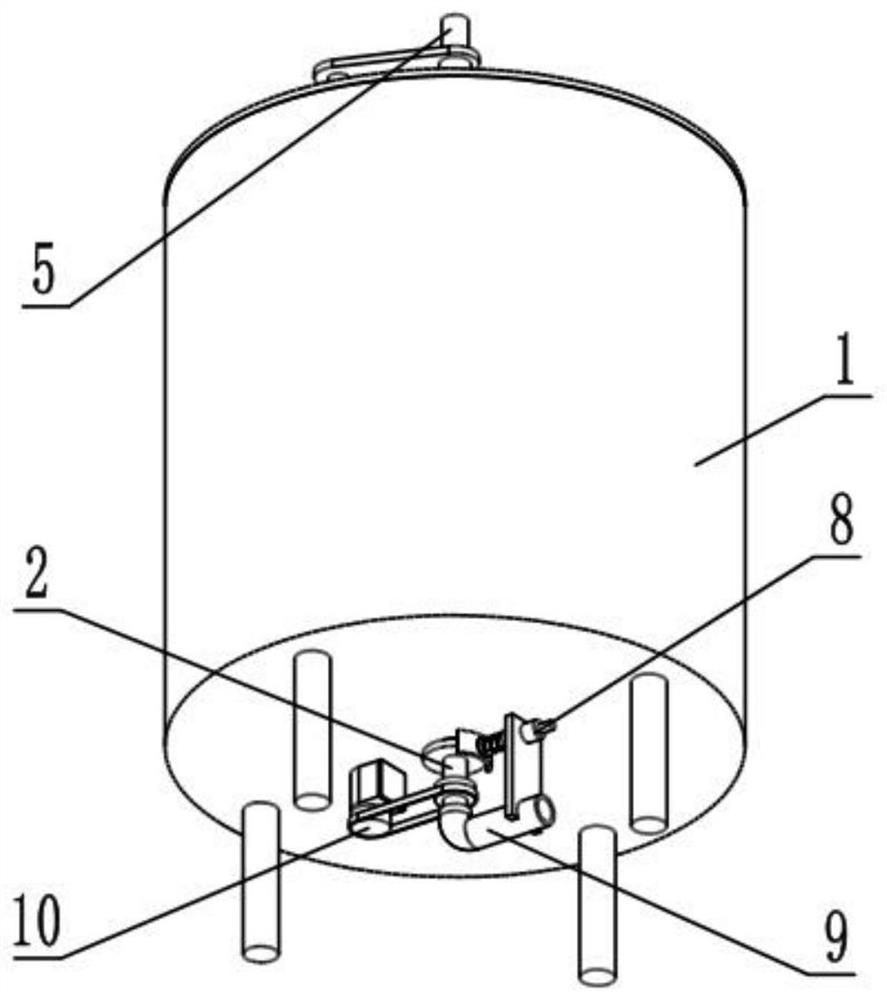

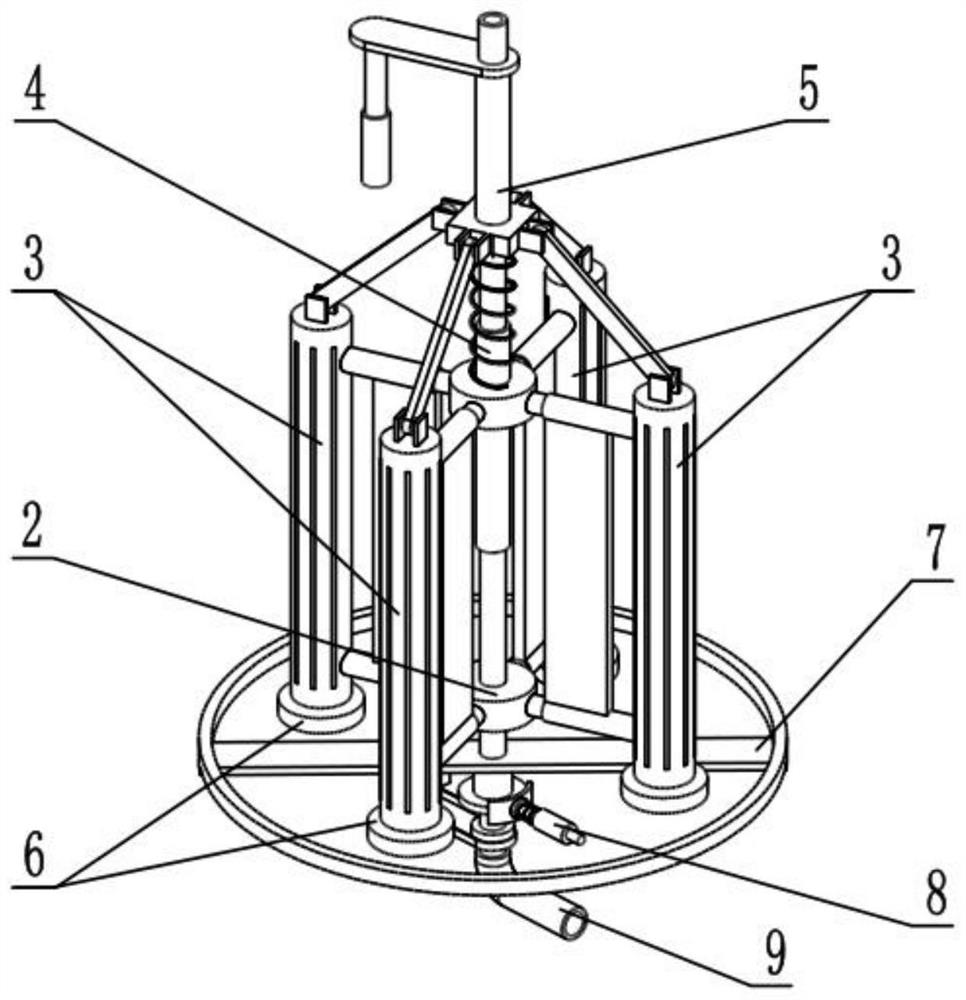

Fermented soybean fermentation tank

Owner:CHONGQING YONGCHUAN FERMENTED SOY BEAN FOOD CO LTD

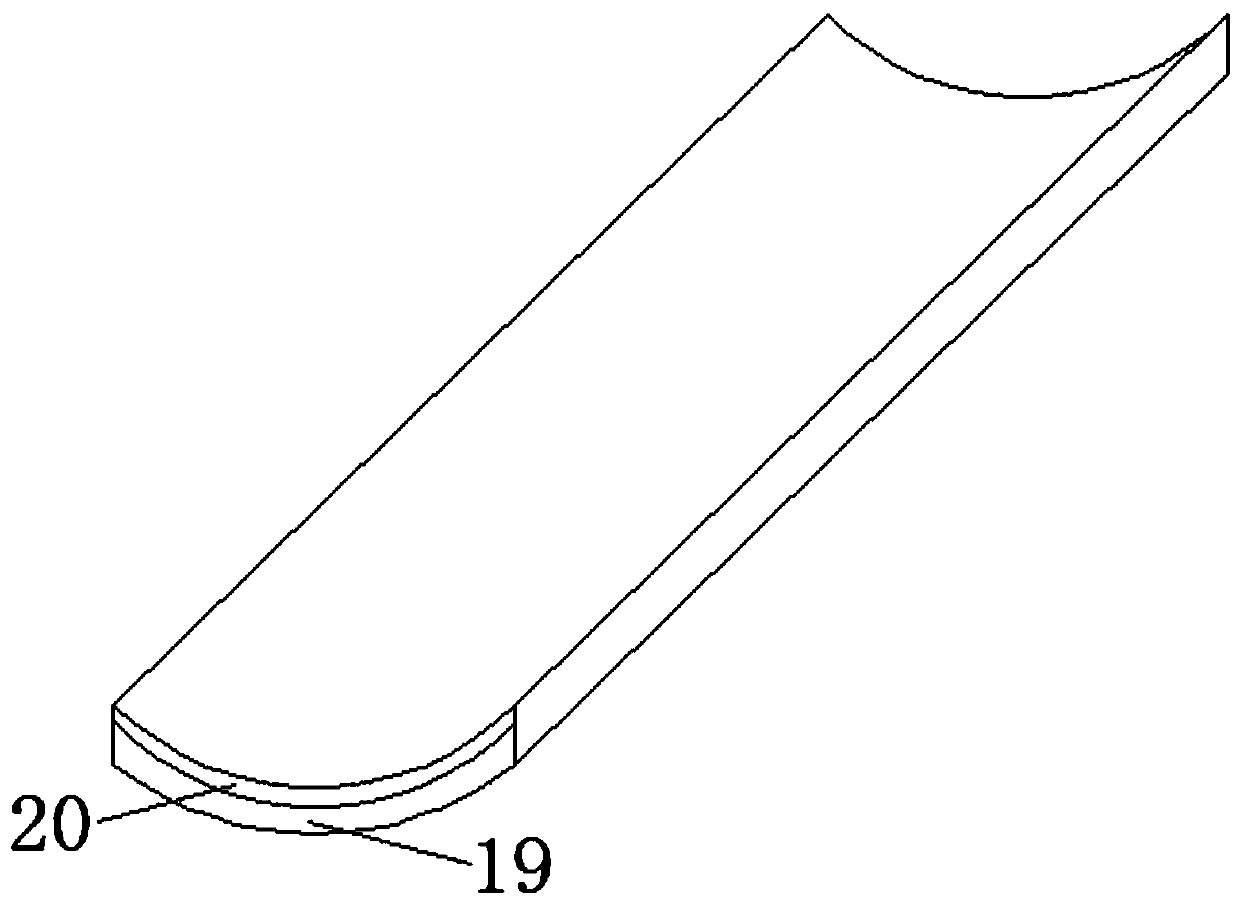

Solar vacuum tube uniform coating equipment

ActiveCN114247597AImprove stack adhesionUniform coatingPretreated surfacesCoatingsElectric machineryEngineering

Owner:LINYI RUIGUANG NEW ENERGY TECH

Special sealing lubricating grease pumpability detection apparatus for shield tunneling machine

PendingCN106645654AEasy to operateThe test data is accurateMaterial testing goodsEngineeringShield tunneling

Owner:XINXIANG HENGXING TECH CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap