Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

76 results about "Scrap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Scrap consists of recyclable materials left over from product manufacturing and consumption, such as parts of vehicles, building supplies, and surplus materials. Unlike waste, scrap has monetary value, especially recovered metals, and non-metallic materials are also recovered for recycling.

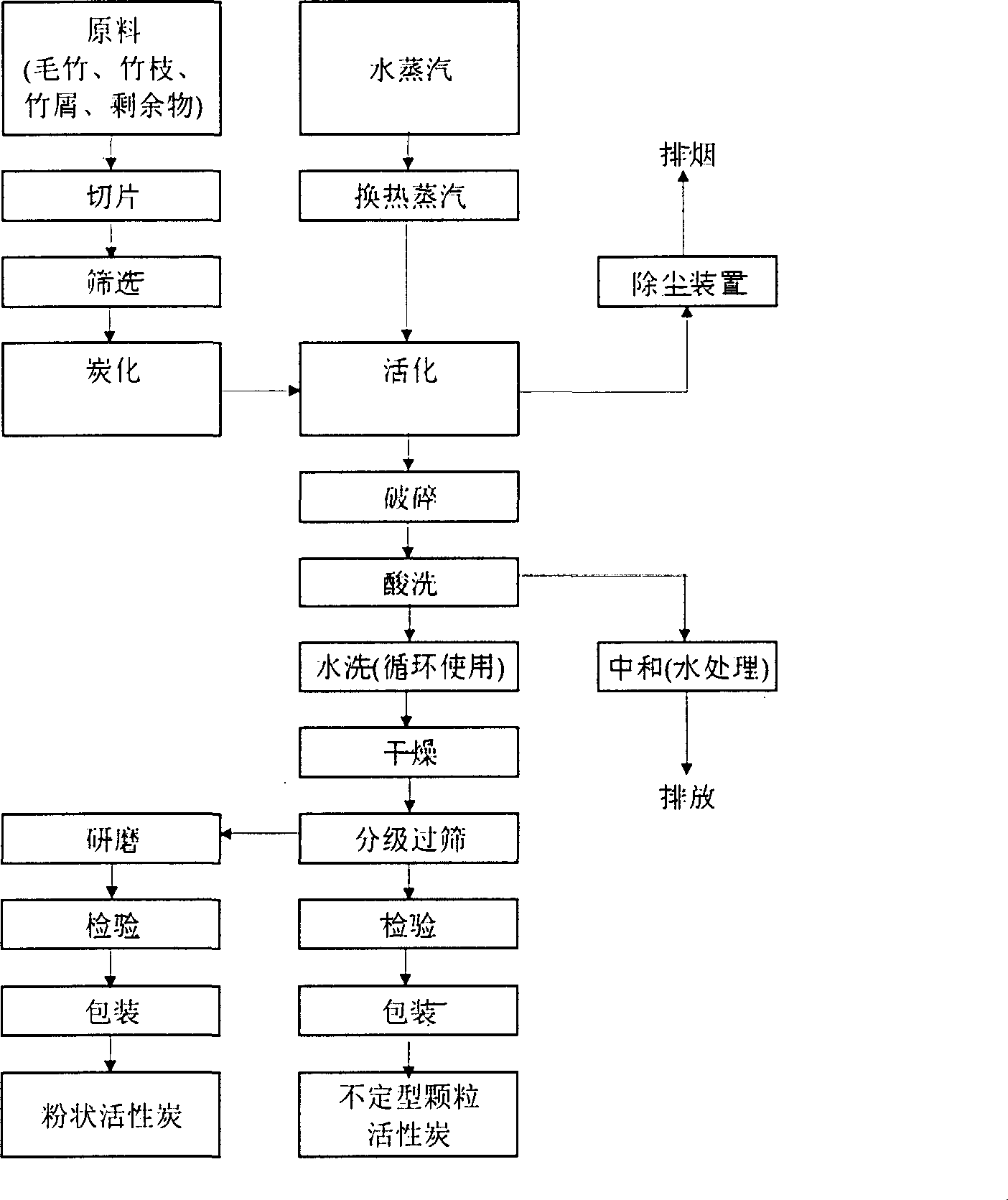

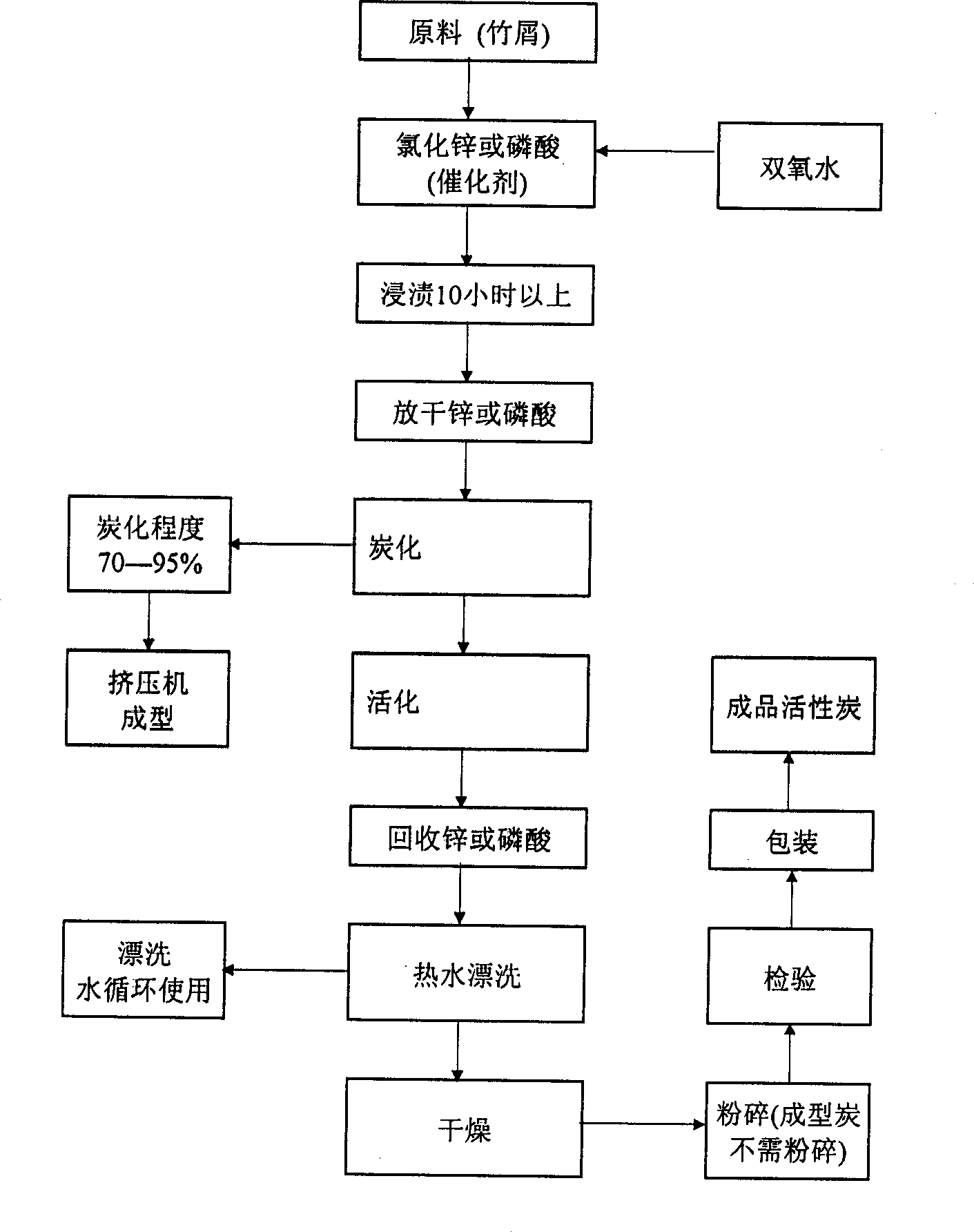

Method for preparing activated char from bamboo material

InactiveCN1333180AImproved decolorizationMesopore developedCarbon compoundsDistillationPhosphoric acid

Owner:尤匡银

Preoxidized-composite electrolyzing method for removing arsenic in groundwater

InactiveCN101139150ALow toxicityImprove adsorption capacityMultistage water/sewage treatmentWater/sewage treatment by oxidationElectrolysisFenton reagent

A method to remove arsenic in underwater by preoxidation-combined electrolyzing relates to a method to remove arsenic from underwater, belonging to the technical field of water treatment. The present invention has solved the defect that more expensive pure nulvalent iron and slower corrosion speed of the pure nulvalent iron have limited the absorption of arsenic on the nulvalent iron. The present invention includes the following steps: the underwater containing arsenic is pre-oxidized by ozone, potassium ferrate, potassium permanganate, H2O2, photocatalysis oxidation reagent or Fenton reagent, thereby transferring As(III) to As(V). The water pre-oxidized passes through a filtering bed containing cast-iron scrap and carbon granules. The oxidizer left in the preoxidation section promotes the reaction of the step.

Owner:HARBIN INST OF TECH

Cutting equipment of novel rectangular plate large-area peeling device

InactiveCN107639710AImprove practicalityEasy to cleanTree debarkingBark-zones/chip/dust/waste removalCouplingEngineering

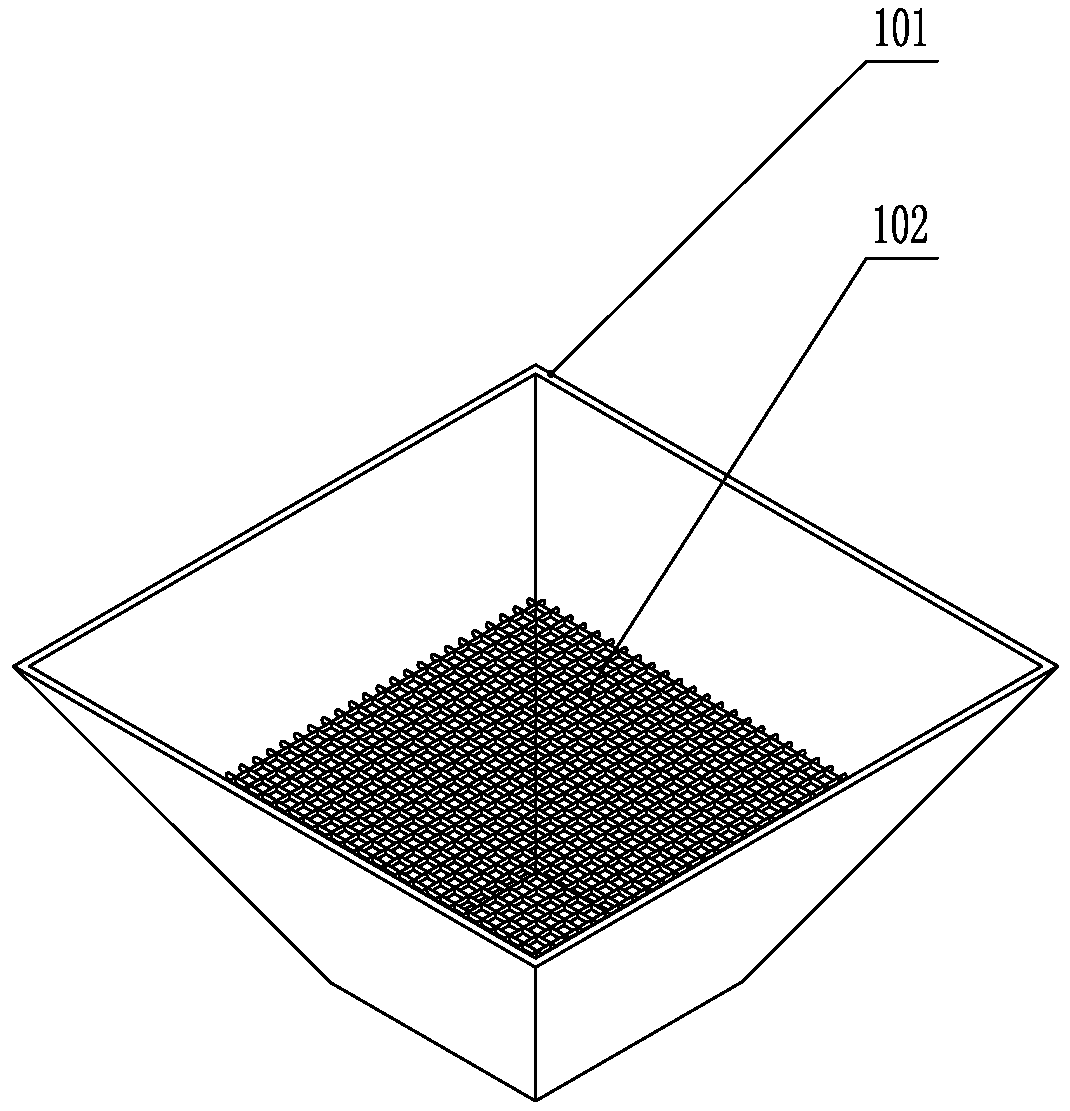

The invention discloses cutting equipment of a novel rectangular plate large-area peeling device. The cutting equipment comprises a base. A waste scrap tank is arranged on the upper side of the base,two support plates are arranged on the side, which is close to the waste scrap tank, of the base and are symmetrically distributed, more than four fixing holes are symmetrically formed in the side, which is close to the support plates, of the base, more than four support rods are arranged on a side of the base and are equidistantly symmetrically distributed, a first annular fixing boss is connected with one end of each of the two corresponding support rods, and an output shaft of a first servo motor is connected with an end of a cutting rotary shaft by couplings. The cutting equipment has theadvantages that rectangular plates can be thoroughly cut by cutting scraper knives arranged on the outer sides of cutting collars, the surfaces of the rectangular plates can be preliminarily polishedby polishing collars, the cutting distances can be adjusted by shaft connecting plates and adjusting wheels according to the heights of the rectangular plates, accordingly, the practicality of the cutting equipment can be greatly improved, and the waste scrap tank can bring convenience for cleaning waste scraps.

Owner:蔡涛涛

Grabbing device of metal waste block conveying mechanism

ActiveCN105858208AEasy to placeImprove the installation effectConveyor partsBottom pressureEngineering

The invention discloses a grabbing device of a metal waste block conveying mechanism. The grabbing device comprises a main support frame and a bottom pressure block, wherein the bottom pressure block is inserted in a mounting through hole at the middle part of the main support frame in a sleeving manner and fixed on the inner side wall of the mounting through hole; the bottom surface of the bottom pressure block is fixed on a bottom support seat; the bottom support seat is positioned below the top plate of the main support frame; a grabbing moving frame is arranged on the ground on the right side of the main support frame; the left end of the top plate of the grabbing moving frame is positioned above the right side of the main support frame; grabbing support plates are fixed on the two sides of the top plate of the grabbing moving frame; the two ends of a grabbing screw are articulated on two grabbing support plates, and a grabbing transmission motor is fixed on one grabbing support plate; a vertical groove body is arranged at the middle part of the top surface of the bottom pressure block; a placing block body is arranged in the vertical groove body; a waste placing groove is formed in the top surface of the placing block body; and a lifting oil cylinder is fixed on the bottom surface of the bottom pressure block. The metal waste block is convenient to fetch, and the fetched metal waste block is convenient to place.

Owner:CHINA FORGING MACHINERY

Automatic external-wall cleaning machine

InactiveCN102871609AAvoid dangerFully completedCarpet cleanersFloor cleanersWireless controlEngineering

Owner:赵锦鸿 +1

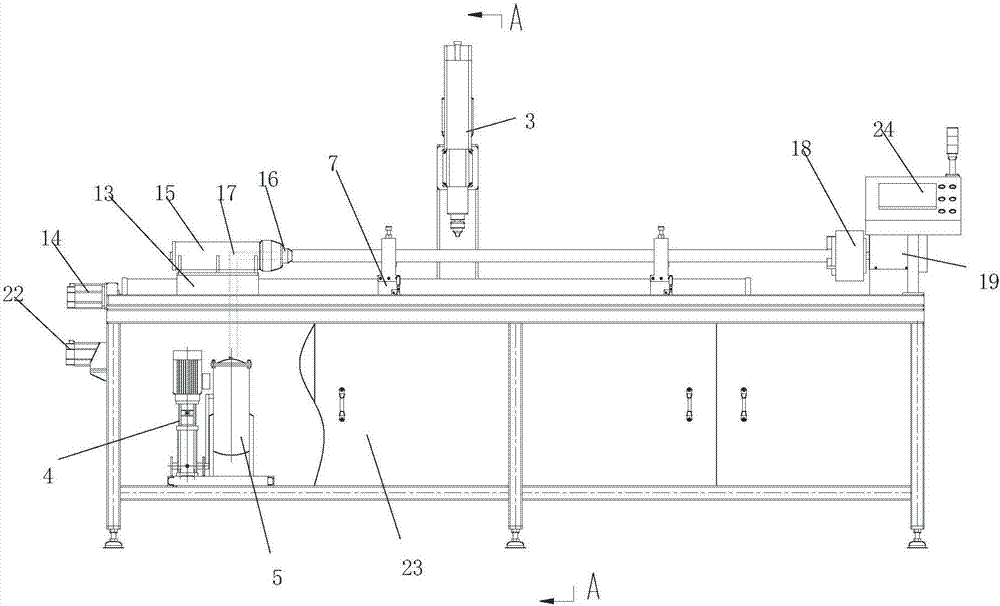

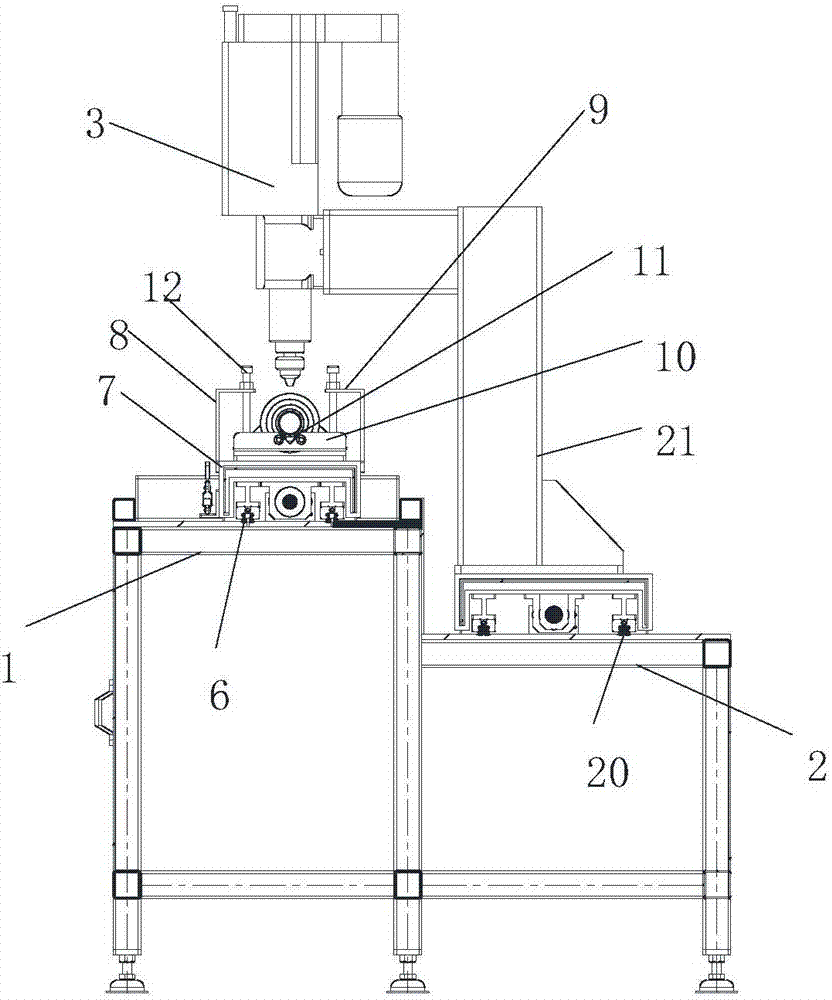

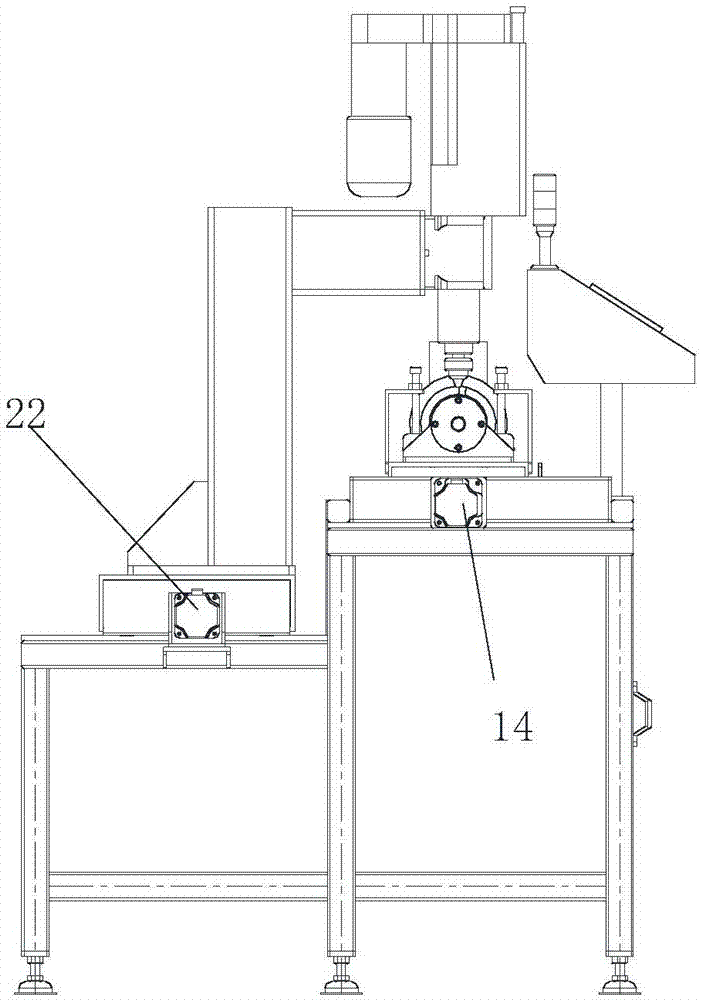

Intelligent steel pipe drilling device

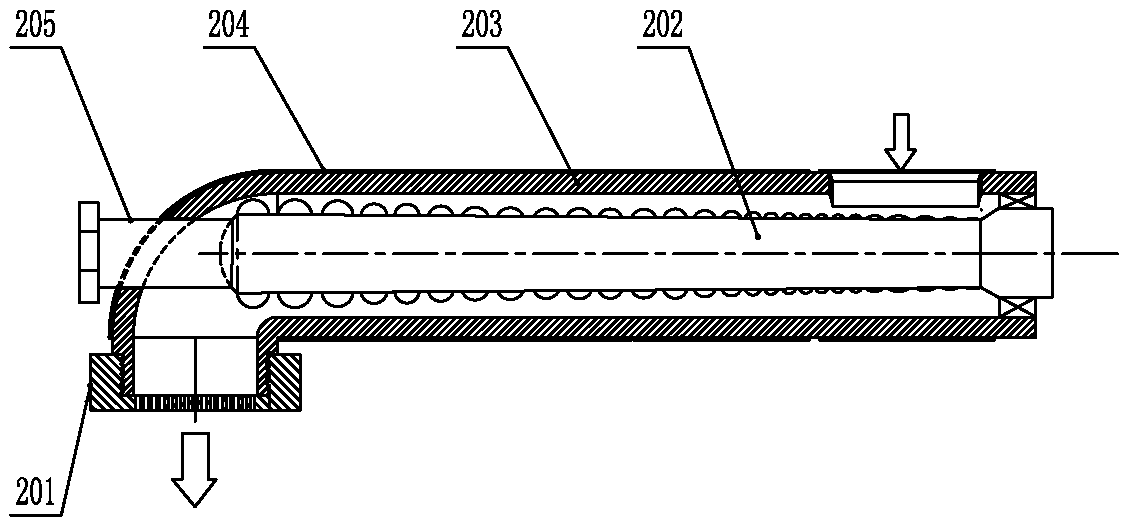

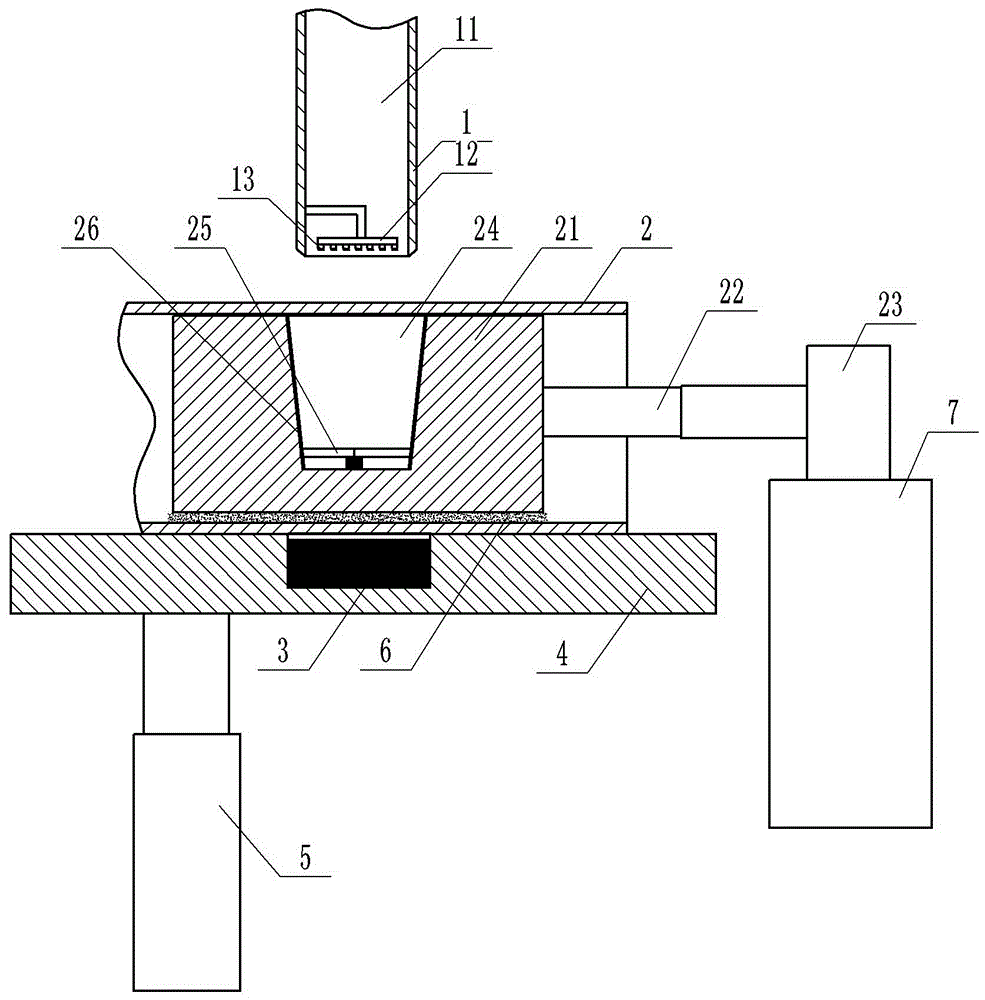

The invention relates to the technical field of drilling devices, in particular to an intelligent steel pipe drilling device. The intelligent steel pipe drilling device comprises a steel pipe fixing workbench, a drilling machine moving workbench, an automatic feed drilling machine, a negative-pressure pump and a negative-pressure tank. A first guide rail is fixedly arranged on the steel pipe fixing workbench. Steel pipe support mechanisms are arranged on the first guide rail. The steel pipe support mechanisms are in sliding fit with the first guide rail. The drilling machine moving workbench is arranged on one side of the steel pipe fixing workbench. A second guide rail is arranged on the drilling machine moving workbench. The bottom of the automatic feed drilling machine is in sliding fit with the second guide rail through a drilling machine bracket. A third stepping motor is arranged on one side of the drilling machine moving workbench. According to the intelligent steel pipe drilling device, the negative-pressure pump and the negative-pressure tank are arranged and communicate with a jackscrew through a gas pipe, scrap iron in a steel pipe enters the negative-pressure tank from the jackscrew under the negative-pressure function, the purpose of collecting the scrap iron is achieved, and it is indicated by the actual use of the applicant that the effect of collecting the scrap iron is extremely good, and the steel pipe is internally cleaned extremely clearly.

Owner:COLLEGE OF APPLIED SCI JIANGXI UNIV OF SCI & TECH

NiCuSiFe alloy

Owner:WUFAN ALLOY ALUMINUM WUJIN

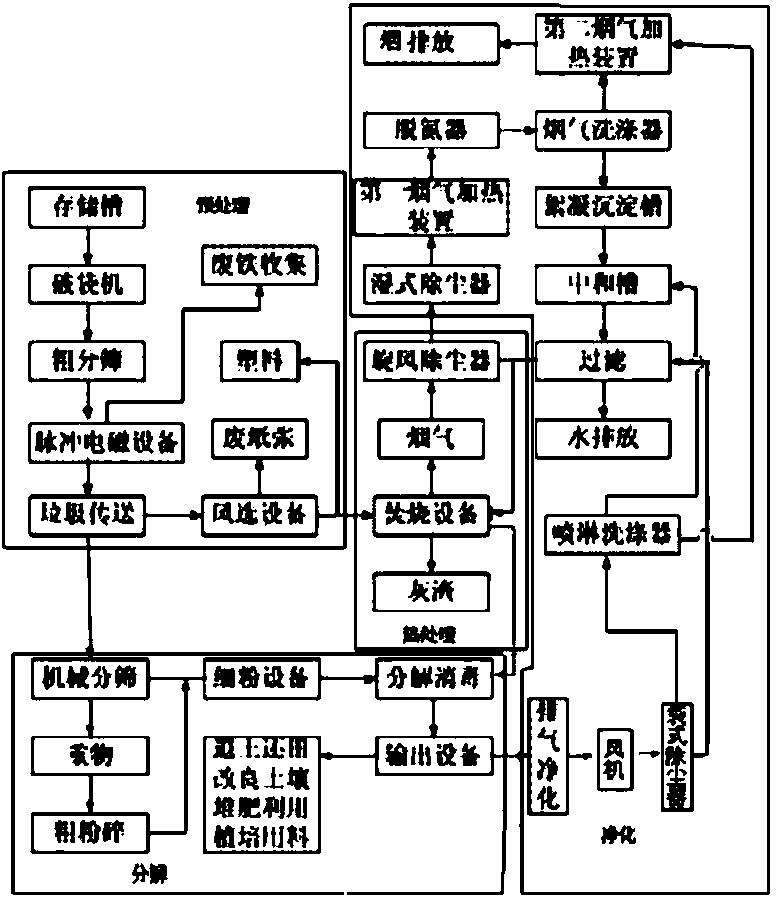

Urban garbage purifying utilizing system and garbage processing method

Owner:广西华都环境投资集团有限公司

Method for recovering fluorescent material from faulty glass bodies of discharge lamps

InactiveUS6869327B2Efficiently good resultEasy to separateDischarge tube luminescnet screensLamp detailsGlass particleCrusher

Owner:GENERAL ELECTRIC CO

Method for making bricks by using construction wastes

The invention discloses a method for making bricks by using construction wastes. The bricks are characterized by comprising the following raw materials: 30-57 parts of crushed aggregates of construction wastes of which the metal particles are removed and the diameter is small than 14mm, 20-40 parts of coal gangue particles, 10-15 parts of phosphate slag with the particle diameter being less than 1mm, 8-15 parts of cement, 0.6-0.8 part of quick lime, 3-18 parts of pulverized fuel ash, 0.01-0.025 part of a hydroxyl silicon sealed curing agent, 8-12 parts of water and 0.1-0.2 part of sodium silicate. The crushed aggregates of construction wastes can be dismantled materials of old buildings or wastes of novel buildings, and an anti-freezing agent or an anti-freezing chlorine salt can be added into the raw materials. The method has the advantages that the proportioning is simple, the energy is renewable, the environment is protected, and the wastes are utilized.

Owner:HEFEI BAOLI ENVIRONMENTAL PROTECTION TECH

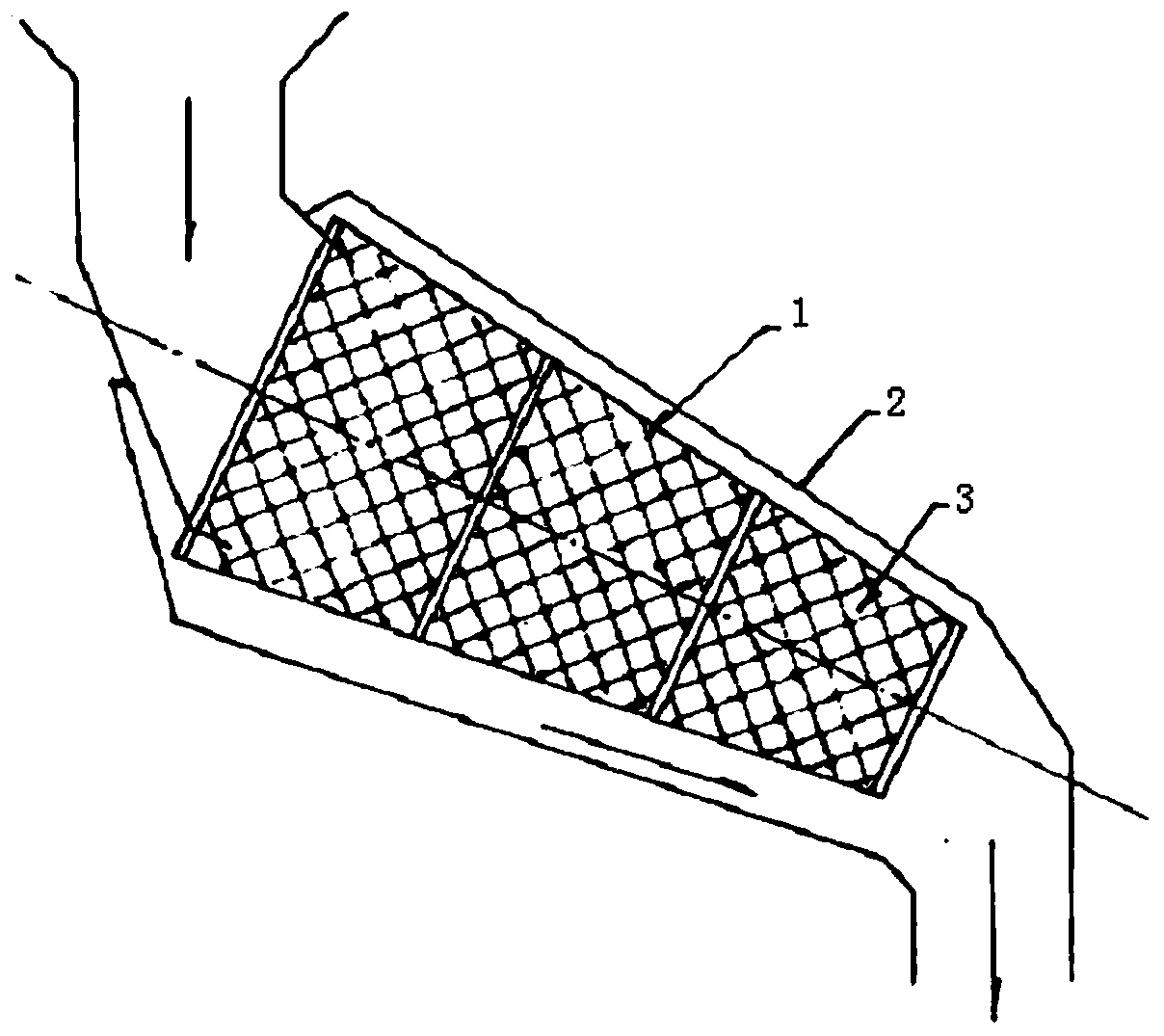

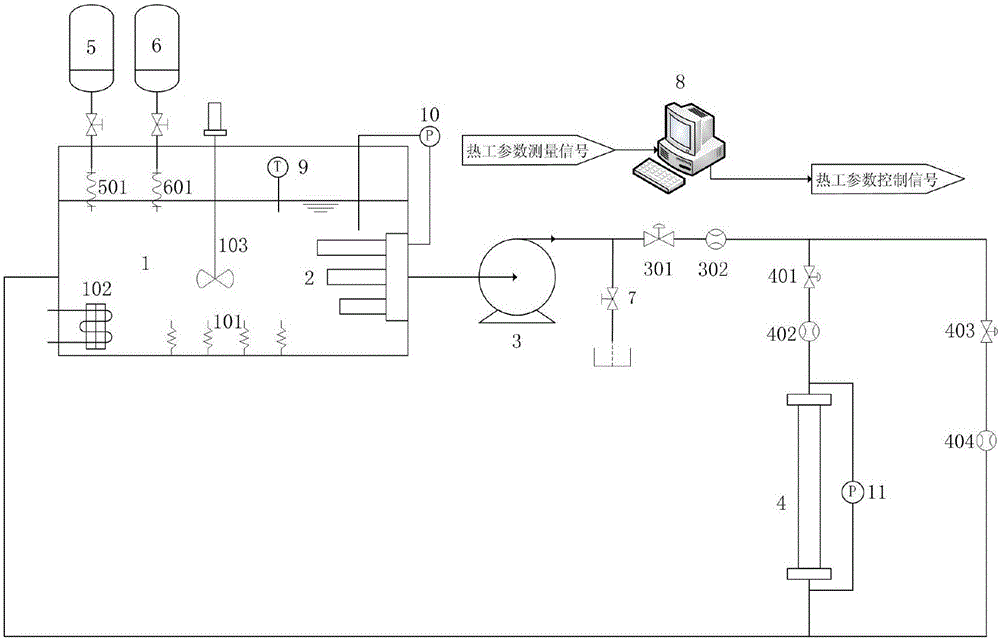

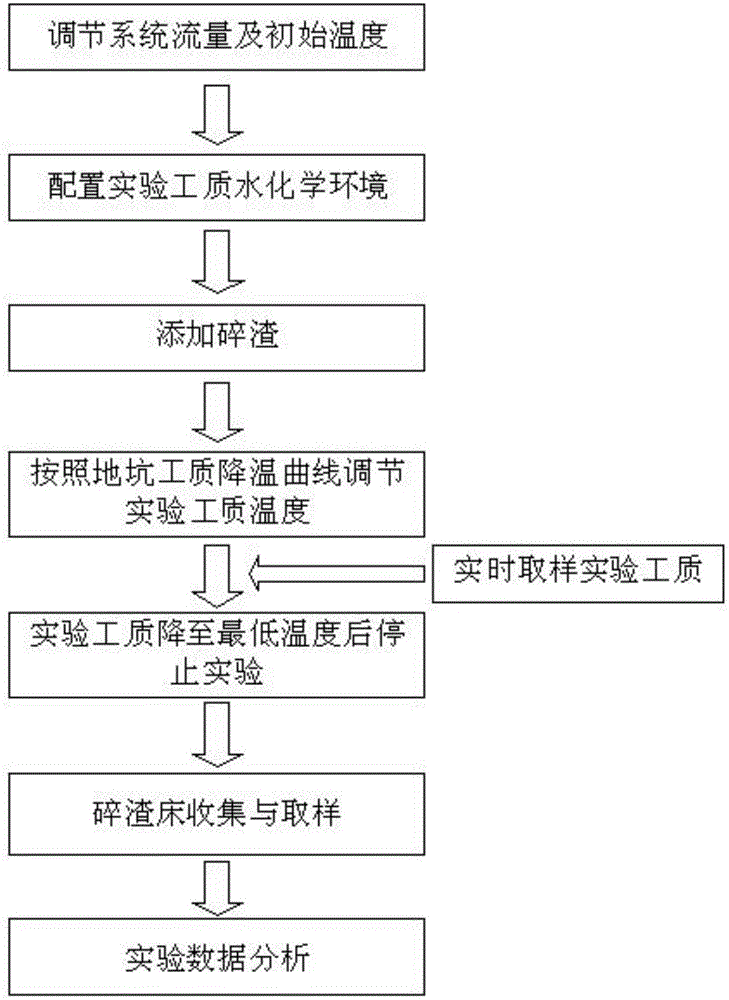

Containment pit strainer overall performance experimental system and method

ActiveCN106448760AClogged hydraulic properties gainHydraulic properties gainNuclear energy generationNuclear monitoringComputer moduleEngineering

Owner:NUCLEAR POWER INSTITUTE OF CHINA

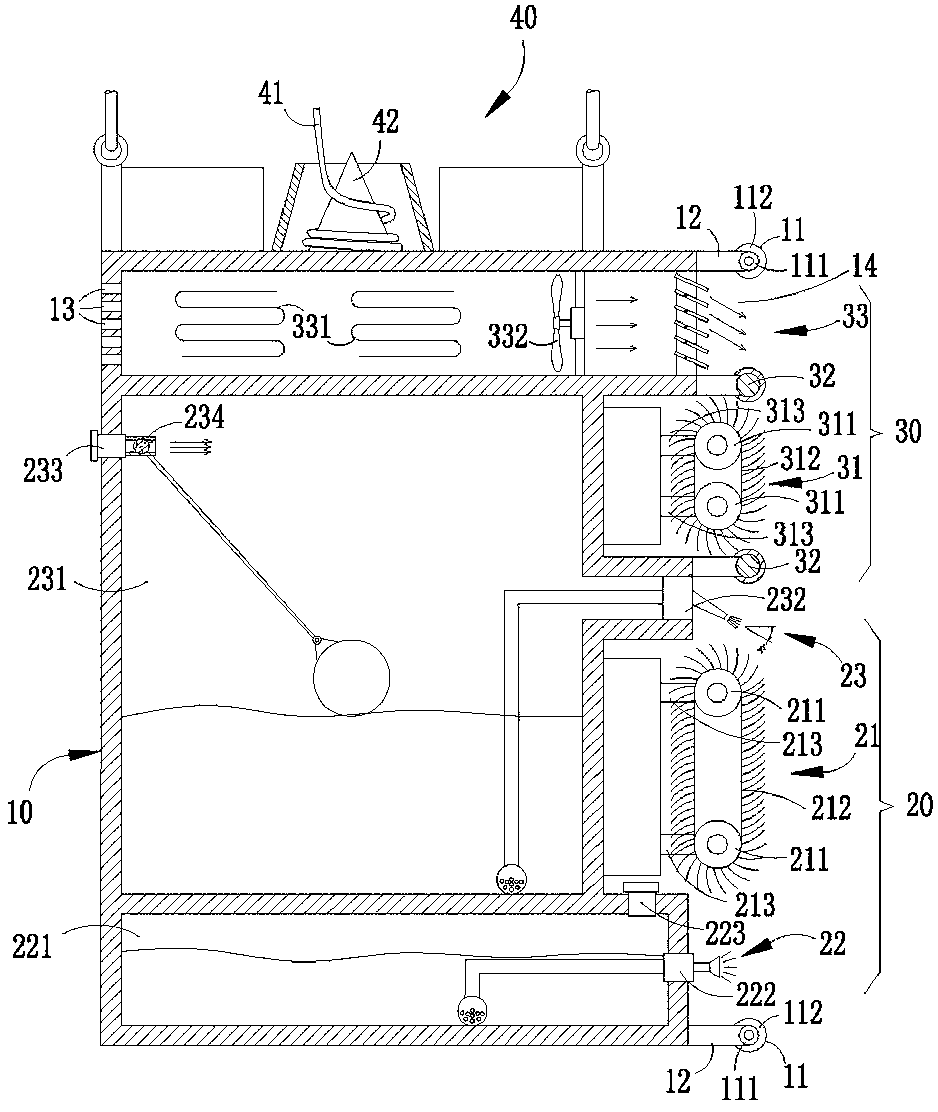

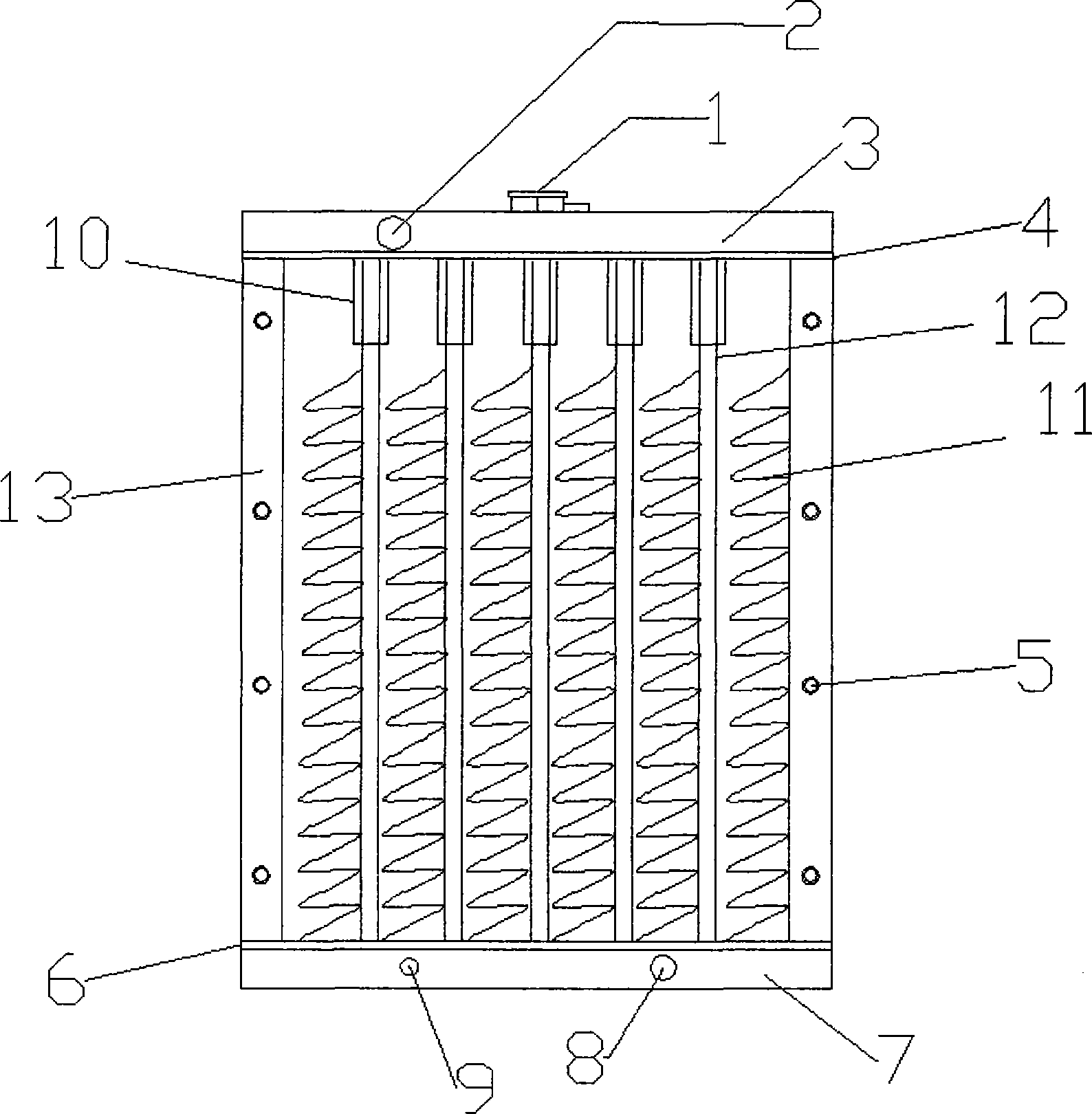

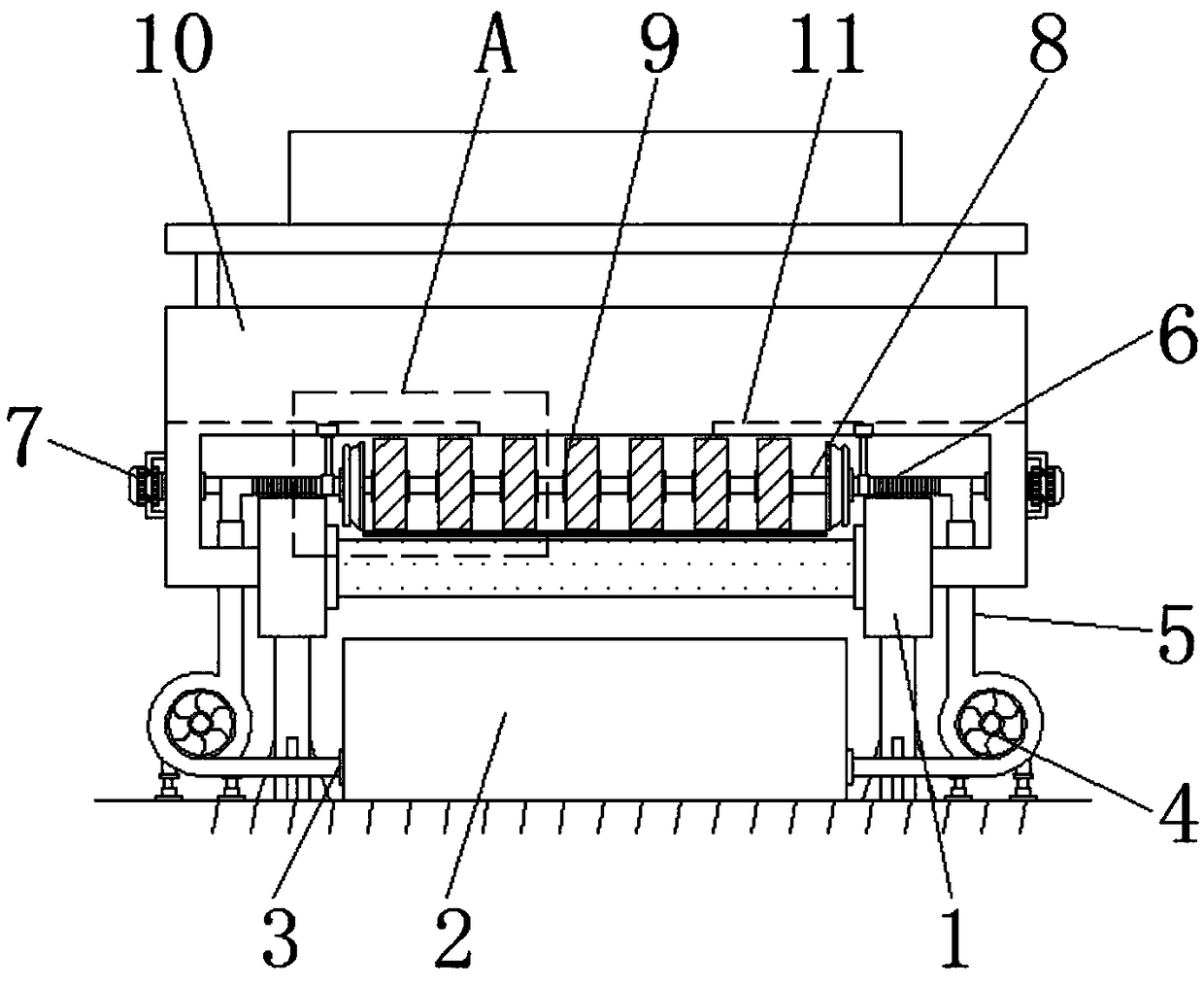

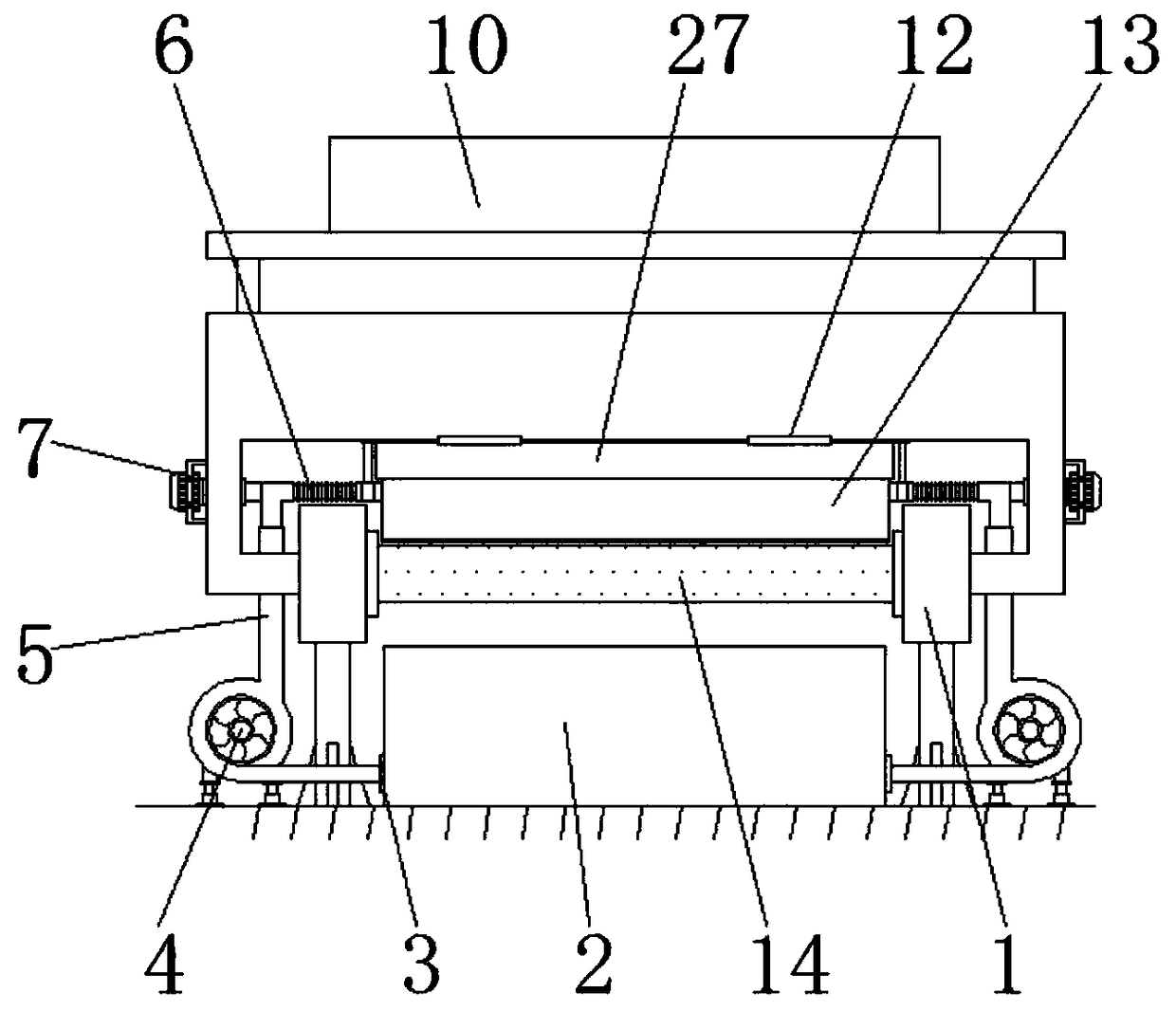

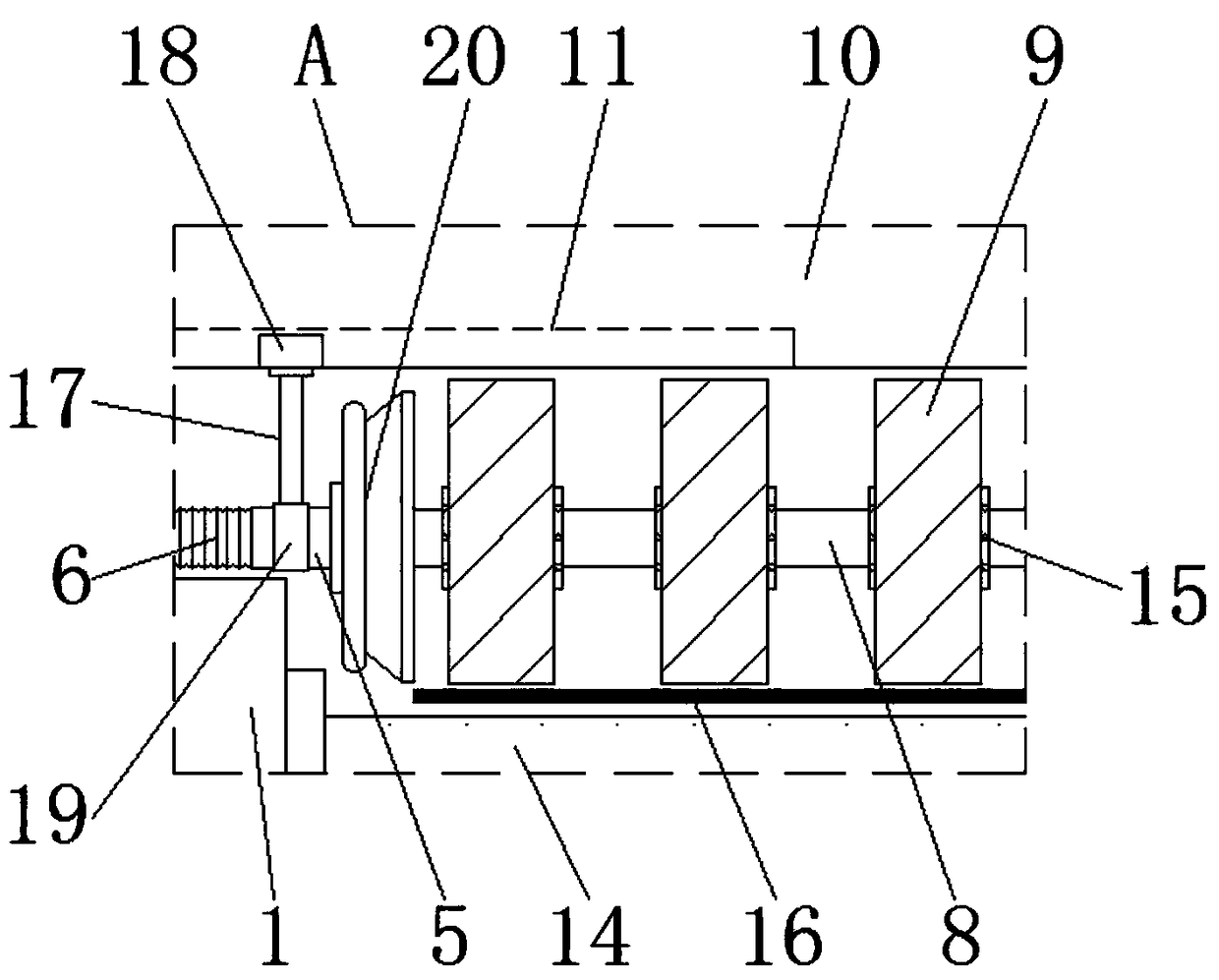

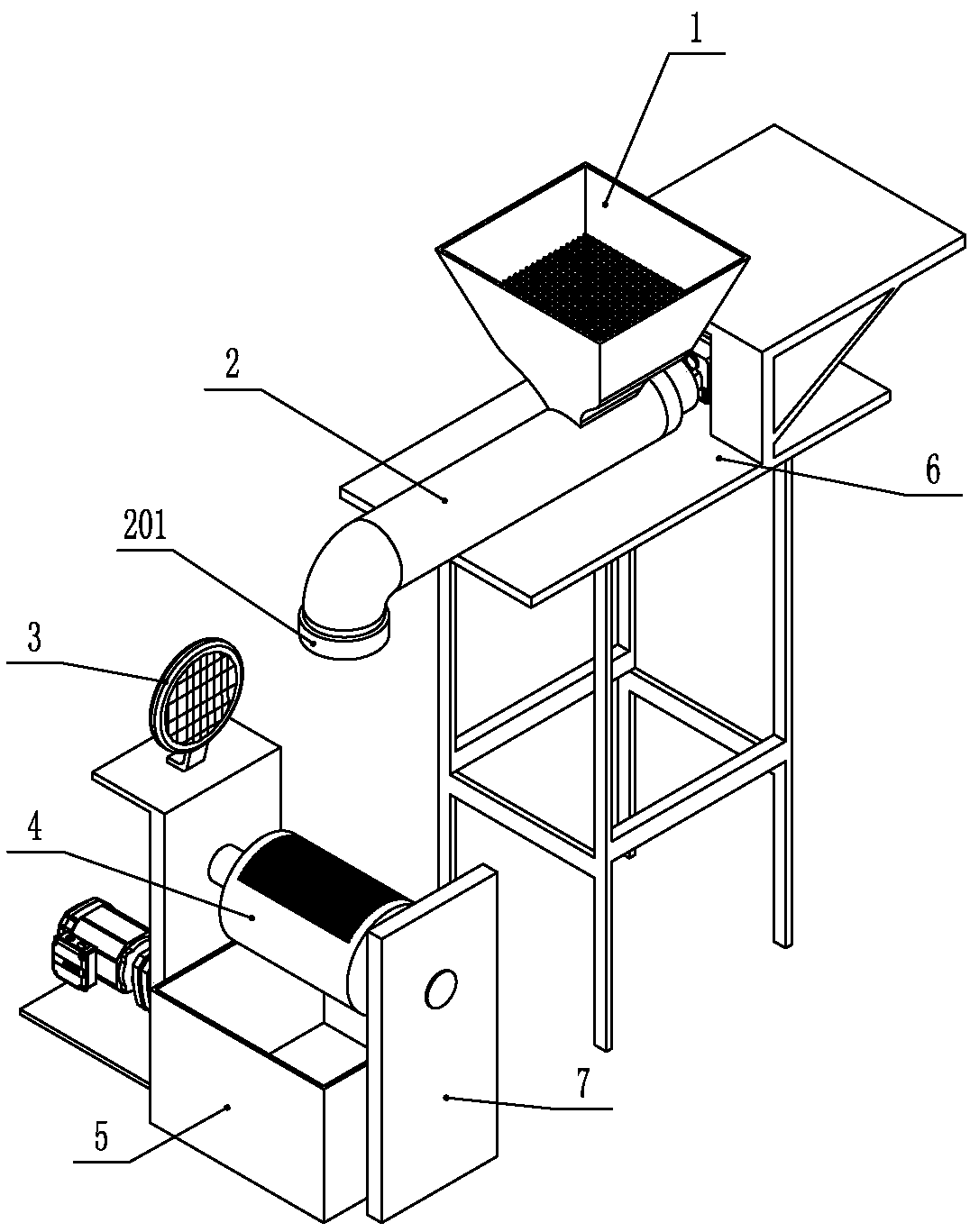

Full-automatic cutting fluid magnetic filter device

PendingCN108262158AImprove adsorption capacityAdsorption fineCleaning using toolsMagnetic separationFiltrationEngineering

The invention discloses a full-automatic cutting fluid magnetic filter device. The full-automatic cutting fluid magnetic filter device comprises a filter cylinder. A water inlet is formed in one sideof the filter cylinder, and a water outlet is formed in the other side of the filter cylinder. A scrap outlet is formed in the lower end of the filter cylinder. The filter cylinder is internally provided with a powerful magnetic bar connected with an air cylinder, and the air cylinder is located at the upper portion of the filter cylinder. The water inlet, the water outlet and the scrap outlet areprovided with control valves correspondingly. According to the provided full-automatic cutting fluid magnetic filter device, cutting fluid filtration is convenient and fast, full automation is achieved, and the labor cost is reduced.

Owner:ZHONGSHAN MLTOR CNC TECH CO LTD

Boron-phosphorus alloy cast iron used in air compressor cylinder block and its manufacturing process

InactiveCN102268587AImprove wear resistanceImprove tensile propertiesProcess efficiency improvementElectric furnaceAlloyCylinder block

Owner:ZHUJI HUAJIA AIR COMPRESSOR

Reinforcing pipe sleeve and clamping sleeve for automobile radiator and intercooler, and use method

ActiveCN103382878AExtended service lifeReduce replacement rateInternal combustion piston enginesEngine cooling apparatusEngineeringIntercooler

Owner:李冬根

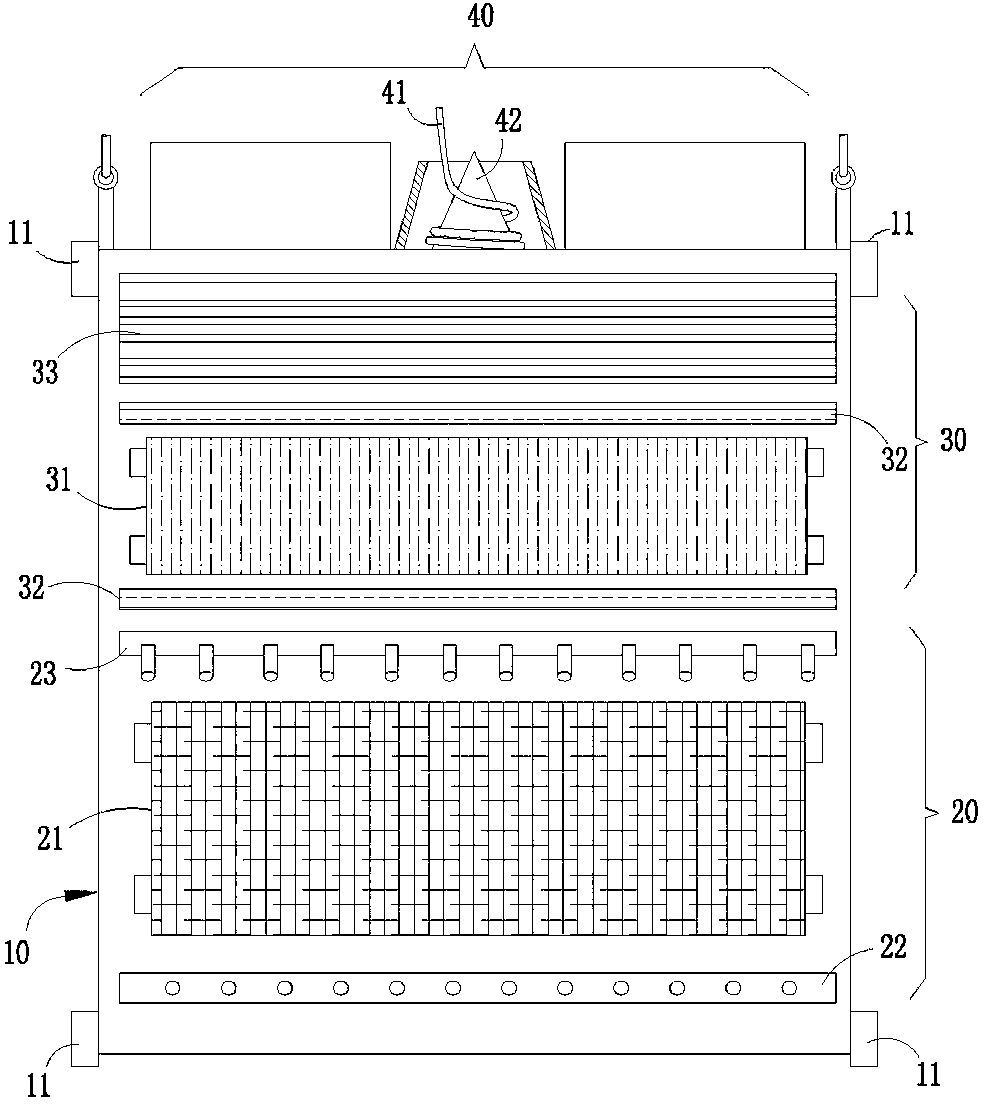

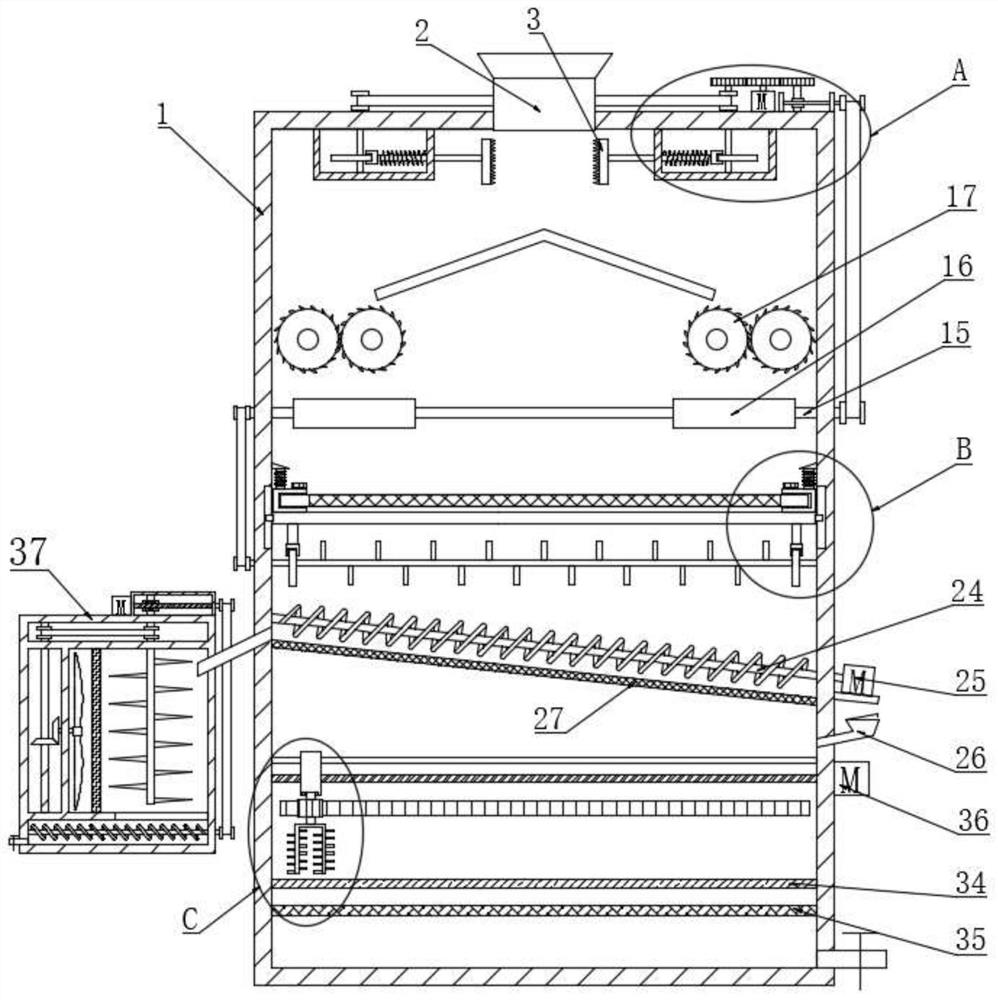

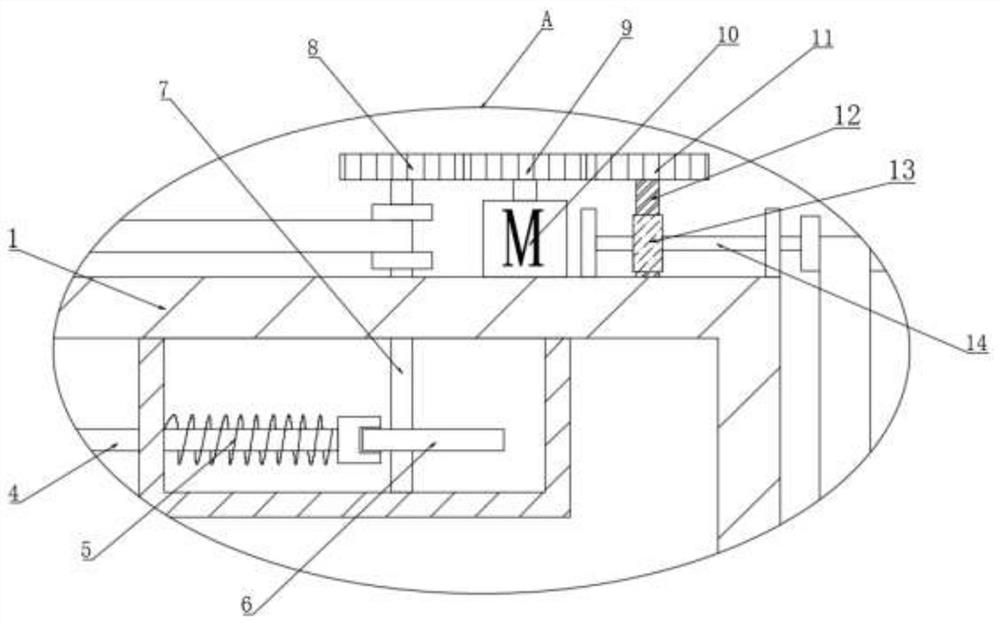

High-quality ceramic stone machining system

InactiveCN107913778AAvoid unmanageable problemsImprove product qualityMagnetic separationGrain treatmentsIron removalStone particle

The invention discloses a high-quality ceramic stone machining system. The high-quality ceramic stone machining system comprises a slurry inlet pipe, a grinding mechanism for grinding slurry, a filtering mechanism for filtering the slurry, a drying mechanism for drying ceramic stone particles, and an iron removal mechanism for removing iron in the ceramic stone particles. The high-quality ceramicstone machining system has the beneficial effects that the slurry can be subjected to adsorbing impurity removal after being dried and formed, iron scraps in the slurry are reduced, and the problem that due to the fact that impurity removal is carried out before an overall process, the iron scraps mixed in the work process cannot be treated is avoided; the product quality is improved, a continuousproduction mode of grinding, filtering and screening, drying and iron removing can be formed, and machining efficiency is greatly improved; and the overall structure is simple, and very good market generalization performance is achieved.

Owner:ZHENGZHOU SOUQU INFORMATION TECH CO LTD

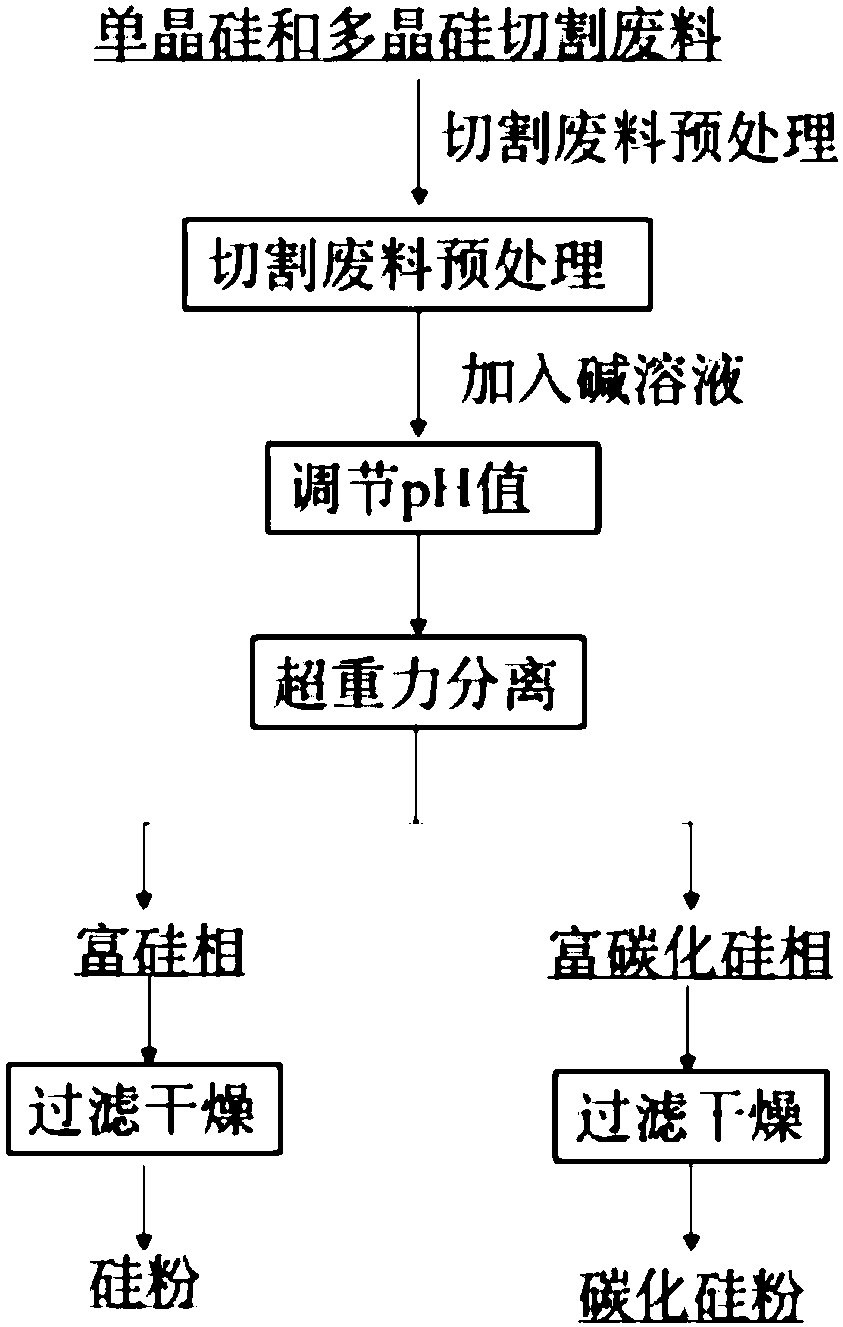

Method for recycling silicon powder from crystalline silicon cutting waste

Owner:CHINA ENFI ENGINEERING CORPORATION

Steel plate machining rust removal device capable of collecting waste scraps conveniently

InactiveCN108687634AEasy to collectAvoid random flyingGrinding carriagesGrinding drivesFixed frameArchitectural engineering

Owner:芜湖良匠机械制造有限公司

CrMo steel scrap dephosphorization and chrome-preservation smelting process

Owner:ZHANGJIAGANG CITY GUANGDA MACHINERY FORGING

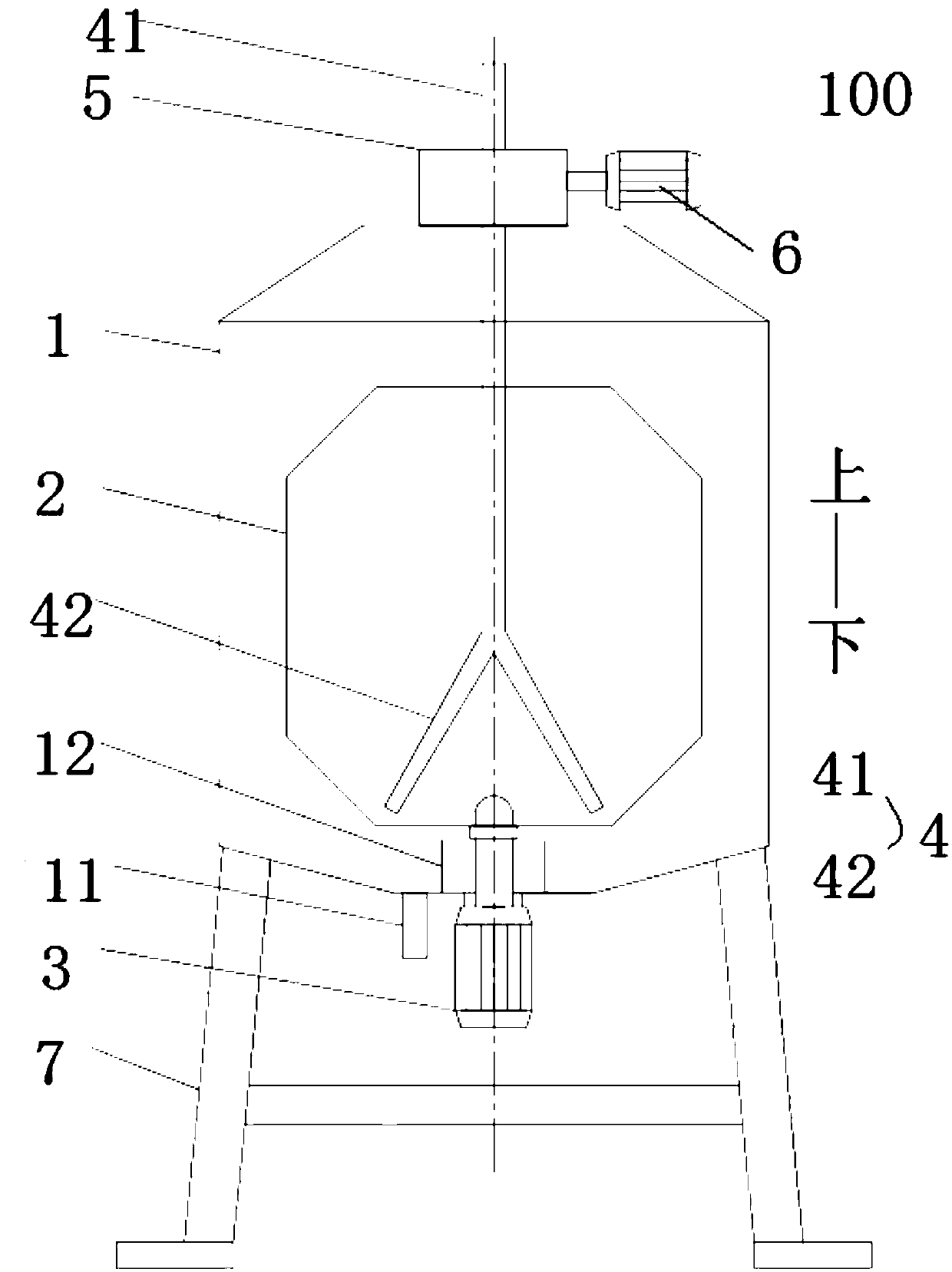

Sewage sludge separation treatment equipment

InactiveCN112759207AImprove the mixing effectImprove crushing effectSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesElectric machineProcess engineering

Owner:吴江市绿源环保科技有限公司

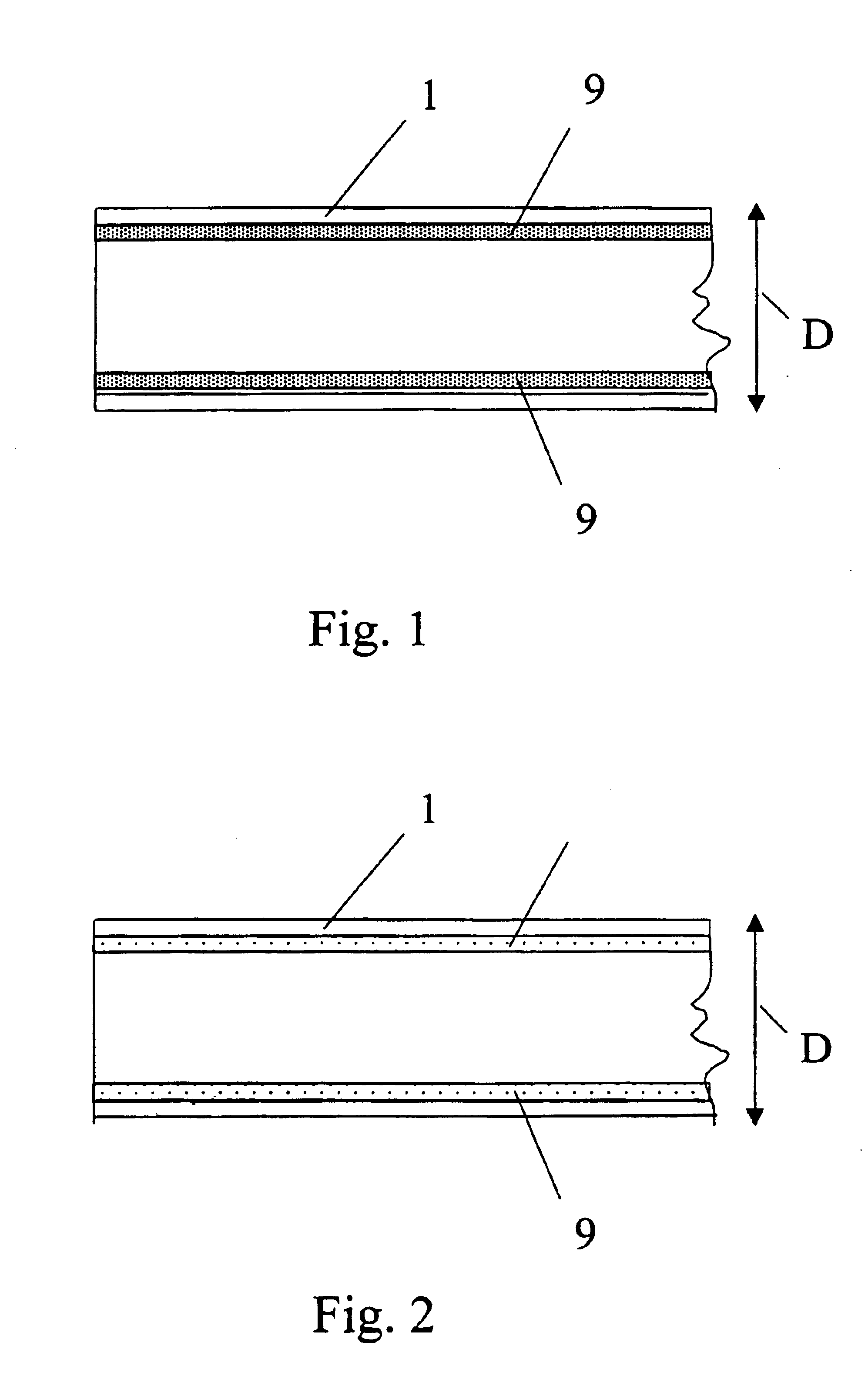

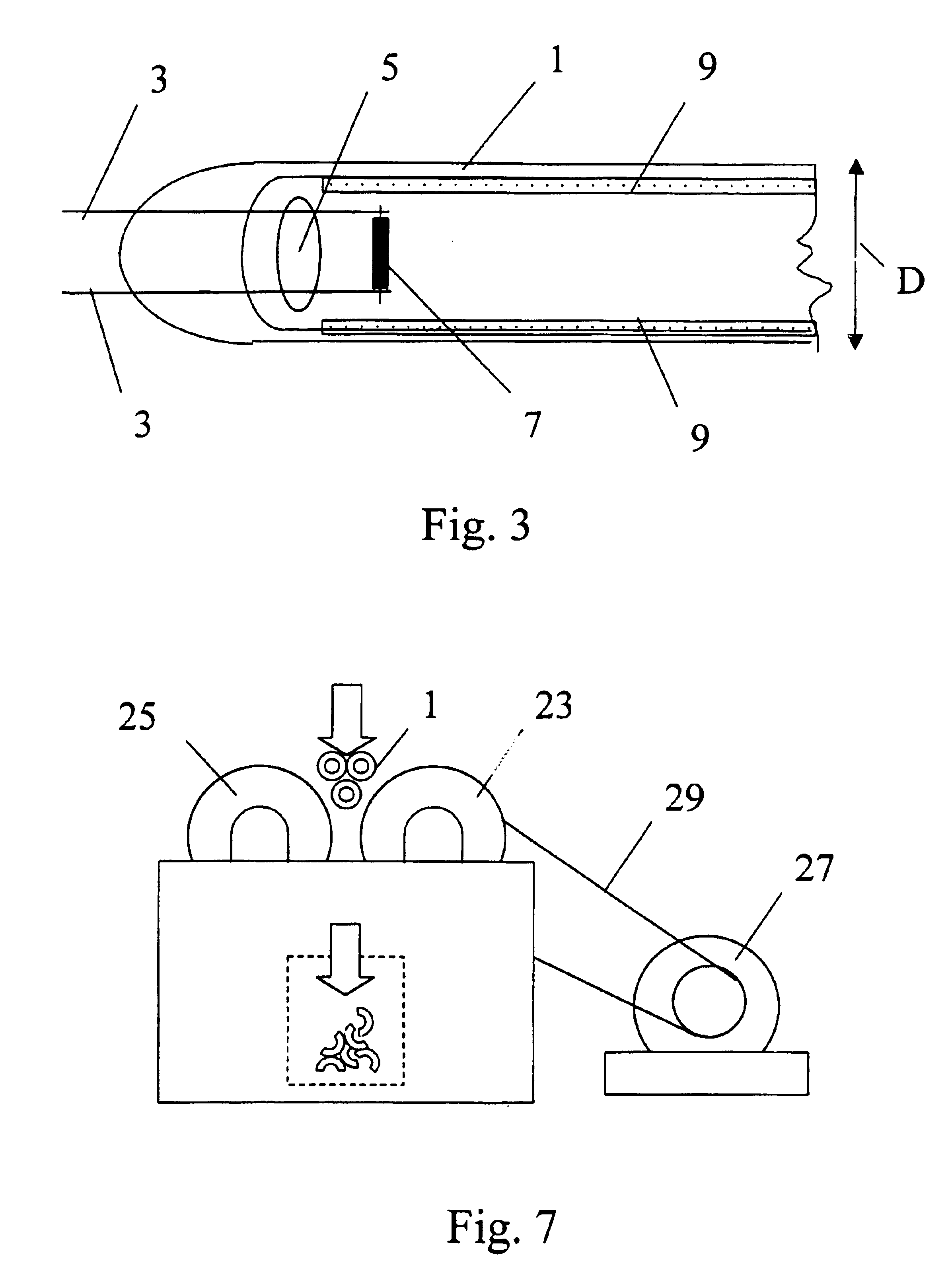

Self-peelable protective coating for cogging and forging process of pure titanium or titanium alloy and production process of self-peelable protective coating

InactiveCN104371385ASimple coating processGood molding effectAlkali metal silicate coatingsProduction rateTitanium

Owner:BEIJING TIAN LICHUANG SCI & TECH OF GLASS DEV

Color steel deburring device

InactiveCN110116241APlay a role in cleaningImprove practicalityFeeding apparatusPositioning apparatusFixed frameArchitectural engineering

Owner:ZHONGXIANG DINGMAO TECH

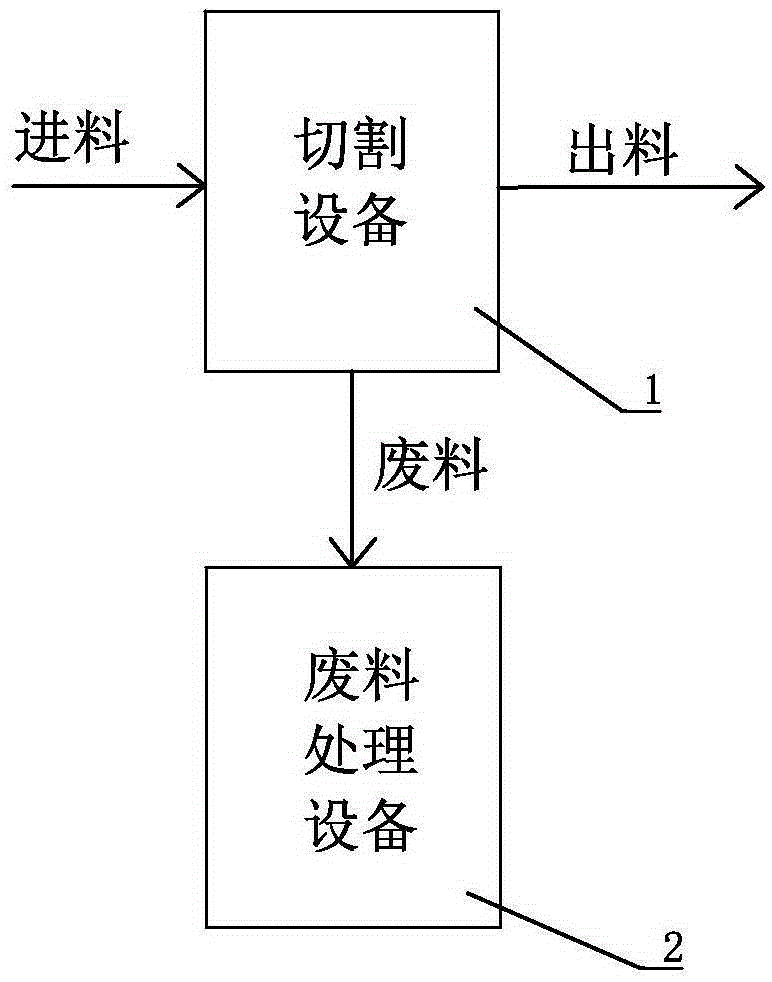

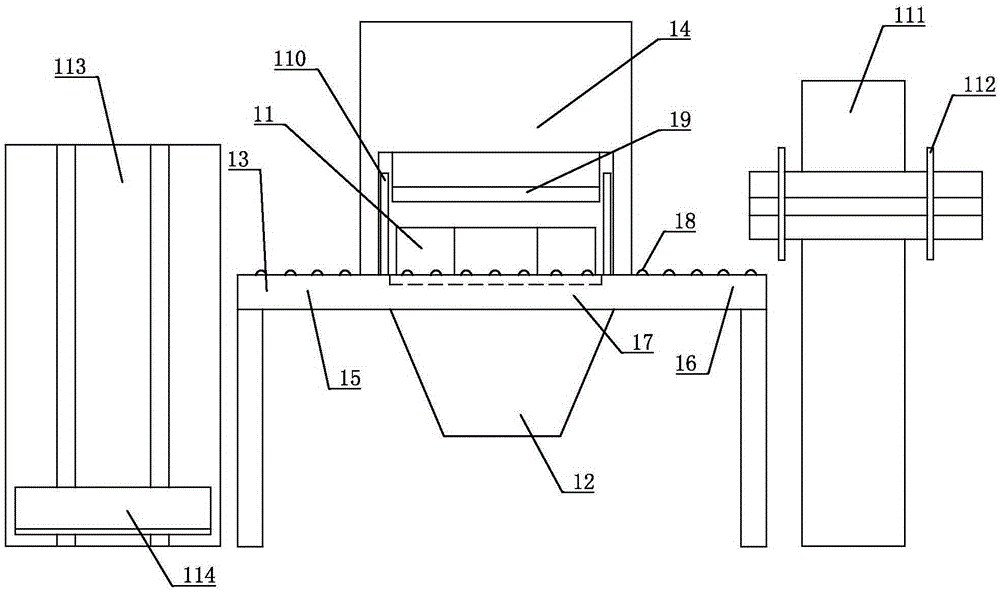

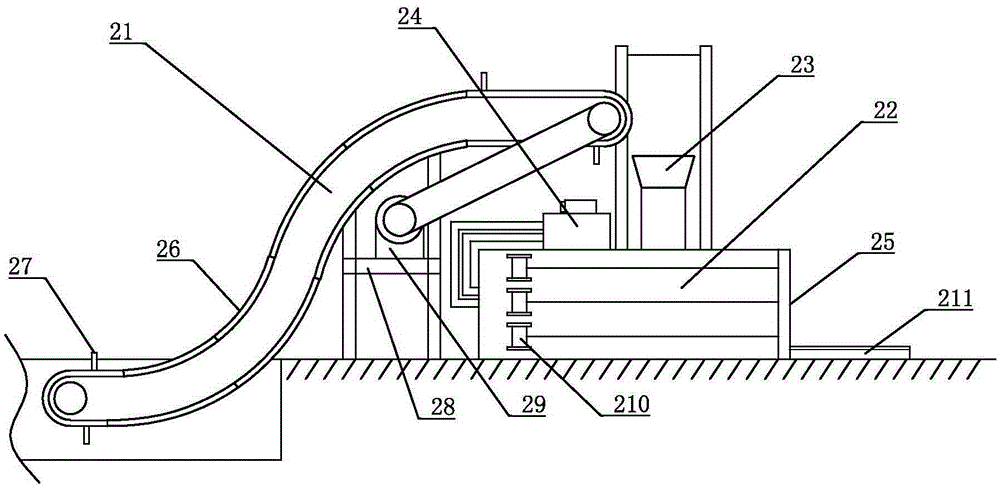

Efficient printed matter cutting machine with waste treatment equipment

InactiveCN105313166ARealize processingImprove production safetyBinding material applicationMetal working apparatusWaste treatmentEquipment use

Owner:广东兴艺数字印刷股份有限公司

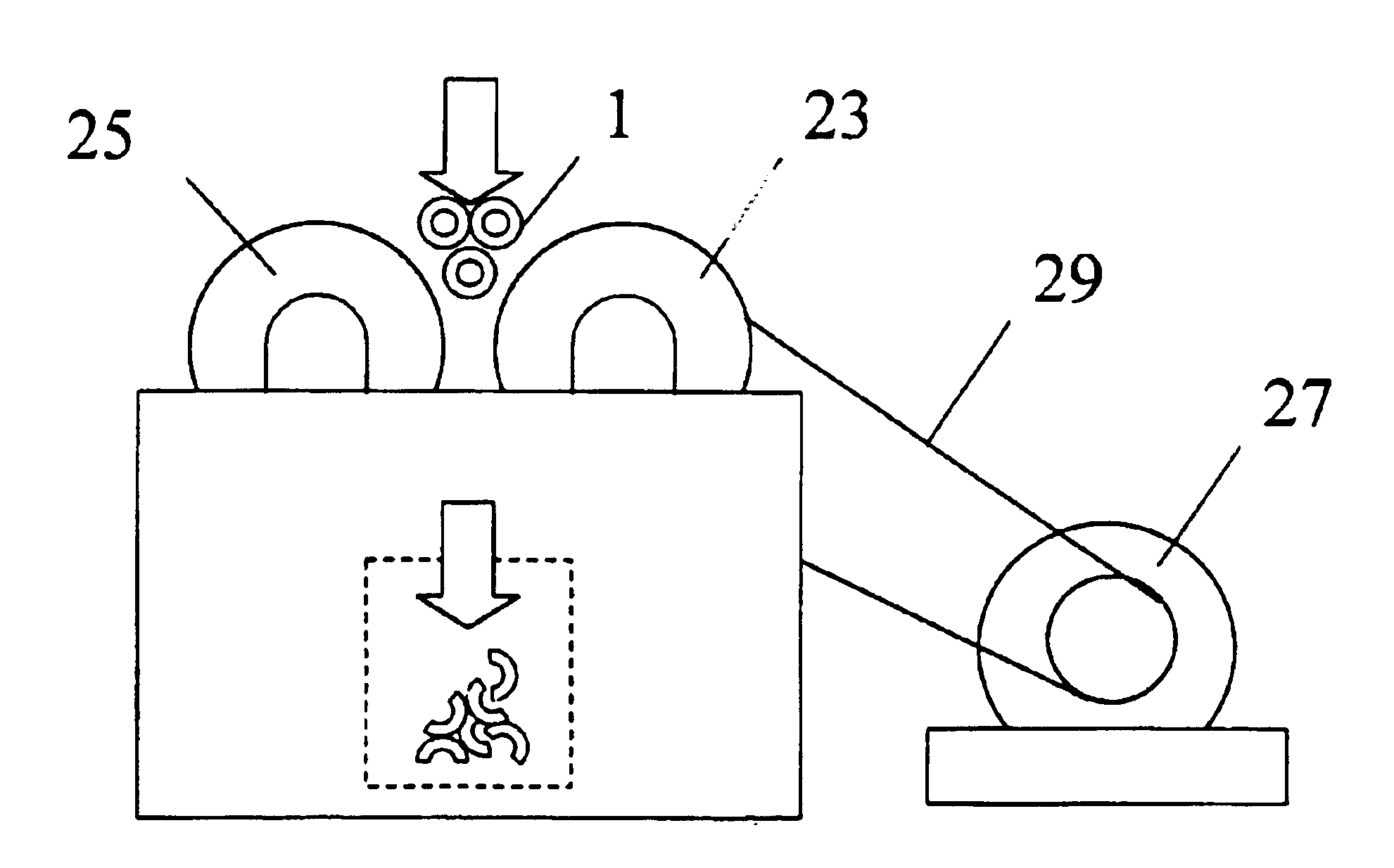

Recycling and regeneration device for FDM printing waste

Owner:NINGXIA KOCEL MOLD

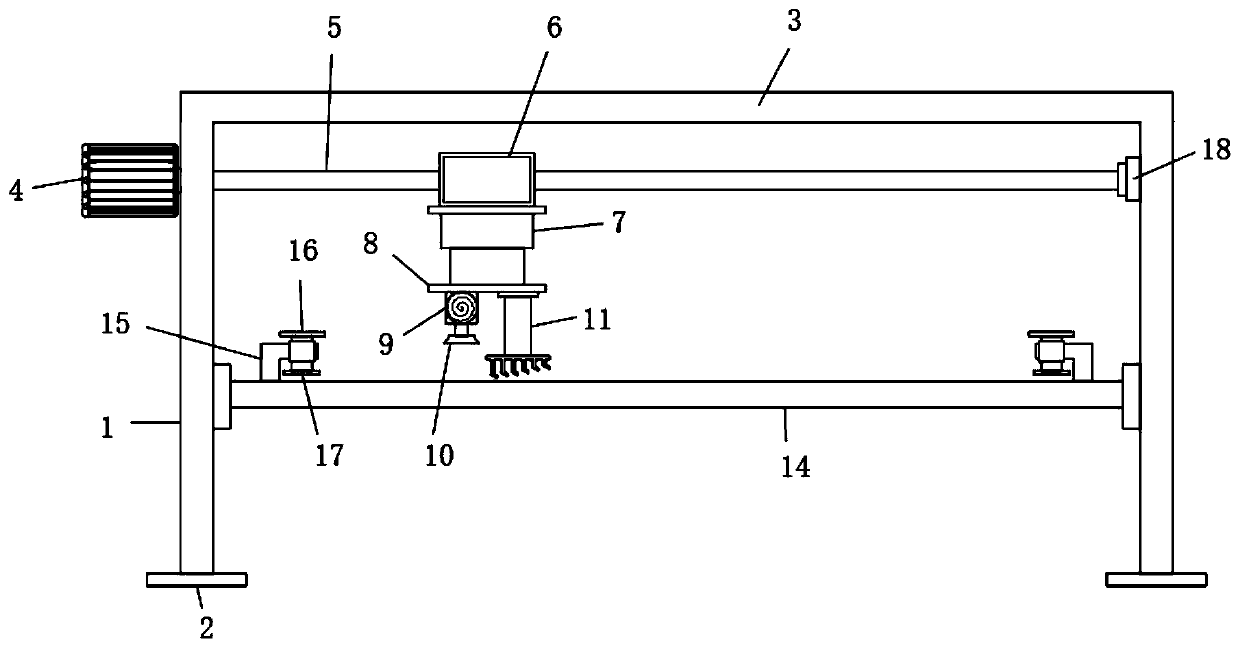

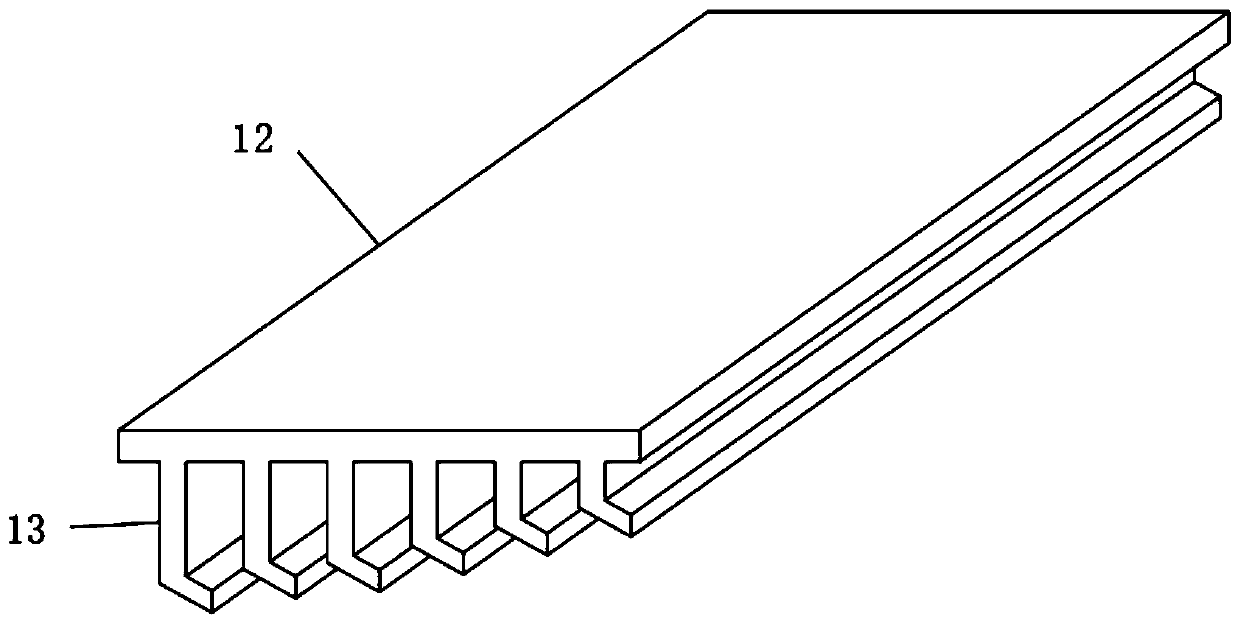

Cutting machine

The invention provides a cutting machine, which comprises a frame support rod (1), wherein the frame support rod (1) is fixed on a base plate (2); an idler wheel (3) is arranged on the base plate (2); the idler wheel (3) is mounted in a guide rail (4); the guide rail (4) comprises a first guide rail main body (5) and a second guide rail main body (6); a guide rail cavity (7) is formed by the first guide rail main body (5) and the second guide rail main body (6); and the bottom of the guide rail cavity (7) is provided with a clearance (8). According to the cutting machine provided by the invention, the guide rail has a split structure and the clearance is arranged on the bottom of the guide rail cavity, so the cloth scraps generated in the cutting process can be timely discharged from the clearance on the bottom after falling into the guide rail cavity, and the process of frequently halting for clearing the cloth scarps is unnecessary, thereby increasing the working efficiency under the condition that the cost is not increased. The cutting machine has simple structure and high stability.

Owner:CHANGSHU HONGFANG MACHINERY

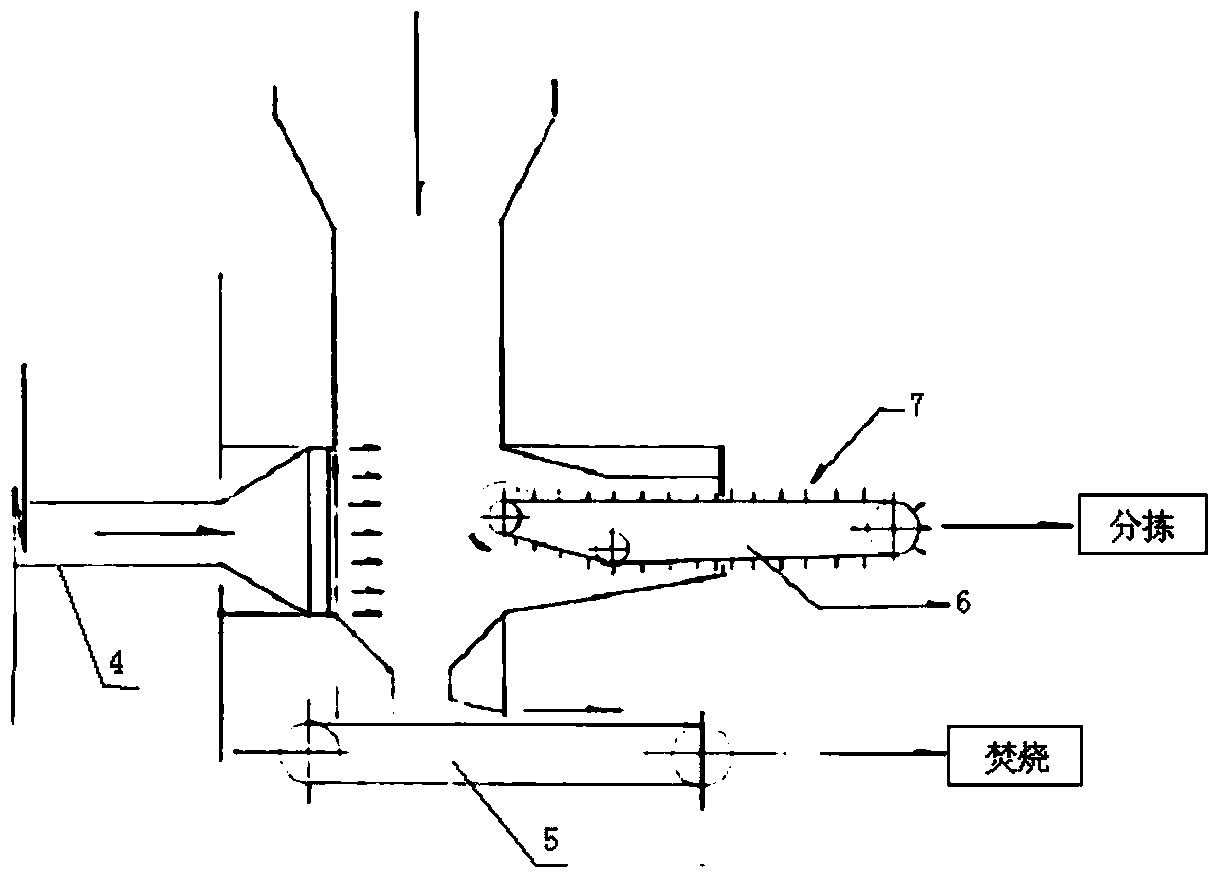

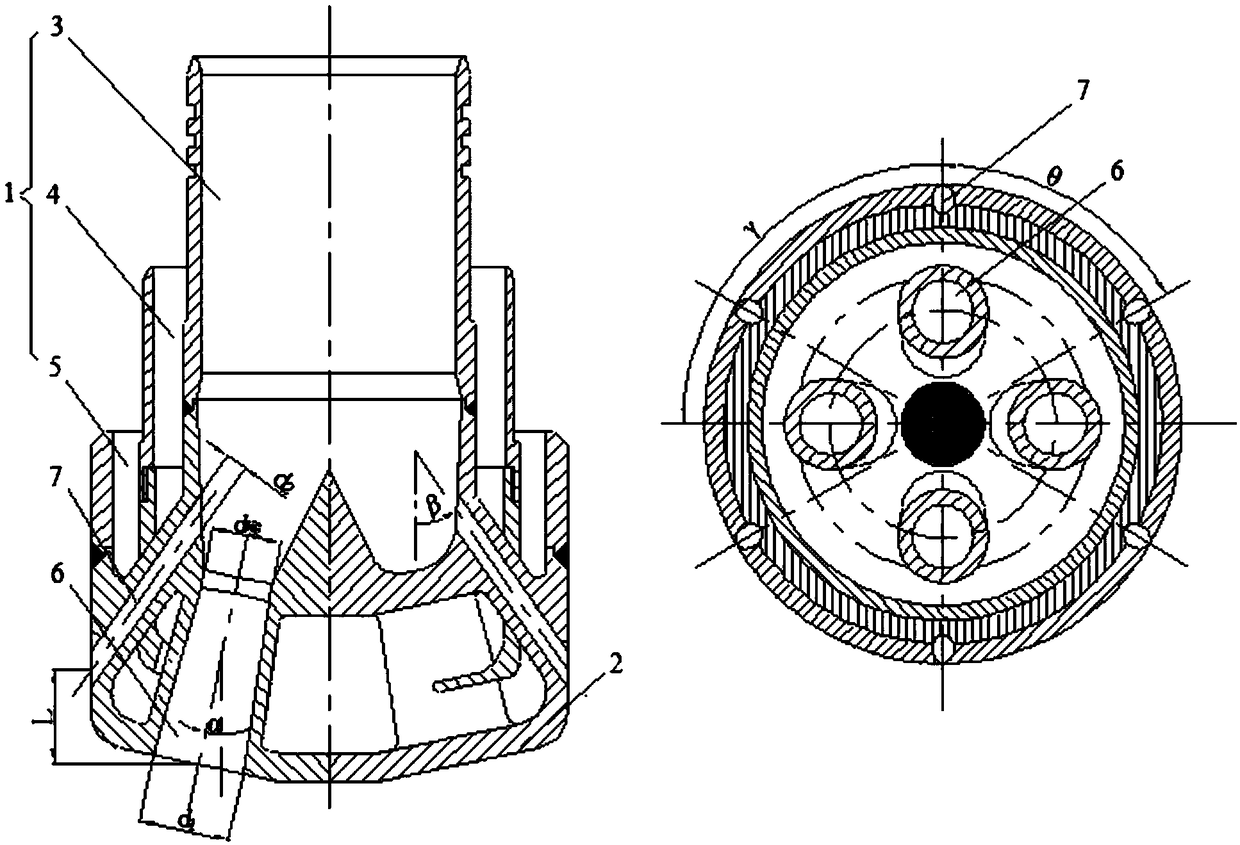

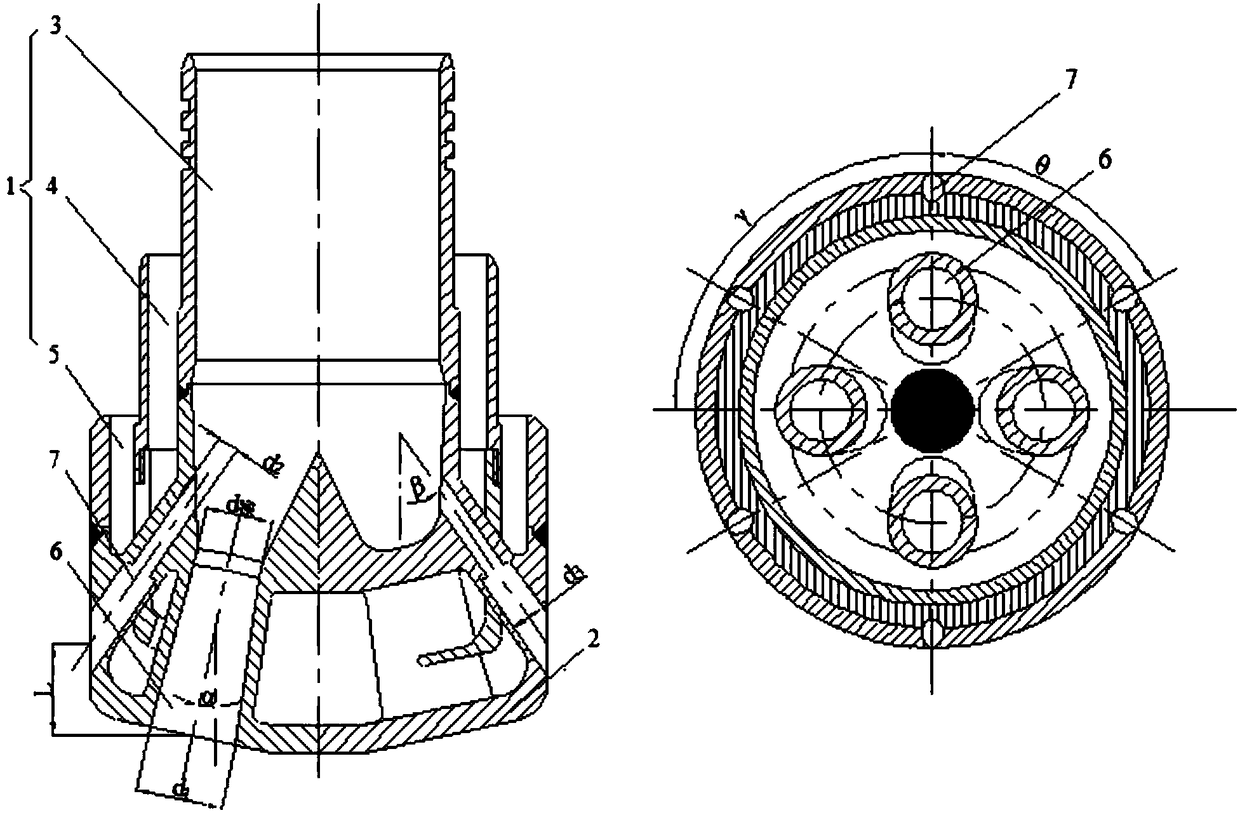

Single-flow-channel secondary combustion oxygen lance capable of improving scrap ratio of converter and application method of single-flow-channel secondary combustion oxygen lance

PendingCN108977620AHigh desulfurization rateIncrease the amount of steel scrap into the furnaceManufacturing convertersProcess efficiency improvementCombustionSpray nozzle

Owner:NORTHEASTERN UNIV

Pipe punching equipment

Owner:CHONGQING YOUWEI PLASTIC CO LTD

Method for producing silicon carbide (SiC) ceramics by polysilicon wire-electrode cutting scraps

The invention discloses a method for producing silicon carbide (SiC) ceramics by polysilicon wire-electrode cutting scraps and belongs to the field of production of functional materials, aiming to solve the problem that scraps are always discarded directly at present. The method includes adding SiC powder to a raw material, namely the polysilicon wire-electrode cutting scraps, and then sintering the mixture to obtain the SiC ceramics. As the polysilicon wire-electrode cutting scraps are taken as the raw material for producing the SiC ceramics, production process is simplified and production cost is lowered.

Owner:SHAANXI JUJIEHAN CHEM CO LTD

Preparing method of plate material for vehicle

Owner:ANHUI TIANYU AUTO PARTS MFG

Frosted cover plastic product injection molding process

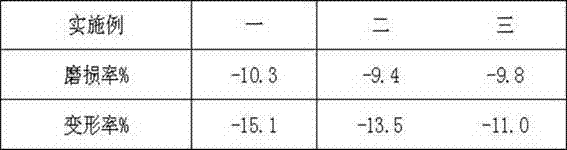

InactiveCN109016423AImprove quality and efficiencyImprove injection molding efficiencyHot runnerQuality control

The invention discloses a frosted cover plastic product injection molding process which comprises at least the following process steps: a storage procedure; an extrusion procedure; mold opening; moldassembly; injection; and pressure maintaining, wherein a hot running of a mold used for injection molding comprises the following temperature sections: a first section of 277-280 DEG C, a second section of 277-280 DEG C, a third section of 270-275 DEG C, a fourth section of 285-290 DEG C, a fifth section of 273-278 DEG C, and a sixth section of 270-275 DEG C. Through the precise control of processparameters of all the sections in the frosted cover plastic product injection molding process disclosed by the invention, not only can the injection molding fluid quality control be achieved, but also the injection molding product quality and the injection molding efficiency can be improved, and the scrap rate can be lowered.

Owner:ZHEJIANG FEITENG MOLDING CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap