Sewage sludge separation treatment equipment

A technology for separation and treatment of sewage sludge, which is applied in the fields of sludge treatment, water/sewage treatment, dehydration/drying/concentrated sludge treatment, etc. Need to wait for the problem to achieve the effect of significant crushing effect and good mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

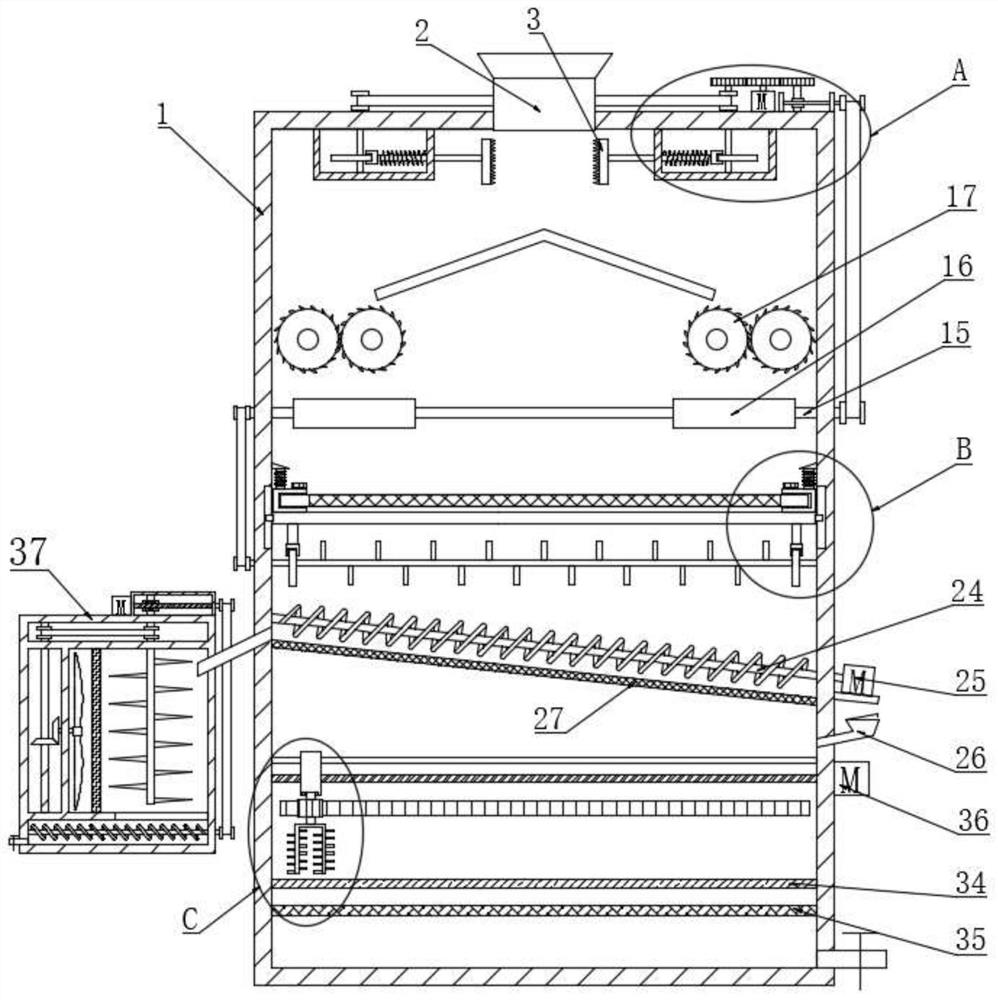

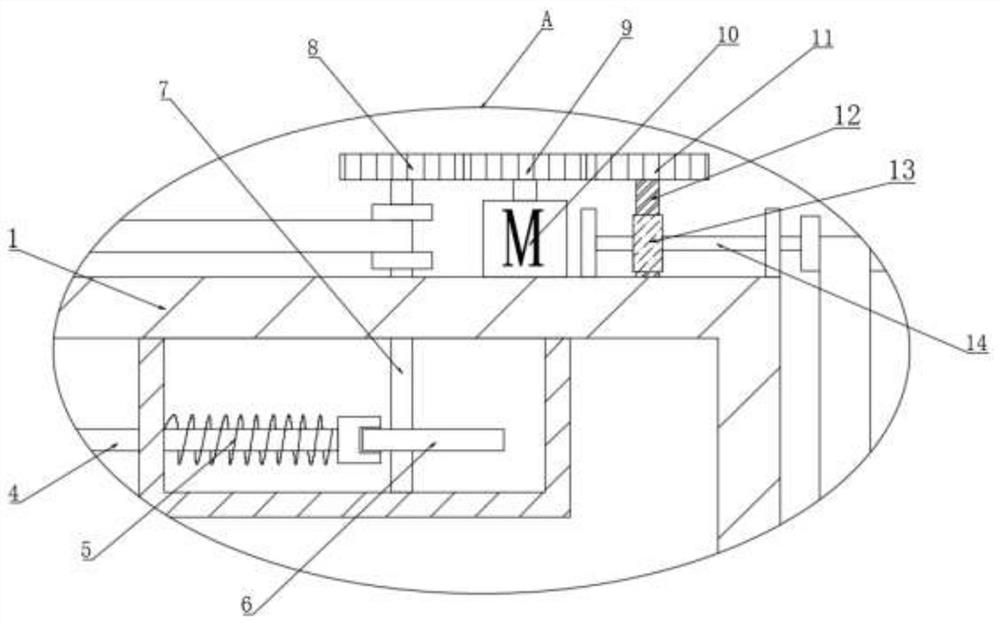

[0030] see Figure 1 to Figure 6, a sewage sludge separation treatment equipment, including a first treatment box 1, the top of the first treatment box 1 is provided with a feed port 2 for feeding, and the bottom of the feed port 2 is symmetrically provided with a The crushing tooth plate 3, the crushing tooth plate 3 is connected with a reciprocating drive assembly through a connecting rod 4, and the reciprocating drive assembly includes a first spring 5, a first cam 6, a first rotating shaft 7 and a first gear 8, the The first rotating shaft 7 is rotationally connected through a synchronous belt, and the first gear 8 is connected with a first rotary drive assembly through a second gear 9. The first rotary drive assembly includes a first motor 10, and the bottom of the crushing tooth plate 3 is An inverted V-shaped buffer plate is provided, and several crushing rollers 17 that are convenient for crushing are arranged under both sides of the inverted V-shaped buffer plate, and a

Embodiment 2

[0043] see Figure 1 to Figure 6 , a sewage sludge separation treatment equipment, including a first treatment box 1 and a second treatment box 37, also includes a second filter screen 27, the second filter screen 27 is provided with a material delivery assembly, the material delivery assembly Comprising a first material delivery shaft 24 and a second motor 25, the first material delivery shaft 24 is provided with material delivery blades, one side of the second filter screen 27 communicates with a second treatment box 37 through a pipeline, the A drying assembly is arranged in the second processing box 37, and the drying assembly includes a fifth rotating shaft 44, a blowing fan blade 45 and an electric heating wire 46. Three rotary drive assemblies, the third rotary drive assembly includes a fourth motor 38, a second worm 39 and a second worm wheel 40, the second worm wheel 40 is fixedly connected to the second stirring shaft 41, the second stirring shaft 41 is provided with a

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap