Equipment for high-efficiency premixing reaction of sludge and lime

A reaction equipment and pre-mixing technology, applied in mixers, mixing methods, sludge treatment and other directions, can solve the problems of high consumption of calcium powder, uneven mixing, and difficulty in realizing sludge properties, so as to save costs and improve mixing effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0015] The structural principle and working principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

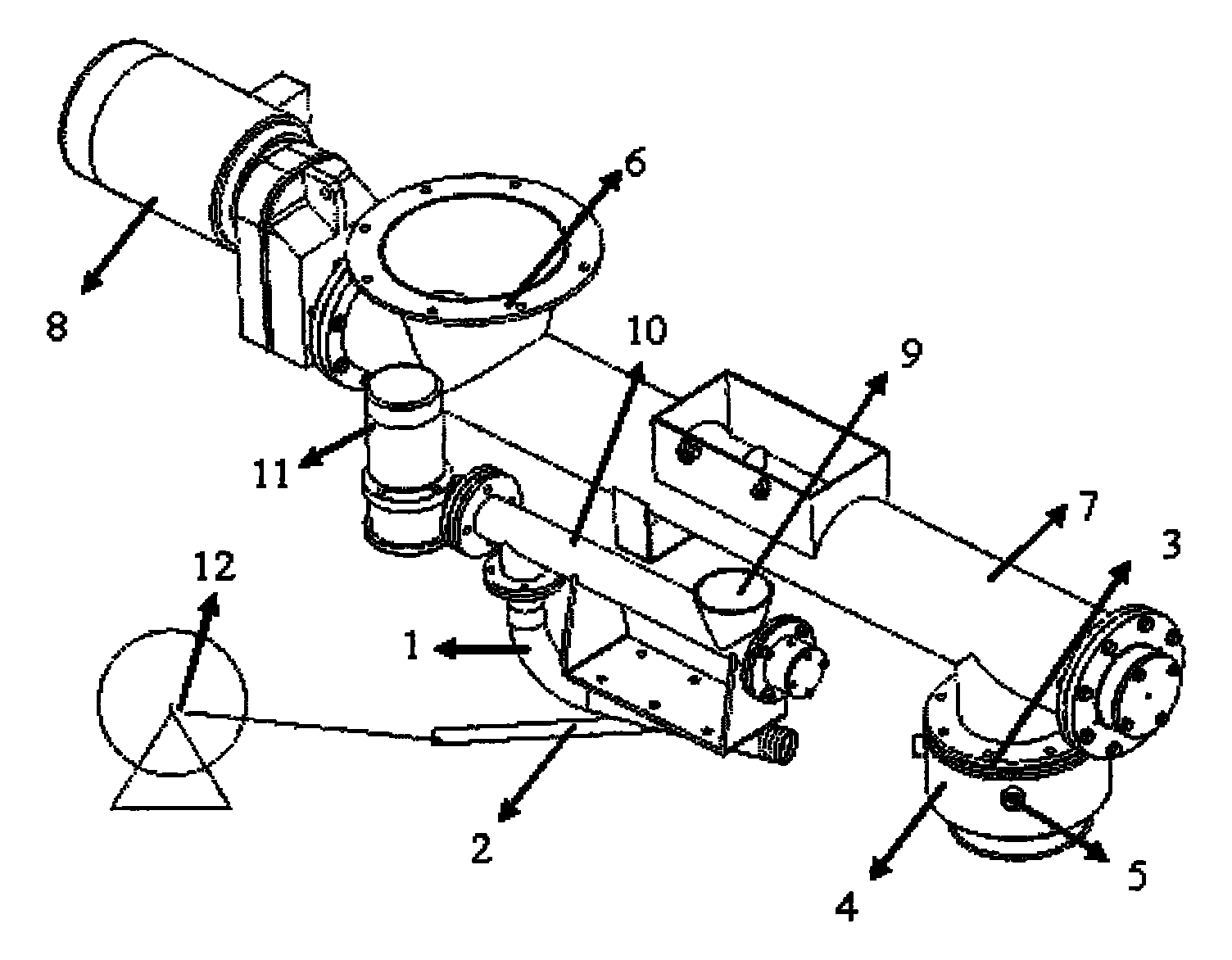

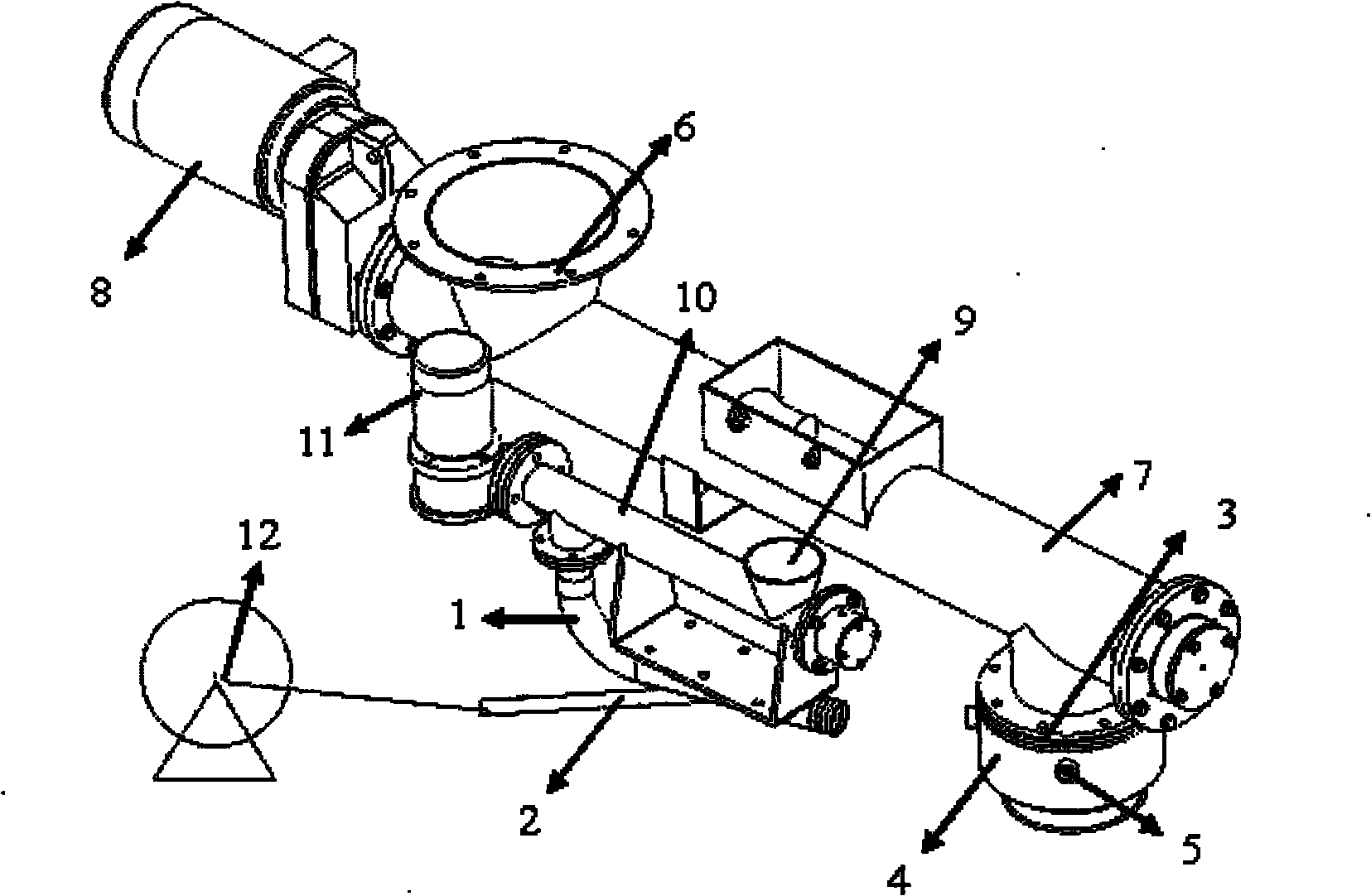

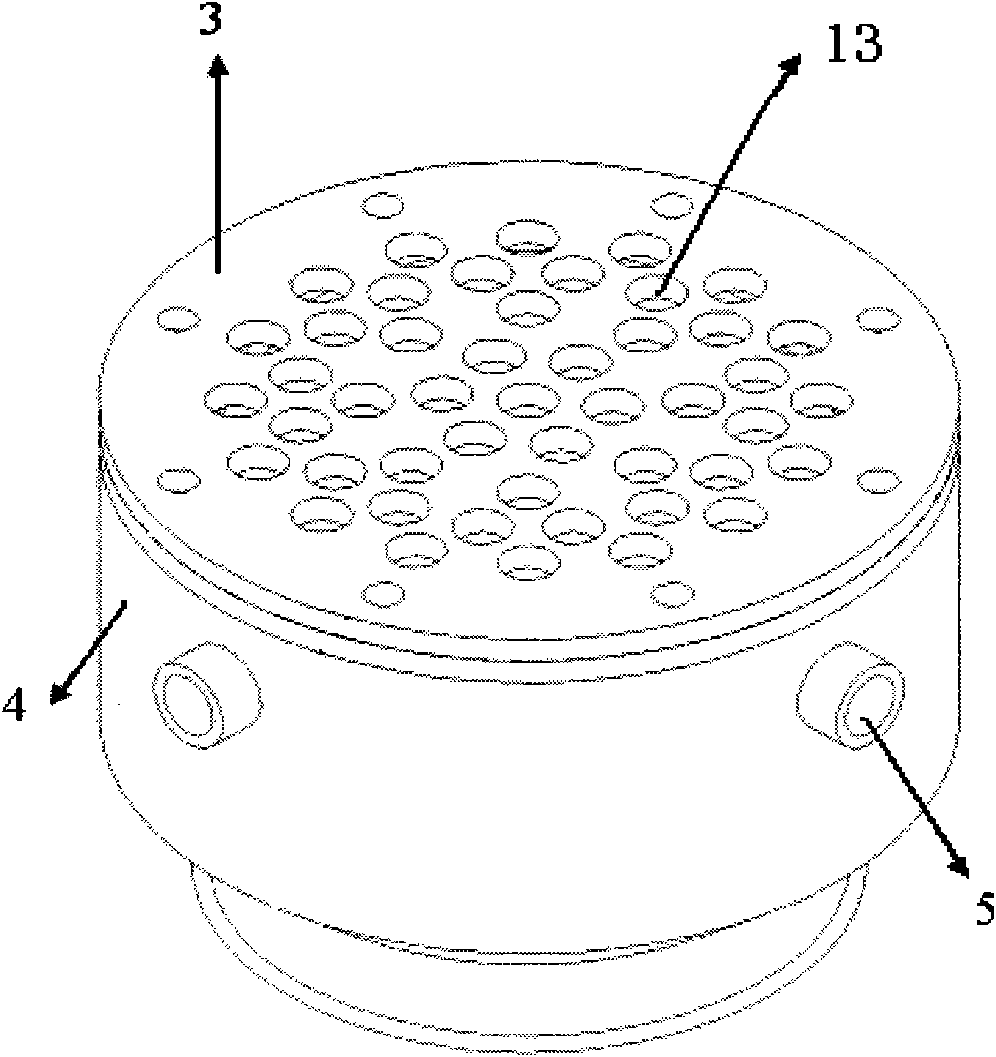

[0016] With reference to the drawings, a high-efficiency premixing reaction equipment for sludge and lime includes a sludge screw feeder 7. A sludge feed port 6 is provided above the sludge screw feeder 7 and one side of the sludge screw feeder 7 is provided The first variable frequency motor 8, the power output end of the first variable frequency motor 8 is connected with the screw shaft in the sludge screw feeder 7, and an extrusion template 3 and an extrusion module 3 are arranged under the other side of the sludge screw feeder 7 Extrusion holes 13 are distributed on the surface, a premix silo 4 is arranged under the extrusion template 3, and the premix silo 4 is equipped with four nozzles 5 on the silo body, and the sludge screw feeder 7 is provided with a lime screw feeder outside 10. The lime screw feeder 10 is provid

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap