Mixing device for processing medical intermediates

The technology of a mixing device and intermediates is applied in the field of mixing devices for the processing of pharmaceutical intermediates, which can solve the problems of insufficient mixing of raw materials and low mixing efficiency, so as to improve product quality, fully mix raw materials, and facilitate cleaning work. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

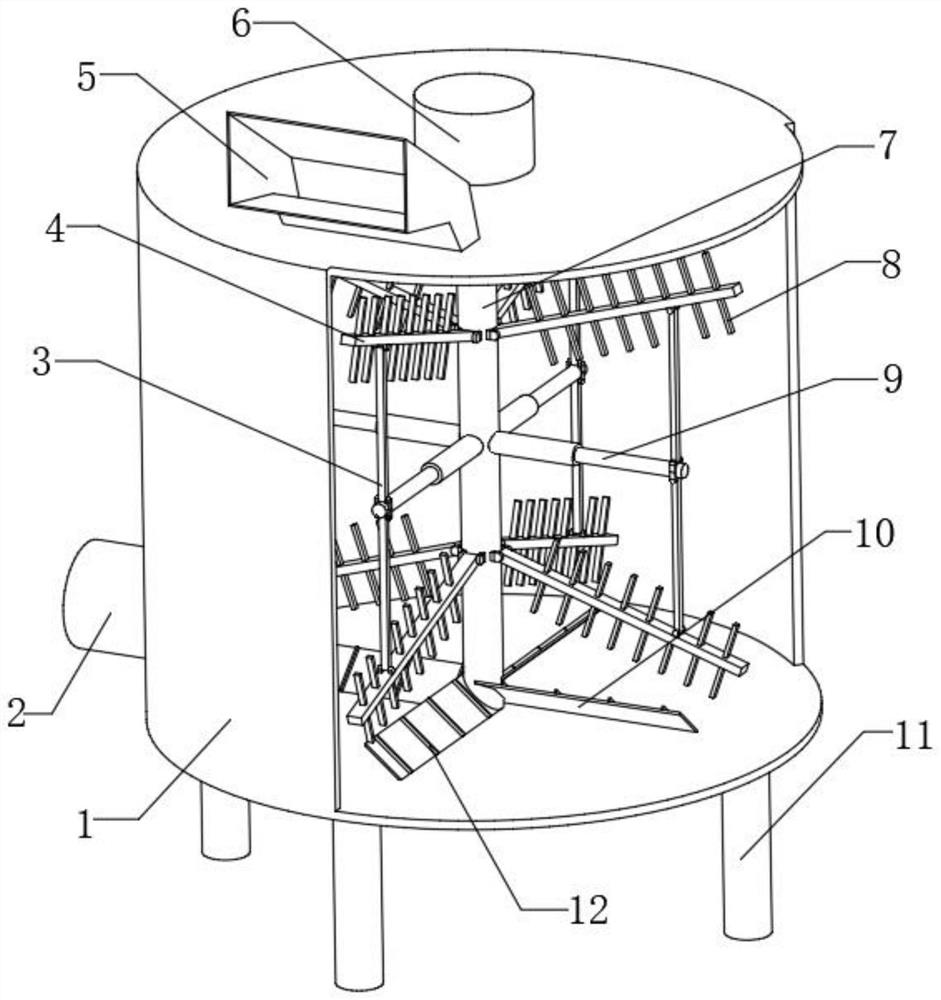

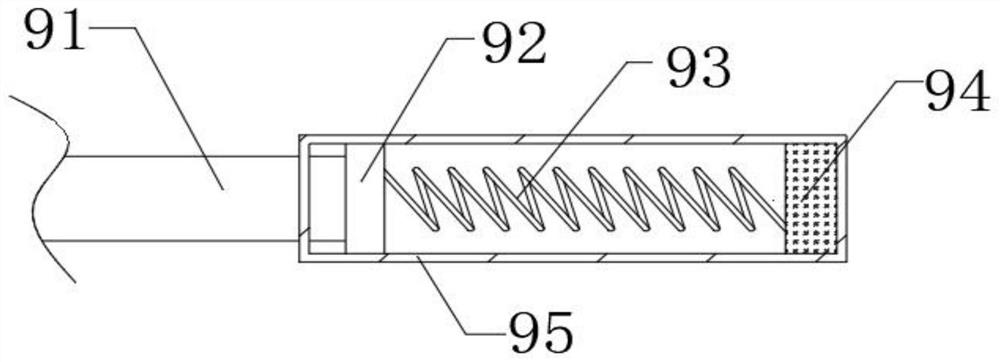

[0026] refer to figure 1 and figure 2 , a mixing device for processing pharmaceutical intermediates, comprising a mixing box 1, the top of the mixing box 1 is rotatably connected to a rotating shaft 7, and the top of the rotating shaft 7 is provided with a motor 6, and the outer wall of the middle part of the rotating shaft 7 is equidistantly fixedly connected to four telescopic mechanisms 9 , and the upper and lower outer walls at one end of each telescopic mechanism 9 are hinged with connecting rods 3, and one end of the two connecting rods 3 is hinged with a swing plate 4, and one end of each swing plate 4 is hinged at the outer wall of the rotating shaft 7, and each swing plate 4 The upper and lower outer walls are fixedly connected with a plurality of stirring rods 8. By setting the telescopic mechanism 9, the connecting rod 3, the swing plate 4, and the stirring rod 8, when the pharmaceutical intermediate is mixed and stirred, the telescopic mechanism 9 uses the connect...

Embodiment 2

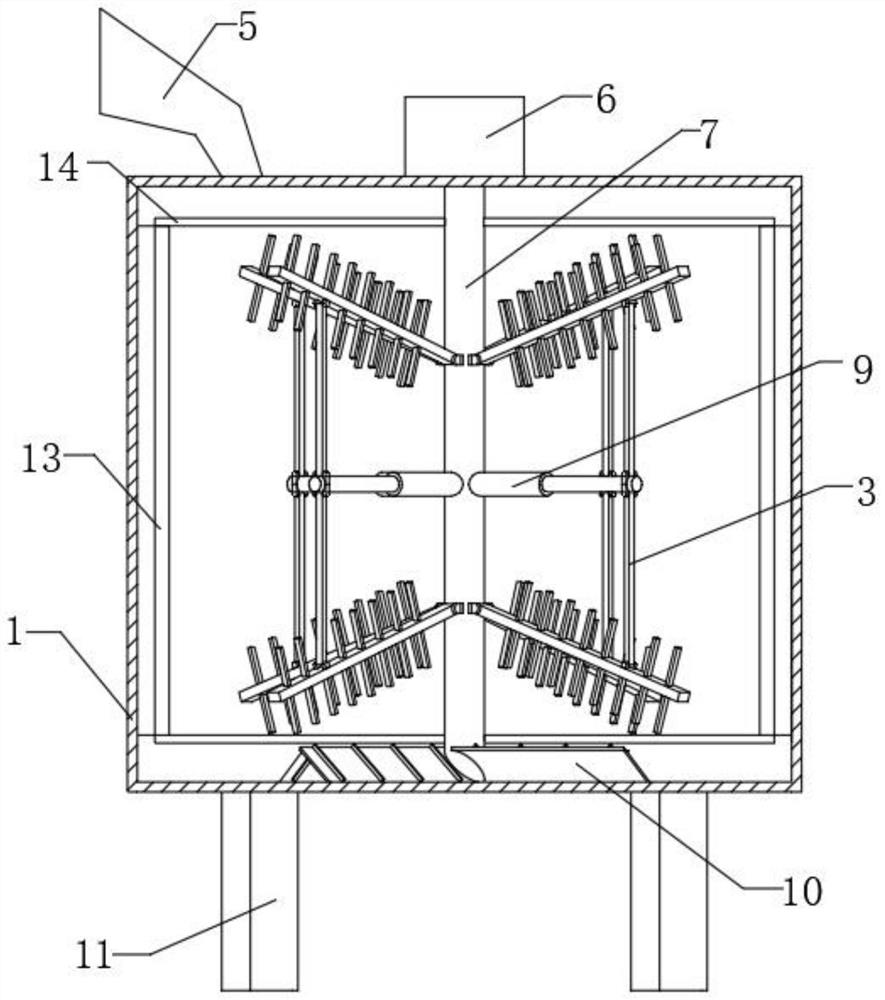

[0034] refer to image 3 , a mixing device for the processing of pharmaceutical intermediates. Compared with Example 1, two horizontal plates 14 are fixedly connected to the outer walls on both sides of the rotating shaft 7, and the outer walls on the opposite side of the two horizontal plates 14 are fixedly connected to scrapers. Plate 13, by arranging horizontal plate 14 and scraper plate 13, can scrape off the raw material attached to the inner wall of mixing box 1, avoiding the situation that the raw material adheres to the inner wall for a long time and makes it difficult to clean, and facilitates the cleaning work of the staff.

[0035] Working principle: Compared with Embodiment 1, two horizontal plates 14 are fixedly connected to the outer walls on both sides of the rotating shaft 7, and the outer walls on the opposite side of the two horizontal plates 14 are fixedly connected to the scraper plate 13. By setting the horizontal plates 14 and The scraper 13 can scrape of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap