Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31 results about "Small footprint" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

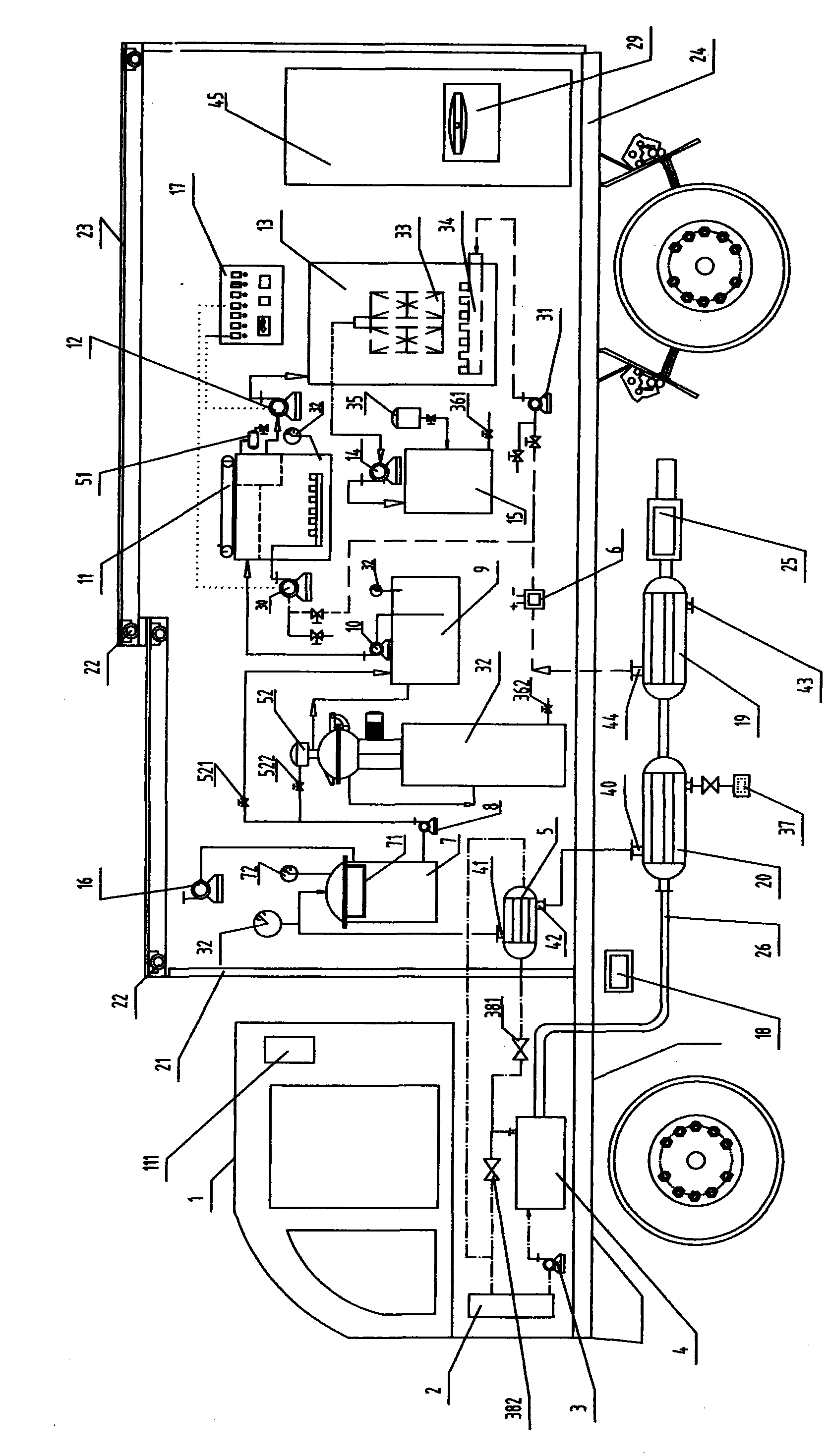

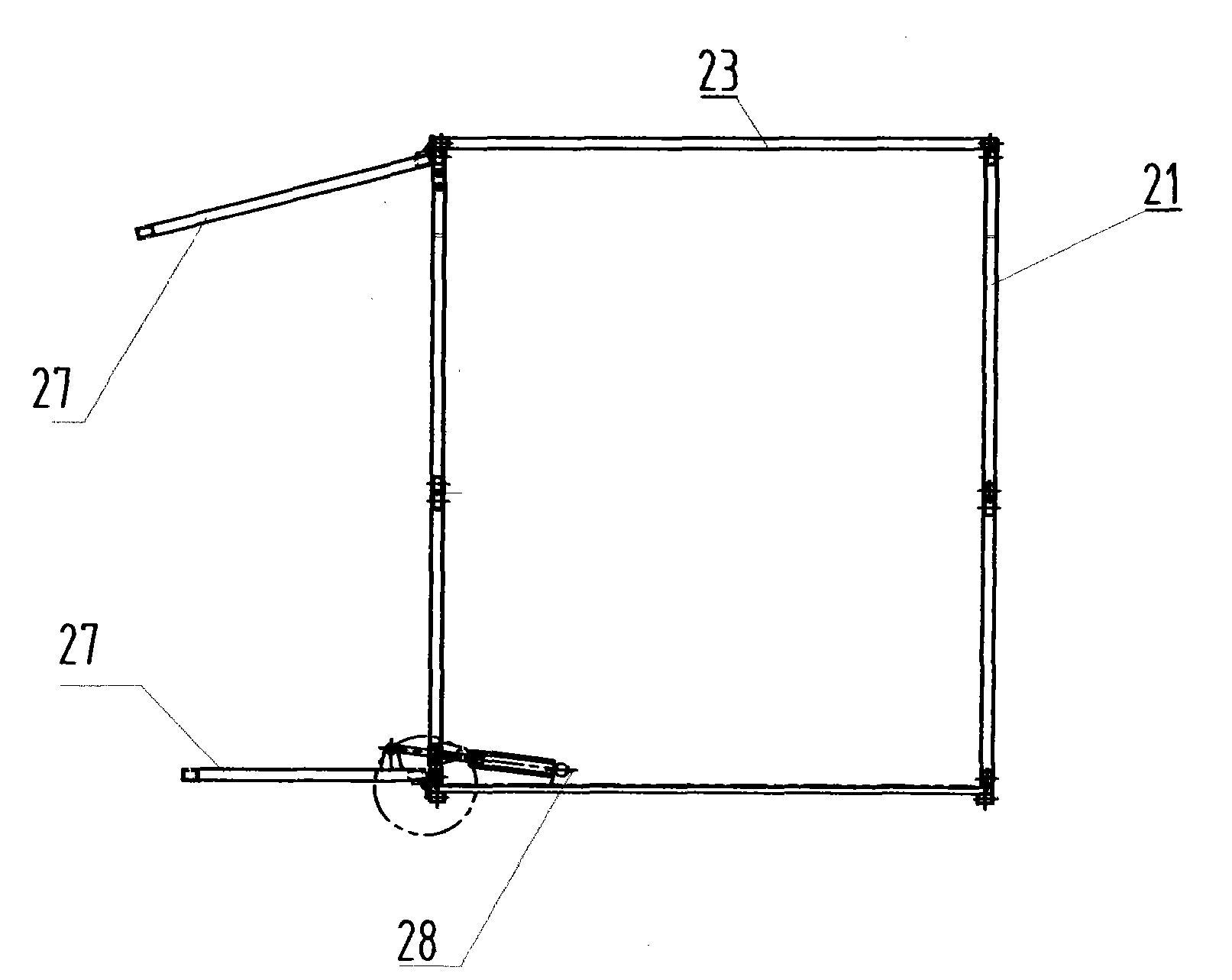

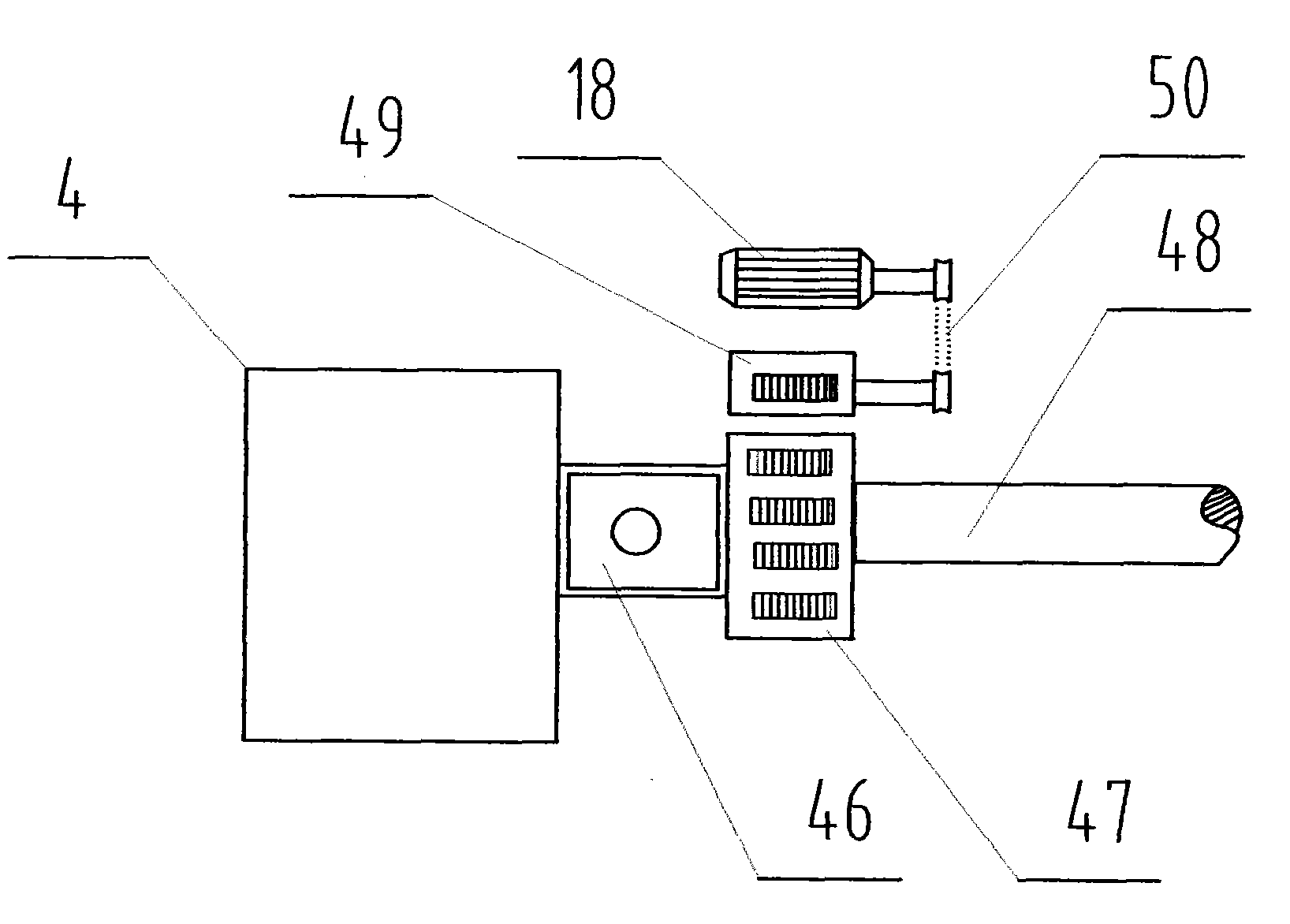

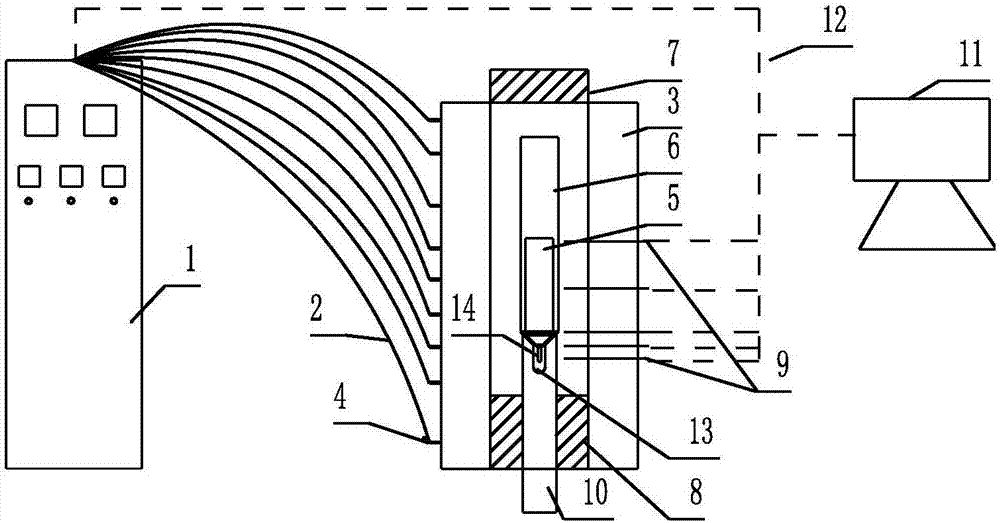

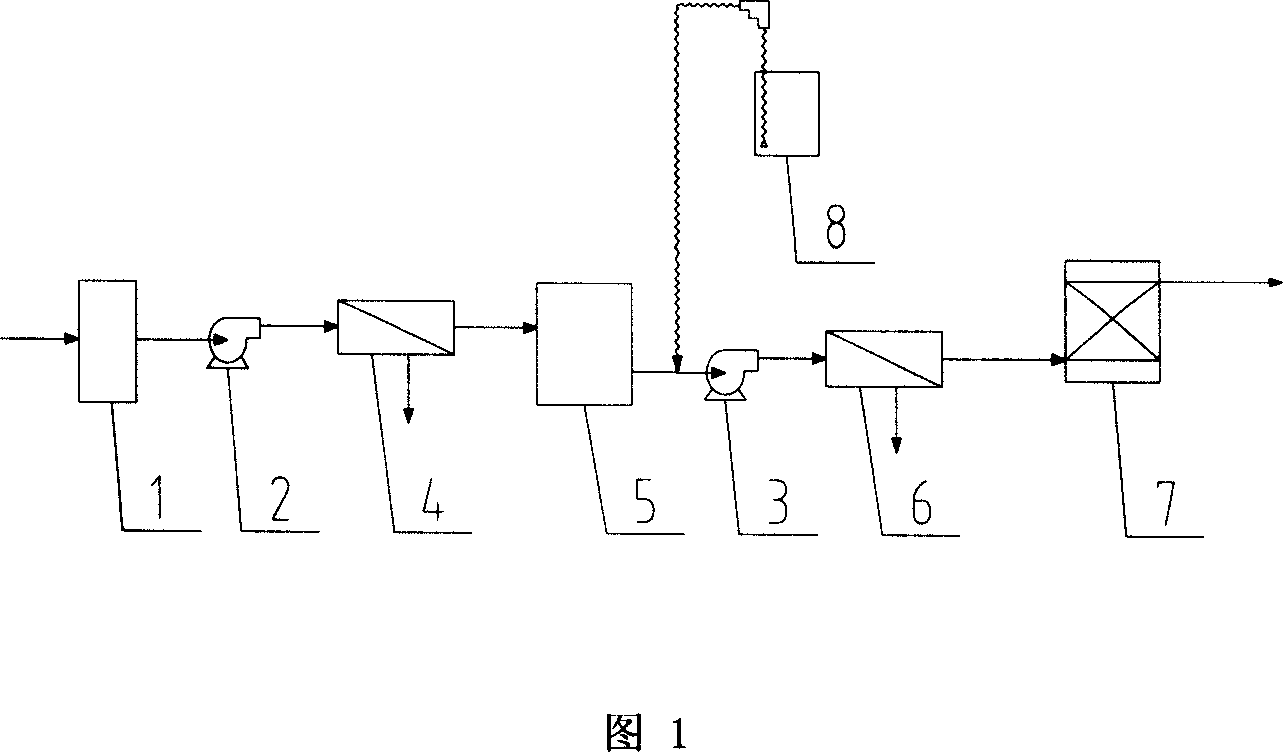

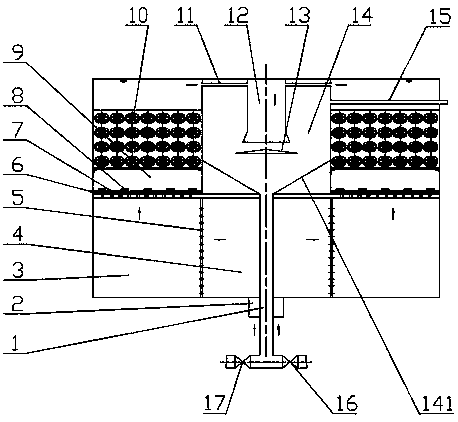

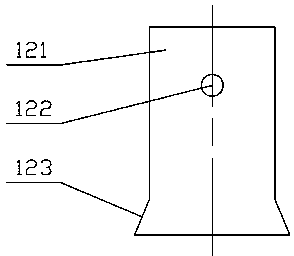

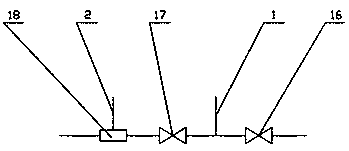

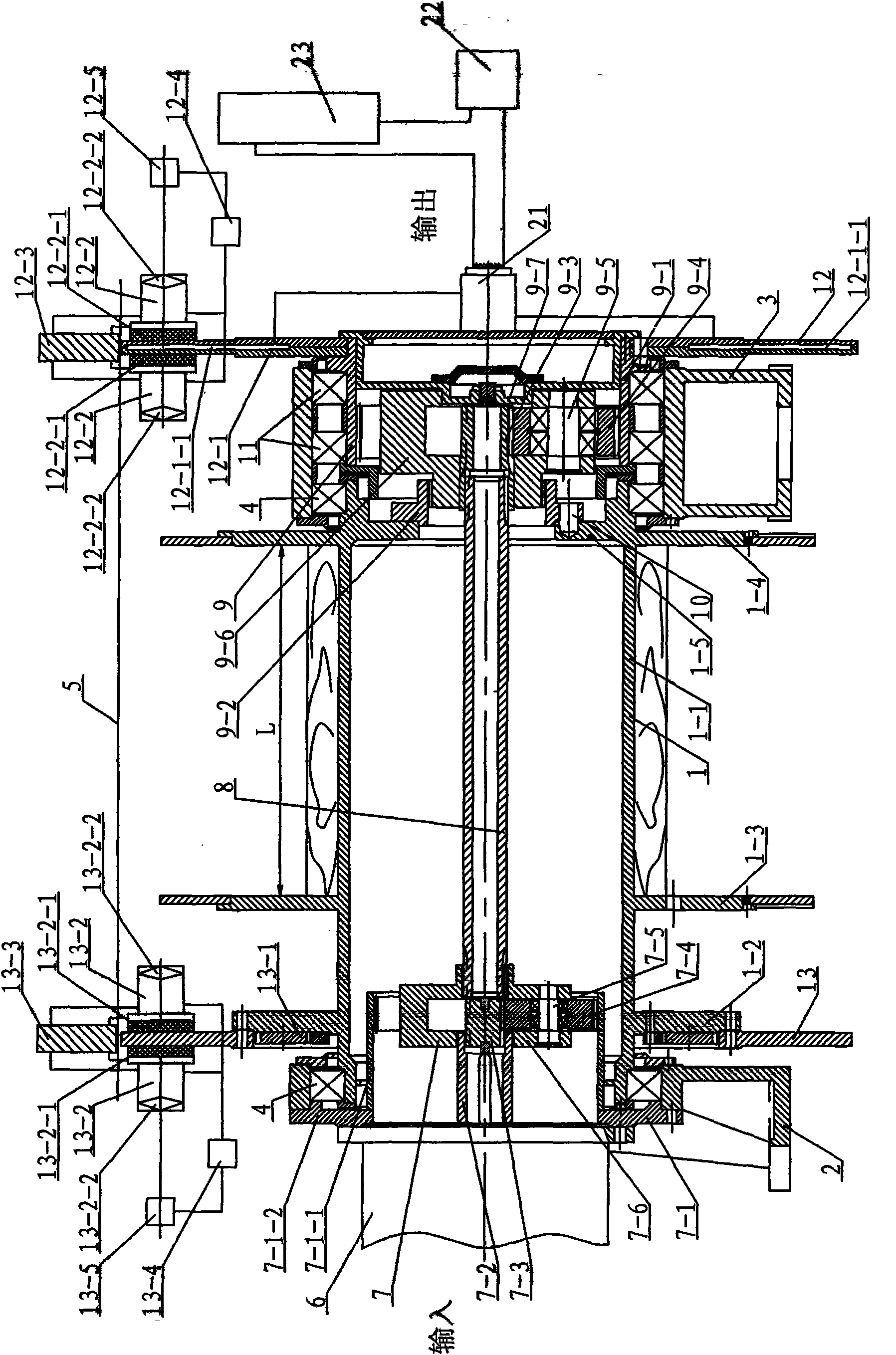

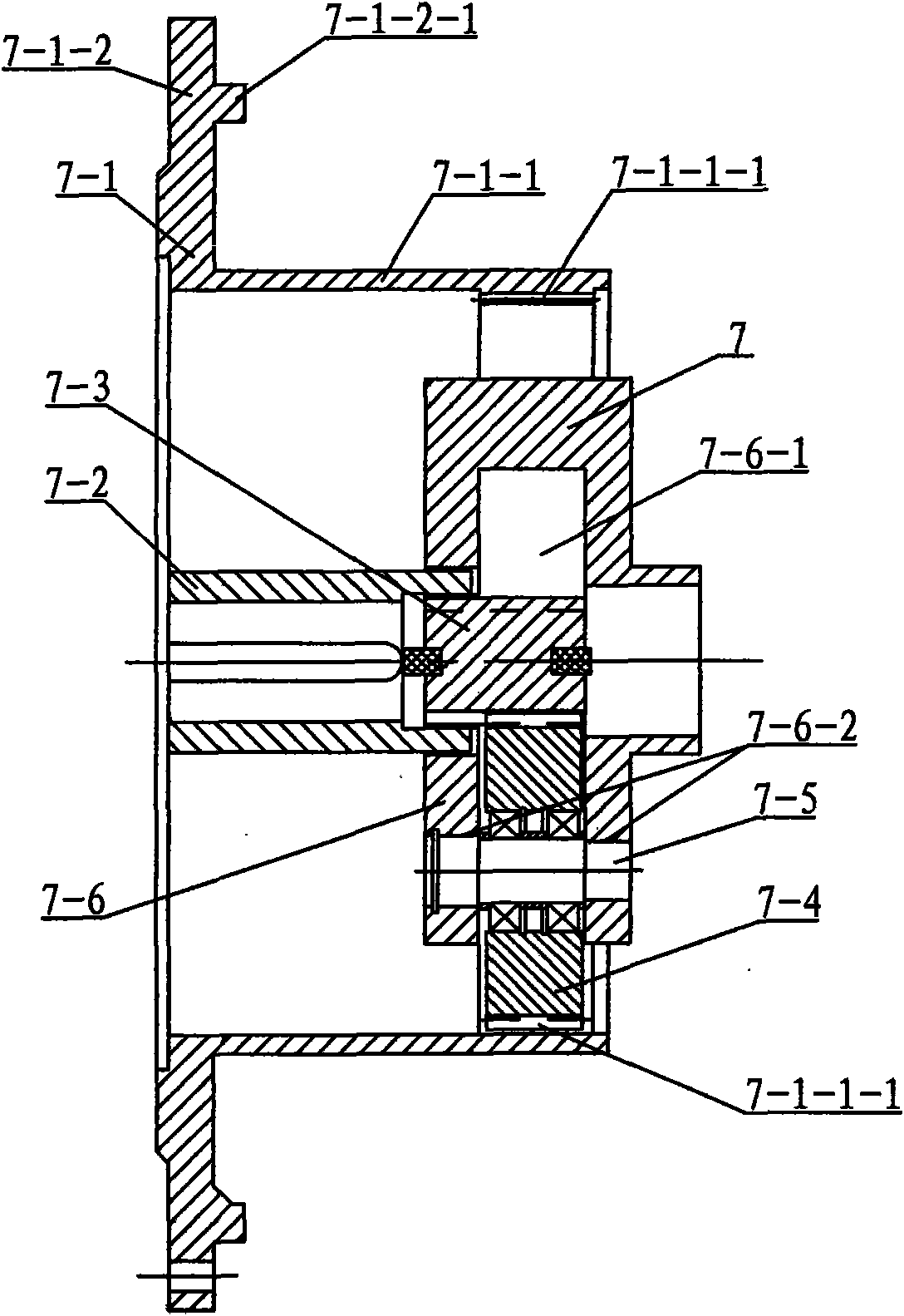

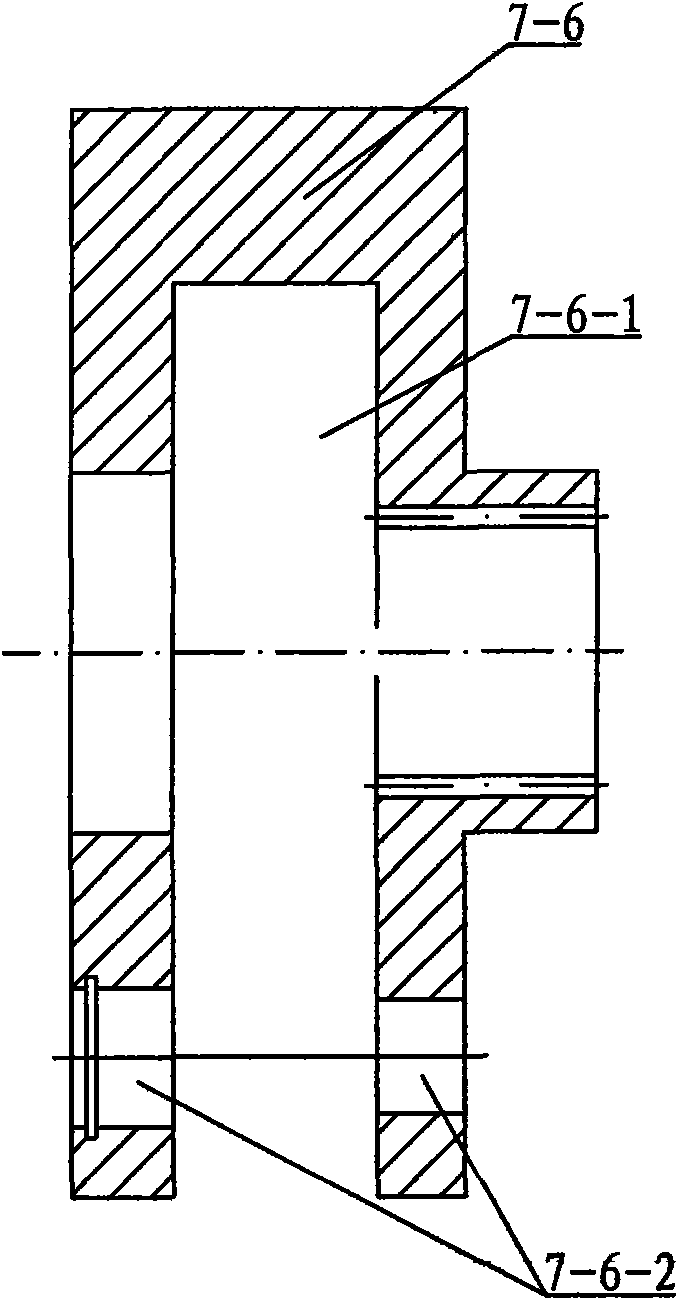

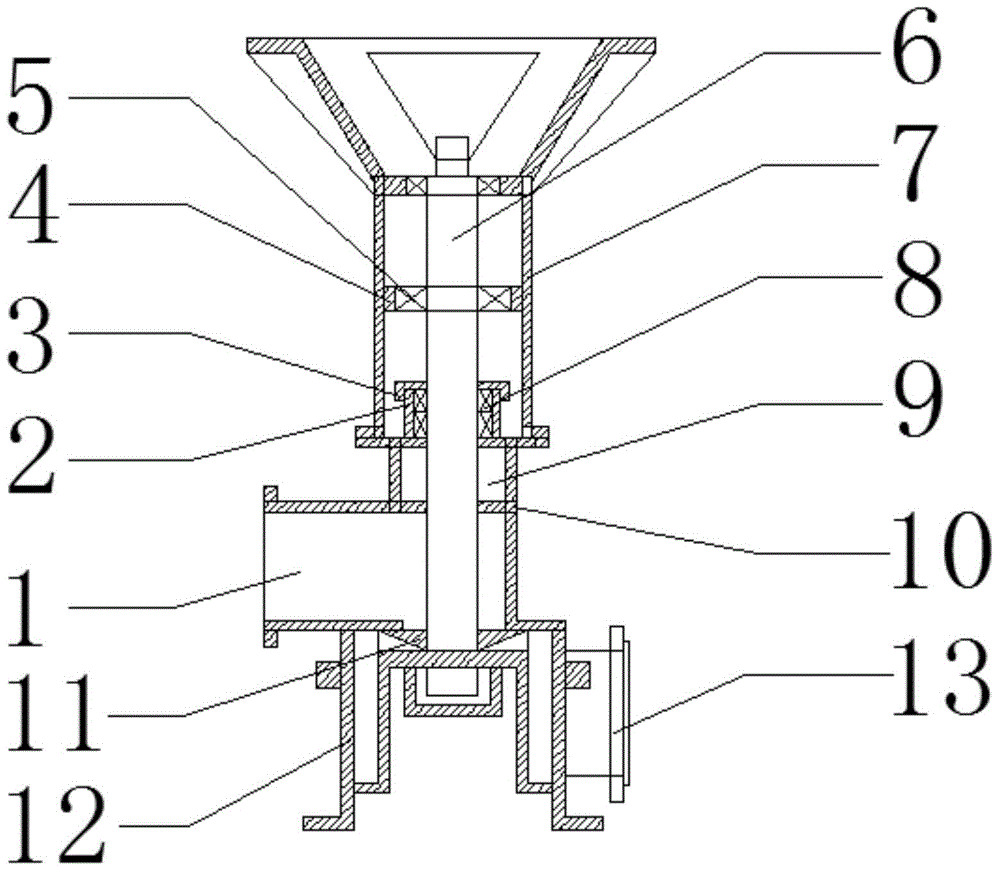

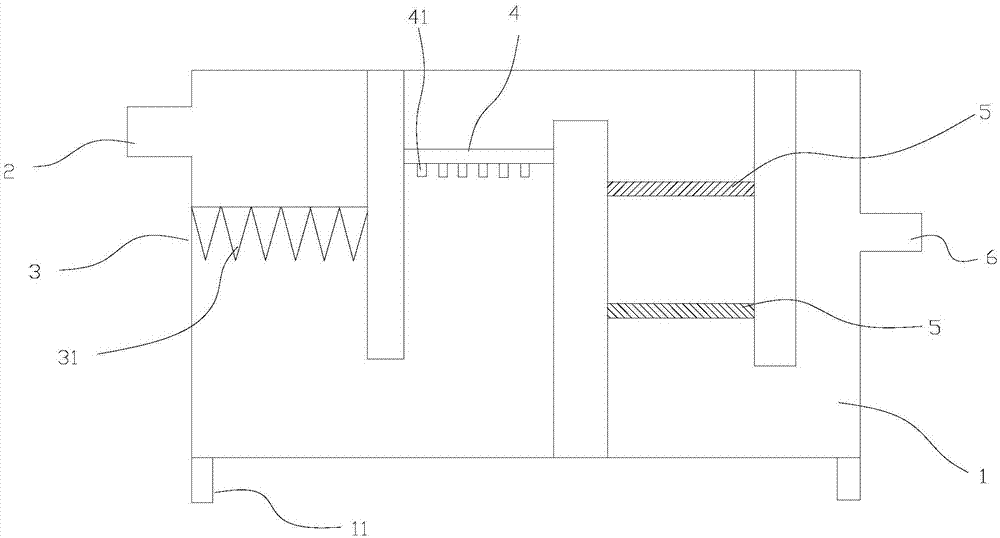

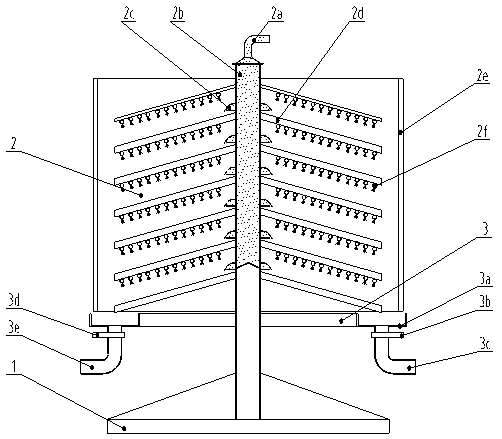

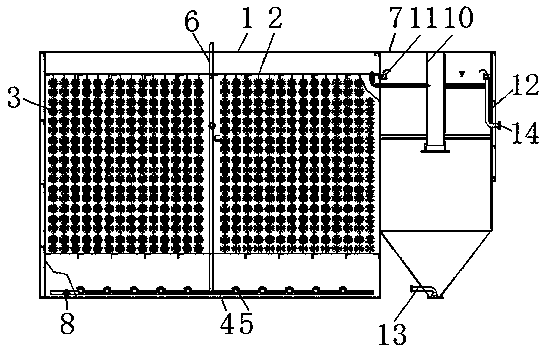

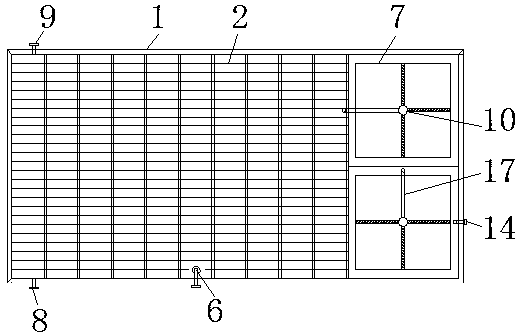

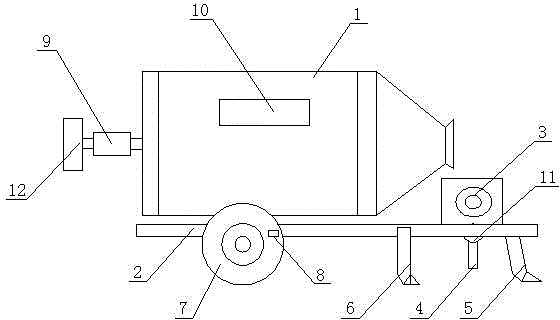

Movable type method and special vehicle for oil-water separation and wastewater purification of mobile kitchen waste

InactiveCN103011494AReduce pollutionStable water qualityBiological treatment apparatusMultistage water/sewage treatmentSmall footprintSewage treatment

The invention relates to a method and equipment for the oil-water separation and wastewater purification and treatment of kitchen wastes. The method and the equipment can carry out field collection or wastewater purification and standarization treatment on the kitchen wastes swill or domestic wastewater in the fields of a restaurant, a hotel, a department, a house, milk plant, a food products factory, a brewery, a hospital, a beverage plant, a slaughterhouse, a chemical plant and the like, separates the swill into drainage oil and kitchen wastewater, continuously carries out fast and continuous purification treatment on the domestic wastewater anytime and anywhere and ensures that the quality of purified water achieves the nationally specified (GB18918-2002) emission standard of a town sewage processing plant. The heating and temperature-regulating type wastewater purification treating equipment disclosed by the invention has the advantages of small occupied area, high wastewater purification starderization speed, low wastewater treating equipment investment, low wastewater treatment cost, and the like. The method and the equipment which are disclosed by the invention have the advantages of good industrial practicability, novelty and creativity.

Owner:周鼎力

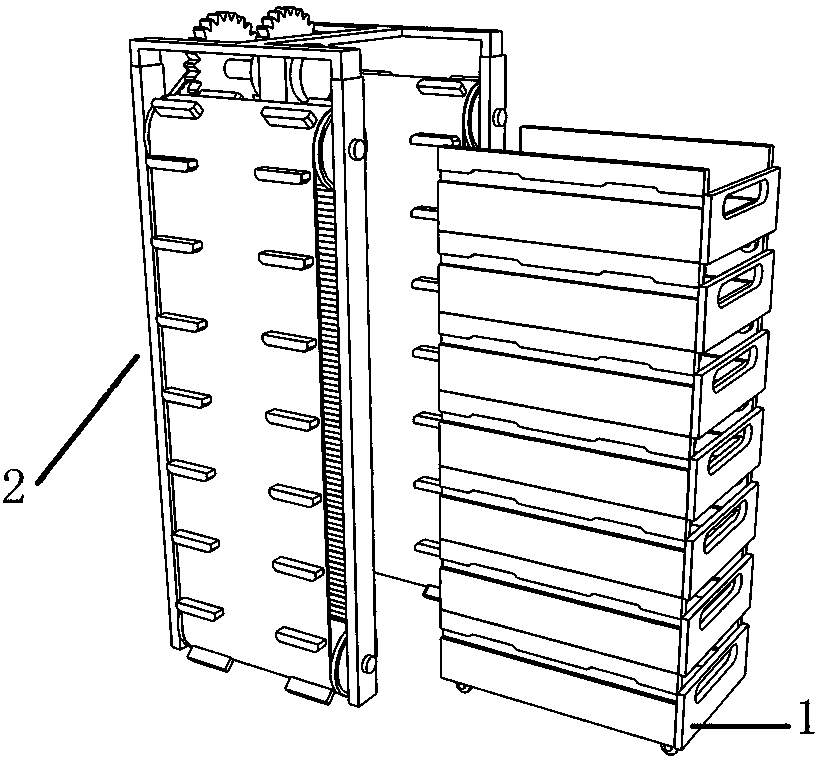

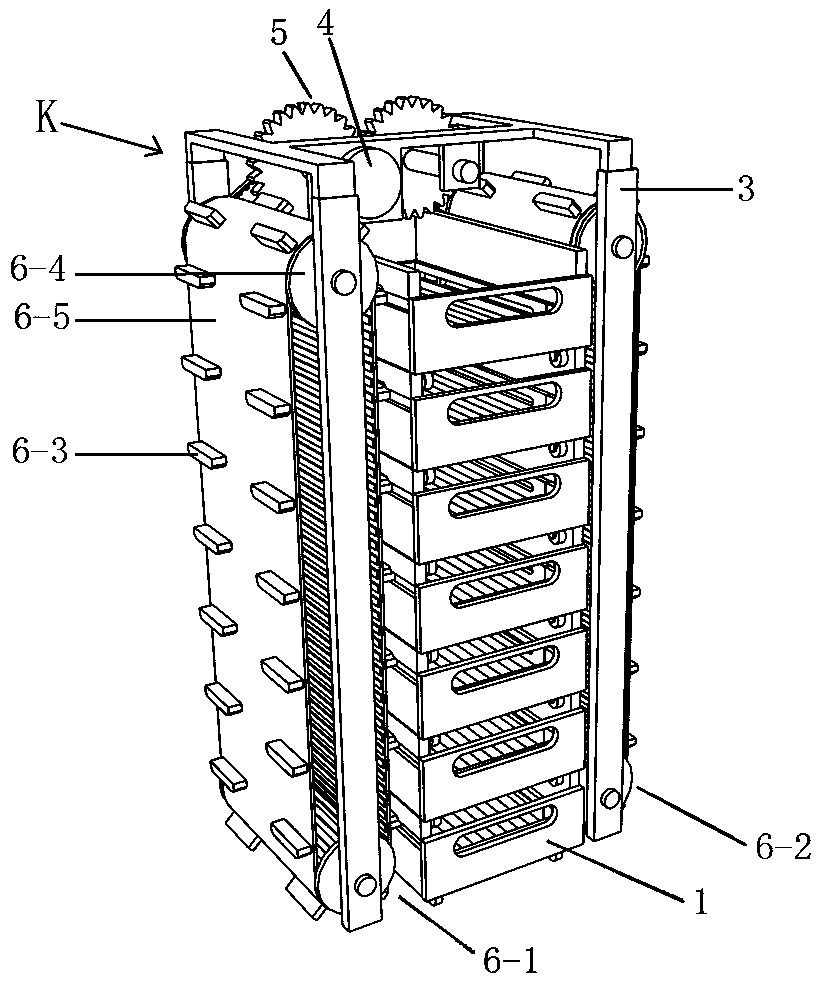

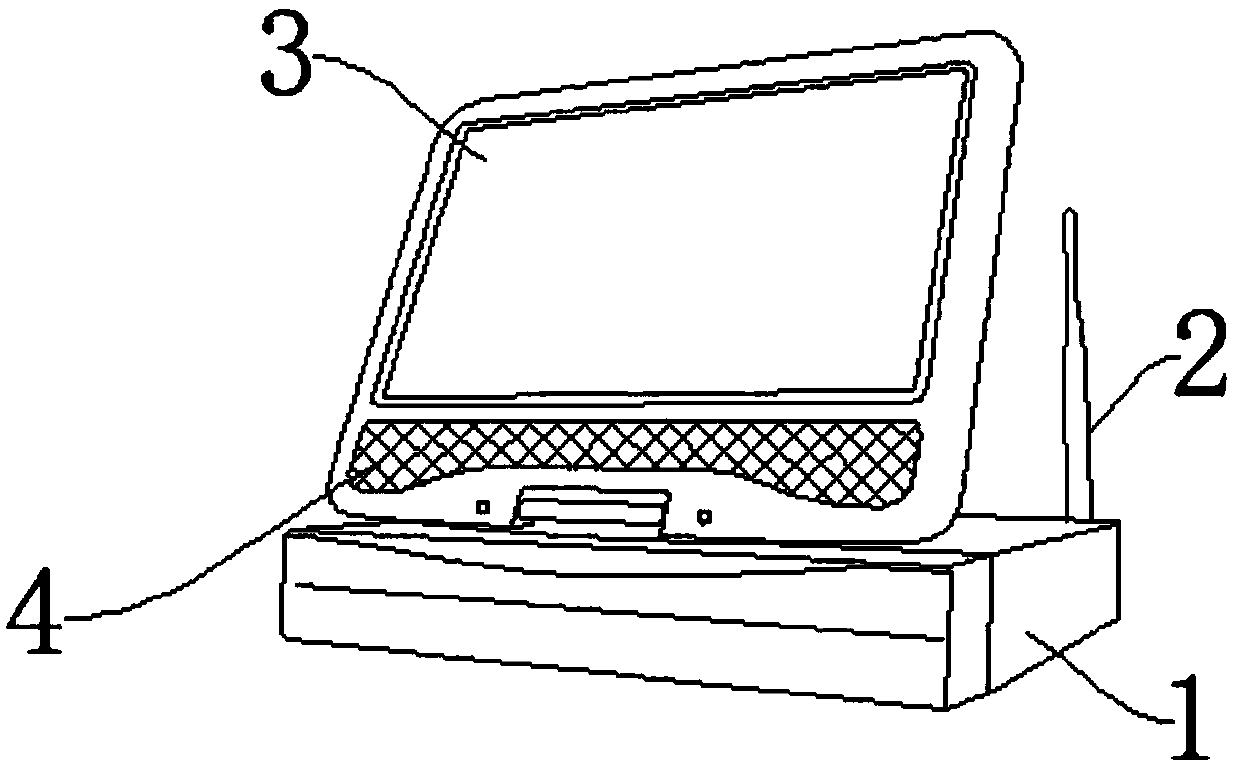

Multifunctional integrated cleaner unit machine

InactiveUS20100294004A1Small footprintReduce manufacturing costOther washing machinesTextiles and paperEngineeringSmall footprint

A multifunctional integrated cleaner unit machine includes a cabinet, washing basin and a full-automatic washing machine located in the cabinet. An enclosing frame is provided on an upper part of the cabinet. A cover corresponding with the full-automatic washing machine is hinged on the enclosing frame. A control panel and a main water inlet are provided at the enclosing frame. A dryer machine is located on one side of the full-automatic washing machine in the cabinet. The washing basin is located in the enclosing frame above the dryer machine. The washing machine, the washing basin and the dryer are combined into an integral machine with the security standard, thereby the multifunctional integrated cleaner unit machine has the advantages of small occupied area, low manufacturing cost, full functions, proper height, time saving in use, convenience, energy saving, convenient installation, little vibration and noise, low transporting cost and uniform integral style.

Owner:HU JIEBO

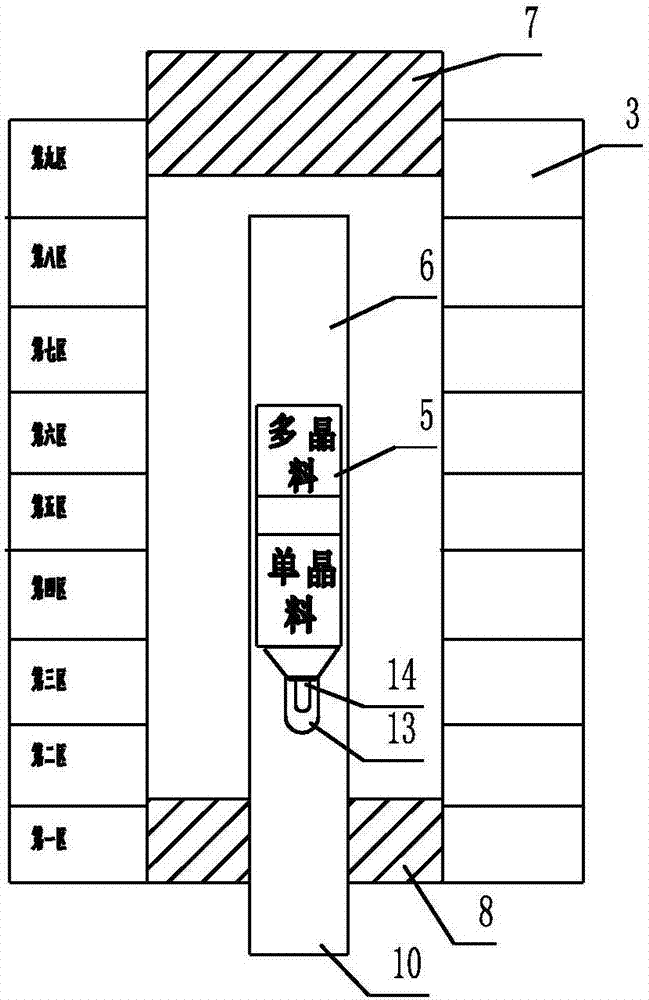

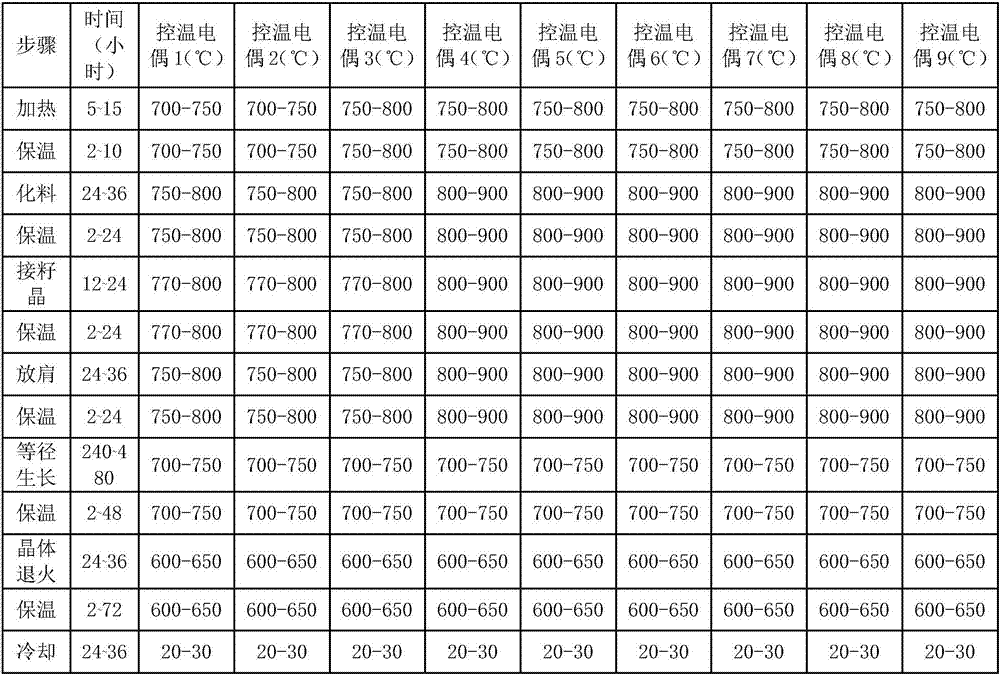

Novel single-crystal furnace for zinc cadmium telluride single crystal and growth process

PendingCN107059132AAchieve growthImprove the growing environmentPolycrystalline material growthFrom frozen solutionsTemperature controlCrucible

Owner:磐石创新(江苏)电子装备有限公司

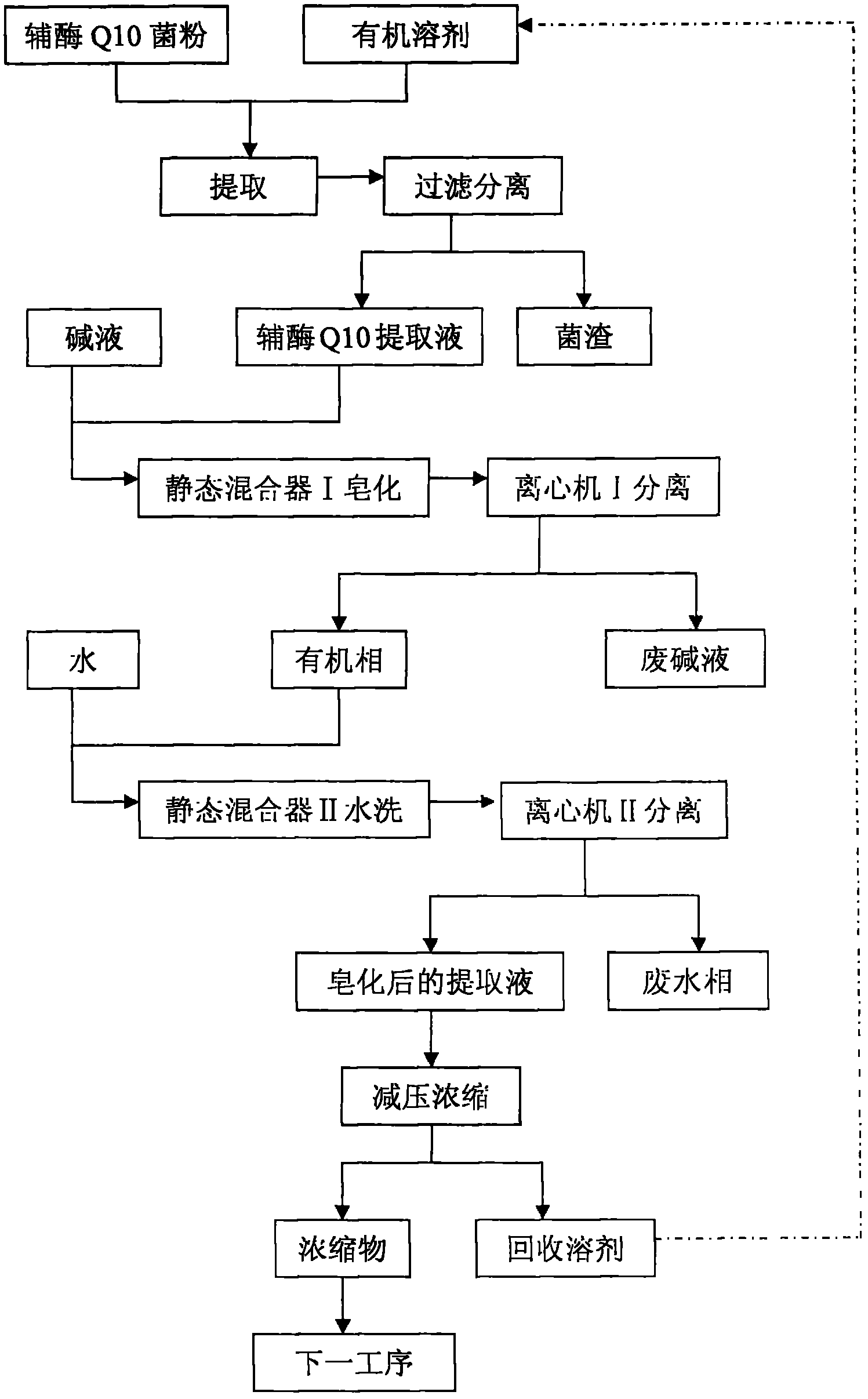

Method for saponifying coenzyme Q10 extracting solution

Owner:INNER MONGOLIA KINGDOMWAY PHARMA +1

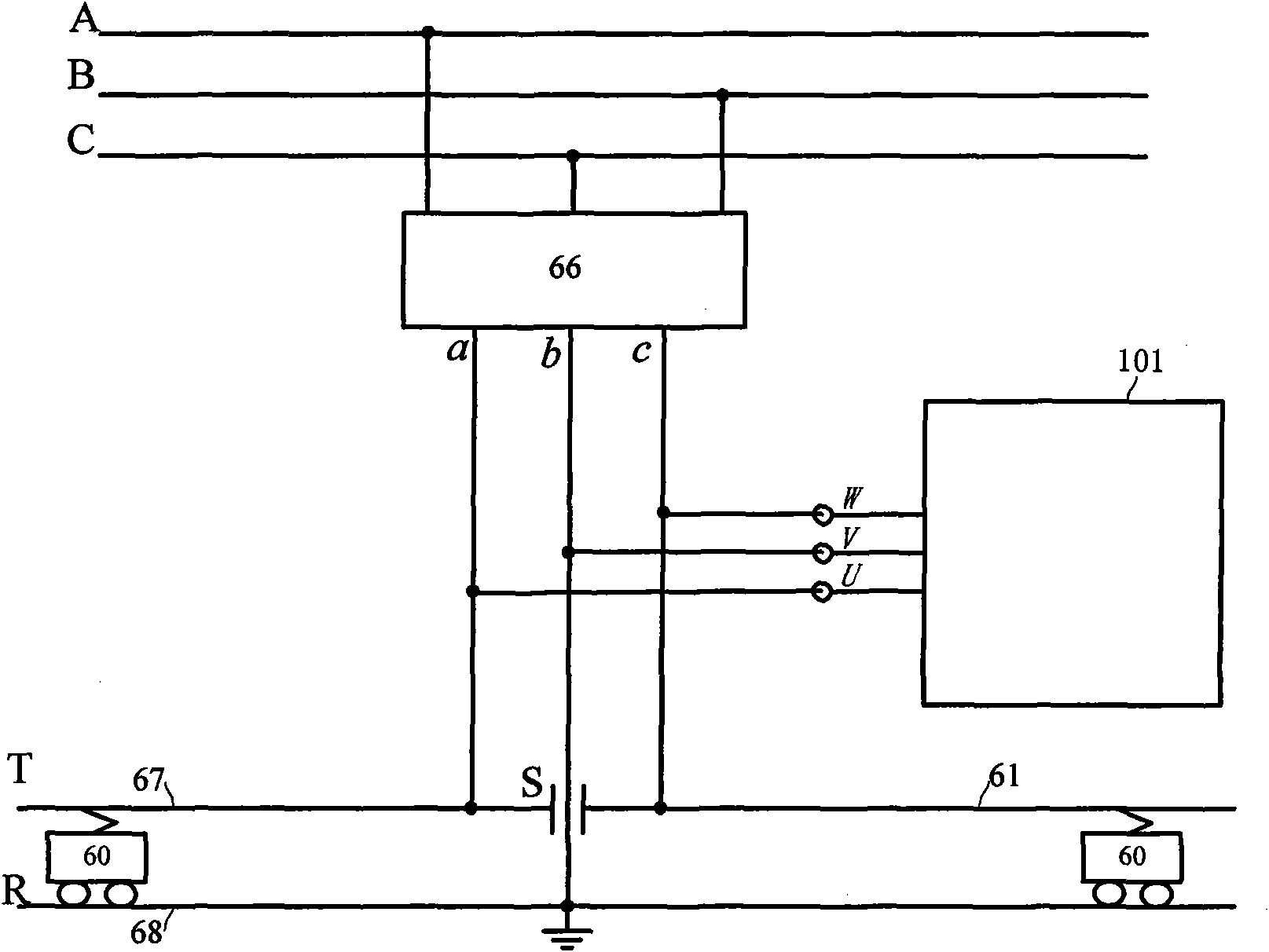

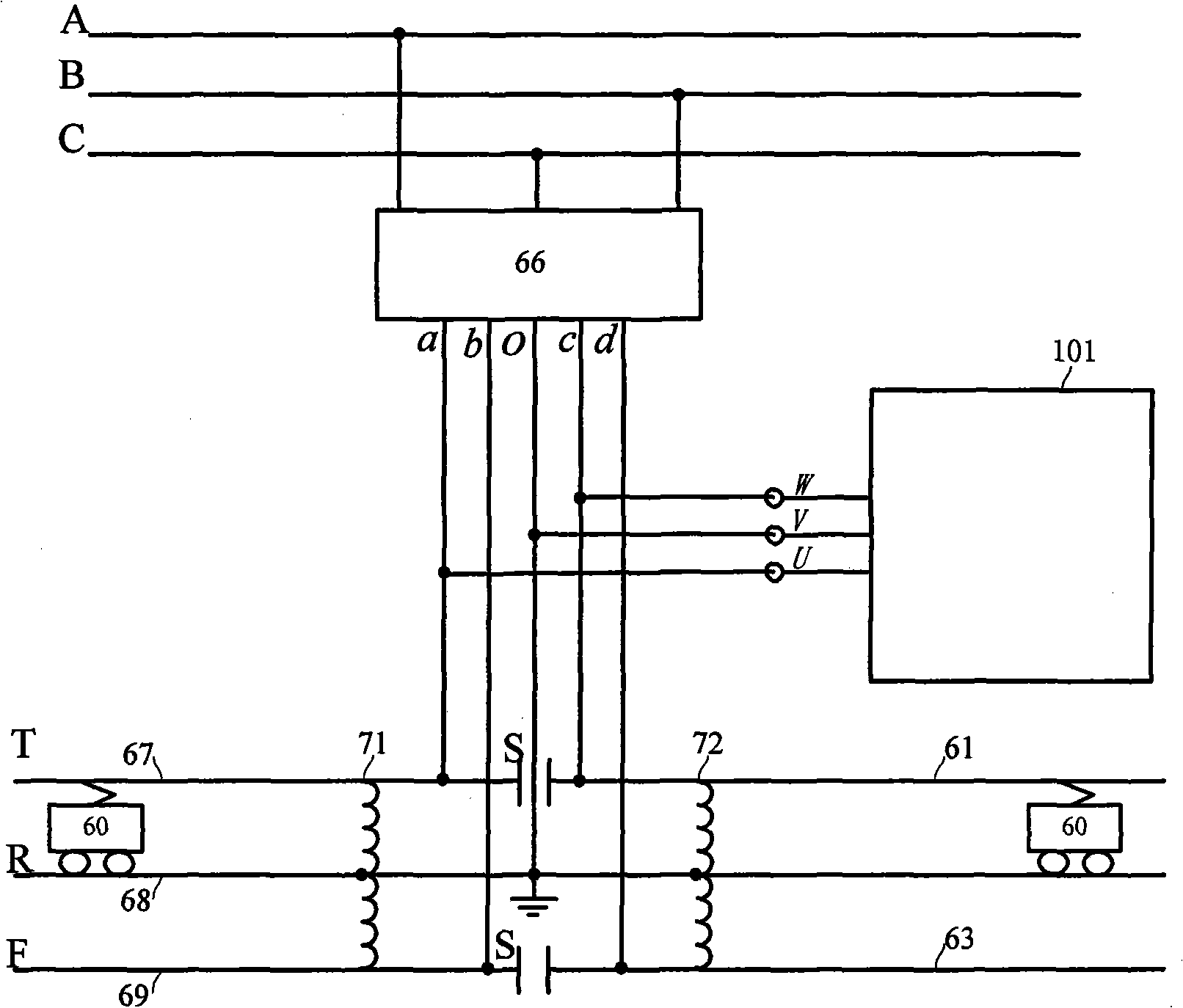

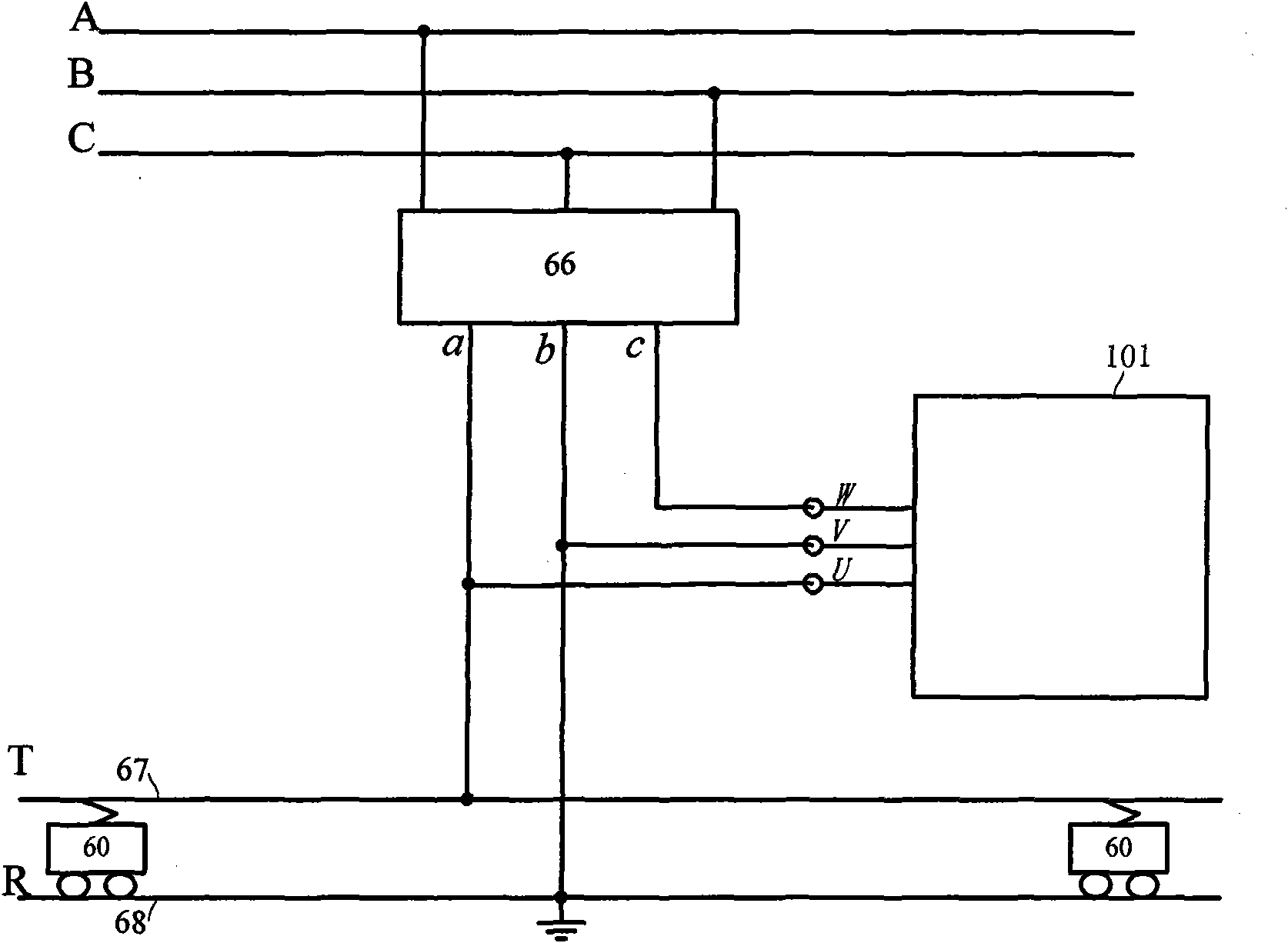

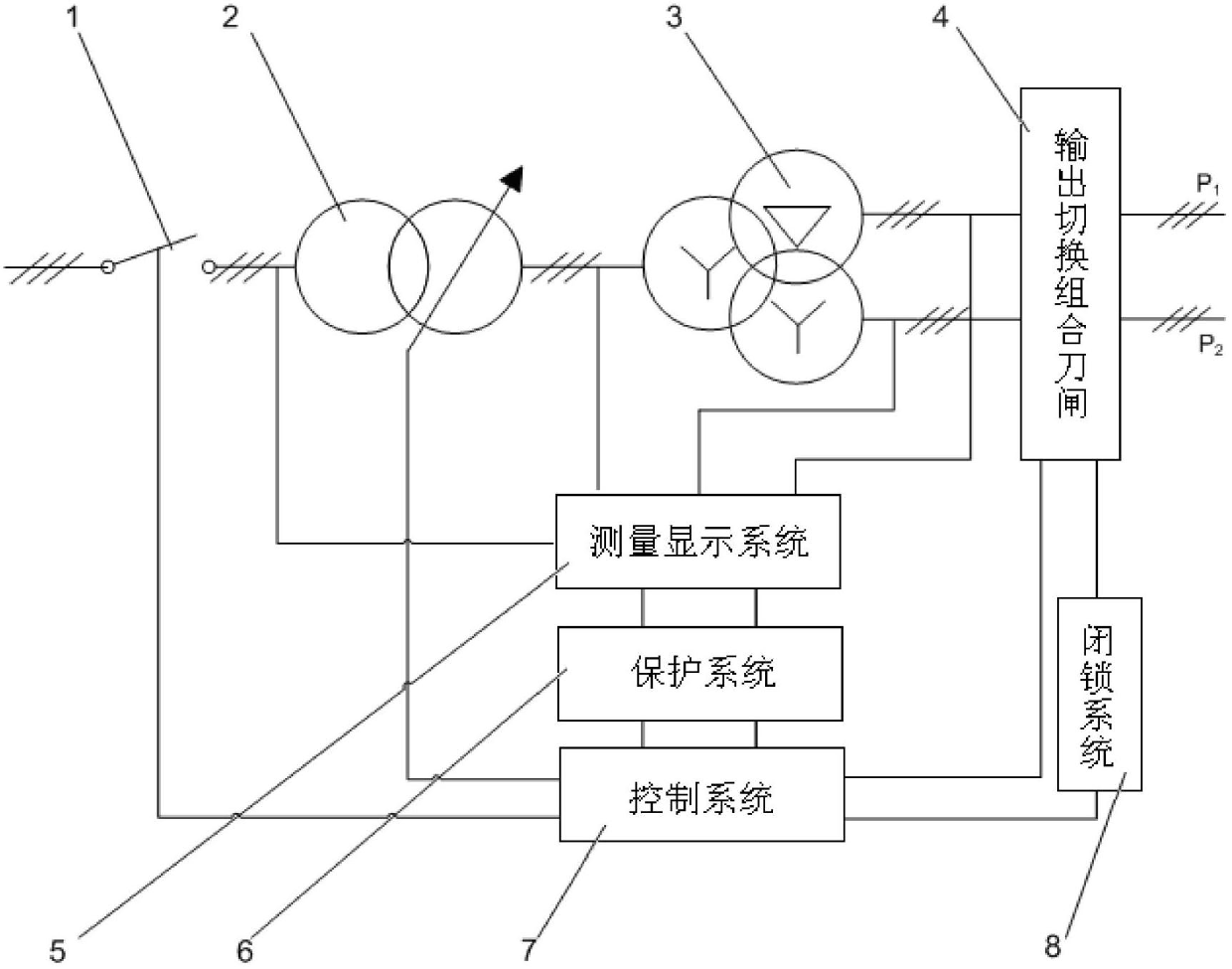

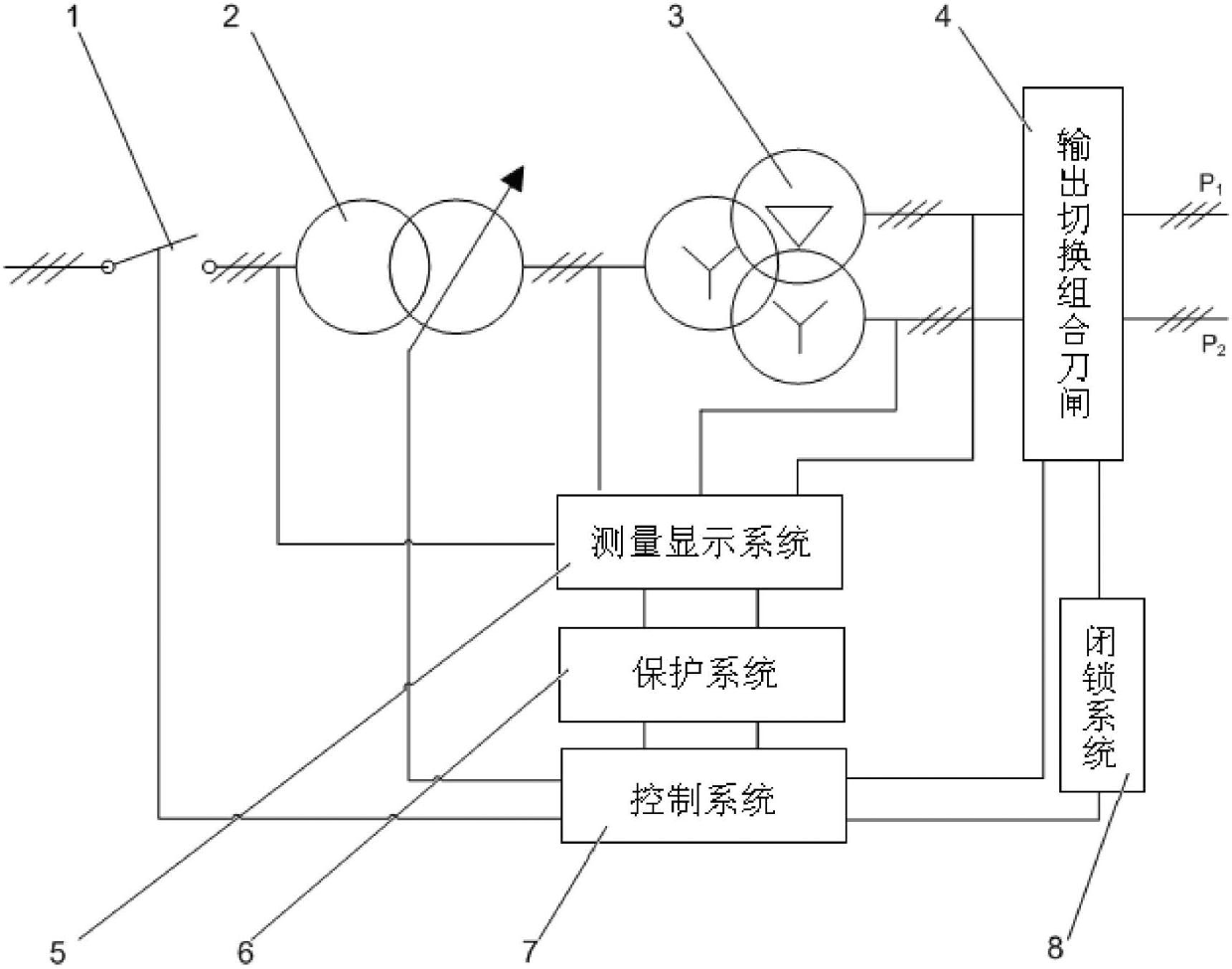

Module combined power quality conditioning system for tractive power supply network

InactiveCN101574935ASmall footprintReduce lossPower supply linesPolyphase network asymmetry elimination/reductionPower qualityCapacitance

Owner:BEIJING JIAOTONG UNIV

Process for preparing industrial high purity water

InactiveCN101085681AHigh resistivityEnsure water qualityGeneral water supply conservationWater/sewage treatment by electrochemical methodsFiltrationWater quality

Owner:上海三邦水处理技术有限公司

Multi-layer steamed bread automatic baking oven

InactiveCN103168805AMeet hygiene requirementsSmall footprintHigh-frequency/infra-red heating bakingHollow article bakingCooking & bakingFree cooling

Owner:丁海涛

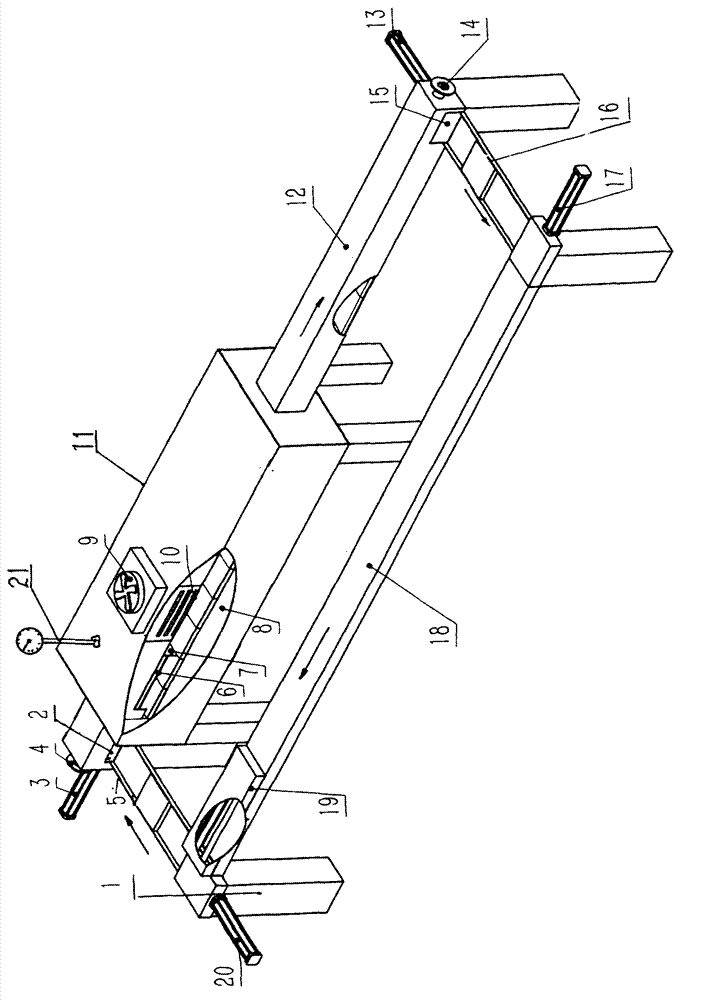

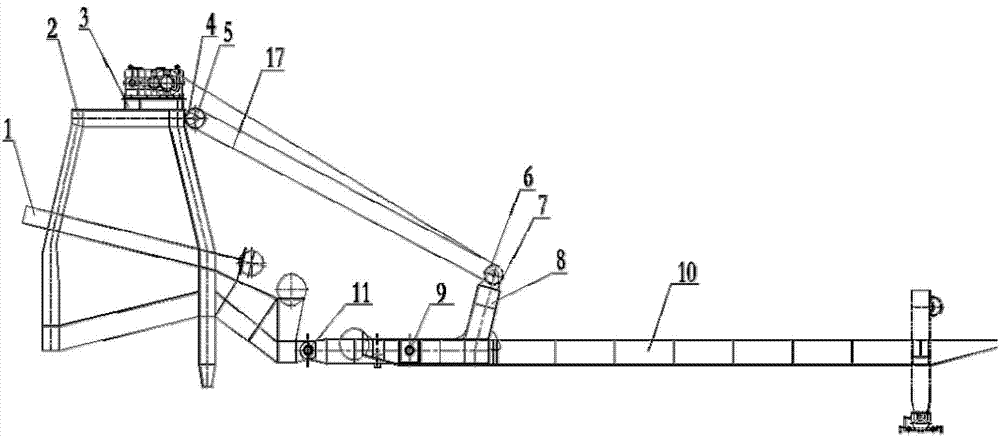

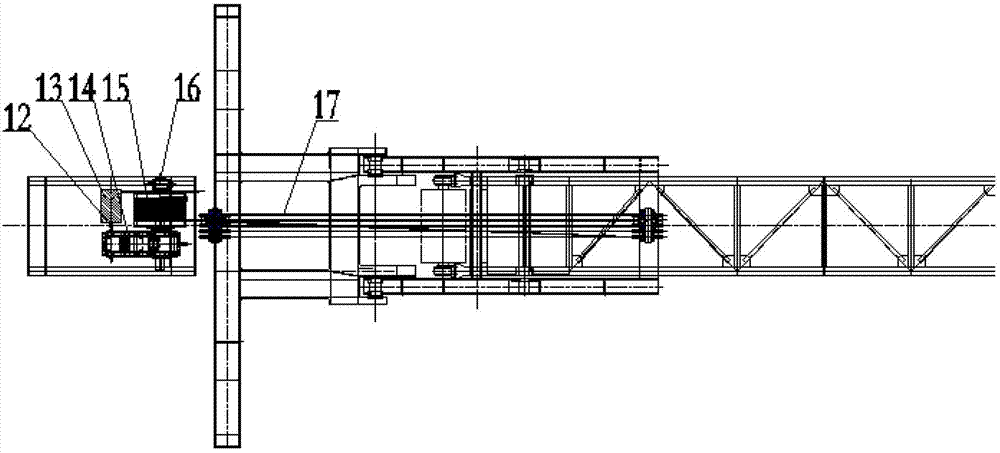

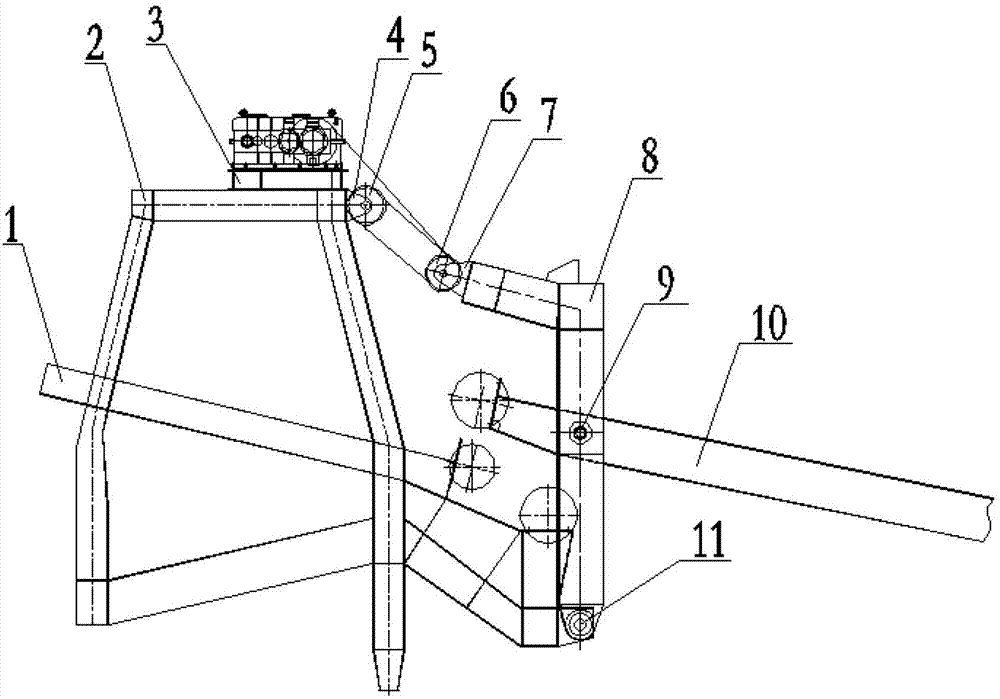

Two tripper cars of electric variable-amplitude type wheel-bucket stack-taking machine

InactiveCN102765606ASave design spaceReduce weightWinding mechanismsLoading/unloadingSmall footprintEngineering

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

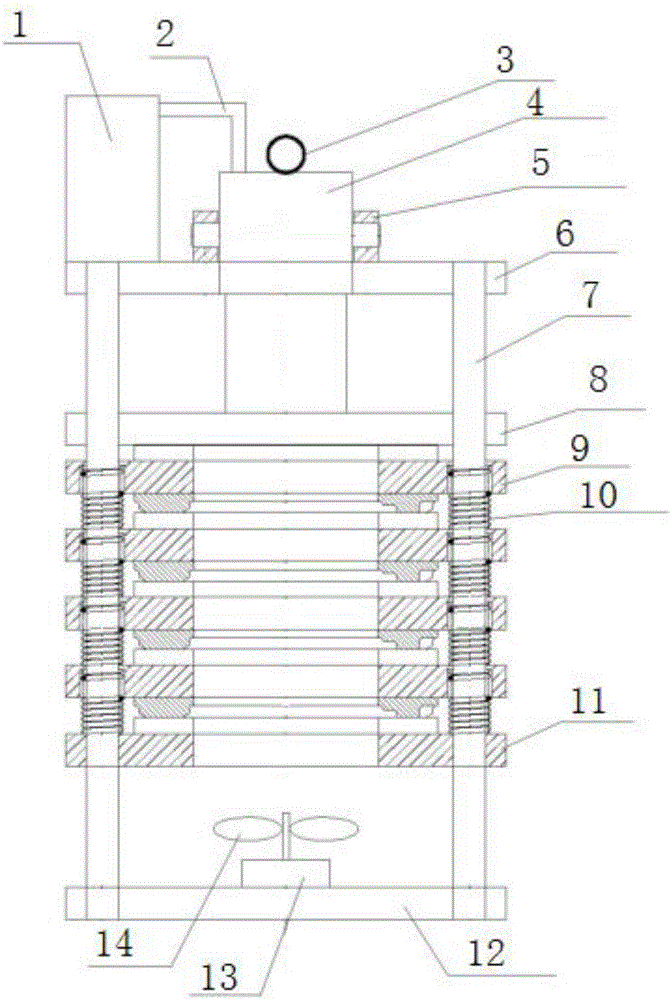

Quenching anti-deformation clamping device for series connection type brake disc

Owner:南京中盛铁路车辆配件有限公司 +1

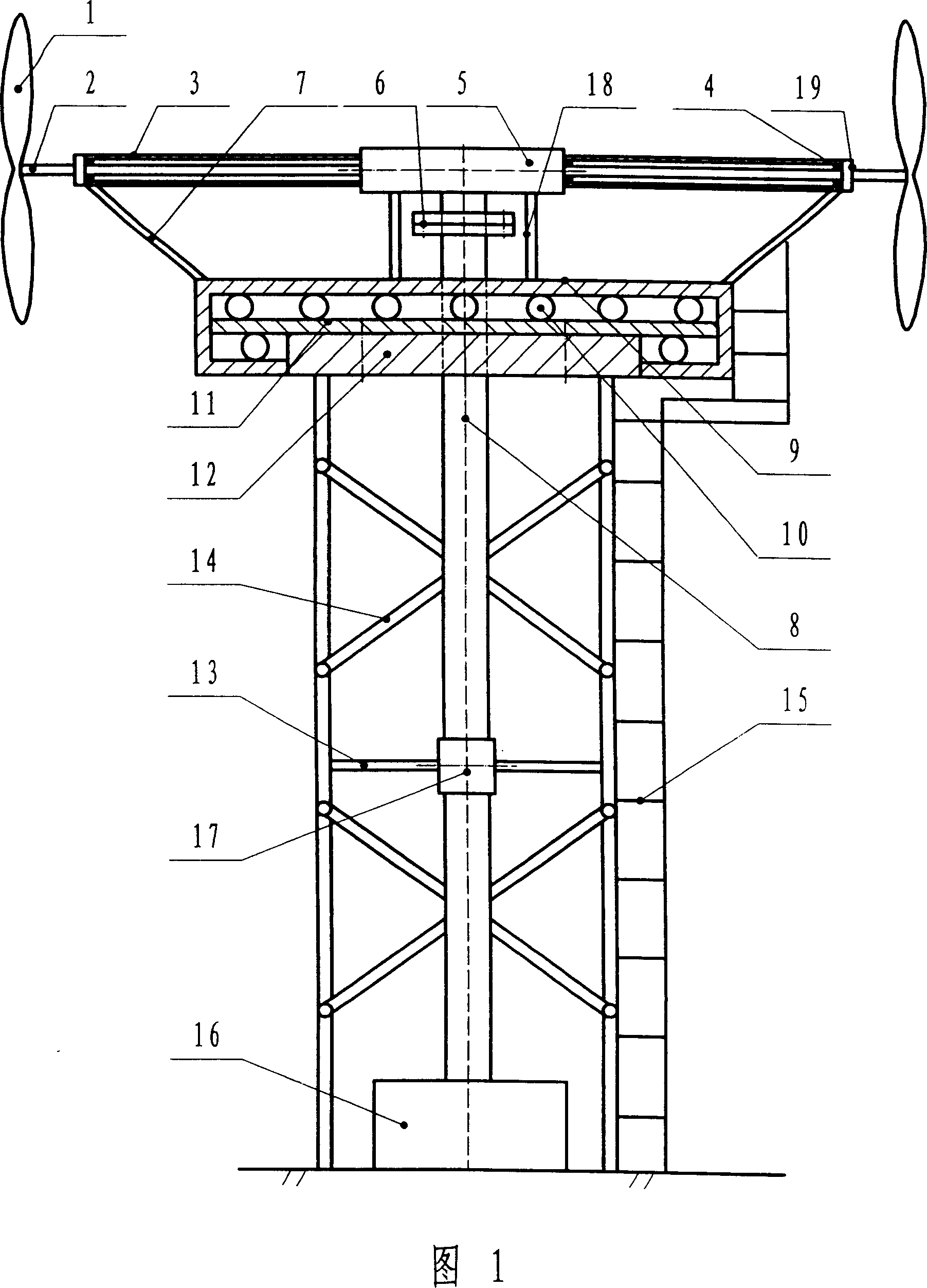

Windpower generating apparatus

InactiveCN101000037ASimple structureLow costWind motor supports/mountsWind motor combinationsWind drivenDrive shaft

Owner:王新民

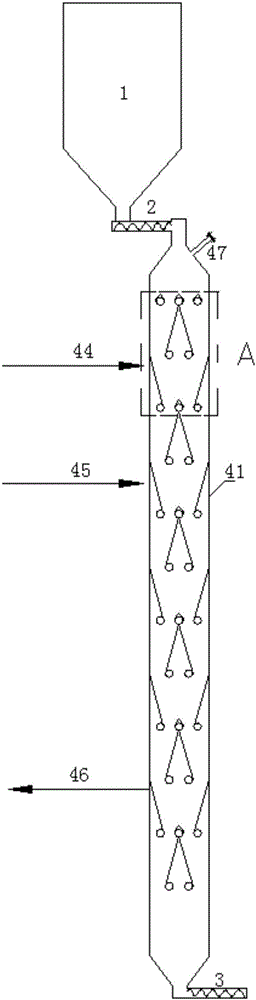

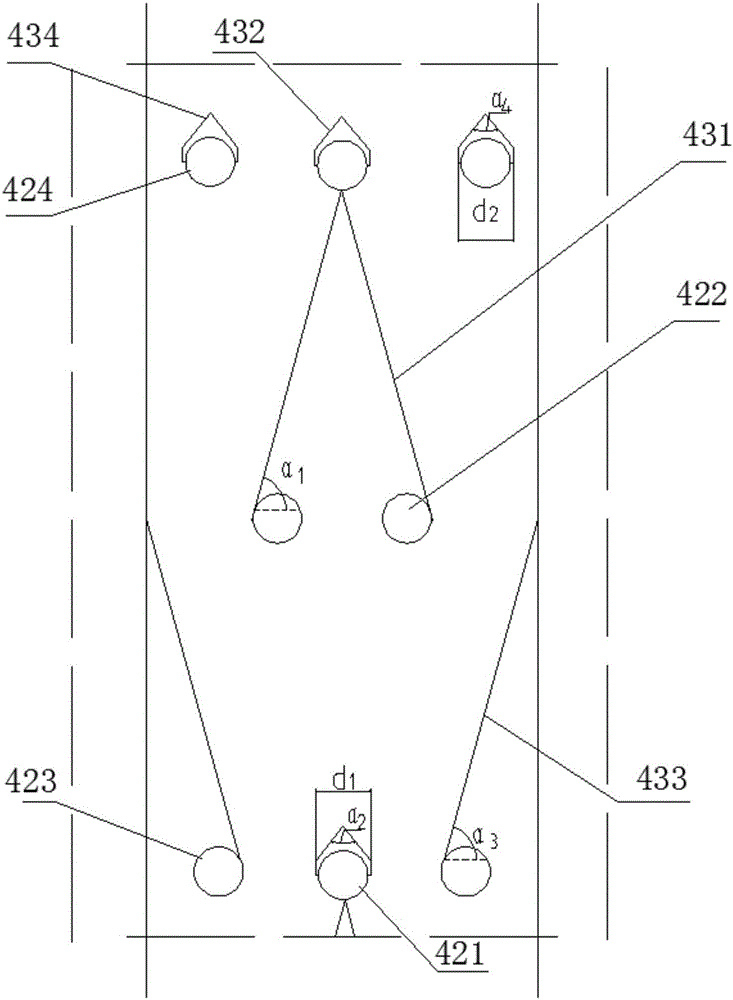

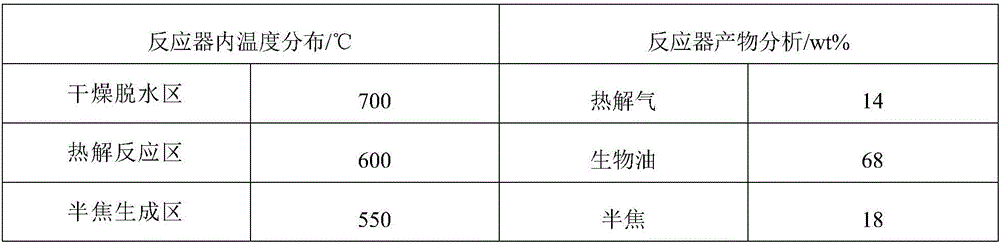

Fast pyrolysis reactor

PendingCN106520155AEffective pyrolysisSimple structureDirect heating destructive distillationBiofuelsVertical projectionNuclear engineering

Owner:SHENWU TECH GRP CO LTD

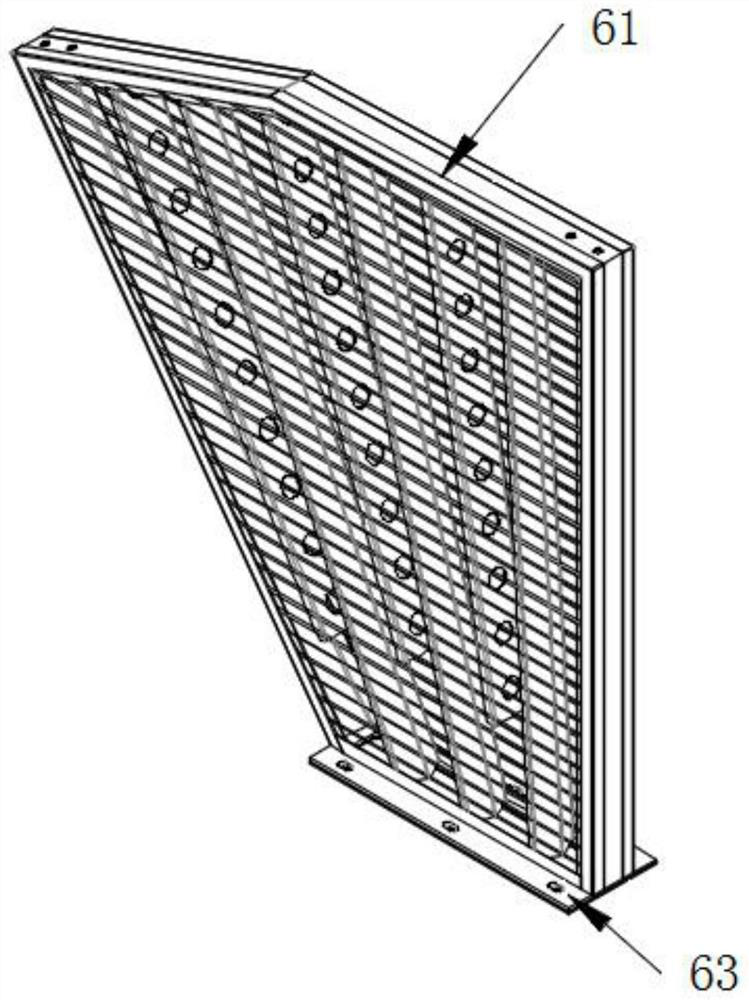

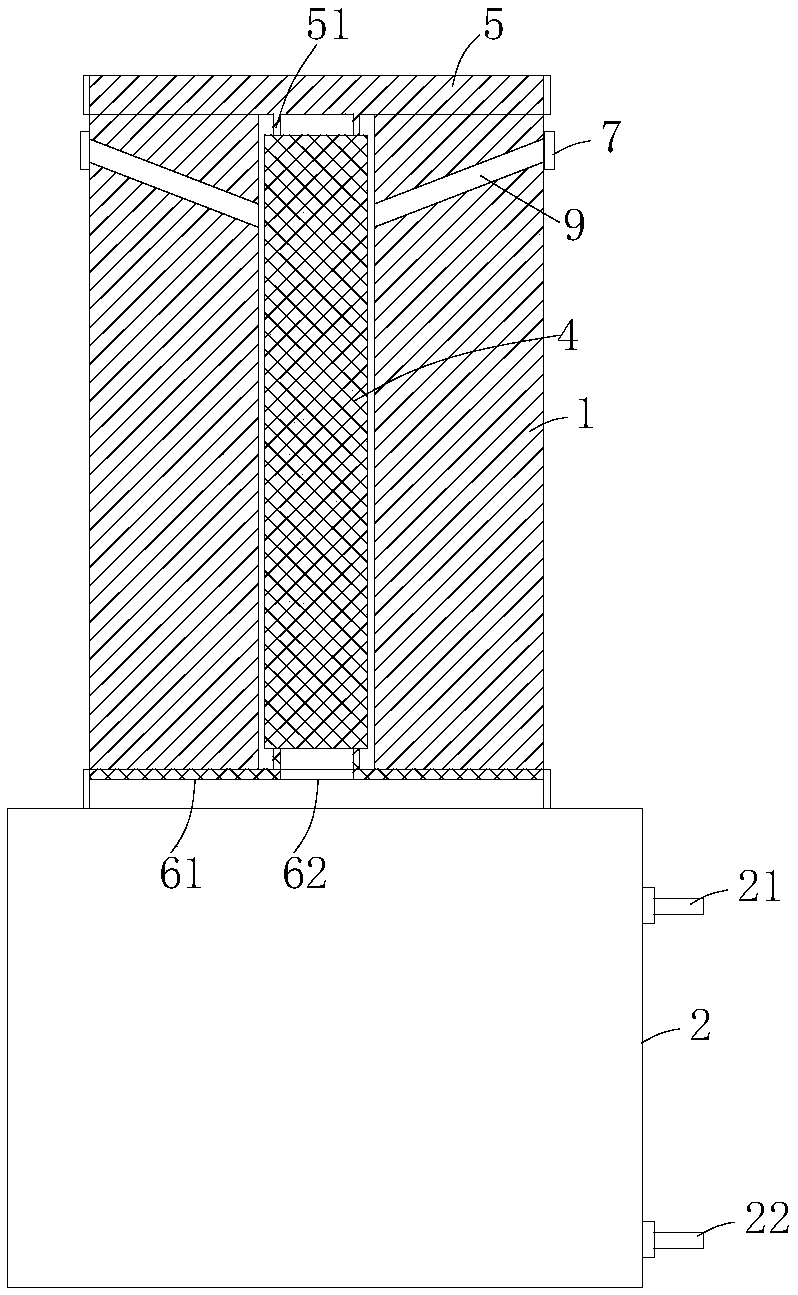

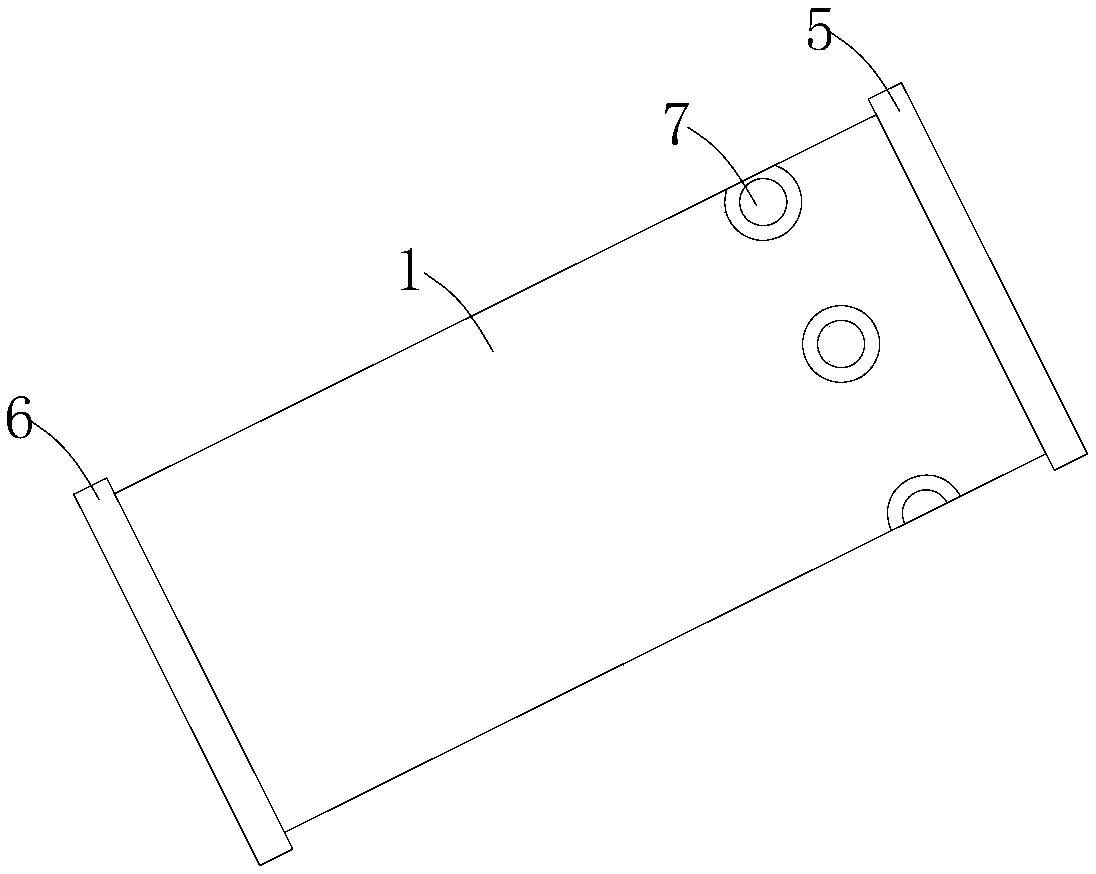

Integrated sewage treatment device

PendingCN108545897ACompact structureSmall footprintWater contaminantsBiological treatment apparatusSludgeSmall footprint

Owner:LANSHEN GRP CORP LTD +1

Voltage continuously adjustable no-load test device for ice melting rectifier

Owner:HUNAN ELECTRIC POWER CORP RES INST +2

Device and method for carrying out low-concentration SO2 smoke desulfurization through alkaline waste liquid

The invention discloses a device and method for carrying out low-concentration SO2 smoke desulfurization through alkaline waste liquid. The device mainly comprises a SO2 smoke absorption tower, an electric mist precipitator, an active ore pulp buffer tank, an active ore pulp absorption-liquid buffer tank, a waste electrolyte buffer tank, a waste electrolyte circulating trough and a tail smoke discharging chimney. Acid gas SO2 in the smelting smoke is absorbed two times through alkaline ingredients in active ore pulp, and then the acid gas SO2 in the smelting smoke is further absorbed through alkaline ingredients in waste electrolytes; meanwhile, ore dust in the smelting smoke is removed, the two kinds of waste alkali liquid including the active ore pulp and the waste electrolytes are greatly used, the technological process is simple, running is reliable, the desulfurization effect is remarkable, investment is low, the floor area is small, operation is easy, desulfurization of the huge amount of low-concentration SO2 smoke can be completed only through low cost, the raw material cost of the desulfurization process is reduced, new waste can not be generated, and the aims that through treatment, environment-friendly collected SO2 meets the standard and economy reaches the standard are achieved in the mode that waste is controlled through waste.

Owner:金川集团镍钴有限公司

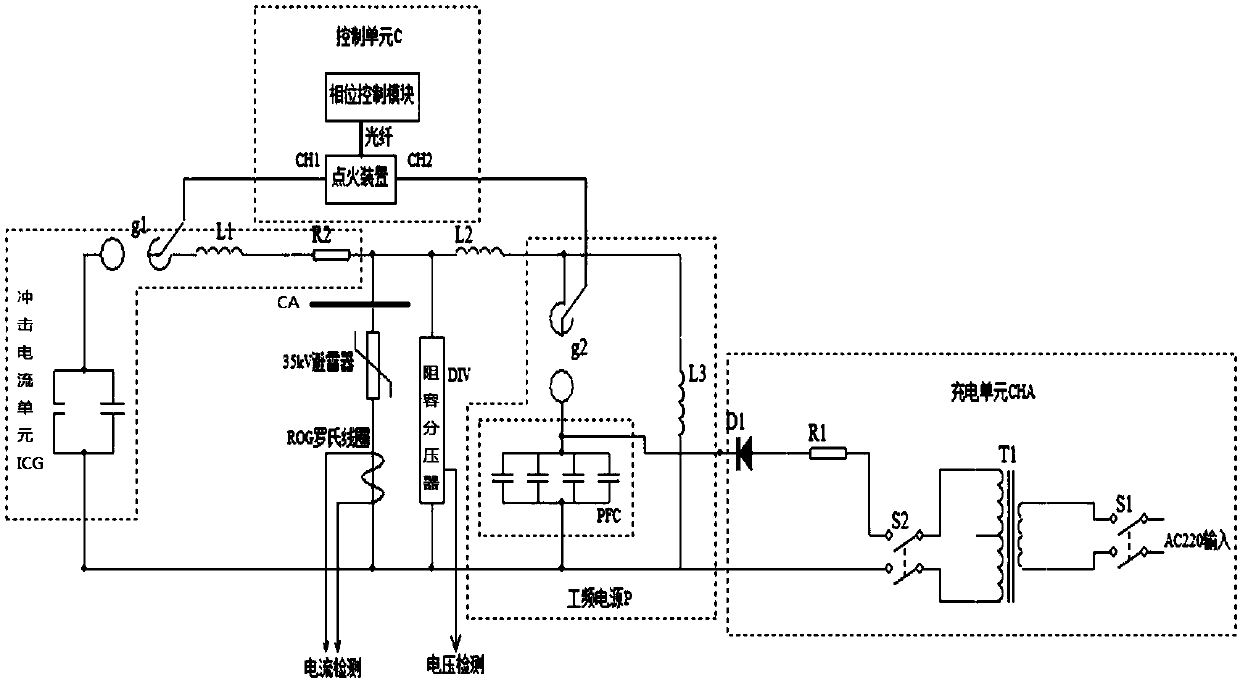

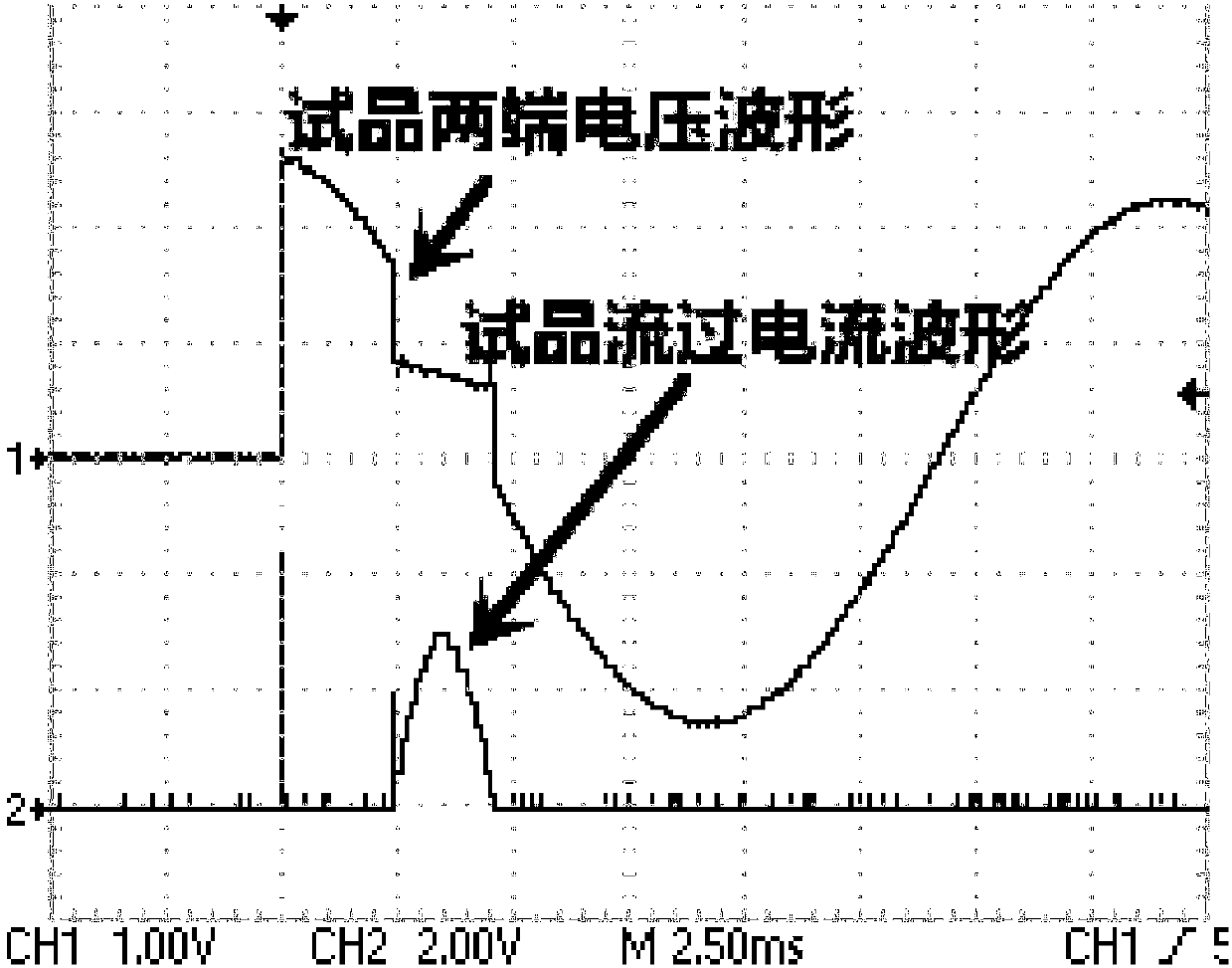

Testing device and method for power frequency follow current interruption capability of 35kV lightning protector

ActiveCN108037399AIn line with the actual operating conditionsVerify lightning protection functionTesting dielectric strengthSmall footprintTime-sharing

Owner:STATE GRID HUBEI ELECTRIC POWER RES INST +3

Novel centrifugal sand pump

InactiveCN104929947ASimple structureEasy to operateSpecific fluid pumpsPump componentsImpellerEngineering

Owner:黄浩

Kitchen waste gas treatment device

InactiveCN107376610AEasy to handleSimple structureCombination devicesGas treatmentTreatment effectSmall footprint

Owner:张粉银

Kindergarten bed with capabilities of vertical lifting storage and size adjustment

Owner:NANJING INST OF TECH

Apple screening and classification device

ActiveCN108940876AProtectEasy to carrySievingGas current separationAgricultural engineeringSmall footprint

Owner:刘彬

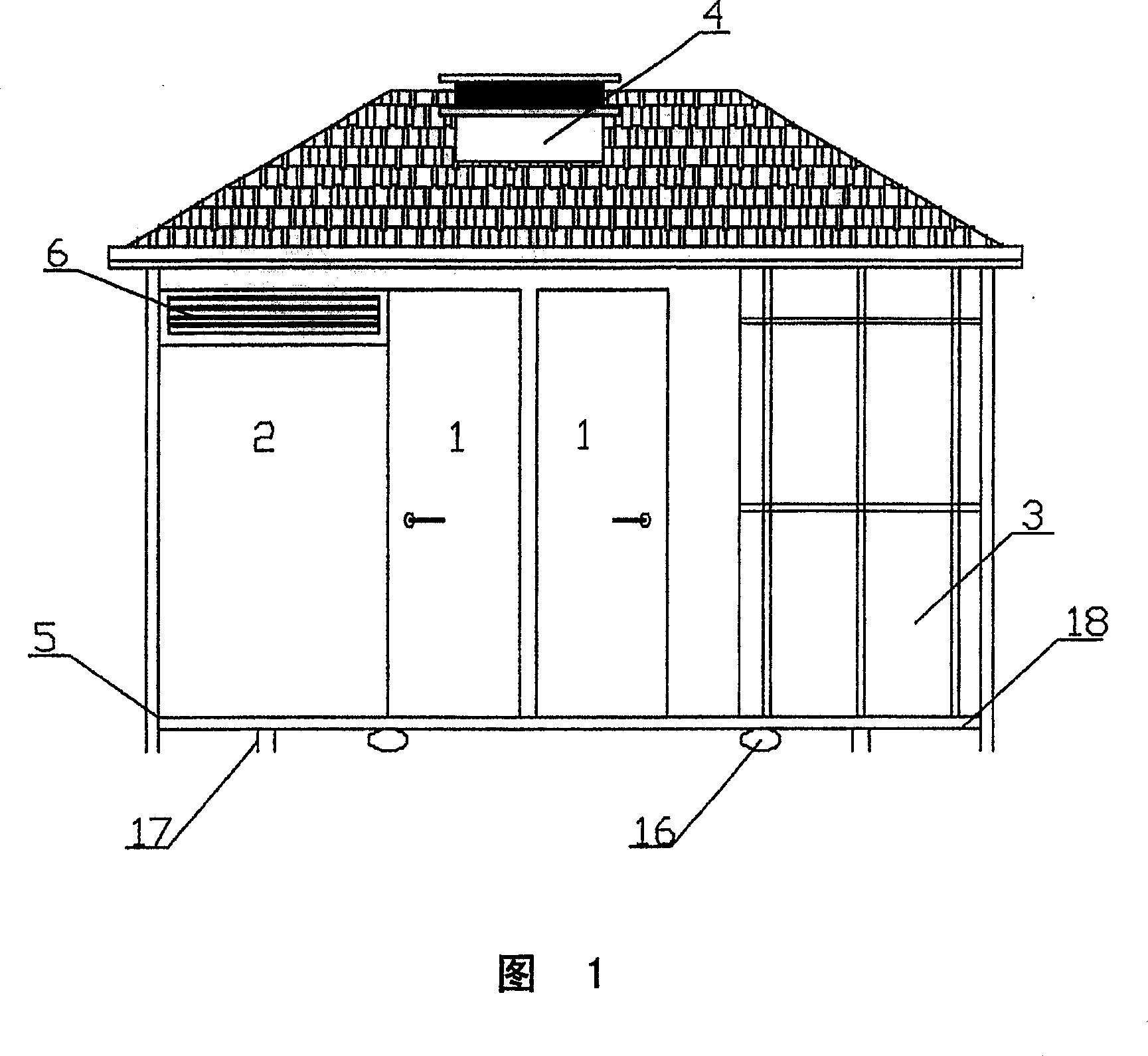

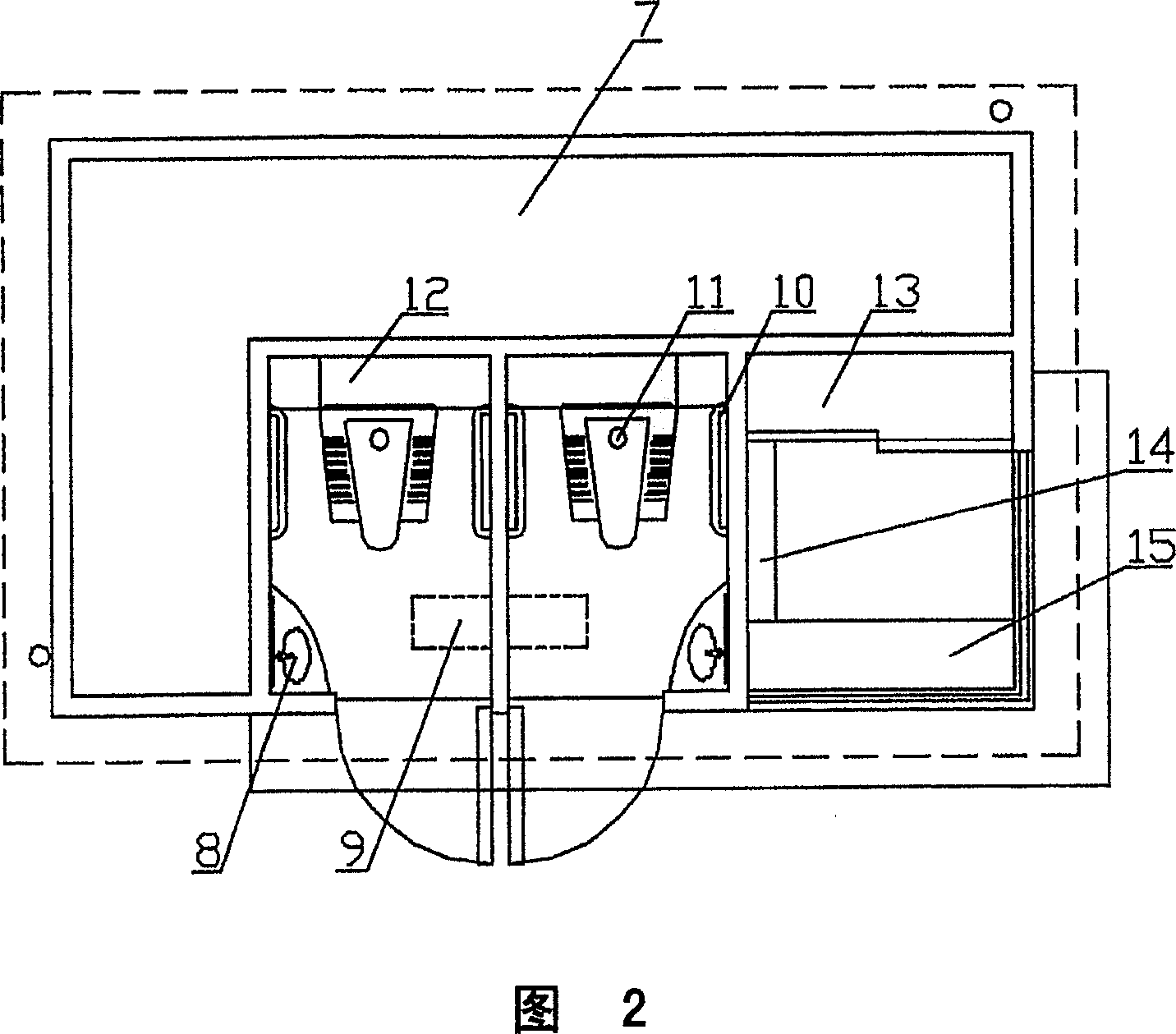

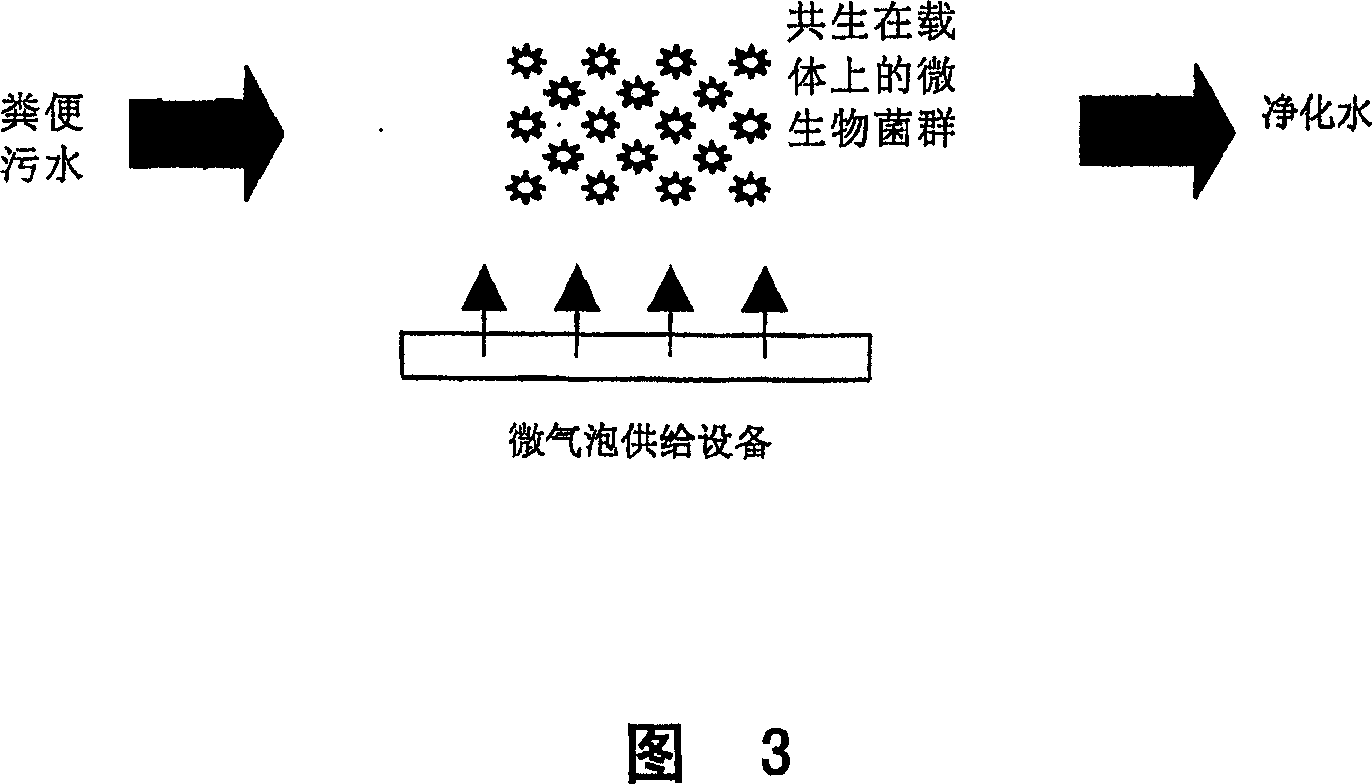

Moveable environmental protection public toilet

Owner:SHANGHAI GI BIOTECH ENG

Efficient tailing sorting machine

PendingCN108283986ARealize recyclingReduce stacking landWet separationEconomic benefitsSmall footprint

Owner:云南天顶科技有限公司

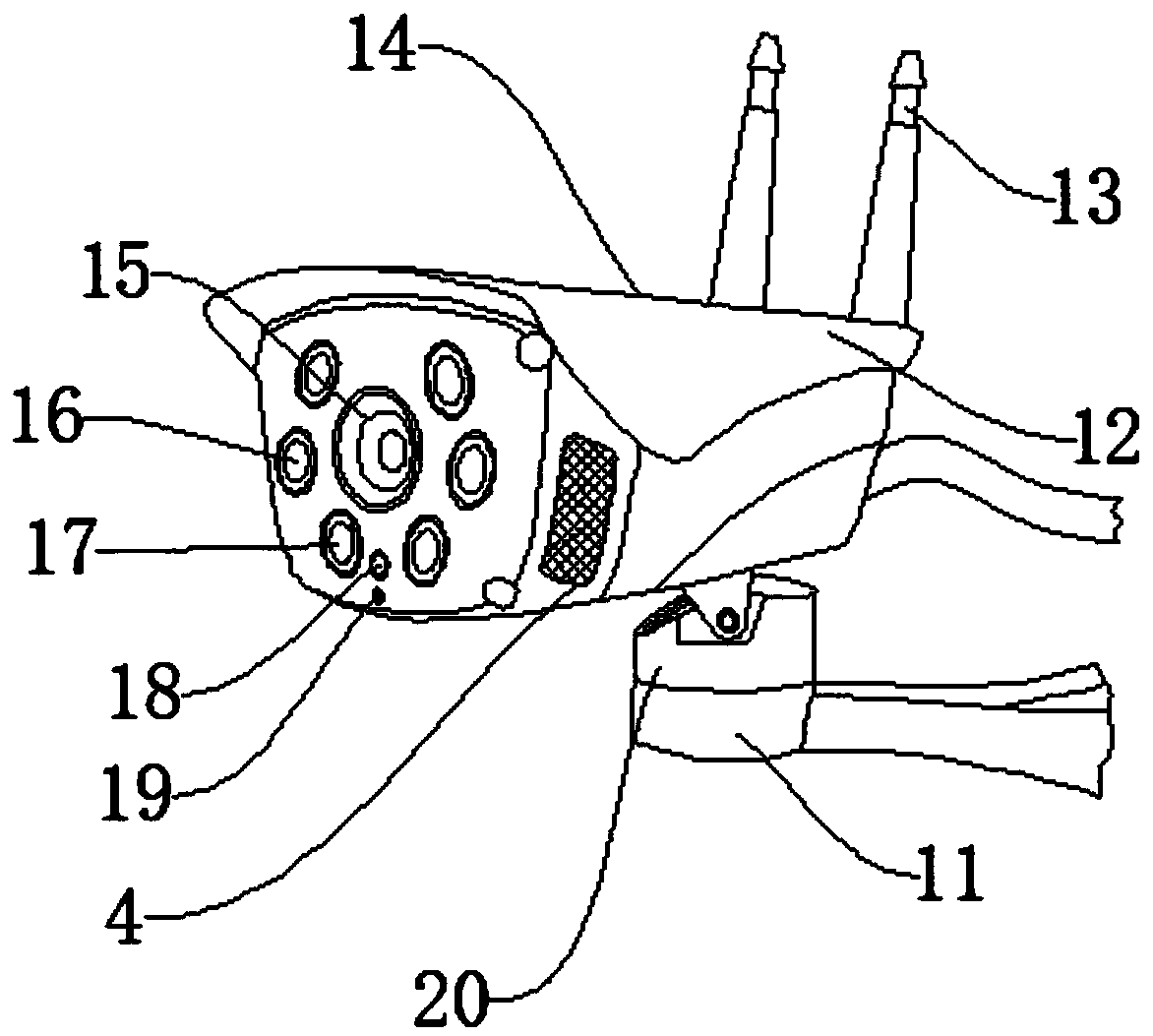

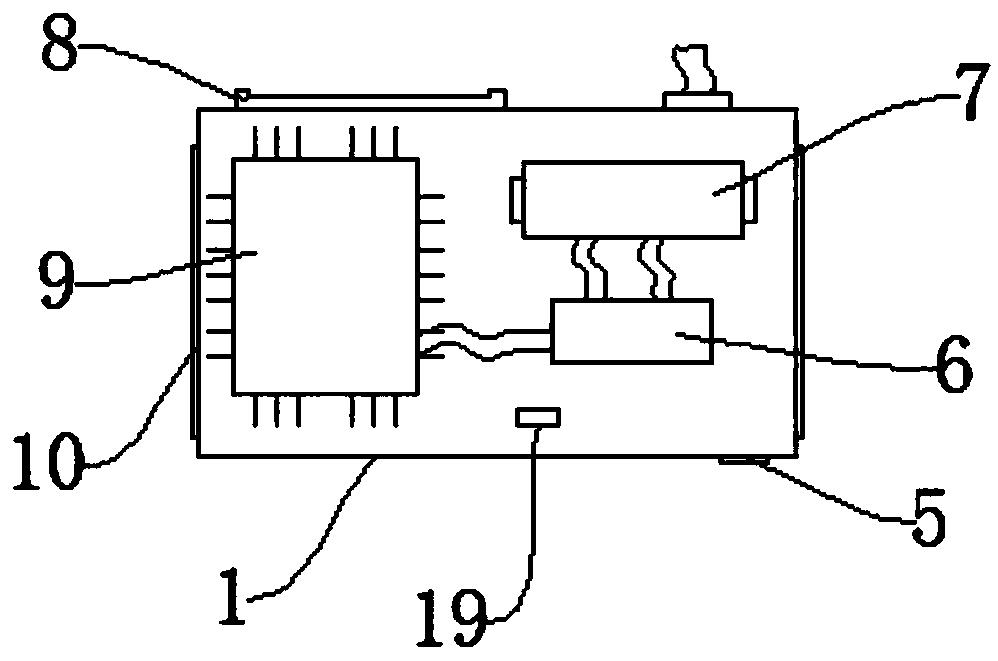

Aquaculture remote real-time monitoring device and using method thereof

Owner:仪陇县首泓种养殖农民专业合作社

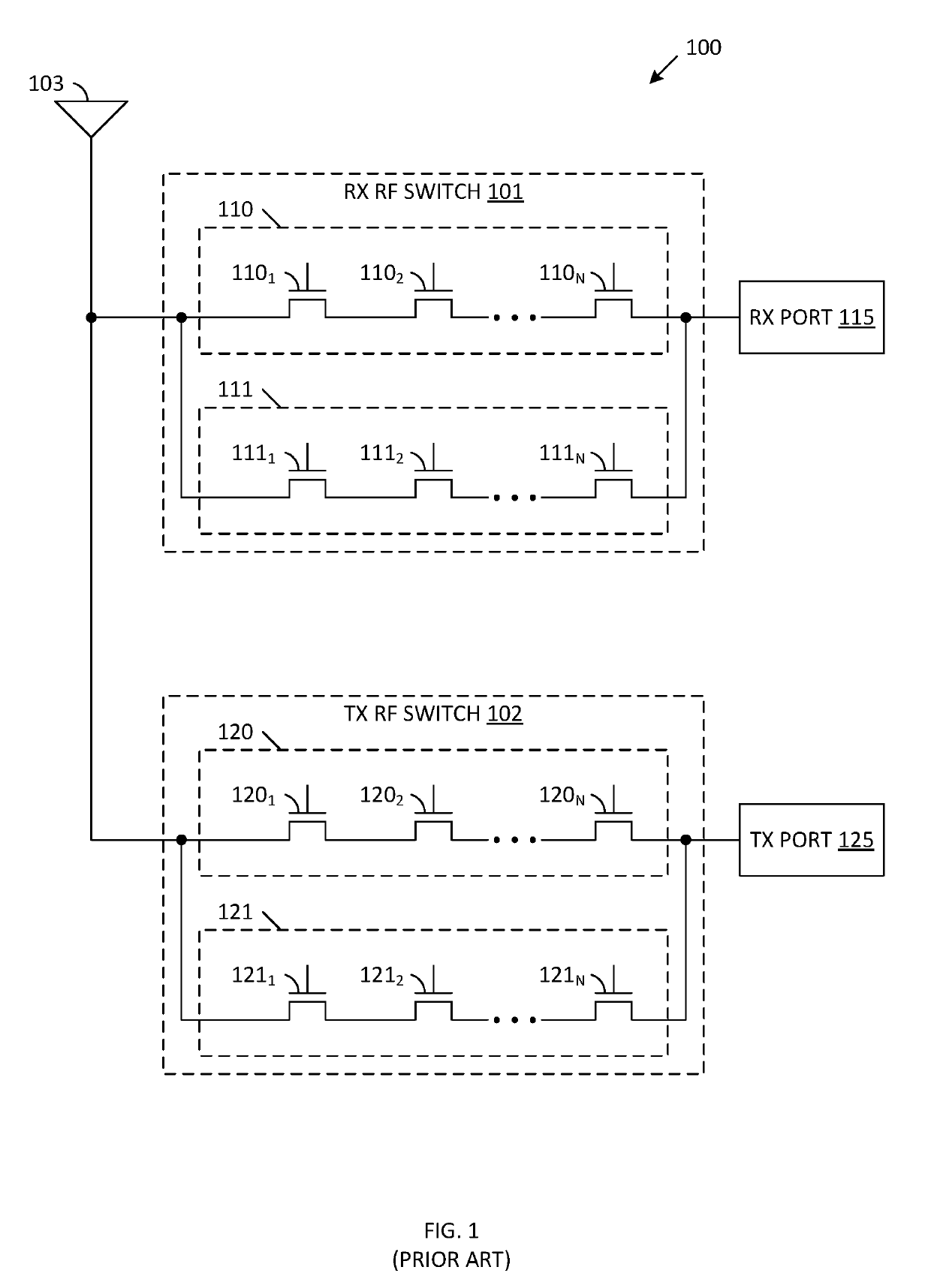

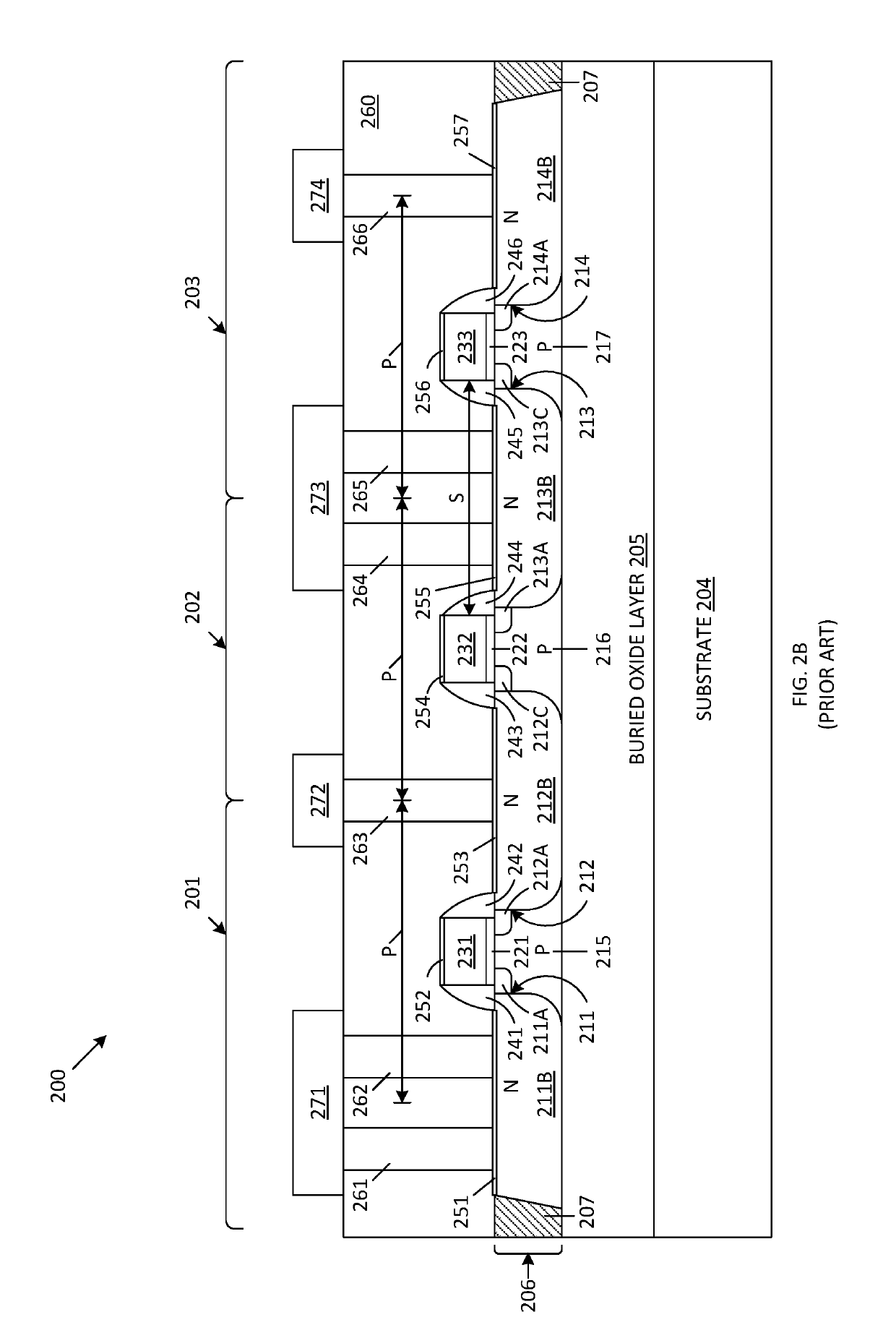

Wide contact structure for small footprint radio frequency (RF) switch

ActiveUS20190259880A1Compact layoutLower on-resistanceTransistorSemiconductor/solid-state device detailsRadio frequencySmall footprint

Owner:NEWPORT FAB

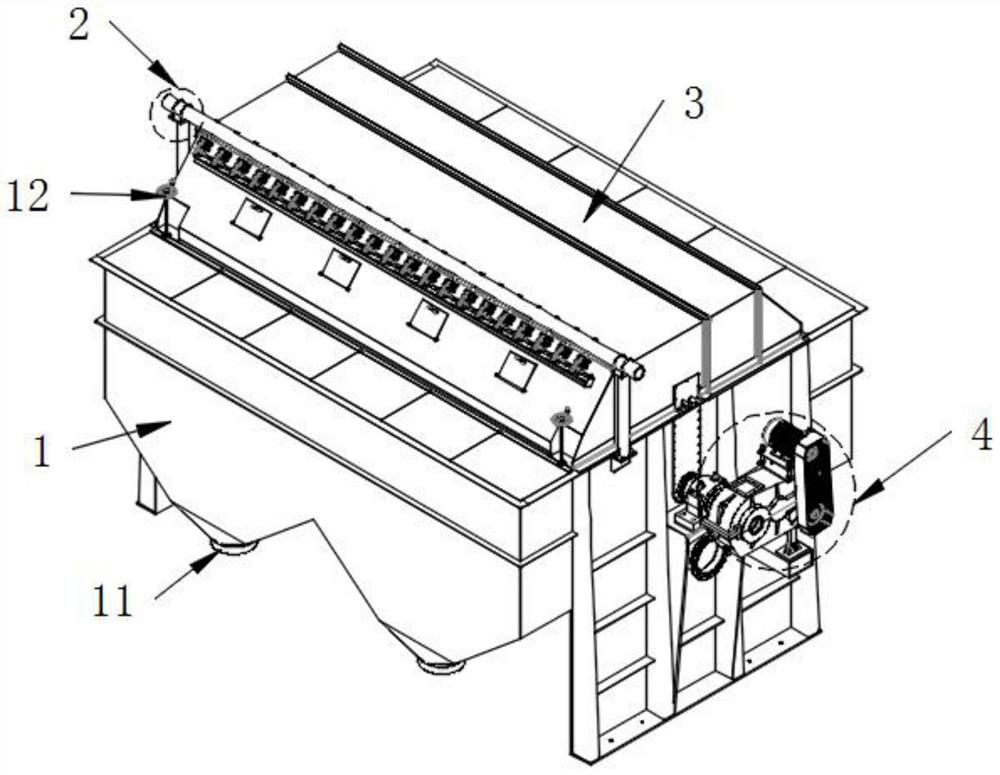

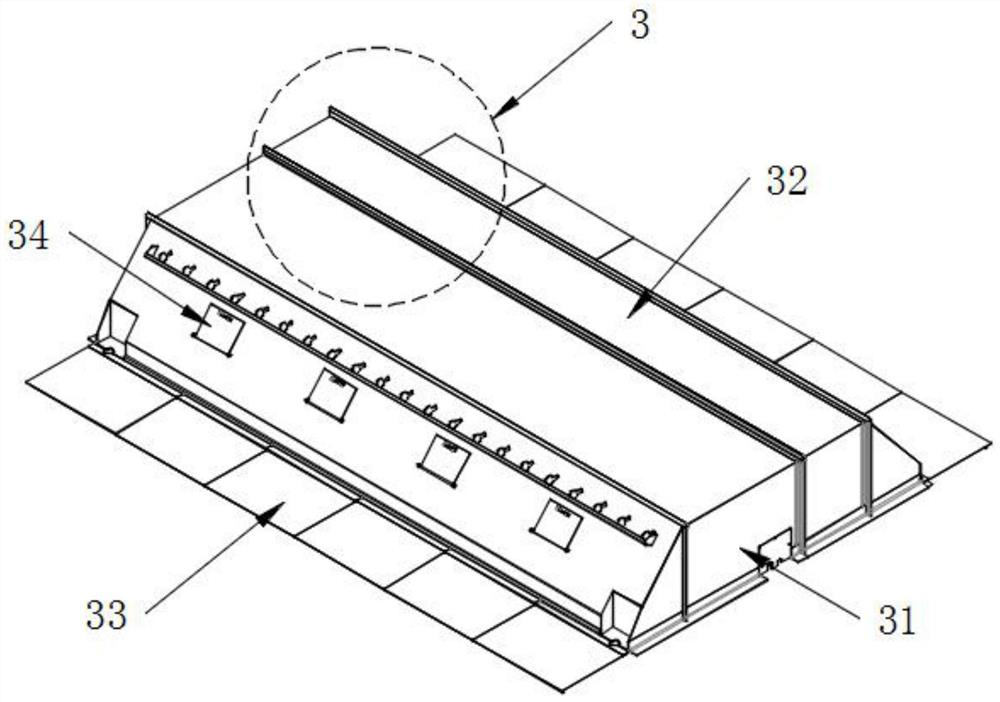

Separated spiral-flow SBR reaction pool

PendingCN107758851AEasy to manageSmall footprintTreatment with aerobic and anaerobic processesSustainable biological treatmentBiochemical engineeringSewage

Owner:江苏天马环保科技集团有限公司

Method for forming judogi girdle

Owner:天津振宇服装有限公司

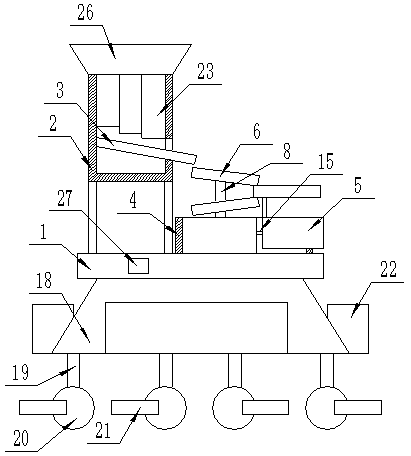

Movable-type and batch-type automatic fertilizer distributor capable of preparing fertilizer quantitatively in field

InactiveCN104919957AReduce mechanical failureSolving Mobility IssuesFertiliser distributersMovable typeAgricultural engineering

Owner:郑殿德

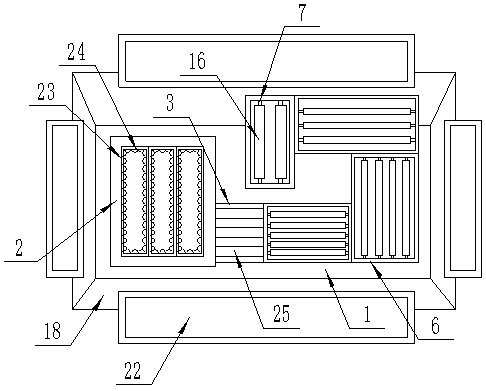

Intensive environmentally-friendly rotary S-shaped fertilizer production equipment

InactiveCN107131750AImprove drying efficiencyConvenient and smoothDrying gas arrangementsDrying chambers/containersAir preheaterHot air oven

The invention relates to intensive environmentally-friendly rotary S-shaped fertilizer production equipment, belongs to the technical field of fertilizer production equipment, and mainly aims to solve the technical problems of low heat energy utilization rate, non-uniform drying, complicated configuration, large occupation area, high electricity consumption, low drying efficiency and low fertilizer yield of existing fertilizer drying equipment. The technical scheme is that the intensive environmentally-friendly rotary S-shaped fertilizer production equipment comprises rotary drums, a material feeding bin, a large particle bin, a small particle bin, a finished product bin, supporting rollers, power conveying gears, an air preheater, an air heating furnace, a material feeding type lifting machine, a material discharging type lifting machine, a double-layer filter screen device and an induced draft fan, wherein the rotary drums comprise an outer rotary drum, a middle rotary drum and an inner rotary drum. The intensive environmentally-friendly rotary S-shaped fertilizer production equipment has the advantages of high heat energy utilization rate, small occupation area, reasonable structural design, high yield and the like.

Owner:李玉斌

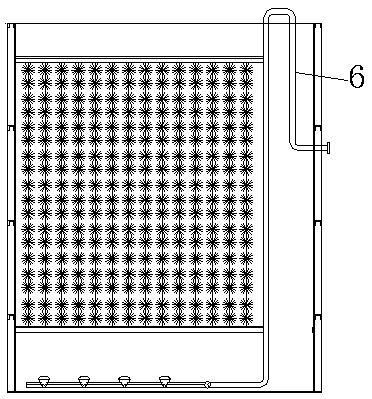

Heavy residue sewage filter

Owner:中国联合装备集团安阳机械有限公司

Multi-station water purification equipment

InactiveCN108635956AEasy to cleanEasy to realize purification treatmentFiltration circuitsInlet channelSmall footprint

Owner:华兰 +3

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap