Heavy residue sewage filter

A filter and heavy slag technology, which is applied in the direction of filtration and separation, fixed filter element filter, chemical instrument and method, etc., can solve the problems of inability to sort and recycle, occupy a large area, and low processing efficiency, and achieve the goal of occupying an area of The effect of small area, high production efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

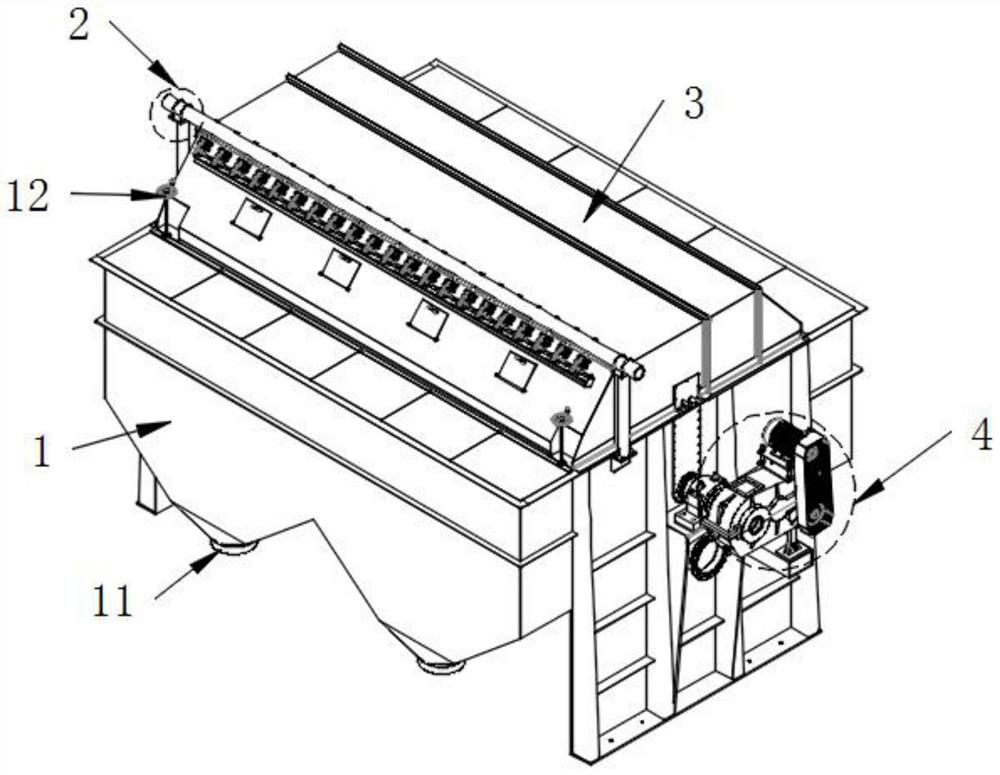

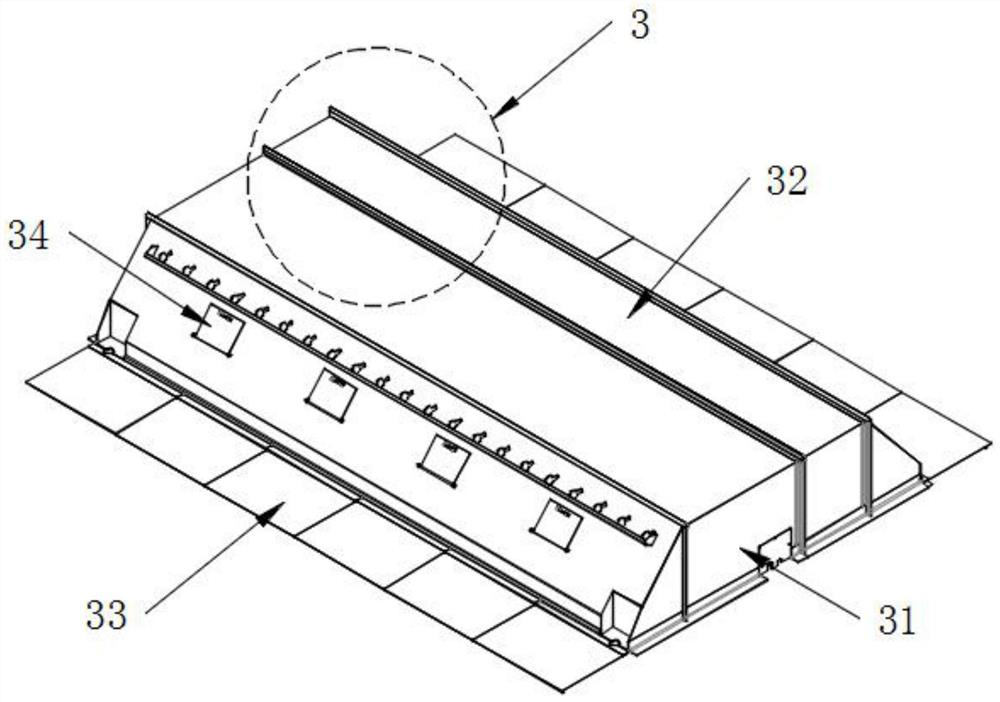

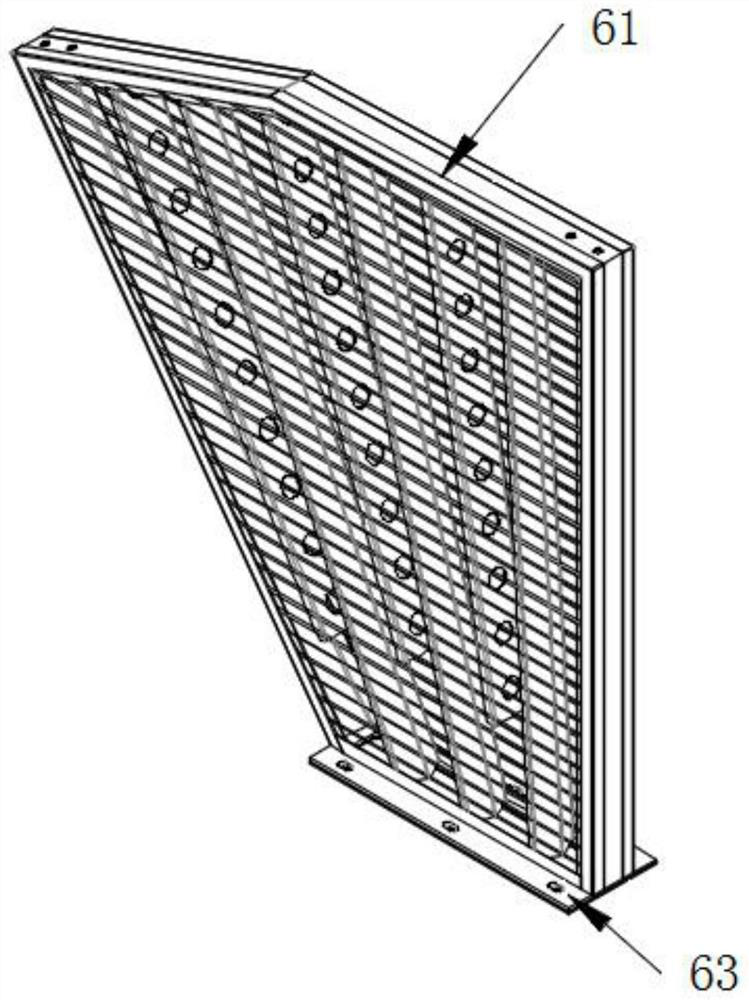

[0036] Such as Figure 1-12 As shown, the specific implementation method is:

[0037] The present invention provides a heavy residue sewage filter, comprising a filter body, the filter body includes a tank body 1, an upper cover 3, a main shaft 5, a filter disc assembly 6, a net washing device 2, a sealing device 7 and a transmission device 4, and the upper cover 3 is provided with On the upper end surface of the tank body 1, the main shaft 5 is arranged at the inner upper end of the tank body 1, the filter disc assembly 6 is arranged in the tank body 1, and at the same time is fixedly sleeved on the main shaft 5, and the net washing device 2 is fixedly installed on the tank body 1, The net washing device 2 is located in the upper cover 3, the sealing device 7 is set on the main shaft 5, and the transmission device 4 is set on the outer wall of the tank body 1;

[0038] The side of the tank body 1 is provided with a slurry inlet and outlet tank 13 in sequence, the side of the ta

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap