Life support system

a life support system and system technology, applied in the direction of air-treatment apparatus arrangement, isotope separation, dispersed particle filtration, etc., can solve the problems of increasing the weight of the aircraft, not being able to meet the needs of the aircraft, and the route taken by the aircraft may not be the shortest and most economical route, so as to reduce the risk of aircraft damage, improve safety, and save weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

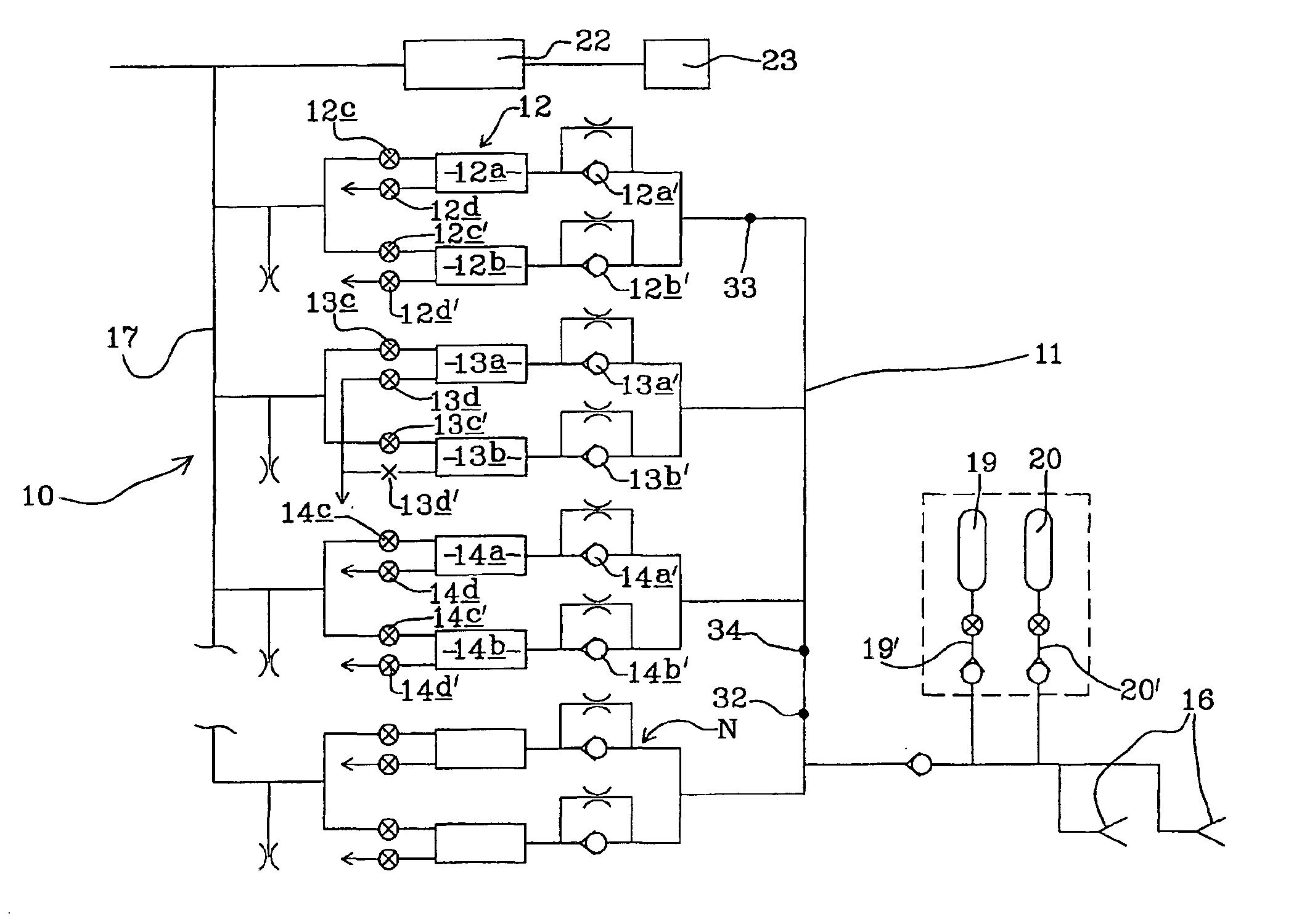

Referring first to FIG. 1 there is shown a typical flight profile of an aircraft in the event of an emergency decompression.

In this example, an aircraft flying at 40,000 feet (line A), when experiencing an emergency such as cabin decompression at B, which result in increased demand for oxygen or oxygen enriched gas, would rapidly descend to a low altitude C of 10,000 feet or less. During this descent, an emergency supply of oxygen would be provided to crew and passengers of the aircraft, from compressed oxygen storage containers, or as a result of a chemical reaction between two or more reagents. At 10,000 feet C, the passengers at least can safely breath atmospheric air. The aircraft continues to fly at this low altitude until it is safe to descent to land D, or until the pilot decides it is safer to ditch the aircraft in the sea.

It will be appreciated that terrain T in many land masses extends above 10,000 feet and thus conventionally there is a risk that during low altitude flight s

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Altitude | aaaaa | aaaaa |

| Altitude | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap