Novel single-crystal furnace for zinc cadmium telluride single crystal and growth process

A single crystal furnace, cadmium zinc telluride technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of unsatisfactory crystal quality, affecting the quality of single crystal, long growth time, etc., to achieve high utilization rate, The effect of improving stability and reducing growth temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

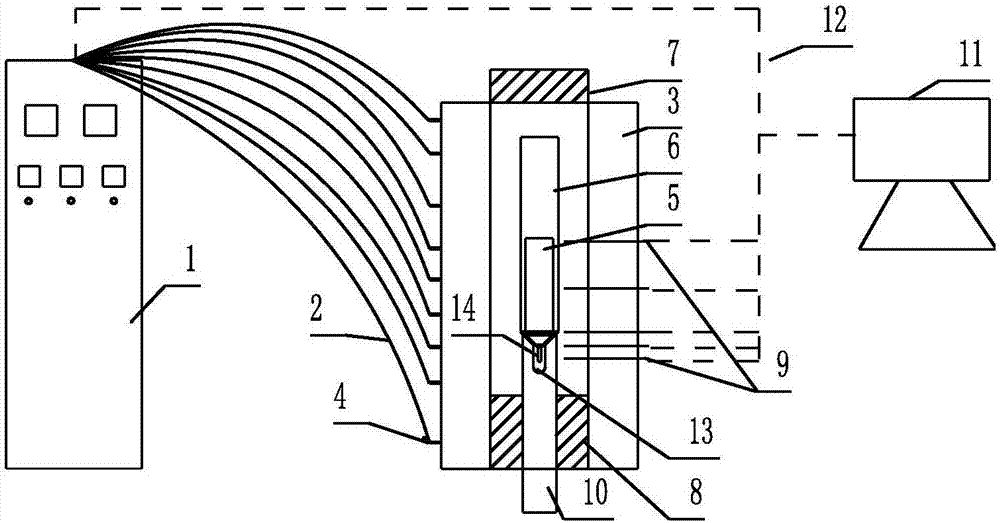

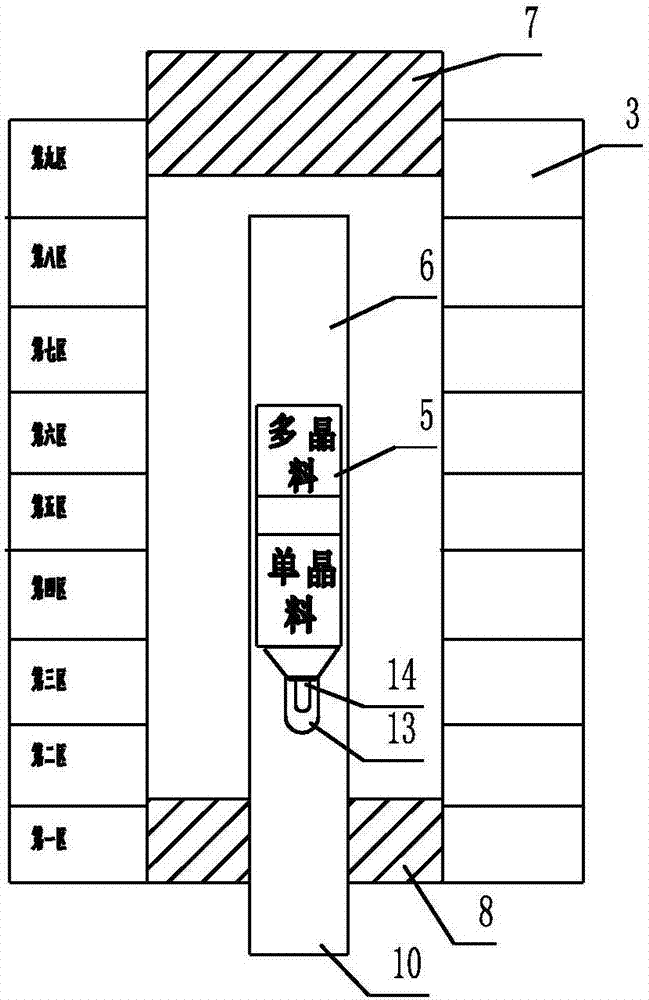

[0044]Example 1: A new type of single crystal furnace for cadmium zinc telluride single crystal, with a furnace body 3 and a heating power supply, a quartz tube 5 inside the furnace 6, a 3-inch PBN crucible inside the quartz tube, and a bottom part of the crucible The seed crystal cavity 13 is provided with a support frame 10 below the quartz tube, and the upper and lower ends of the furnace are provided with sealing plugs 7, 8. The furnace 6 of the furnace body 3 is provided with nine heating zones from bottom to top, That is: the first area, the second area, the third area, the fourth area, the fifth area, the sixth area, the seventh area, the eighth area, and the ninth area; Electrodes 4 and cables 2; and a temperature control system is also provided, each area is provided with an automatic control switch, and is controlled and connected to the controller 11 through the signal line 12, and a temperature control couple and a temperature measurement are also provided in each area

Embodiment 2

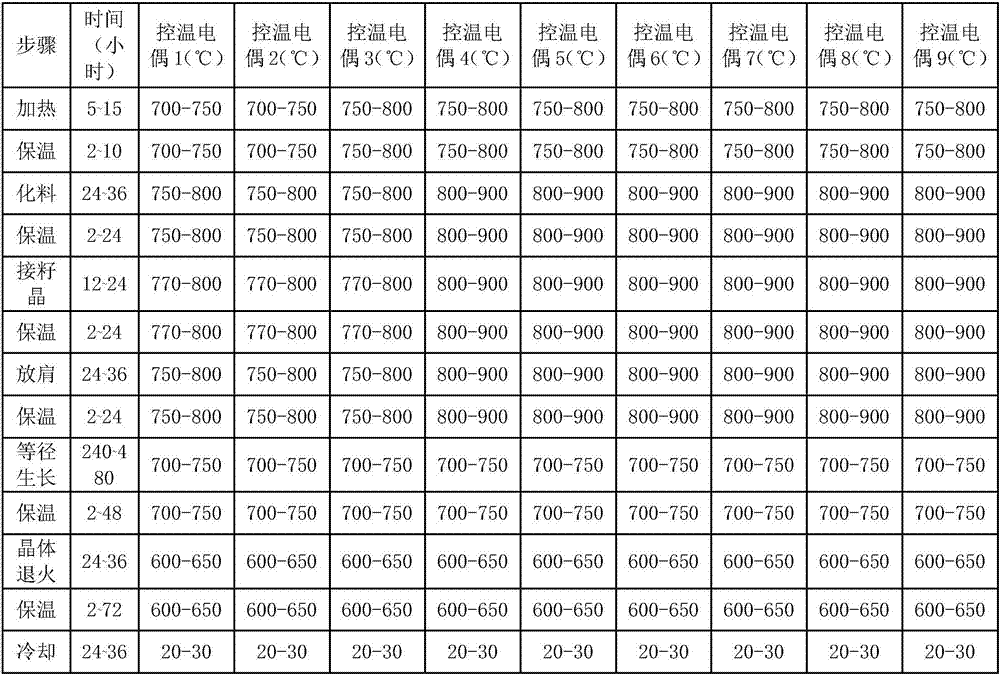

[0071] Embodiment 2: Using the single crystal furnace in Embodiment 1, the growth process steps are as follows:

[0072] 1) Ingredients and tube sealing:

[0073] The stoichiometric ratio satisfies Cd 1-x Zn x Put 4 kg of CdZnTe polycrystalline material synthesized by Te (x = 0.1), 2000 g of Te (99.99999% high-purity raw material) and direction seed crystal into a 3-inch PBN crucible and put it into a quartz tube Vacuum until the vacuum reaches 4.5×10 -5 When Pa is sealed, use a hydrogen-oxygen torch torch.

[0074] 2) Furnace loading: vertically load the sealed quartz tube into the single crystal furnace, adjust the bottom support height so that the CdZnTe polycrystalline material in the crucible corresponds to the 4th, 5th and 6th zones of the single crystal furnace.

[0075] 3) Install galvanic couples: take the middle positions in the first, second, third, fourth, fifth, sixth, seventh, eighth, and ninth areas of the single crystal furnace Place the temperature control

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap